Inorganic/organic hybridization nanometer composite resin and light-emitting diode (LED) packaging materials prepared by the same

An organic hybridization and nano-composite technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of inability to balance high refractive index adhesion and mechanical properties, low refractive index, affecting material light transmission and mechanical properties, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

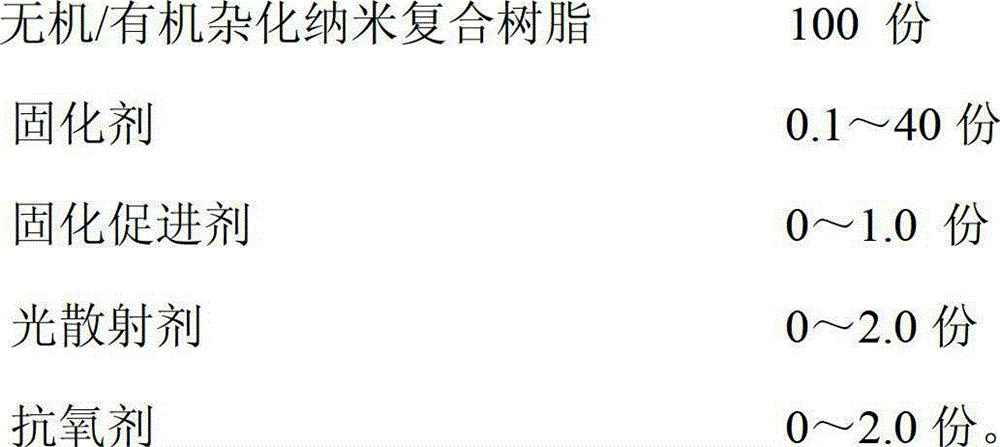

Method used

Image

Examples

Embodiment 1

[0054] (1) Preparation of nano-oxide sol: Dissolve 5.0 g of anhydrous zinc acetate in 50 mL of absolute ethanol, and stir evenly with electromagnetic. Mix 0.5g of sodium hydroxide, 2.0g of deionized water and 20mL of absolute ethanol evenly, and add dropwise to the ethanol solution of zinc acetate, and react at 20°C for 3 hours to obtain a zinc oxide sol with an average particle size of 10nm.

[0055] (2) Preparation of epoxy phenyl oligosiloxane: 10g of epoxy alkyl silane OC 6 h 9 CH 2 CH 2 Si(OCH 3 ) 3 , 100g phenylsilane (C 6 h 5 ) 2 Si(OCH 2 CH 3 ) 2 , 30g alkane-based silane (CH 3 ) 2 Si(OCH 3 ) 2 , 10g of deionized water, 1g of catalyst dibutyltin dilaurate and 80g of 1,4-dioxane were placed in a three-necked flask, stirred evenly, and reacted at 80°C for 6h. After the reaction, the reaction solution was decompressed at 70°C Rotary evaporation for 1 h to remove water, solvent and by-products to obtain colorless and transparent epoxy phenyl oligosiloxane. ...

Embodiment 2

[0059] (1) Preparation of nano-oxide sol: Dissolve 13.5g of titanium isopropoxide and 16.5g of zirconium butoxide in 120mL of isopropanol, and mix evenly with electromagnetic stirring. Mix 3.0g propionic acid, 1.0g deionized water and 100mL isopropanol evenly, and add dropwise to the isopropanol solution of titanium isopropoxide and zirconium butoxide, react at 80°C for 4 hours, and the average particle size is 72nm titania-zirconia sol.

[0060] (2) Preparation of epoxy phenyl oligosiloxane: 30g of epoxy alkyl silane OC 6 h 9 CH 2 CH 2 Si(OCH 3 ) 3 , 100g phenylsilane (C 6 h 5 ) 2 Si(OCH 3 ) 2 , 10g alkane-based silane (CH 3 CH 2 CH 2 CH 2 ) 2 Si(OCH 3 ) 2, 20g of deionized water, 1.8g of catalyst dibutyltin diacetate and 100g of tetrahydrofuran were placed in a three-necked flask, stirred evenly, and reacted at 70°C for 16h. After the reaction, the reaction solution was rotated at 50°C for 2h to remove water , solvents and by-products to obtain colorless an...

Embodiment 3

[0064] (1) Preparation of nano-oxide sol: Dissolve 50g of zirconium butoxide in 300mL of butanol, and mix evenly with electromagnetic stirring. Mix 10g of acetic acid, 100g of deionized water and 50mL of butanol evenly, add dropwise to the zirconium butoxide solution, and react at 60°C for 8h to obtain a zirconia sol with an average particle size of 25nm.

[0065] (2) Preparation of epoxy phenyl oligosiloxane: OCH 20g of epoxy alkyl silane 2 CHCH 2 OC 3 h 6 SiPh(OCH 2 CH 3 ) 2 , 100g phenylsilane CH 3 (C 6 h 5 )Si(OCH 3 ) 2 , 20g alkane silane CH 3 Si(OC 2 h 5 ) 3 , 1g of deionized water, 5.0g of catalyst stannous octoate and 400g of ethylene glycol dimethyl ether were placed in a three-necked flask, stirred evenly, and reacted at 100°C for 24h. After the reaction, the reaction solution was rotated at 100°C for 0.5 h remove water, solvent and by-products to obtain colorless and transparent epoxy phenyl oligosiloxane.

[0066] (3) Preparation of inorganic / organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com