Large-size horizontal machining-center high-speed main-axle oil gas lubricating system

An oil-air lubrication, high-speed spindle technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of high price, and achieve the effect of less heat generation, reliable lubrication, and low temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

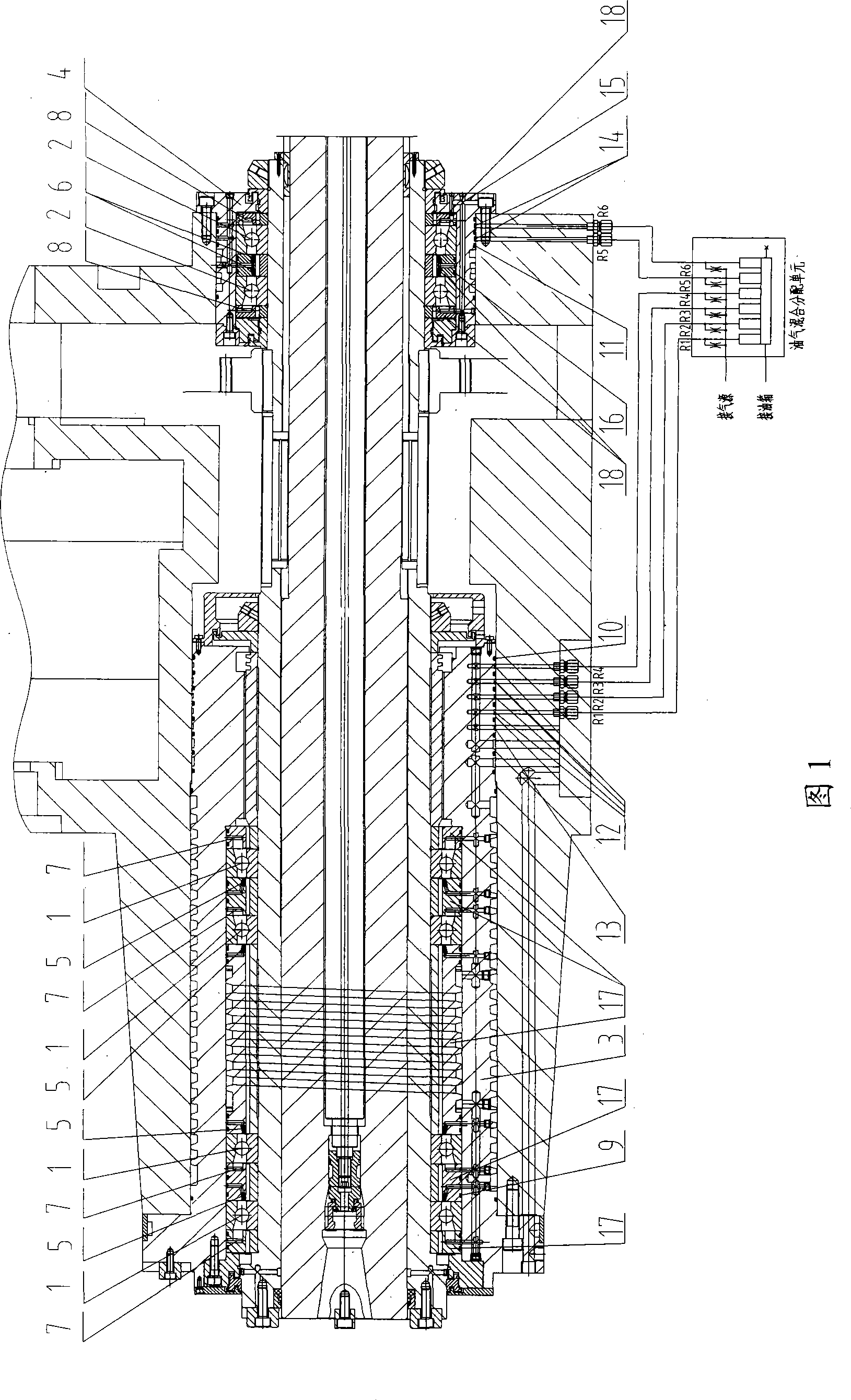

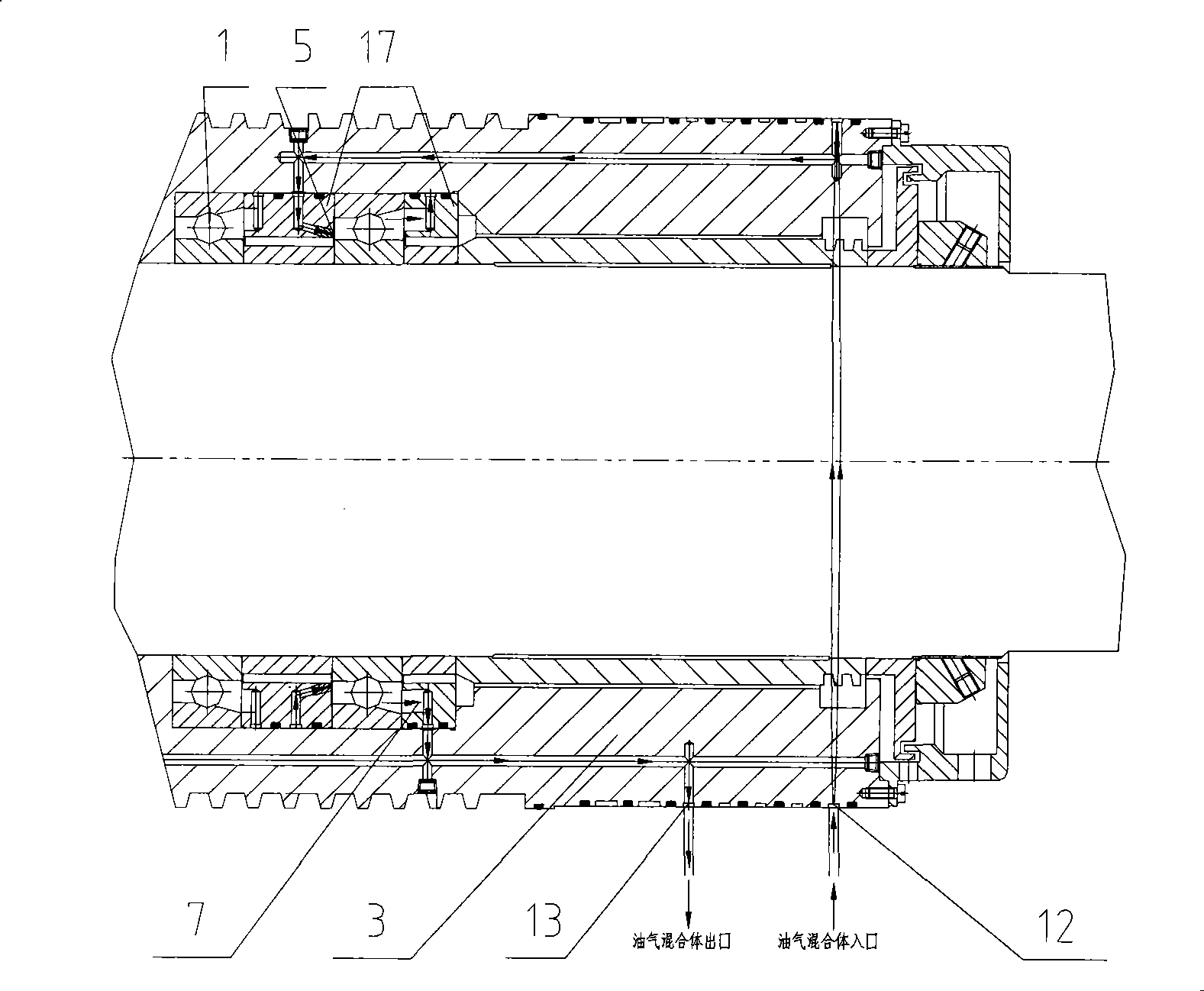

[0015] The oil-air lubrication system for the high-speed spindle of a large horizontal machining center consists of two parts. The first part is an oil-air generating device, and the second part is an oil-air delivery device. It is characterized in that:

[0016] 1. The oil-air generating device in the oil-air lubrication system of the high-speed spindle of a large horizontal machining center

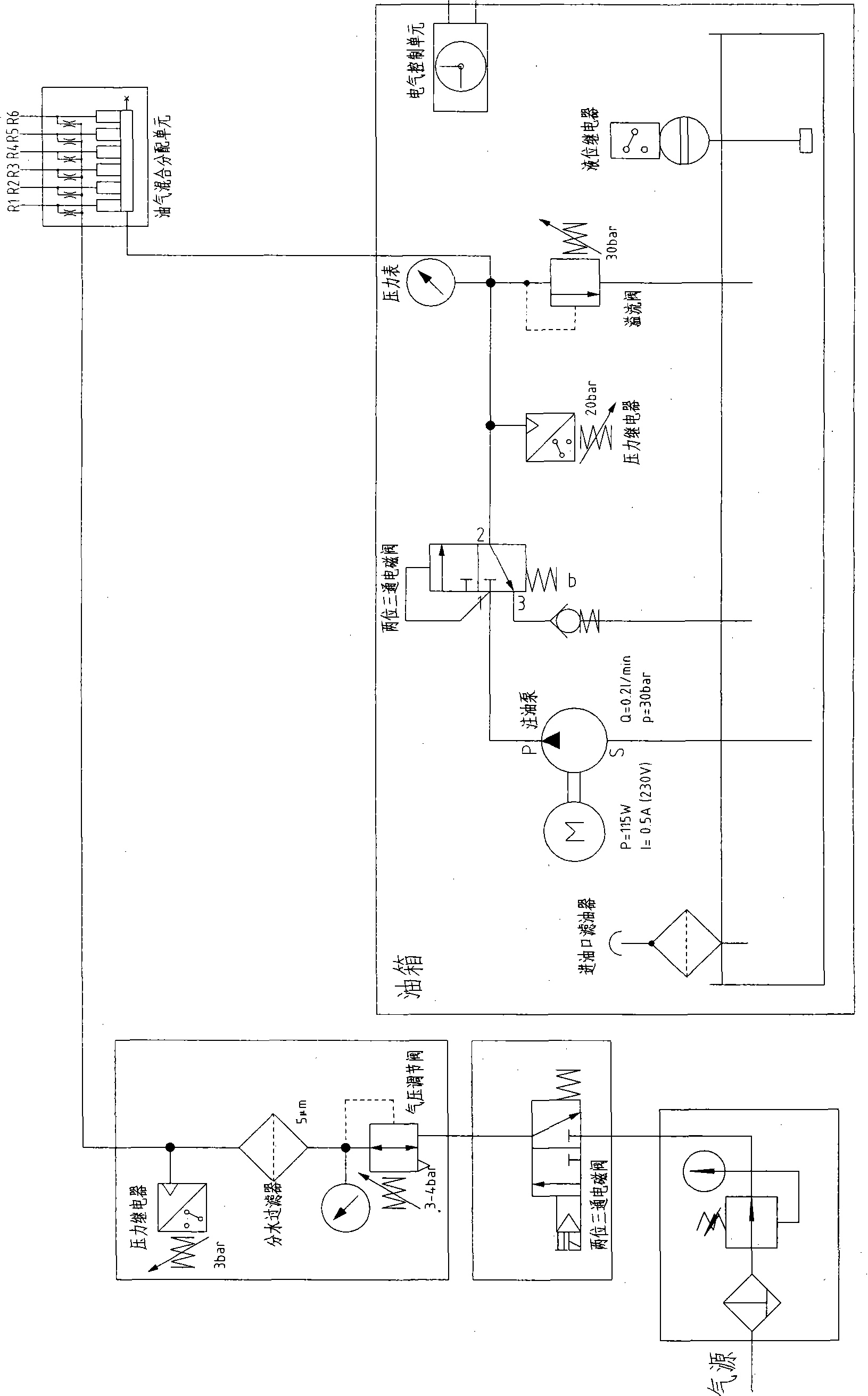

[0017] The oil and gas generating device for the high-speed spindle of the large horizontal machining center has an external air source and oil tank, see figure 2 , the air source is connected to the oil-gas mixing distribution unit through a two-position three-way solenoid valve, an air pressure regulating valve, a water separation filter, and a pressure relay. A high-pressure oil injection pump, a liquid level relay, an electrical control unit, and a two-position three-way solenoid Valve, pressure relay, relief valve, pressure gauge to oil-gas mixing and distribution unit, characteriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com