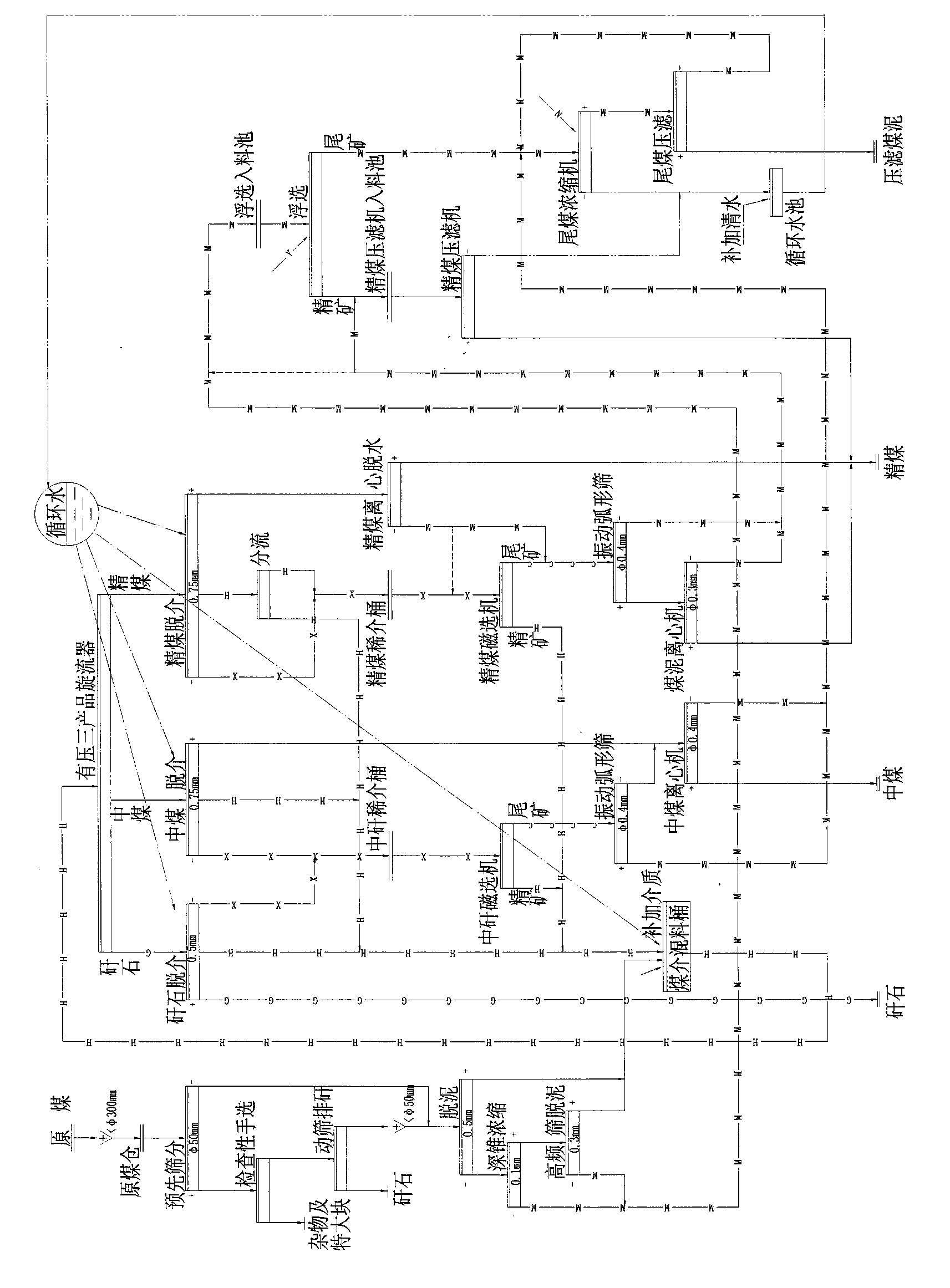

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

A heavy medium cyclone, three-product technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of high production and operation cost, high construction investment, large plant volume, etc., and achieve production and operation costs. The effect of low, high sorting efficiency and simple process system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] This embodiment is a three-product dense medium cyclone coal preparation process for graded desliming with pressure feeding. The equipment used in this process includes: pre-screening and grading screen, crusher, primary desliming vibrating screen, secondary desliming High-frequency screen, coal-medium mixing barrel, pressurized three-product cyclone, gangue de-medium sieve, medium coal de-medium sieve, clean coal de-medium sieve, magnetic separator, deep cone concentration, coarse coal slime recovery and fine coal Slime separation and recovery system equipment (vibrating curved screen, coal slime centrifuge, flotation machine, clean coal filter press, tailing coal filter press, tailing coal thickener), etc. According to the scale of the plant, this process is adopted, and the workshop is arranged in a modular manner. The main equipment includes: primary deslimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com