Method for extracting alumina from coal gangue

A technology of coal gangue and alumina, which is applied to the preparation of alumina/hydroxide and alumina/hydroxide, and can solve the problems that are not conducive to the preparation of high-purity alumina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

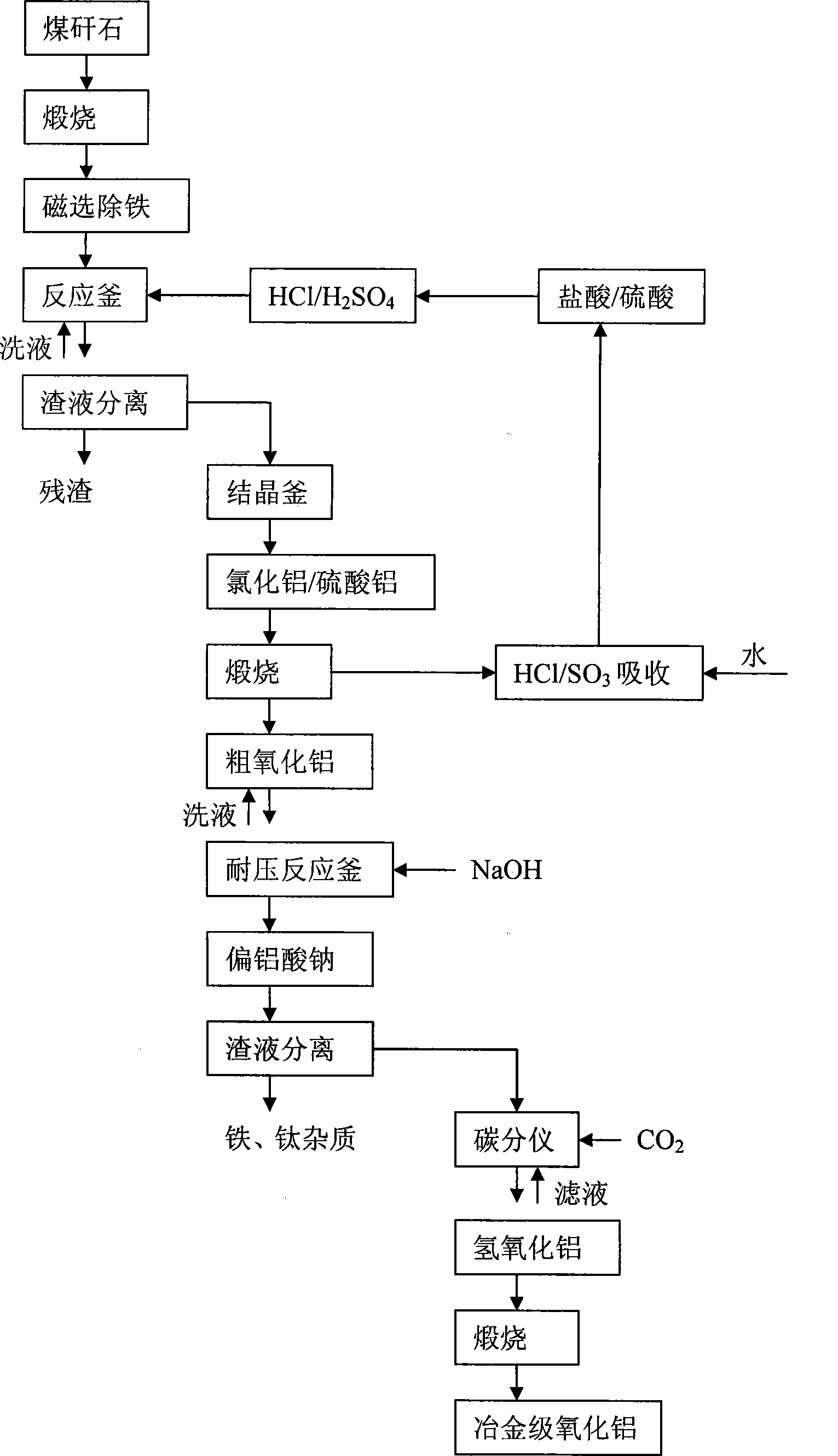

Image

Examples

Embodiment 1

[0020] Take 2500g coal gangue, mechanically crush it to ≤200 mesh, and put it into a fluidized bed furnace for calcination. The calcination temperature is 600℃, and the calcination time is 3h. Then use a magnetic separator to remove iron; weigh the gangue lime after preliminary iron removal Put 500g of the material in the reaction kettle, add 1500ml of 25% hydrochloric acid, control the heating temperature at 100°C, and keep stirring for 2h. After the acid dissolution is completed, the mixed solution is cooled to 90°C and placed in a sedimentation tank. The upper layer liquid is directly filtered by suction, the filtrate is sent to the crystallization reaction kettle, the lower layer slag mixture is washed, discarded, and the lotion is returned It is reused in the acid-dissolving reactor, and the crystalline aluminum chloride is separated after crystallization. The obtained crystalline aluminum chloride is heated to 500° C. and calcined at low temperature to obtain crude alumina. ...

Embodiment 2

[0023] Take 2500g of coal gangue, mechanically crush it to 200 mesh, and put it into a fluidized bed furnace for calcination. The calcination temperature is 600℃, and the calcination time is 3h. Then use a magnetic separator to remove iron; weigh the gangue lime material after preliminary iron removal 500g was placed in the reaction kettle, 1300ml of hydrochloric acid with a concentration of 30% was added, the heating temperature was controlled at 90°C, and the reaction was continued for 1.5h. After the acid dissolution is completed, the mixed solution is cooled to 90°C and placed in a sedimentation tank. The upper layer liquid is directly filtered by suction, the filtrate is sent to the crystallization reaction kettle, the lower layer slag mixture is washed, discarded, and the lotion is returned It is reused in the acid-dissolving reactor, and the crystalline aluminum chloride is separated after crystallization. The obtained crystalline aluminum chloride is heated to 450 DEG C, a...

Embodiment 3

[0026] Take 2500g of coal gangue, mechanically crush it to 200 mesh, and put it into a fluidized bed furnace for calcination. The calcination temperature is 600℃, and the calcination time is 3h. Then use a magnetic separator to remove iron; weigh the gangue lime material after preliminary iron removal Put 500g in the reaction kettle, add 1400ml of sulfuric acid with a concentration of 45%, control the heating temperature at 105°C, and keep stirring for 1h. After the acid dissolution is completed, the mixed solution is cooled to 90°C and placed in a sedimentation tank. The upper layer liquid is directly filtered by suction, the filtrate is sent to the crystallization reaction kettle, the lower layer slag mixture is washed, discarded, and the lotion is returned It is reused in the acid-dissolving reactor, and the crystalline aluminum sulfate is separated after crystallization. The obtained crystalline aluminum sulfate is heated to 800°C, and after low-temperature calcination, coarse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com