Dry presorting and tailings discarding process for ultra-poor magnetite

An ultra-lean magnetite, dry-type technology, applied in the field of ultra-lean magnetite dry-type pre-selection and tailings disposal process, can solve the problems of high mineral processing cost, high steel consumption, low efficiency, etc., achieve significant economic benefits, increase income Grinding grade and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

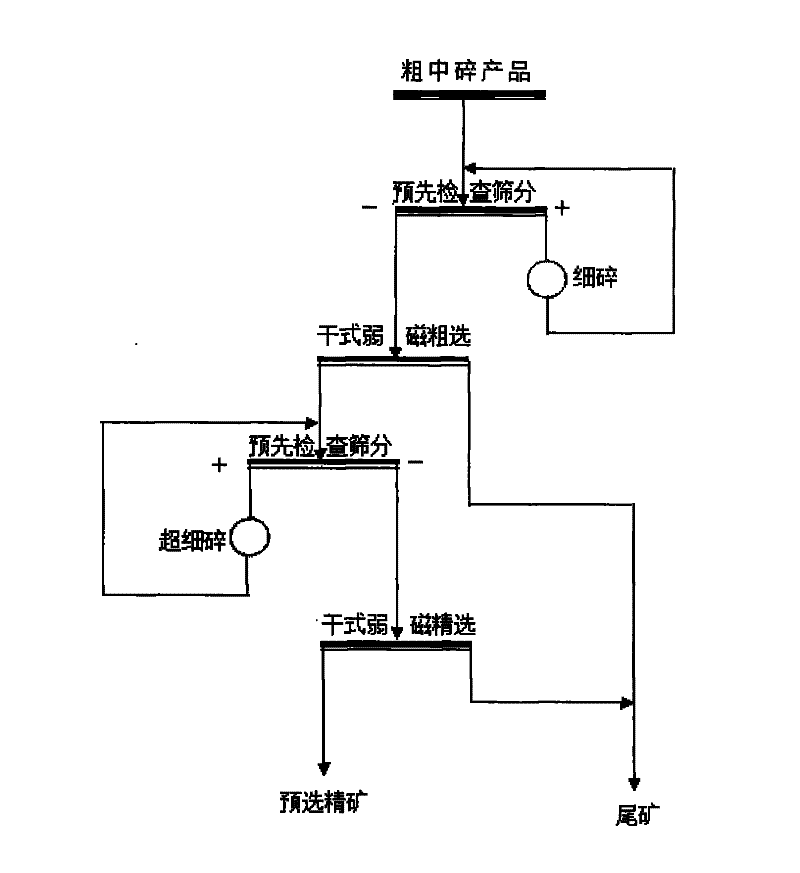

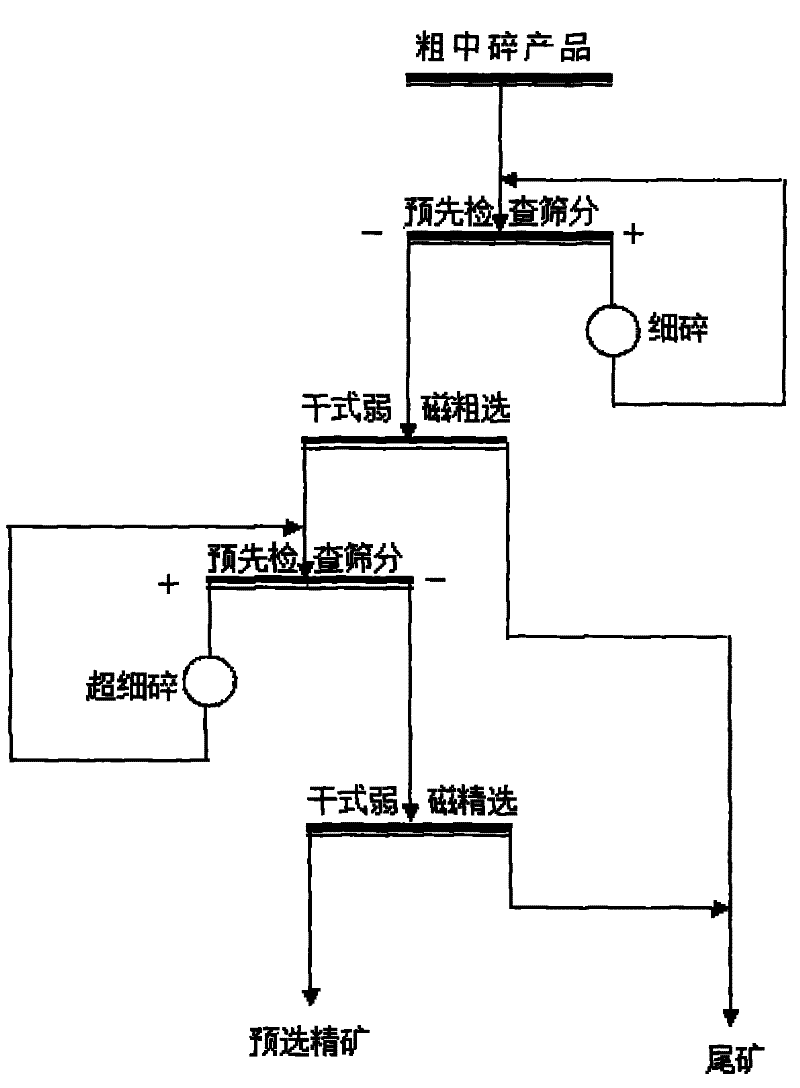

Method used

Image

Examples

Embodiment 1

[0014] Ore source: Inner Mongolia Baotou Iron and Steel Co.

[0015] Raw ore technical indicators: mining ore particle size 0 ~ 1000mm, raw ore sample multi-element chemical analysis results and raw ore sample iron phase analysis results are shown in Table 1 and 2 respectively.

[0016] Table 1: Results of multi-element chemical analysis of raw ore

[0017] Analysis Project

[0018] Table 2: Analysis results of raw ore iron phase

[0019] Iron phase

[0020] The dry pre-selection tail throwing process steps are as follows:

[0021] (1) Coarse crushing:

[0022] Equipment: Superior MK-II54-75 gyratory crusher, ore discharge particle size ≤ 250mm.

[0023] (2) medium crushing:

[0024] Equipment: CH880MC cone crusher, the ore discharge particle size is ≤70mm, and the obtained products enter a closed-circuit fine crushing process.

[0025] (3) finely crushed:

[0026] Equipment: CH8800EFX cone crusher, ore discharge port e=8mm.

[0027] (4) Closed circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com