Efficient crushing and three-section type screening method of coking coal gravity middings

A three-stage technology for coking coal, applied in the field of coal crushing, dissociation and separation technology, can solve the problems of low recovery rate of scarce coking coal, and achieve the effect of improving separation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

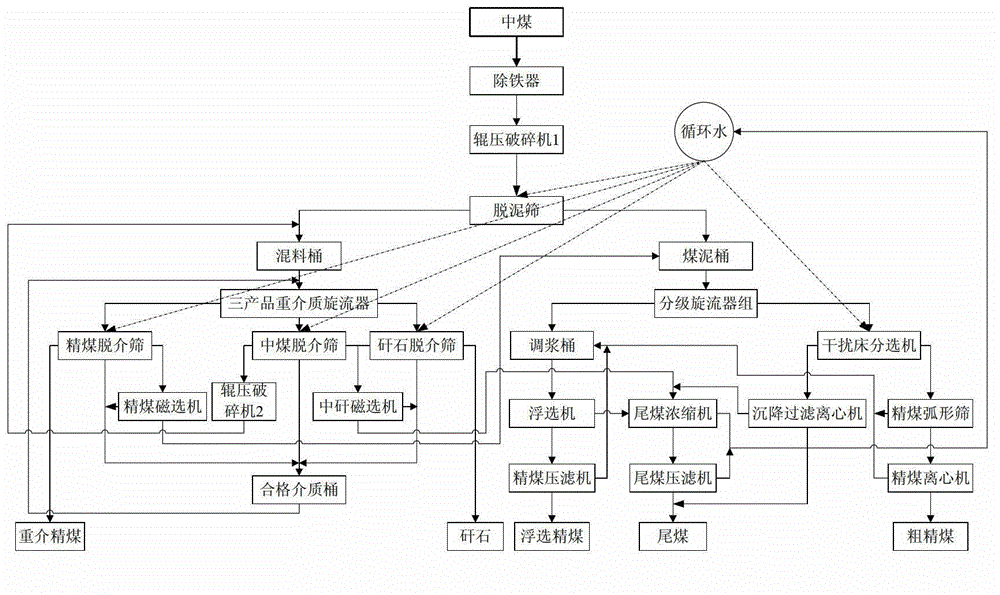

[0027] Example 1: figure 1 In the middle, the scarce coking coal re-selected coal passes through the iron remover near the head of the belt conveyor to remove iron impurities and enters the roller crusher 1, and the crushed product enters the wet desliming screen with a sieve hole of 1mm. After the sieve material is mixed with the return material of the roller crusher 2, it is pumped to the three-product heavy medium cyclone, the light product enters the clean coal medium removal sieve, the concentrated medium extracted from the first stage enters the qualified medium barrel, and the thin medium extracted from the second stage enters the qualified medium barrel. The medium enters the clean coal magnetic separator, the magnetically separated concentrate enters the qualified medium barrel, the tailings enter the slime barrel, and the screened product is the dense medium clean coal product; the intermediate product of the three-product dense medium cyclone enters the medium coal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com