Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Avoid Metal Contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

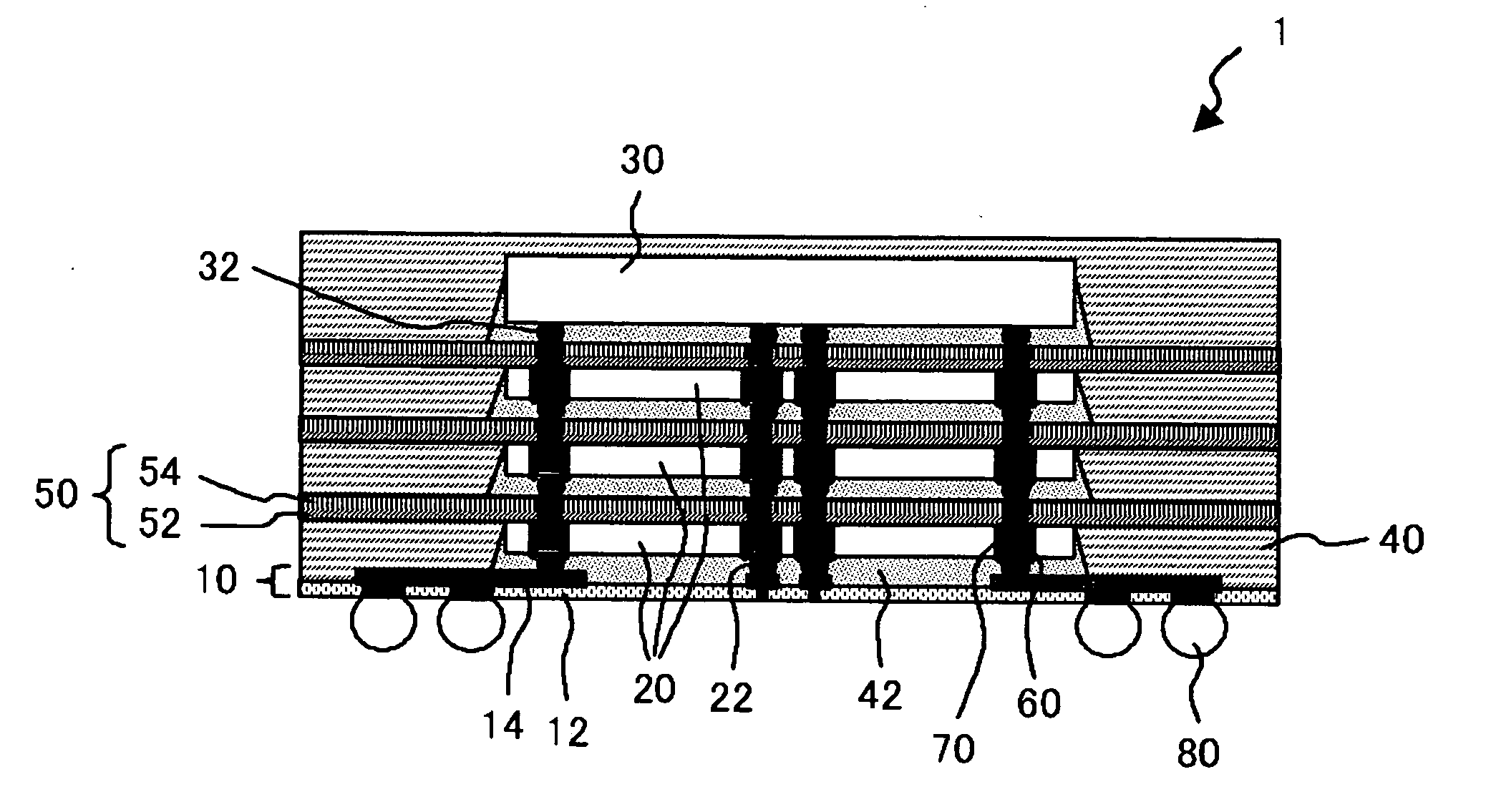

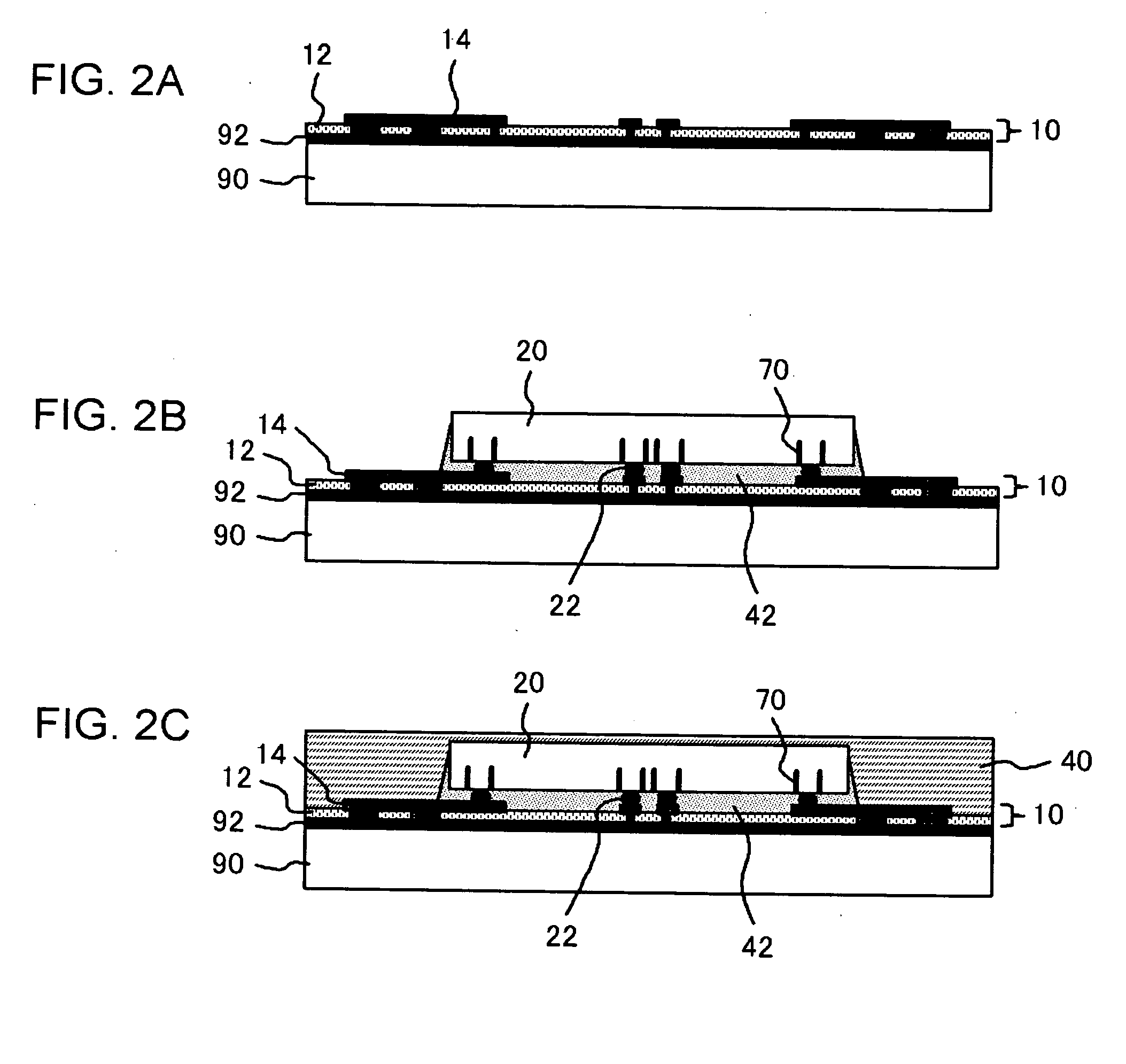

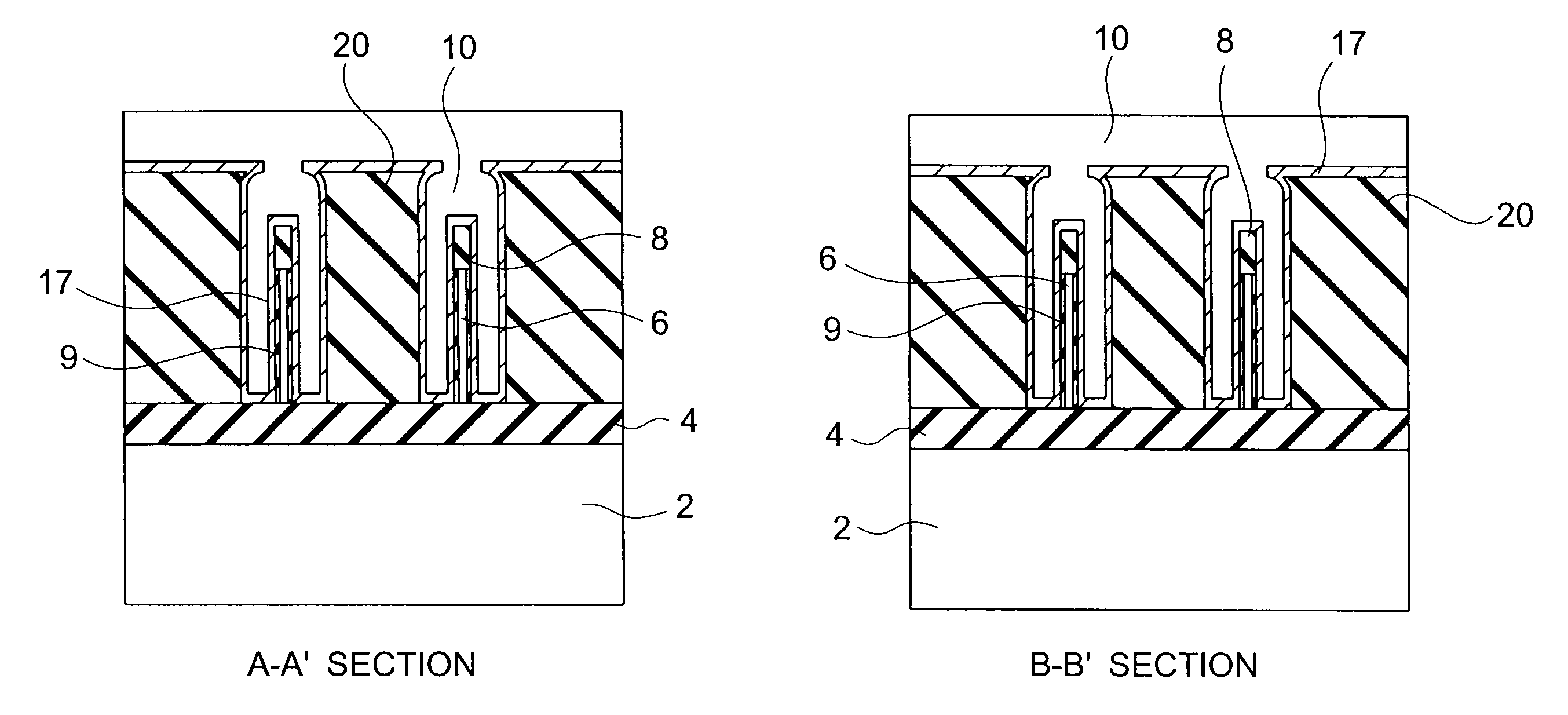

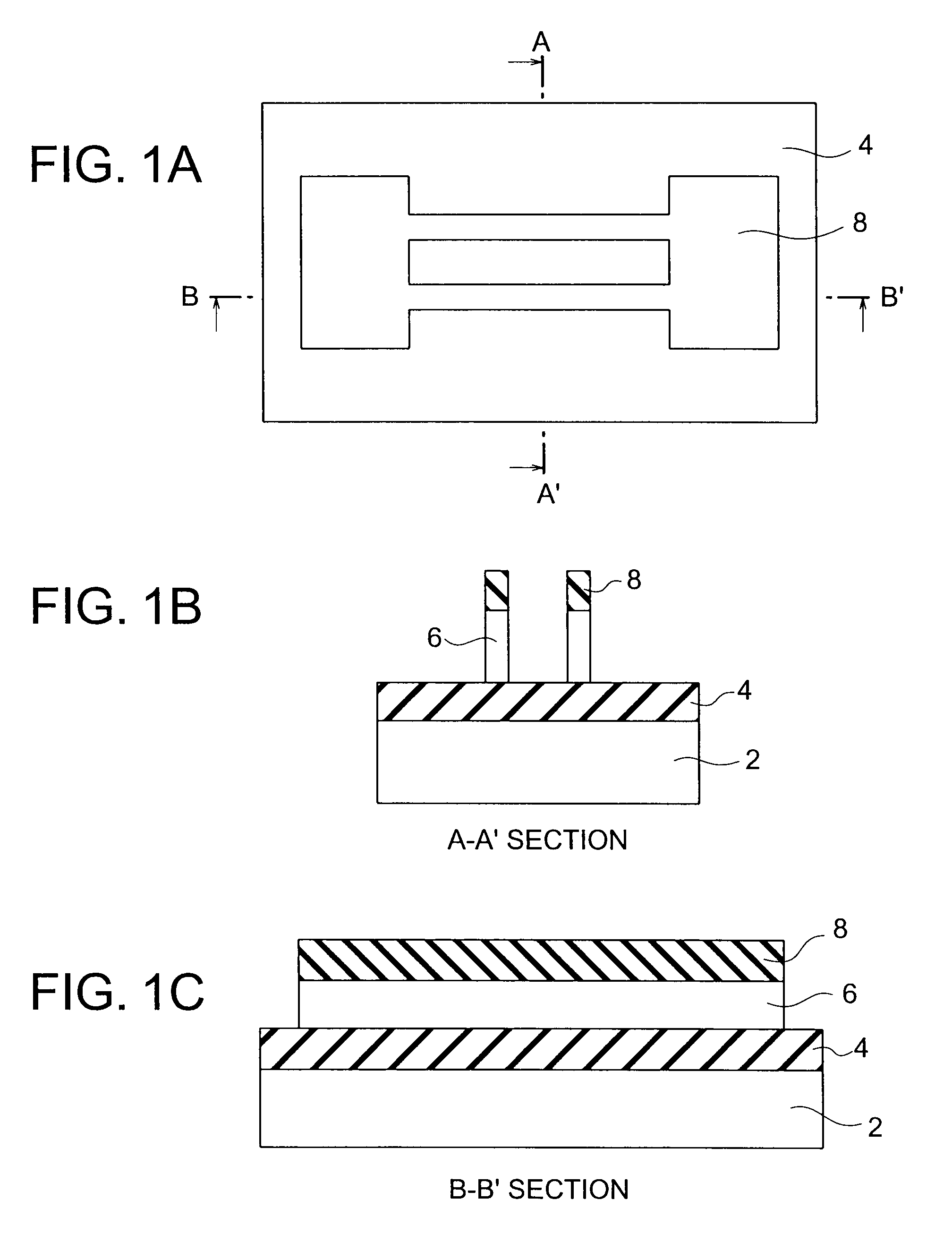

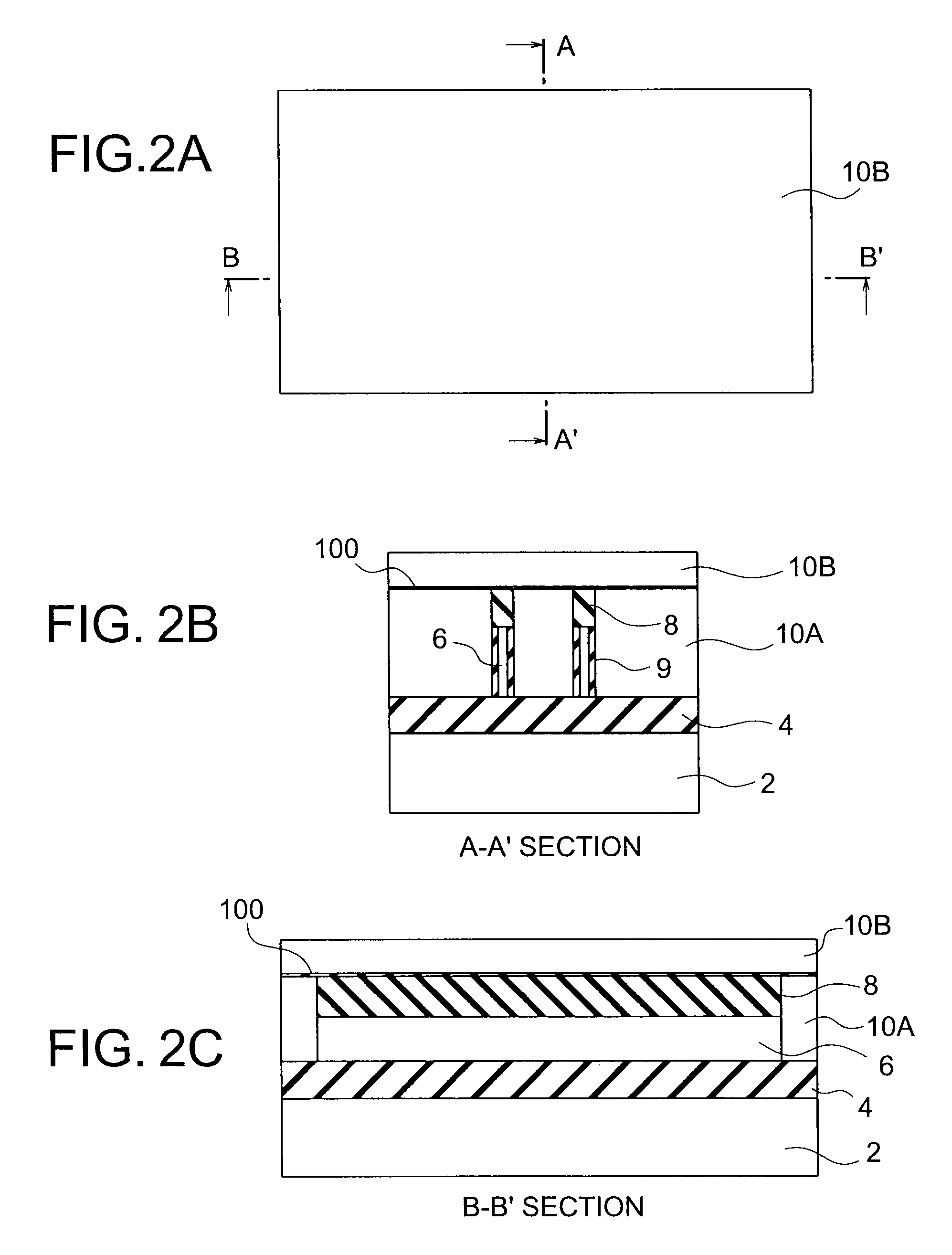

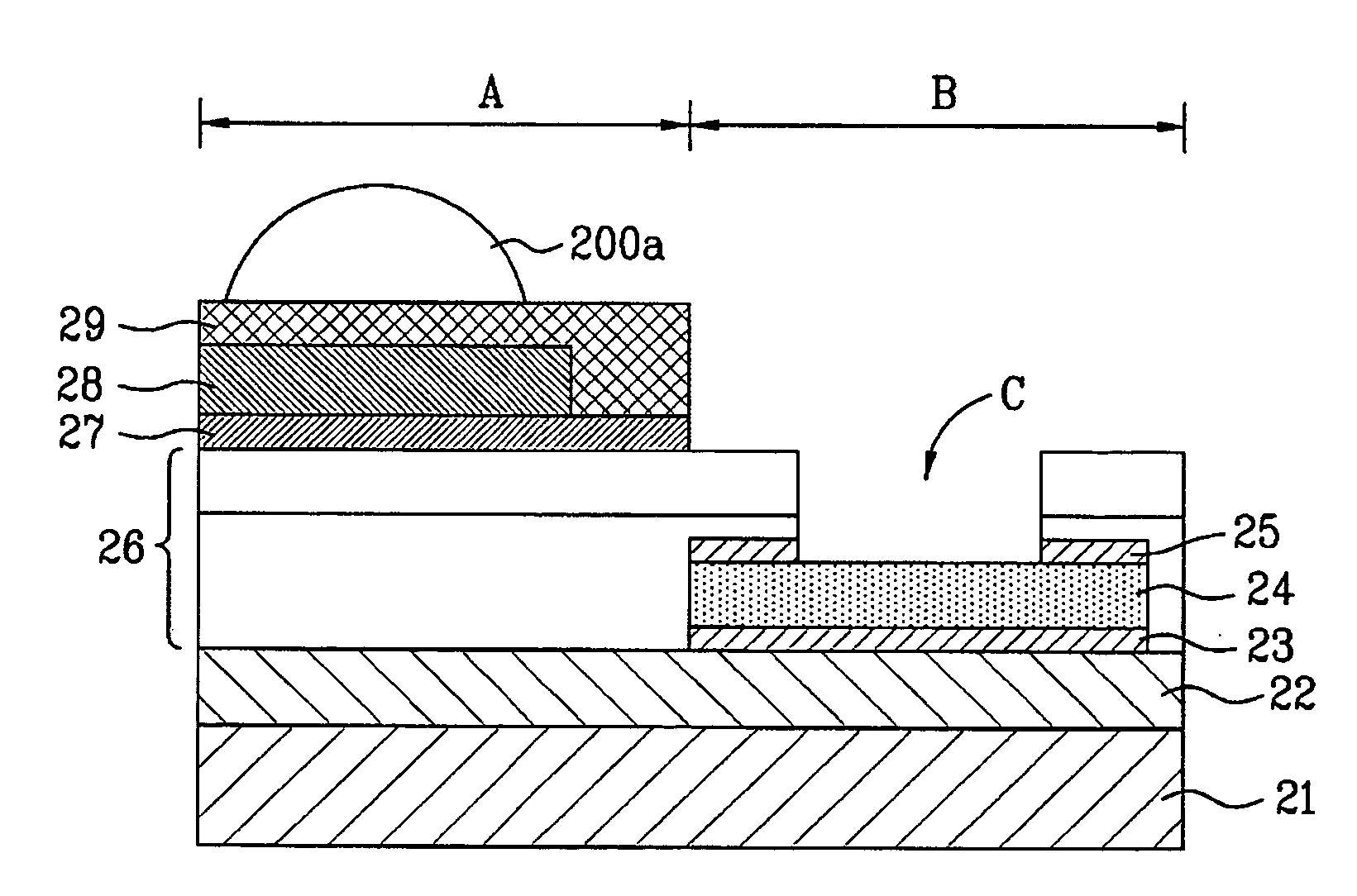

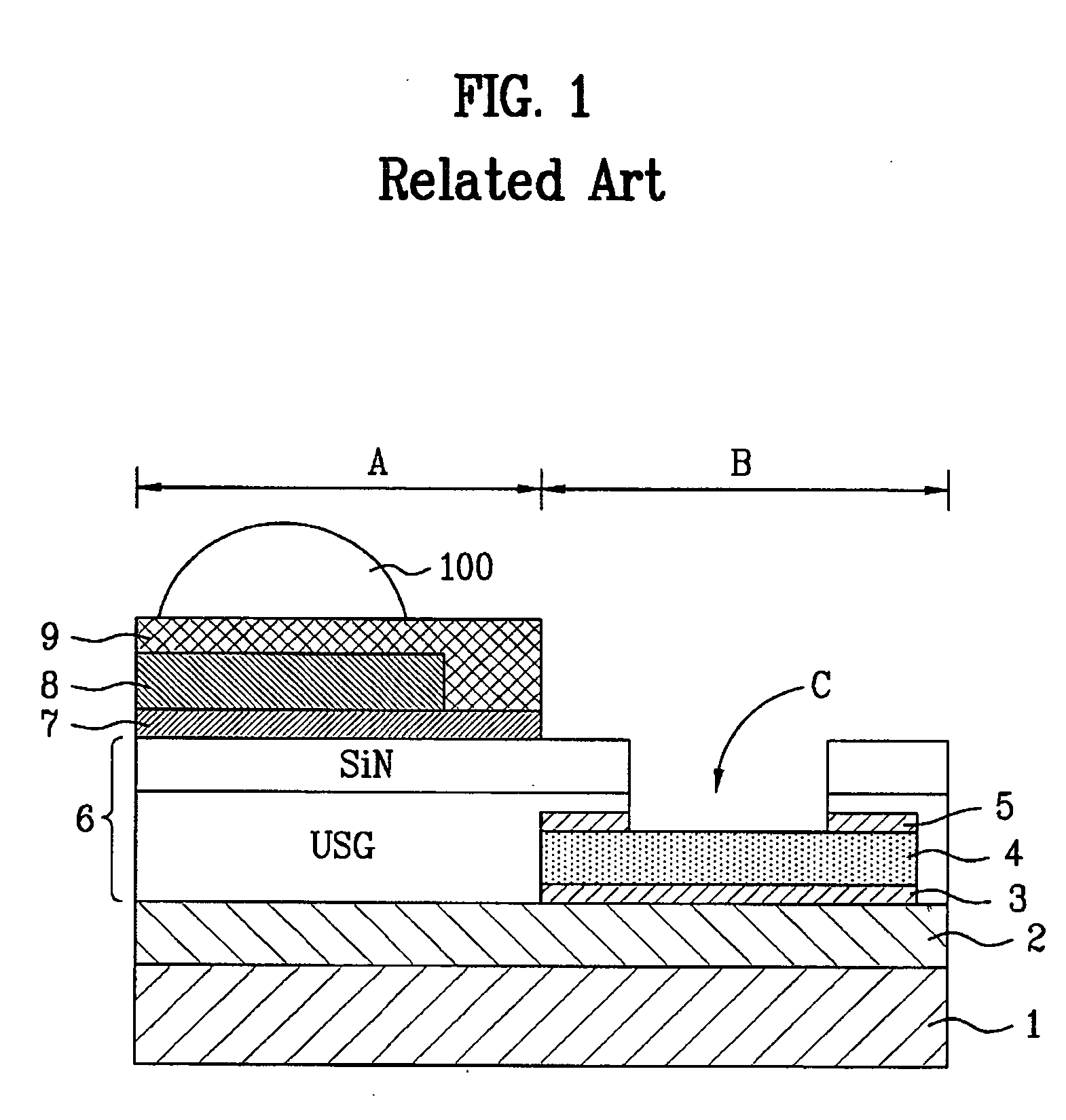

Semiconductor device and method of manufacturing the same

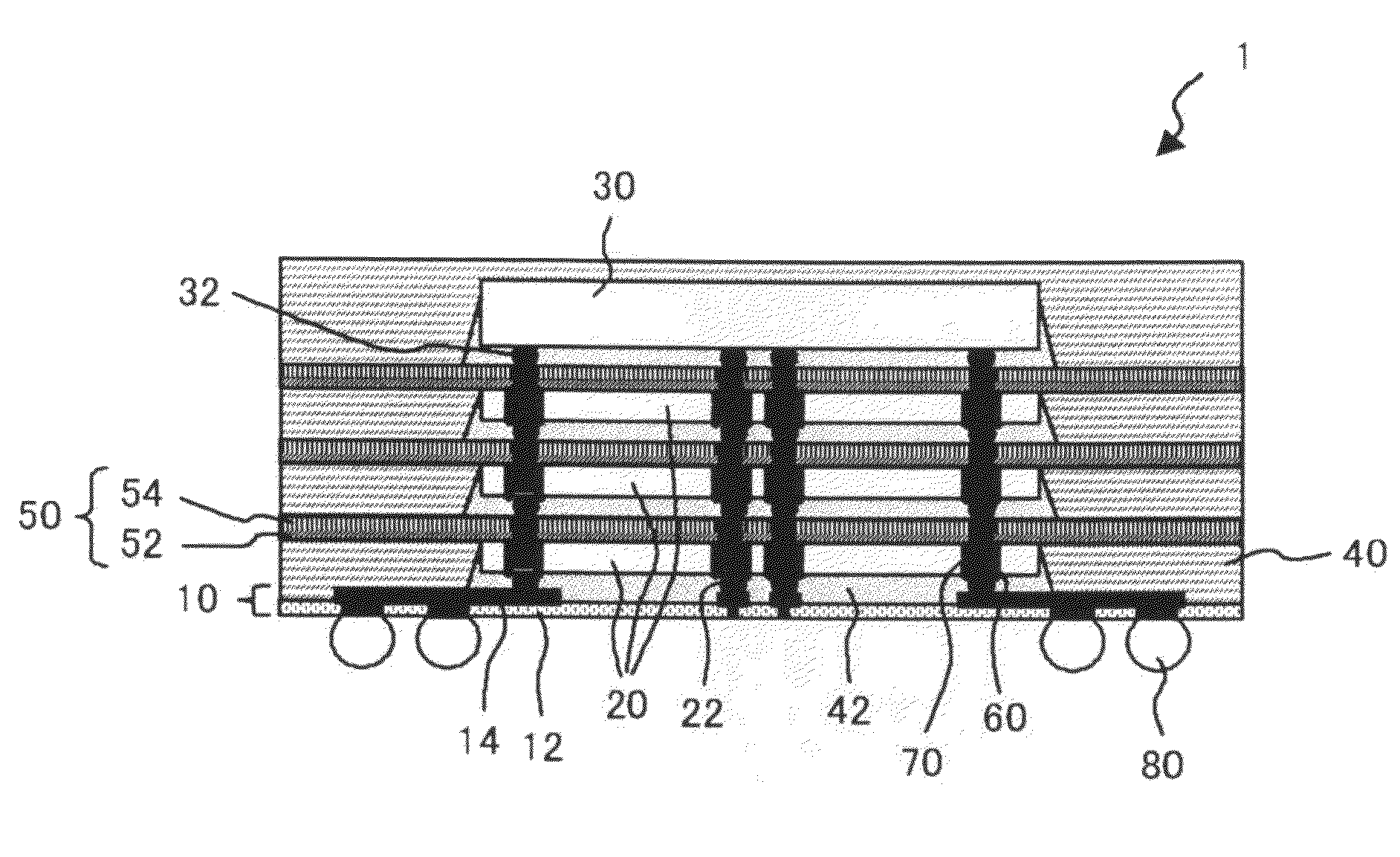

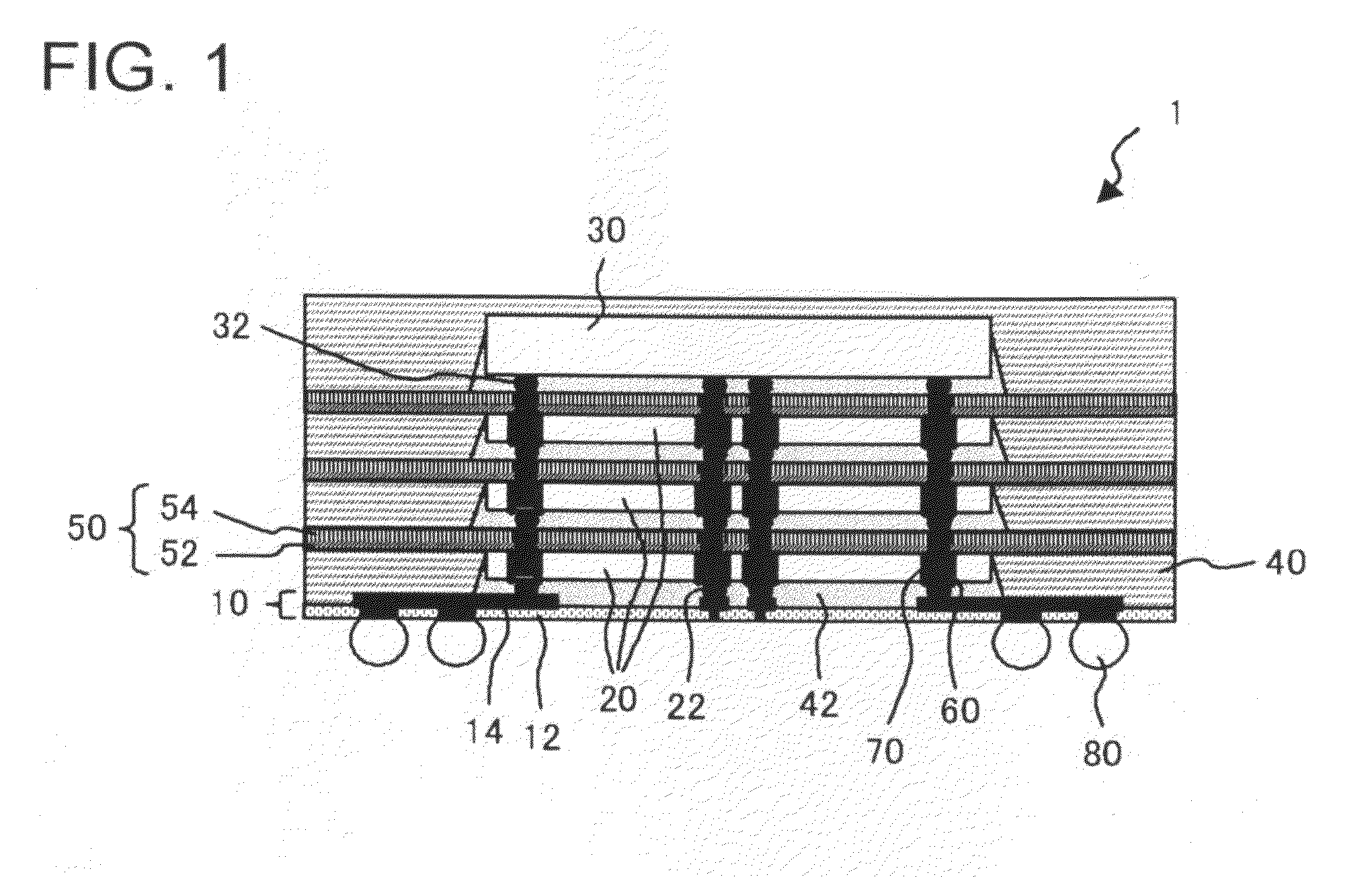

InactiveUS20070126085A1Reduce path lengthRun at high speedSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A semiconductor device includes an interconnect member, a first semiconductor chip, a second semiconductor chip, a resin layer, an inorganic insulating layer, and a through electrode. The first semiconductor chip is mounted in a face-down manner on the interconnect member. The resin layer covers the side surface of the first semiconductor chip. This inorganic insulating layer is in contact with the back surface of the first semiconductor chip, and directly covers the back surface. Also, the inorganic insulating layer extends over the resin layer. The through electrode penetrates the inorganic insulating layer and the semiconductor substrate of the first semiconductor chip. The second semiconductor chip is mounted in a face-down manner on the inorganic insulating layer that covers the back surface of the first semiconductor chip in the uppermost layer.

Owner:NEC ELECTRONICS CORP

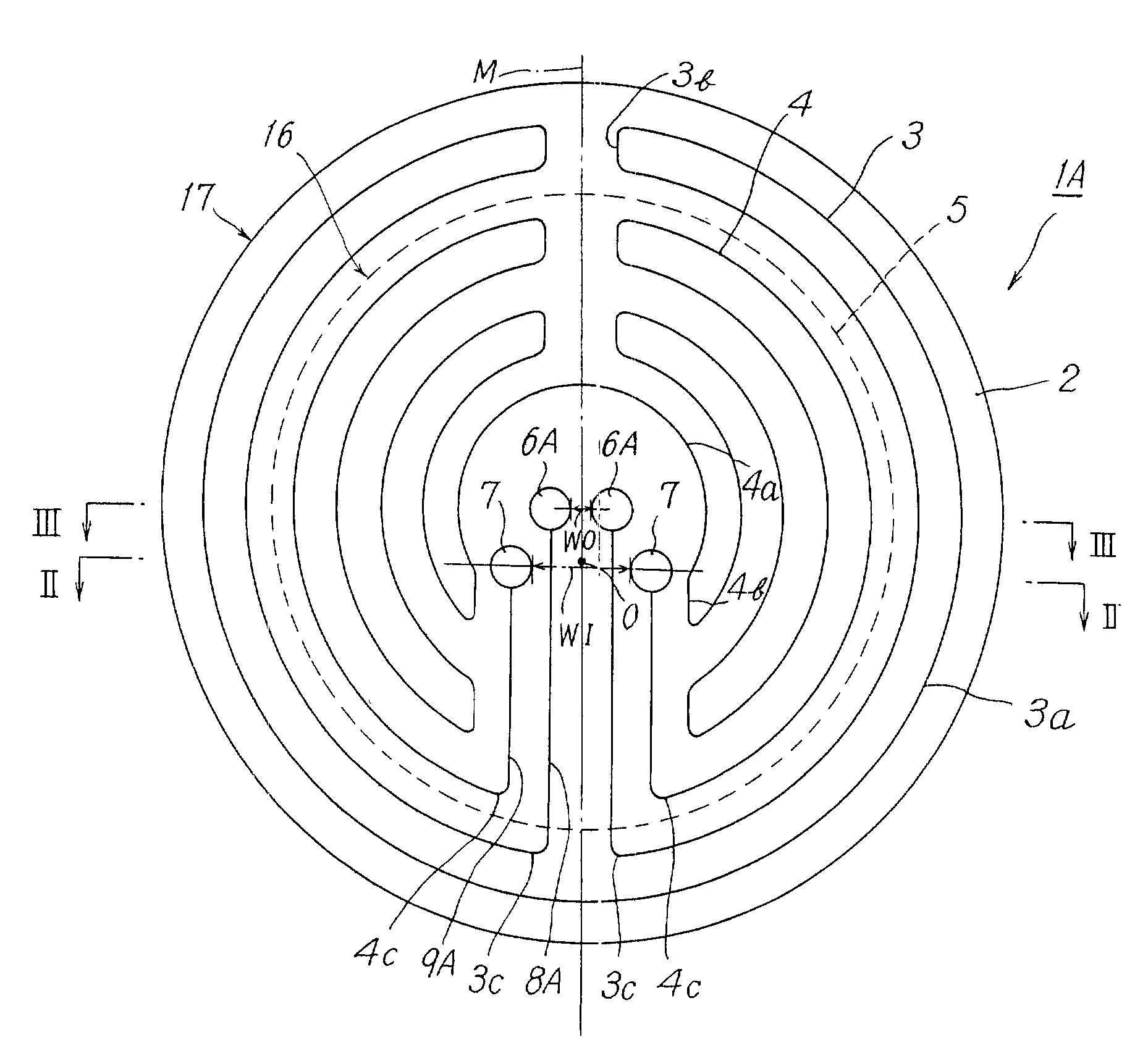

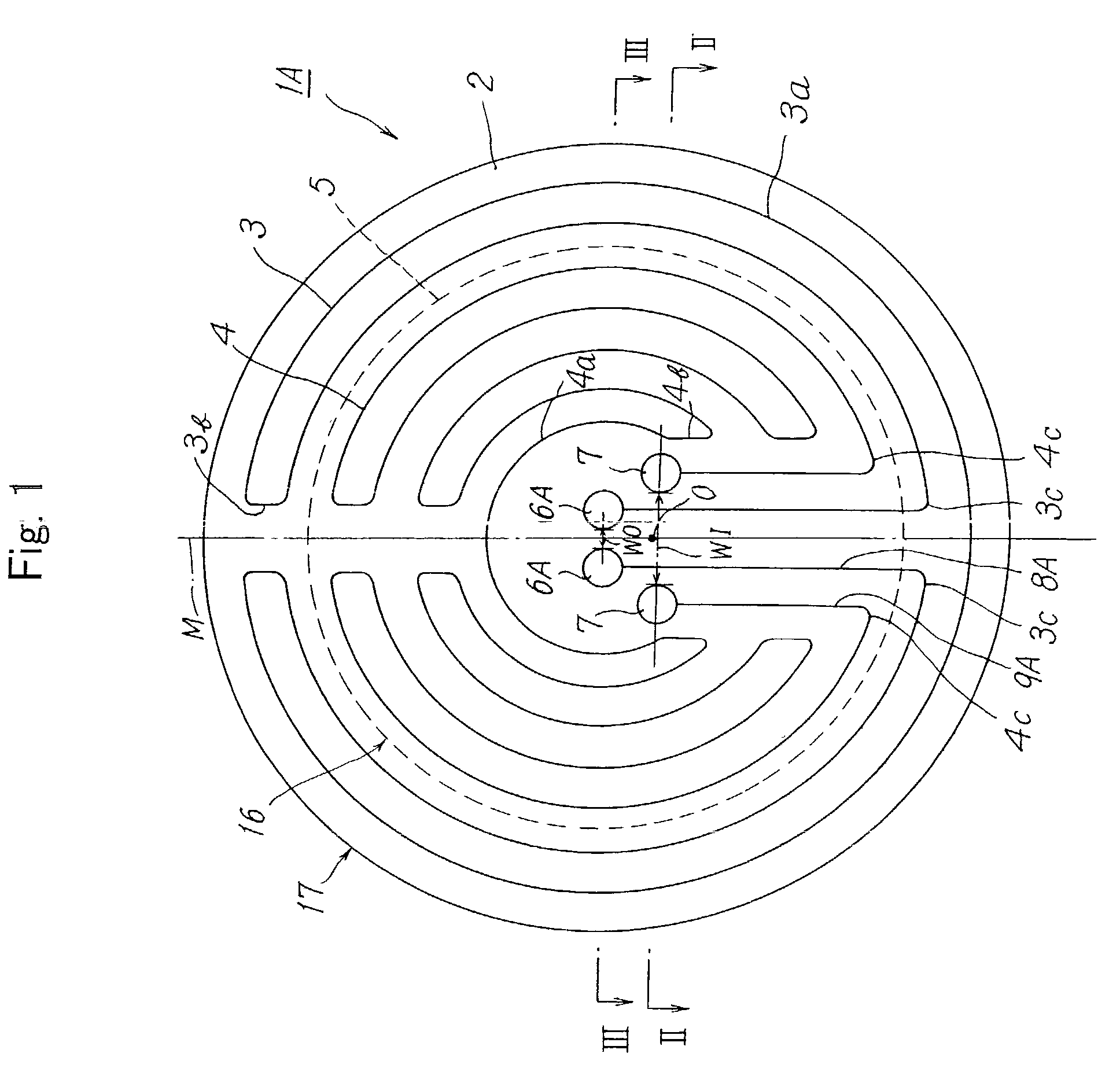

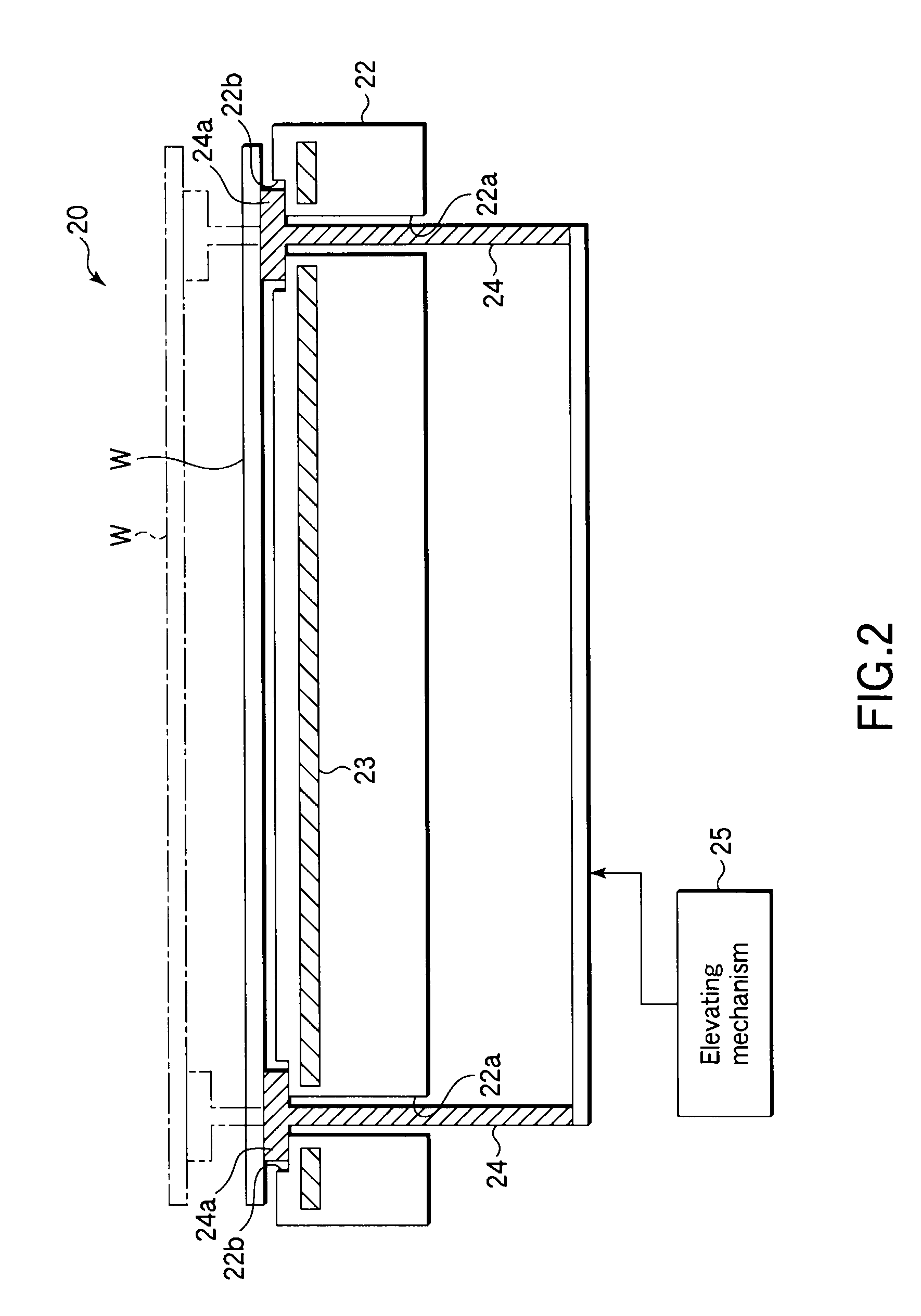

Heating apparatus

InactiveUS7279661B2Prevent increase in heat capacity of heatingEasy to fixOhmic-resistance electrodesHeater elementsEngineeringSemiconductor

A heating apparatus for a semiconductor producing system is provided, including a heater having a mounting face, an opposed back face, a first resistance heating element, a second resistance heating element provided along substantially the same plane as the first heating element, a first terminal connected with the first heating element and a second terminal connected with the second heating element. A supporting member is fixed to the back face of the heater. First and second power supply means are respectively connected with the first and second terminals and contained in an inner space of the supporting member. A conductive connector connects the first heating element and the first terminal but not the second heating element. The first heating element is provided in a first zone, the second heating element is provided in a second zone, and the conductive connector is provided in the plane and the second zone.

Owner:NGK INSULATORS LTD

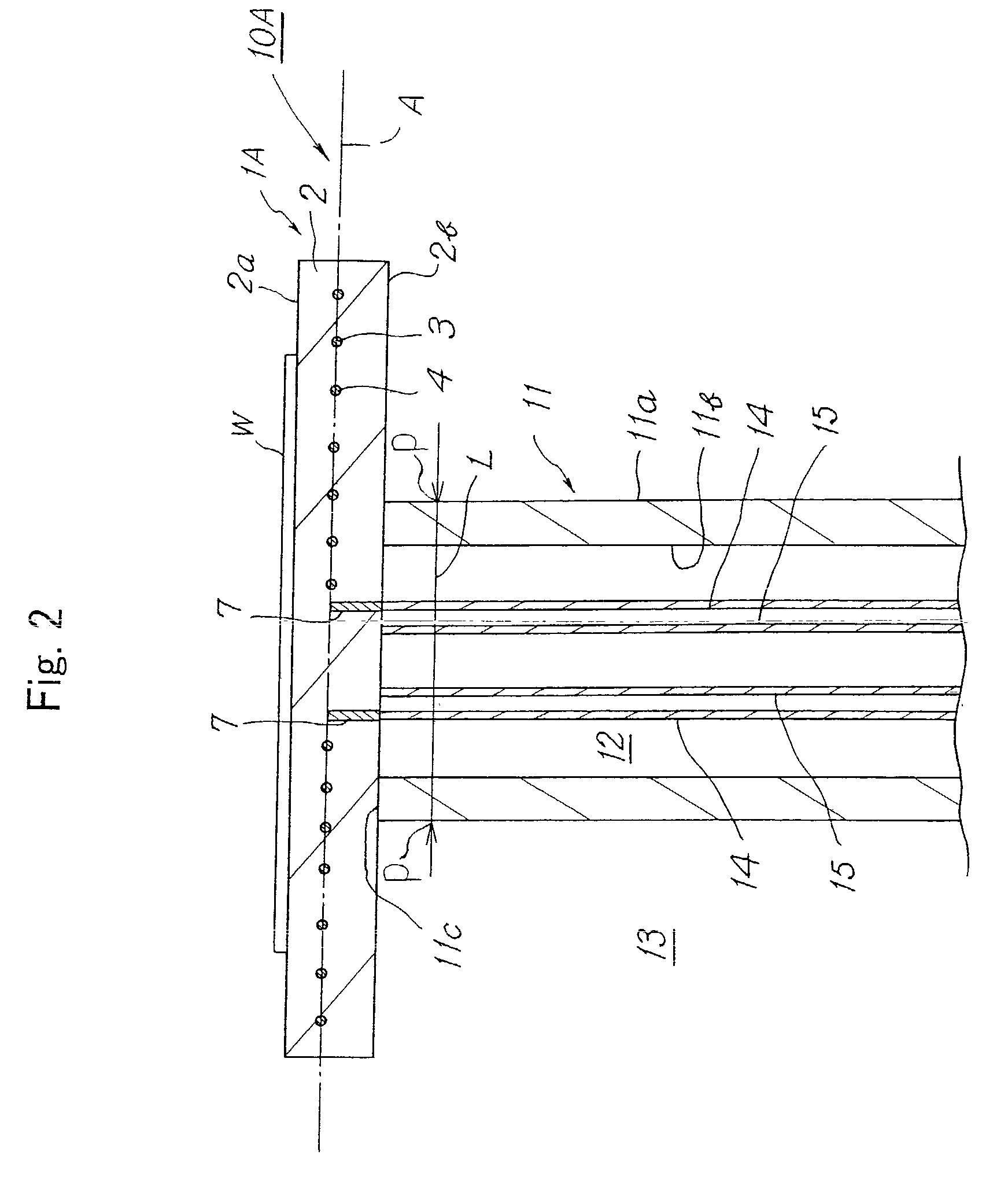

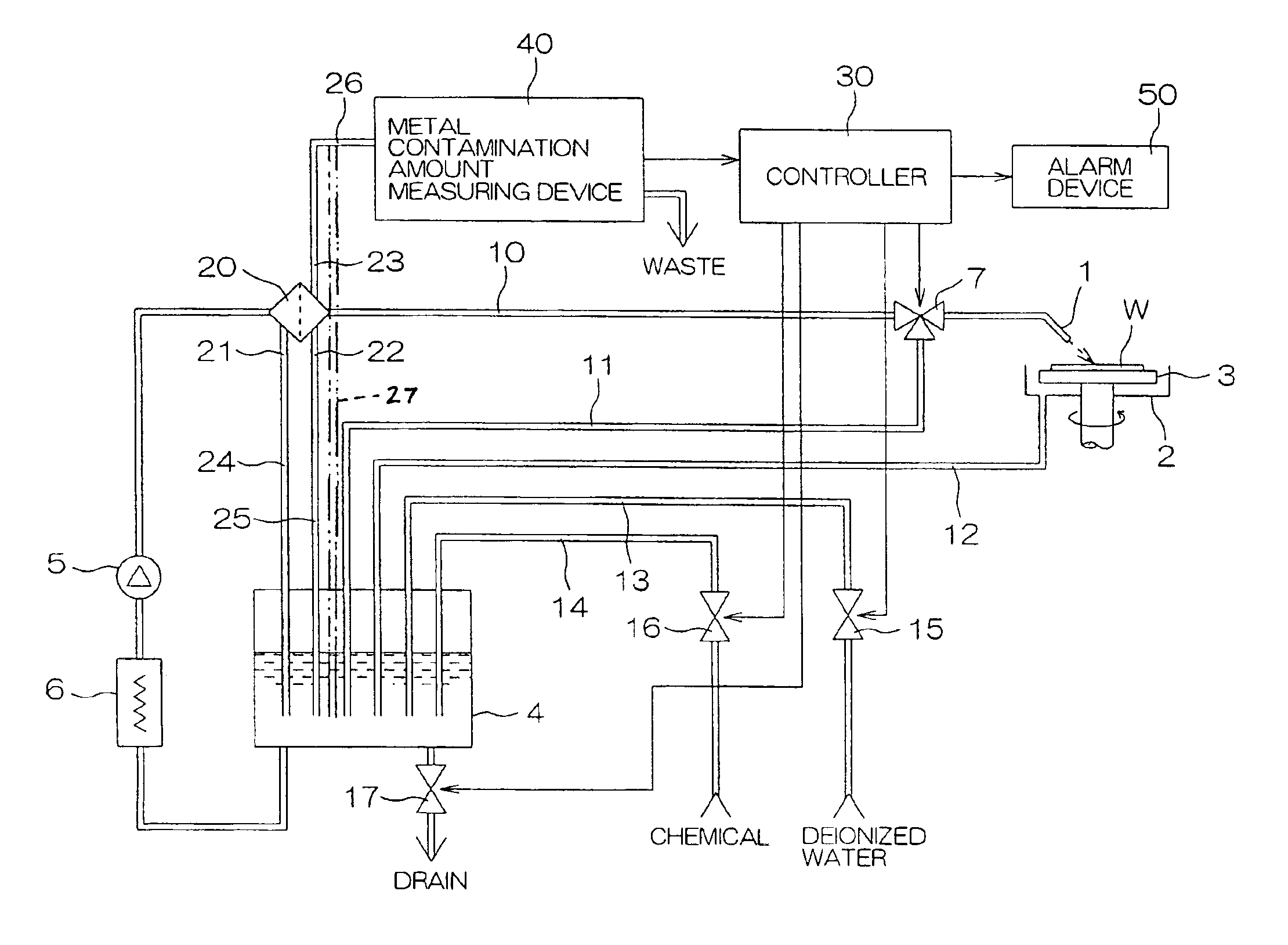

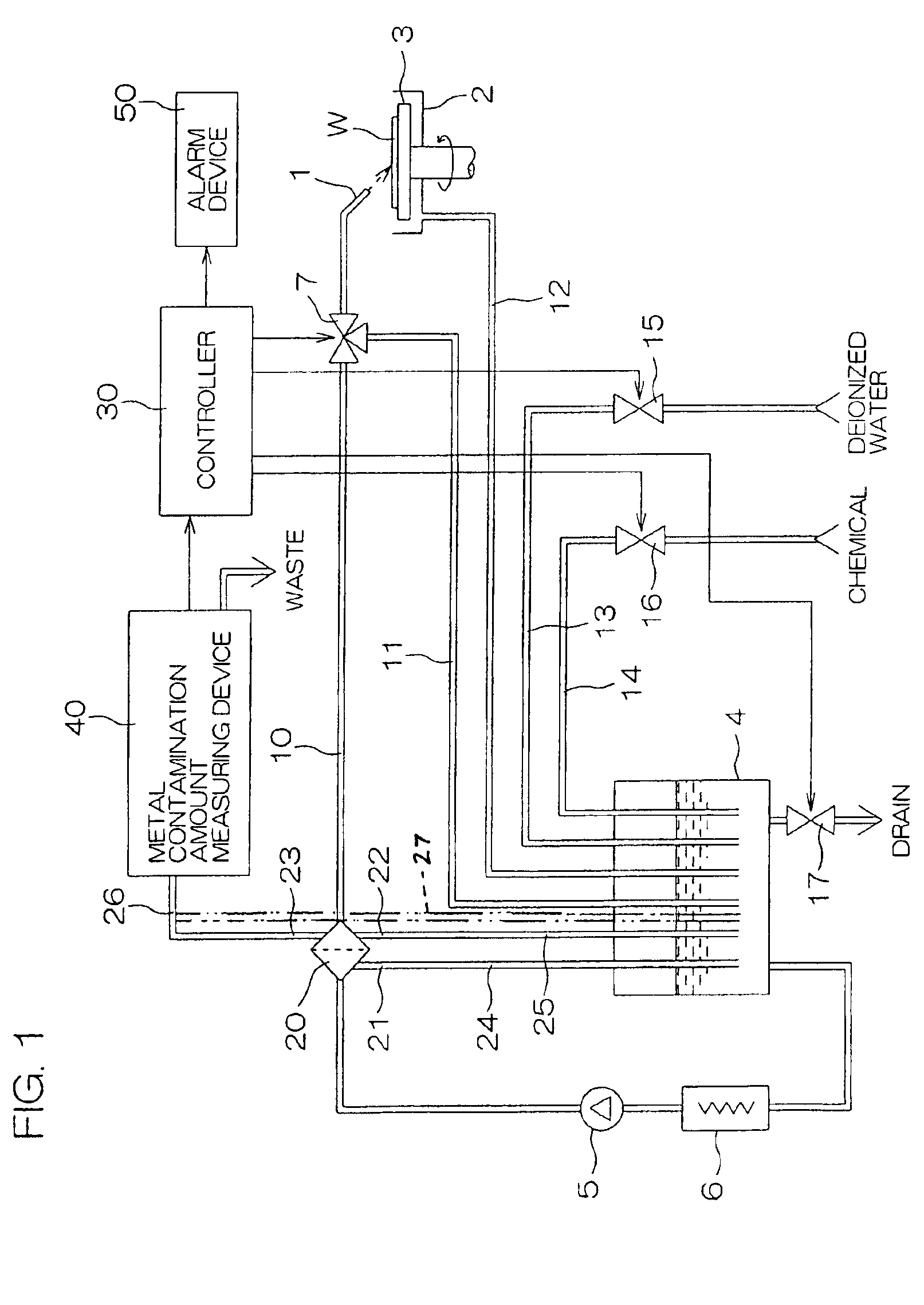

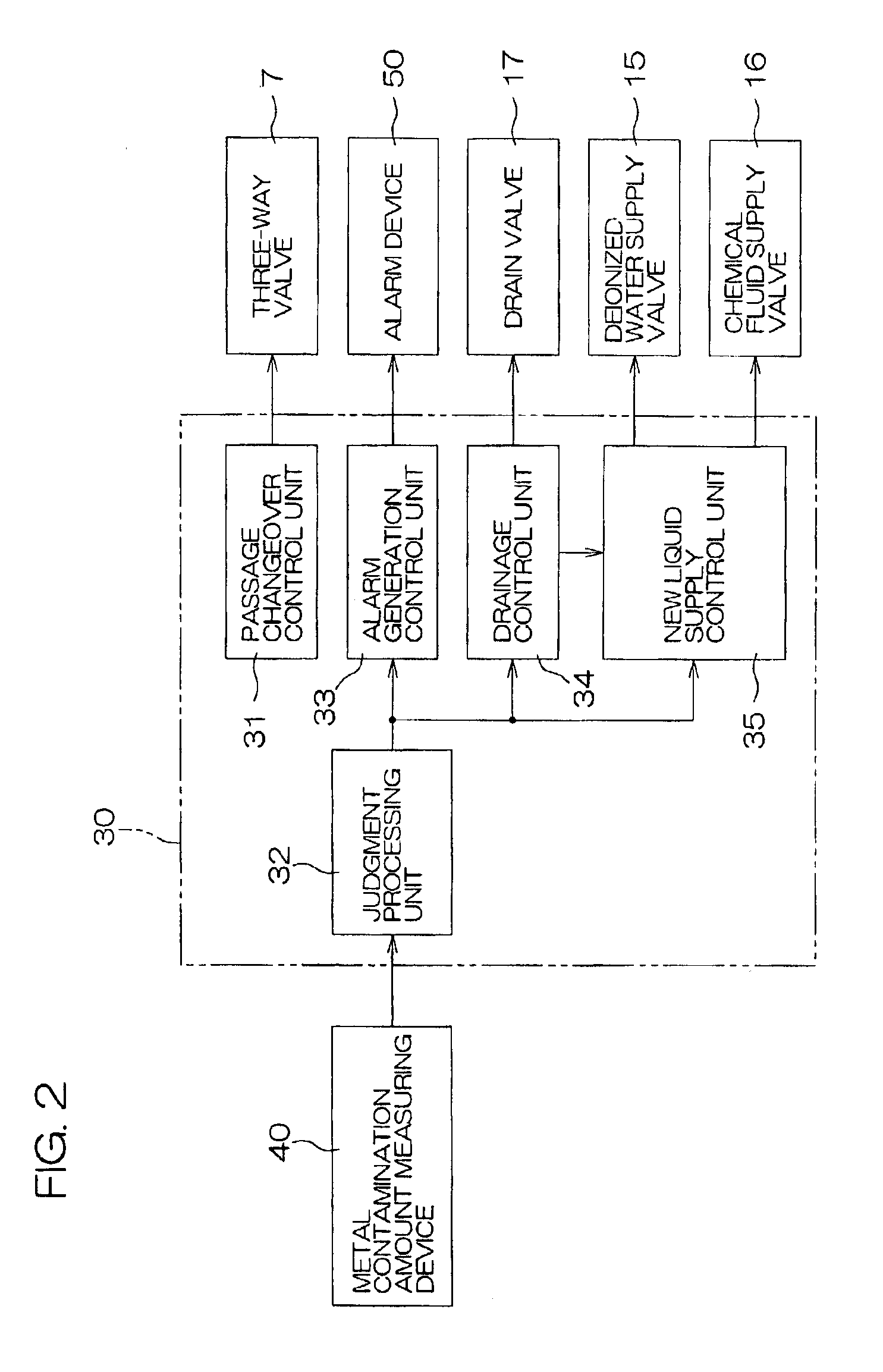

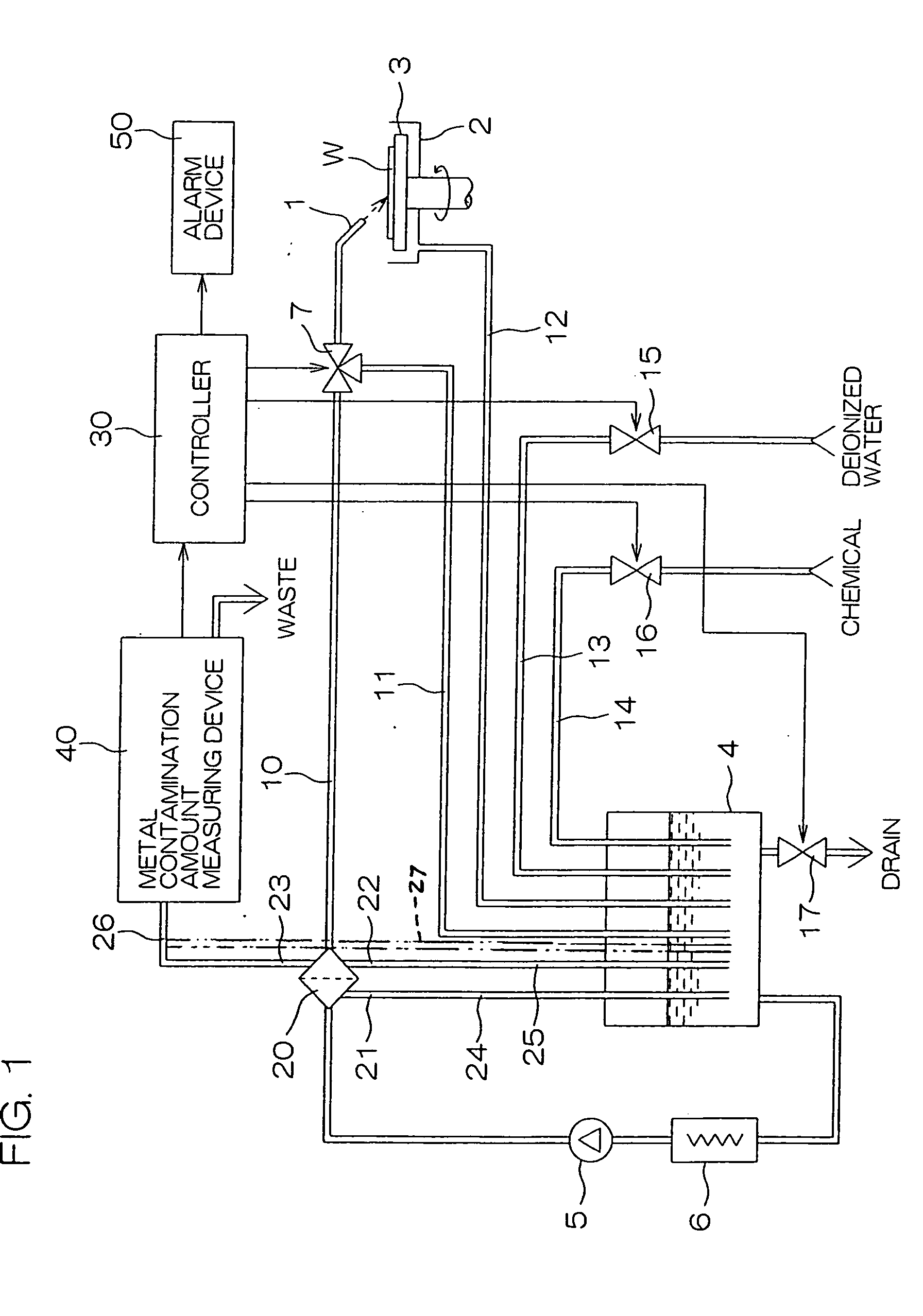

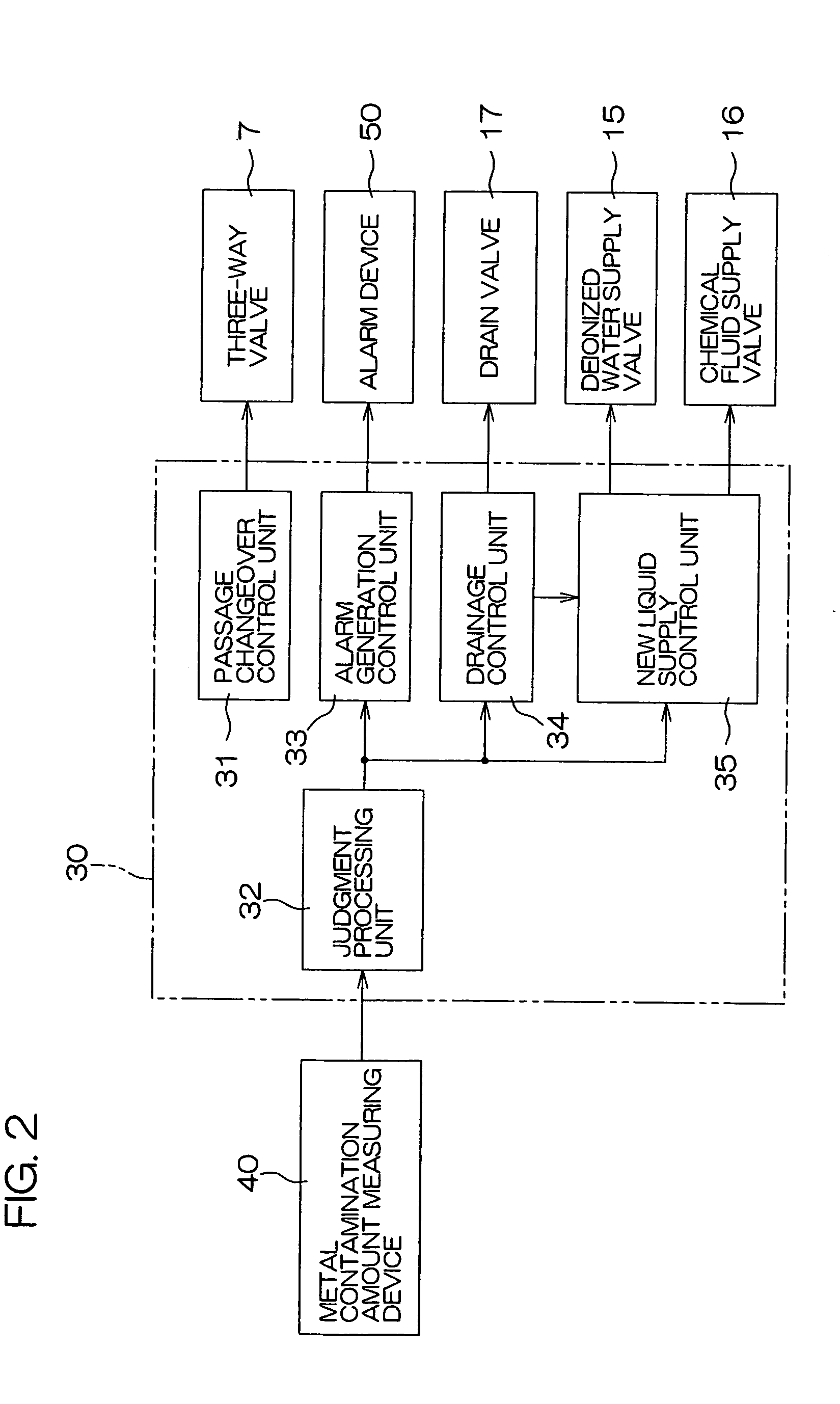

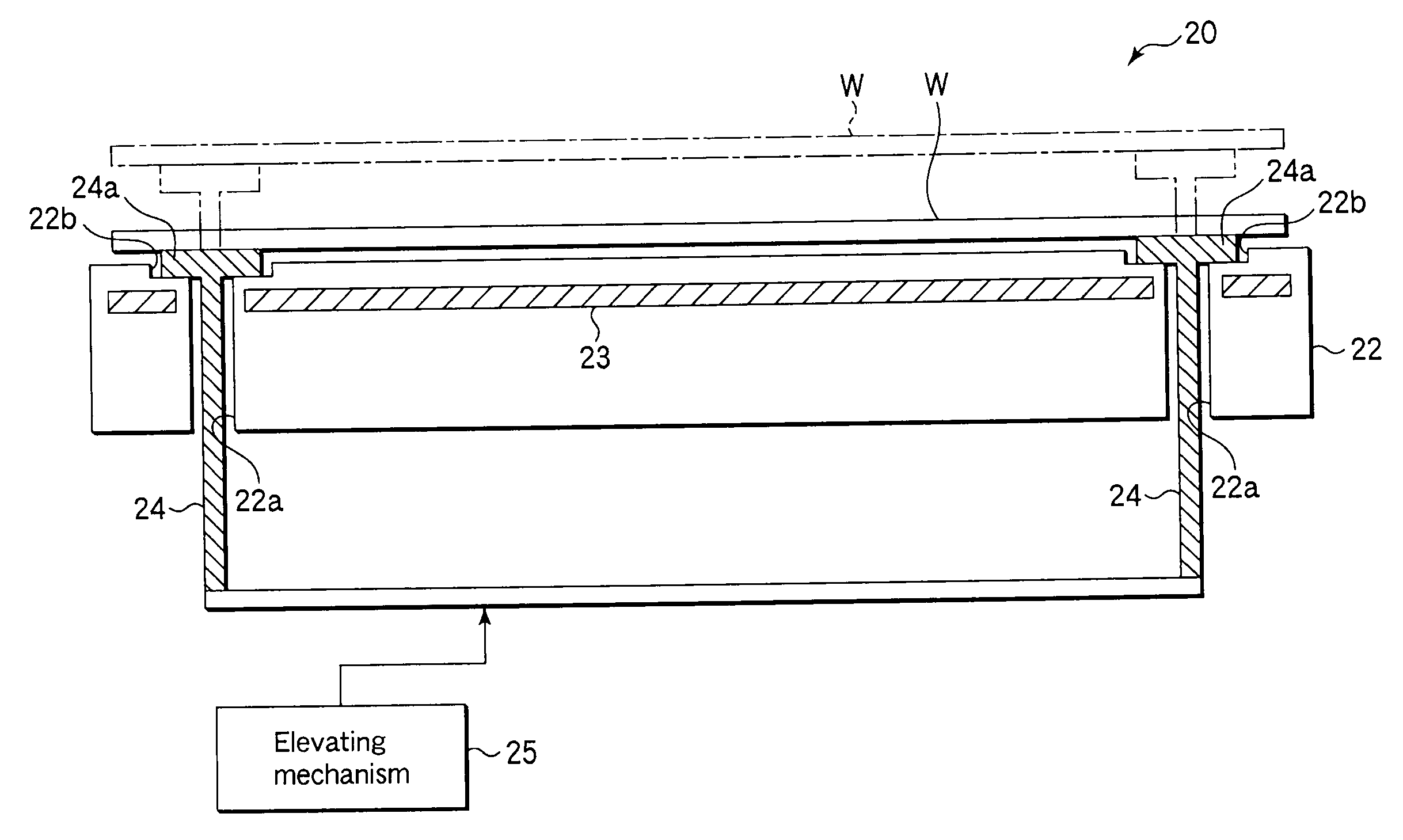

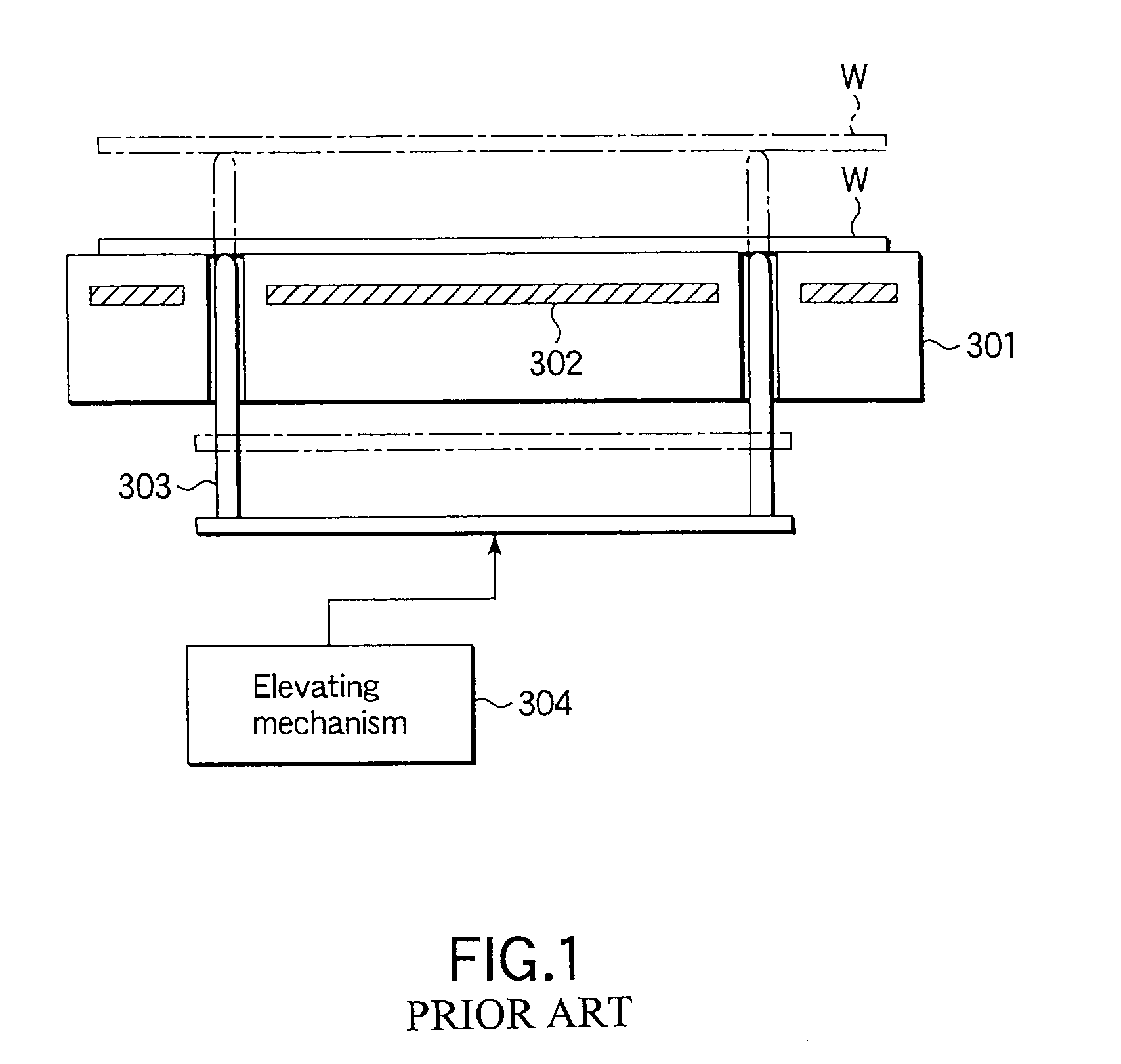

Substrate processing apparatus and substrate processing method

InactiveUS6878303B2Avoid Metal ContaminationReduce consumptionDecorative surface effectsSemiconductor/solid-state device manufacturingSpray nozzleMetal contamination

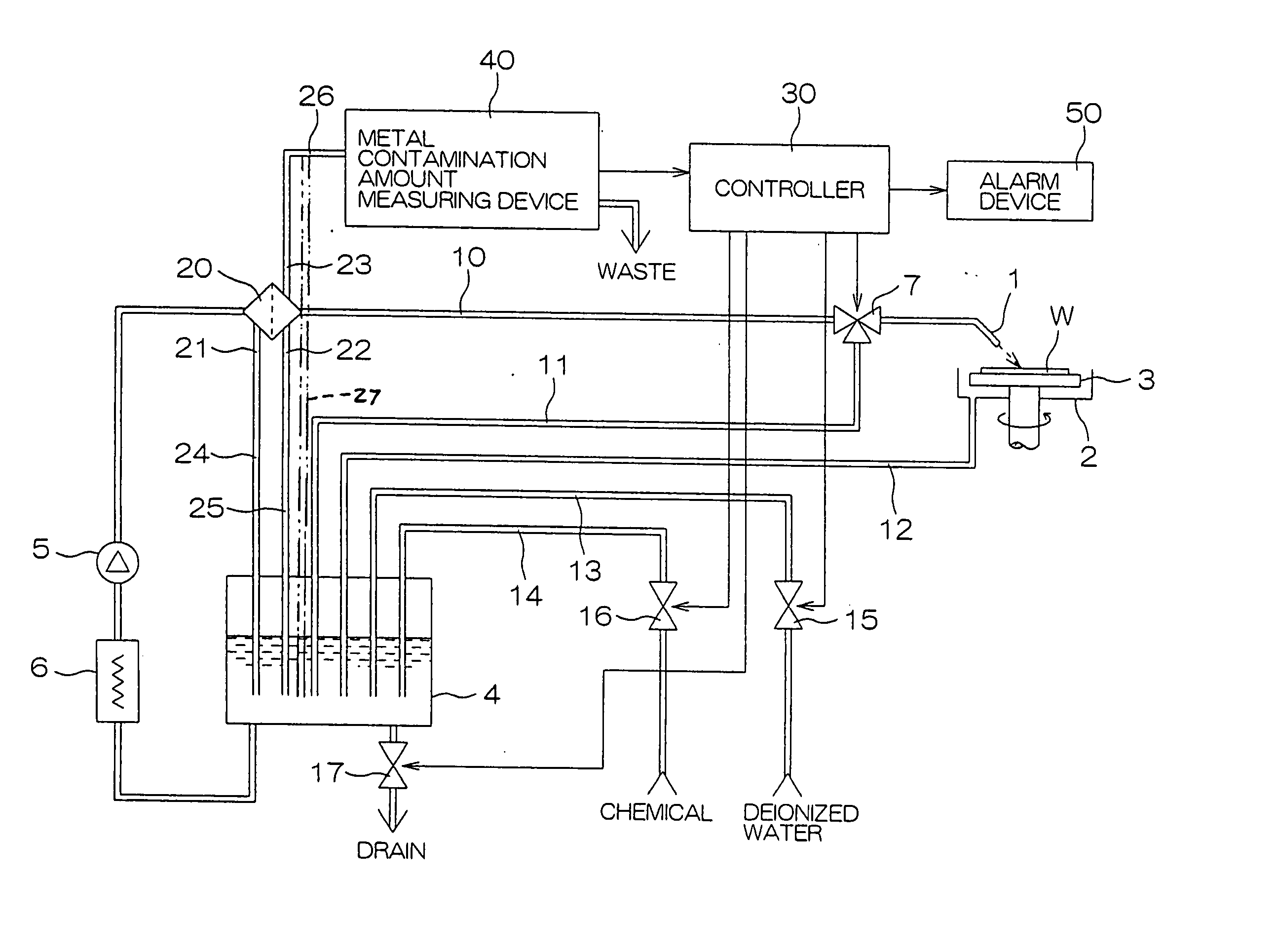

A substrate processing apparatus for supplying a treatment liquid onto the surface of a substrate to treat the same. This apparatus is provided with: a spin chuck for holding and rotating a substrate; a nozzle for supplying a treatment liquid to the substrate held by the spin chuck; a circulating passage arranged such that the treatment liquid supplied to the substrate from the nozzle and used for substrate treatment is circulated to the nozzle and reutilized for substrate treatment; a metal contamination amount measuring device for measuring the metal contamination amount in the treatment liquid passing through the circulating passage; and a judgment processing unit for judging whether or not the value measured by the metal contamination amount measuring device has exceeded a predetermined set value.

Owner:DAINIPPON SCREEN MTG CO LTD

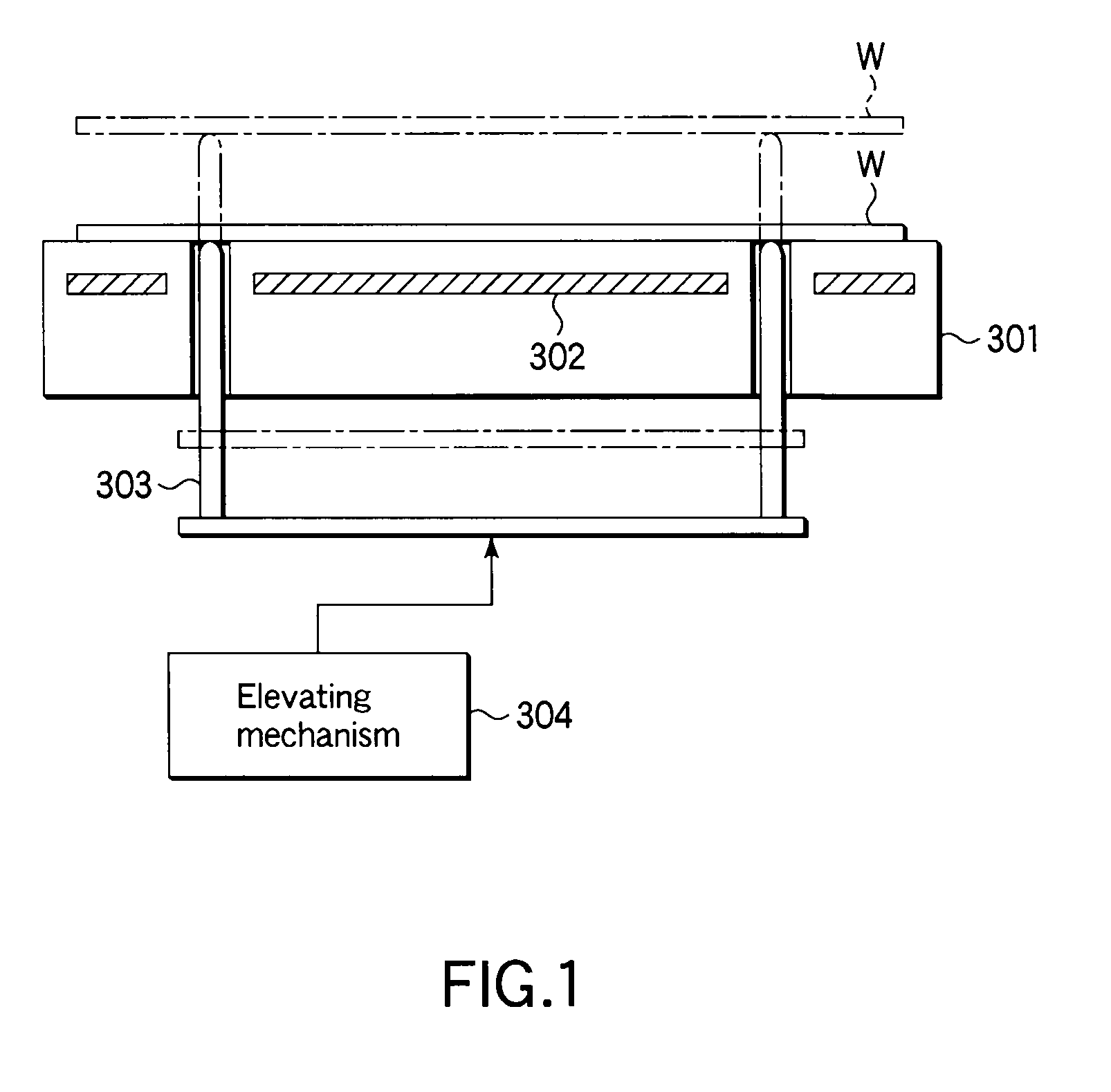

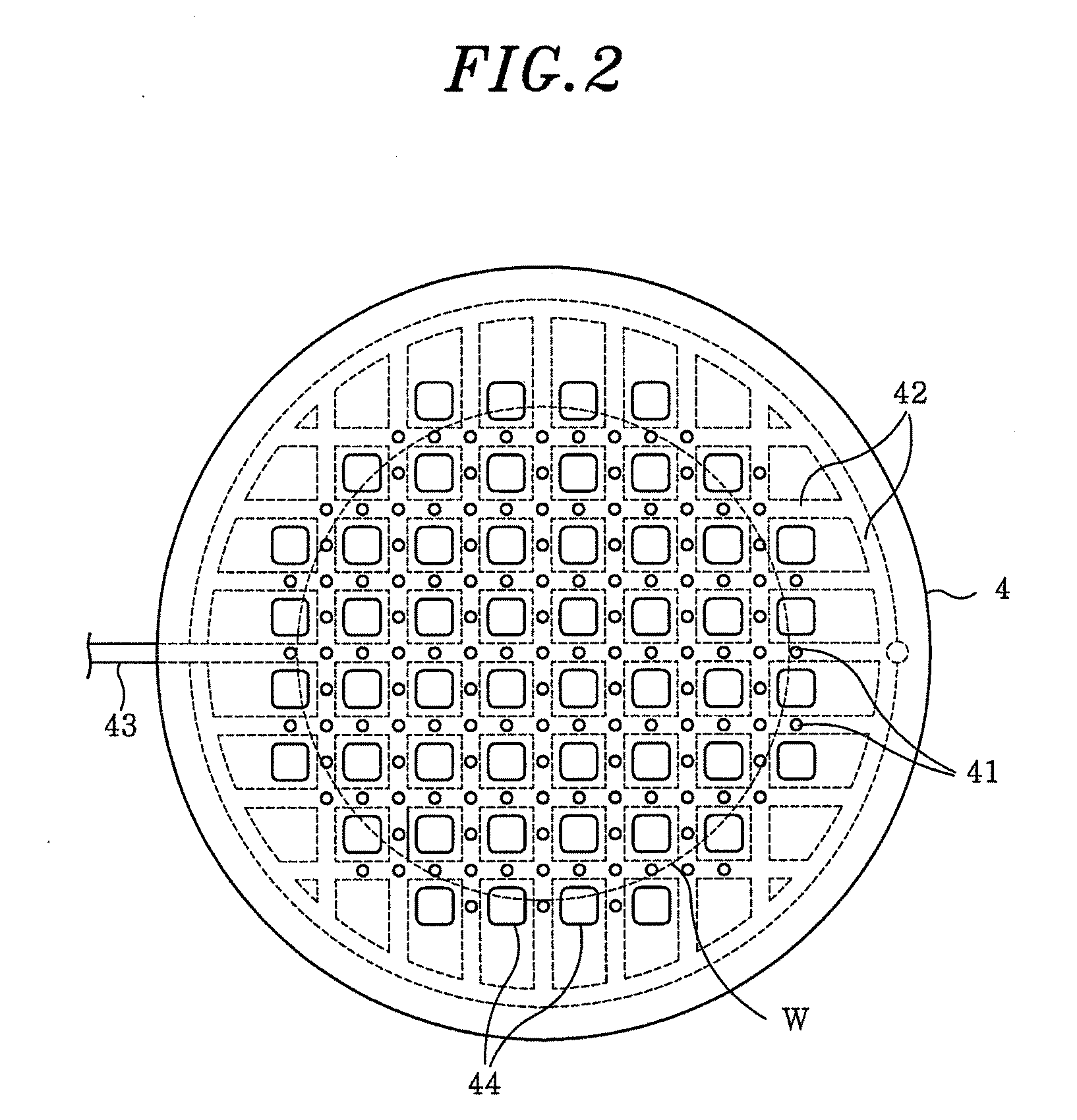

Substrate processing apparatus, substrate placing table used for same, and member exposed to plasma

InactiveUS20090041568A1Improve temperature uniformityPrevent particle generationConveyorsSemiconductor/solid-state device manufacturingEngineeringStructural engineering

A substrate table includes a substrate table main body provided with a heater embedded therein and having an upper surface serving as a heating face for heating a target substrate, and lifter pins inserted in the substrate table main body and configured to be moved up and down. Recessed portions are formed in the heating face of the substrate table main body at positions corresponding to the lifter pins and have a bottom lower than the heating face. Each of the lifter pins includes a lifter pin main body and a head portion formed at a distal end of the lifter pin main body and having a diameter larger than the lifter pin main body, the head portion being formed to correspond to each recessed portion and to be partly accommodated in the recessed portion. The head portion has a head portion upper end for supporting the target substrate and a head portion lower surface opposite to the head portion upper end. The lifter pins are movable between a first state where the head portion lower surface engages with the bottom of the recessed portion, and a second state where the head portion lower surface separates upward from the bottom of the recessed portion.

Owner:TOKYO ELECTRON LTD

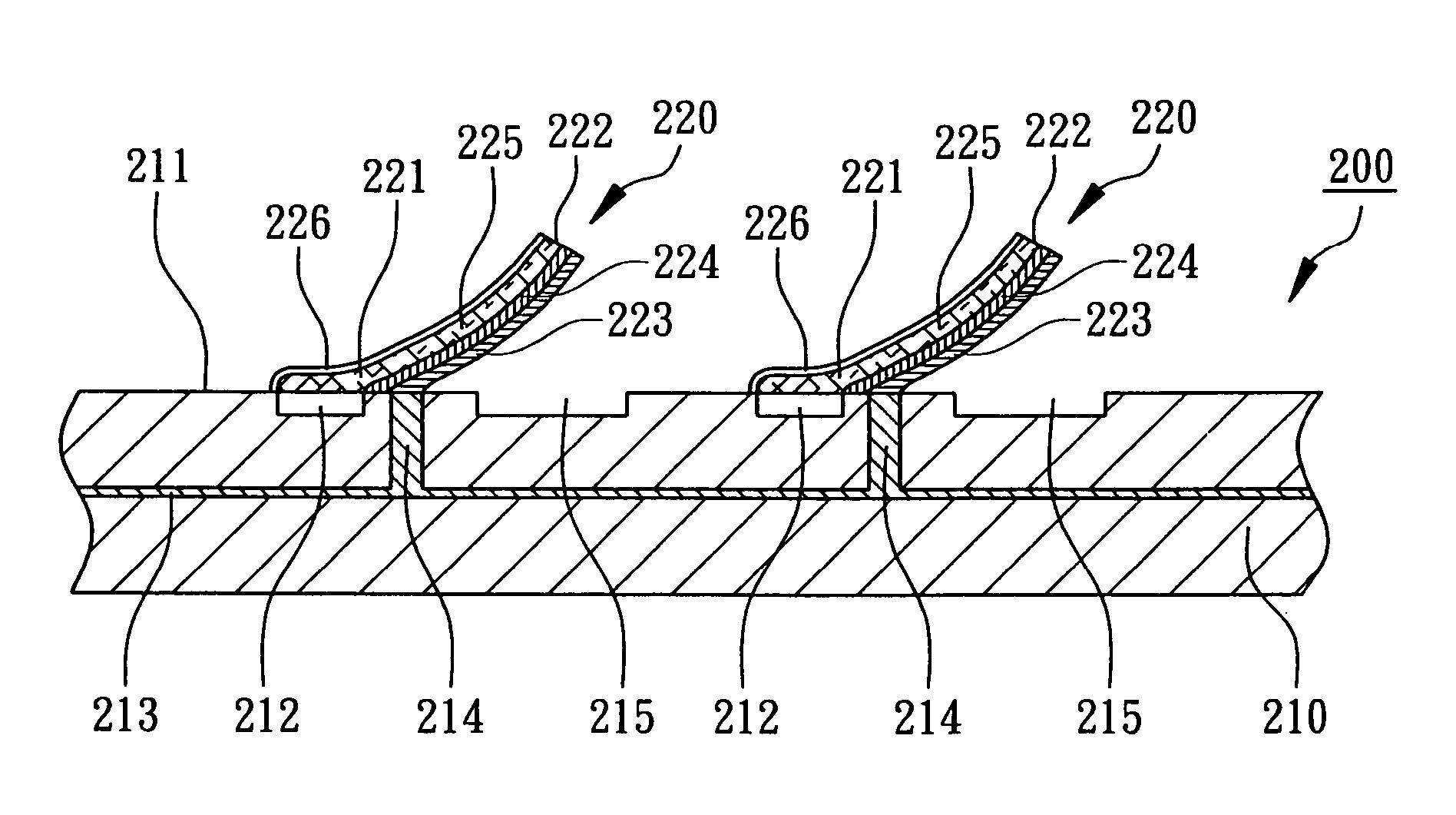

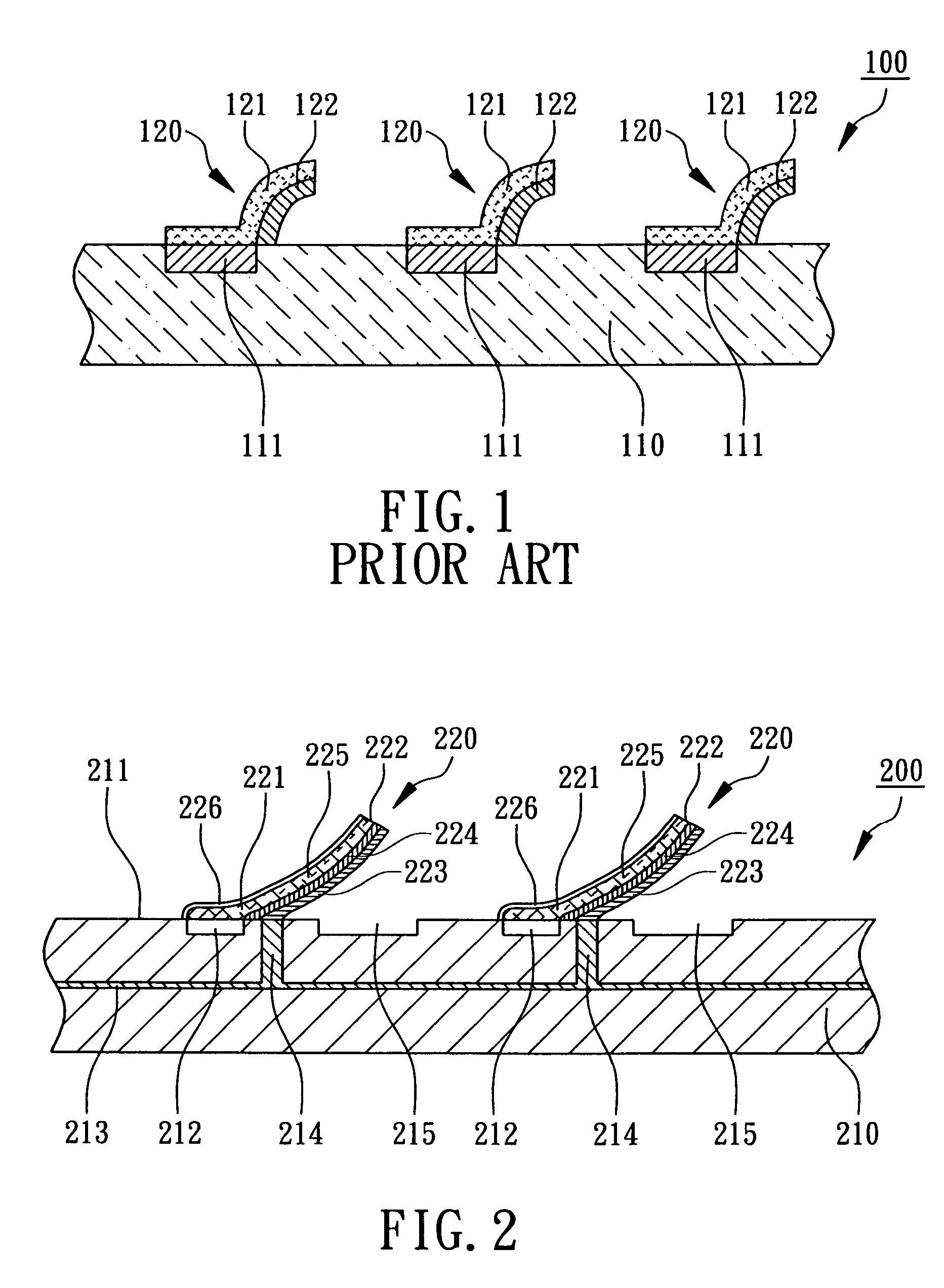

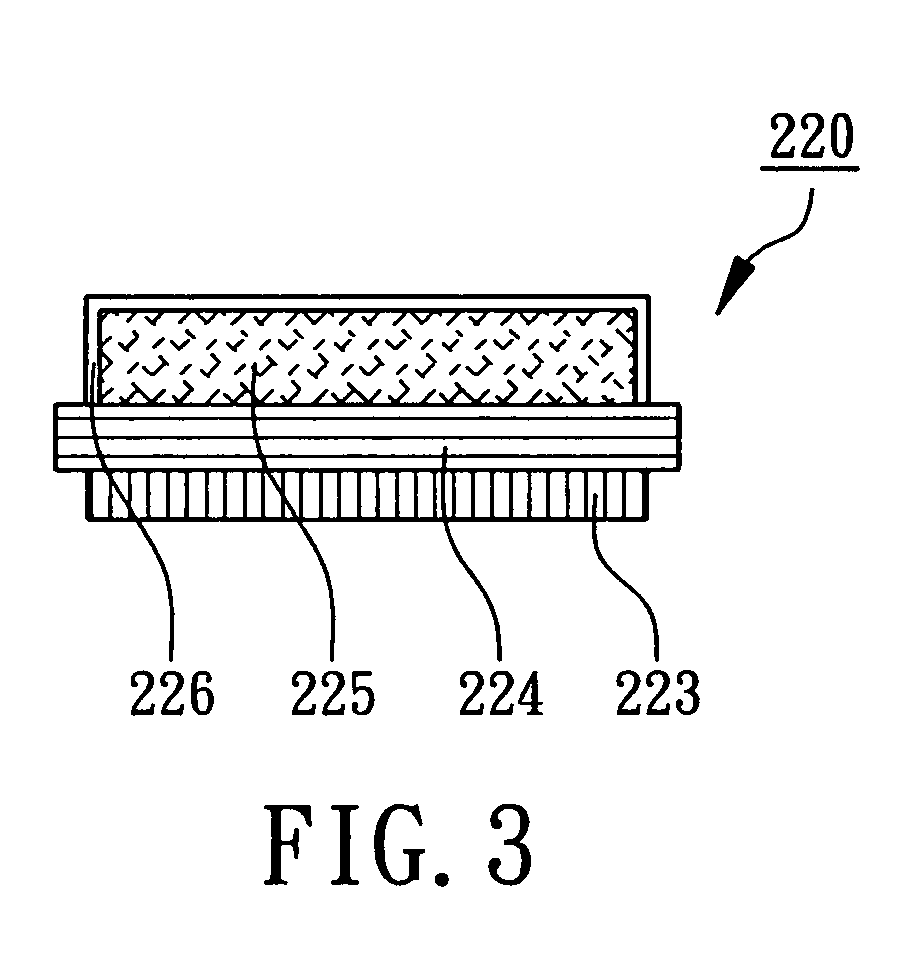

Electronic device with a warped spring connector

InactiveUS20060042834A1Absorb moreAvoid Metal ContaminationElectrical measurement instrument detailsSemiconductor/solid-state device detailsGround planeThermal expansion

An electronic device comprises a substrate and at least a warped spring connector. The substrate has a signal bonding pad and a ground plane. The warped spring connector is disposed on the substrate and is connected to the bonding pad. The warped spring connector includes at least a ground lead electrically connected to the ground plane, a dielectric layer on the ground lead, and a transmitting lead on the dielectric layer. The transmitting lead is bonded to the bonding pad. The ground lead is isolated from and close to the transmitting lead to solve cross-talk and noise problem. Furthermore, the coefficient of thermal expansion of the transmitting lead is different from that of the dielectric layer or the ground lead such that the warped spring connector has a suspending end suspending away from the substrate.

Owner:CHIPMOS TECH INC

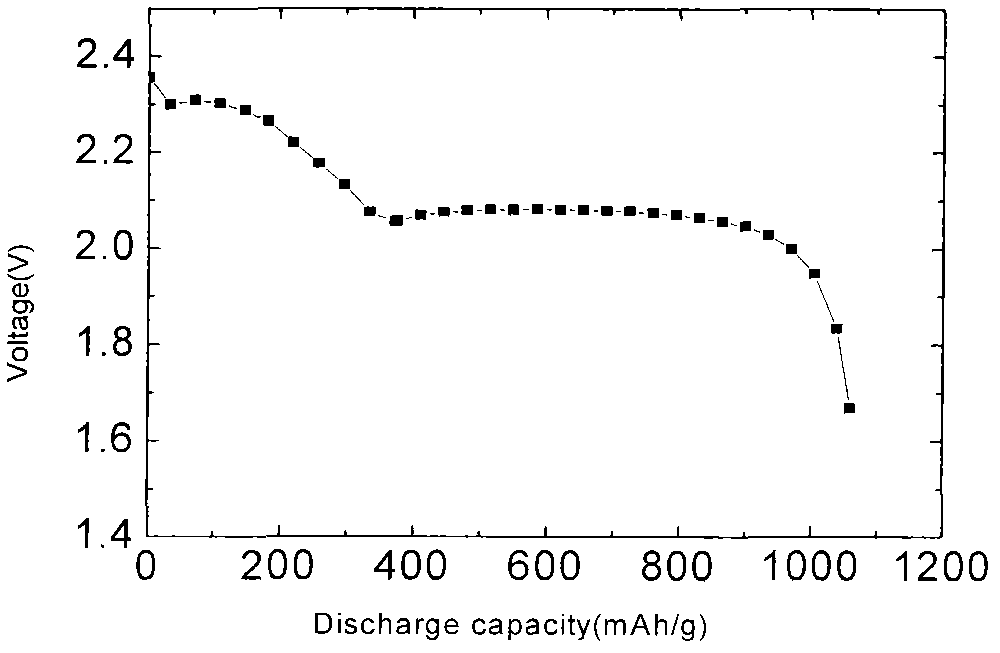

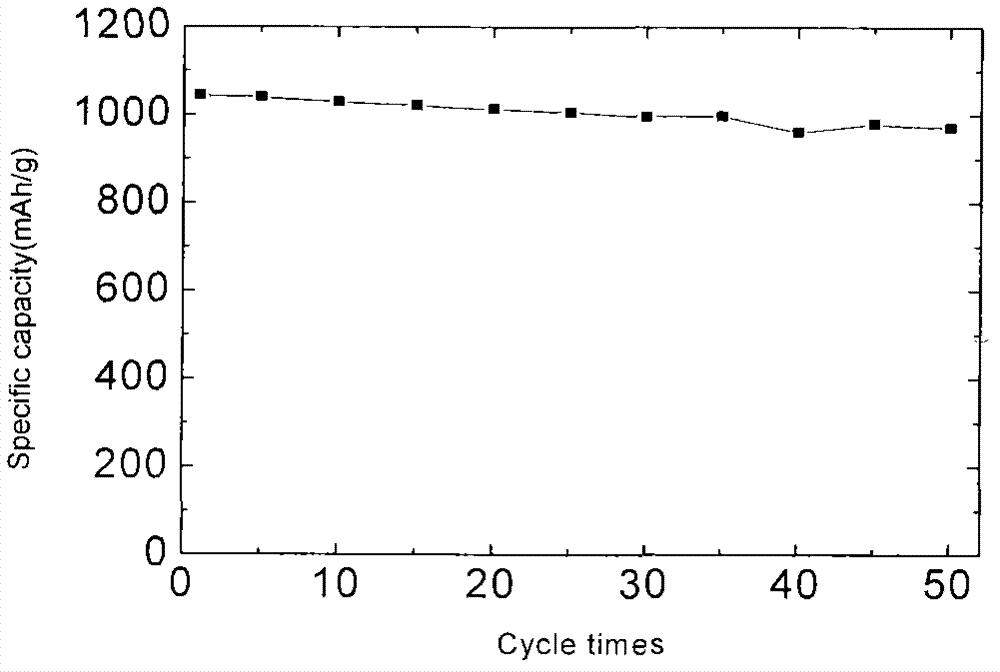

Carbon/sulfur composite positive material having long cycle life, and preparation method thereof

InactiveCN103247799ARich cross-linked network structureSimple structureCell electrodesCarbon fibersSulfur

A grafted carbon nanofiber / sulfur composite material having a high specific capacity and a long cycle life and applied in a lithium sulfur battery is obtained through carrying out melt compounding of grafted carbon nanofibers having an outstanding conductive performance and a network structure and elemental sulfur at a reaction temperature of 110-380DEG C for 2-60h, and the mass content of sulfur in the composite material is 40-85%. The initial discharge specific capacity of the composite positive electrode material is 1186mAh / g, and the discharge specific capacity of the composite positive electrode material after 50-time cycle still maintains 948mAh / g, so the composite positive electrode material has a good cycle stability.

Owner:NO 63971 TROOPS PLA

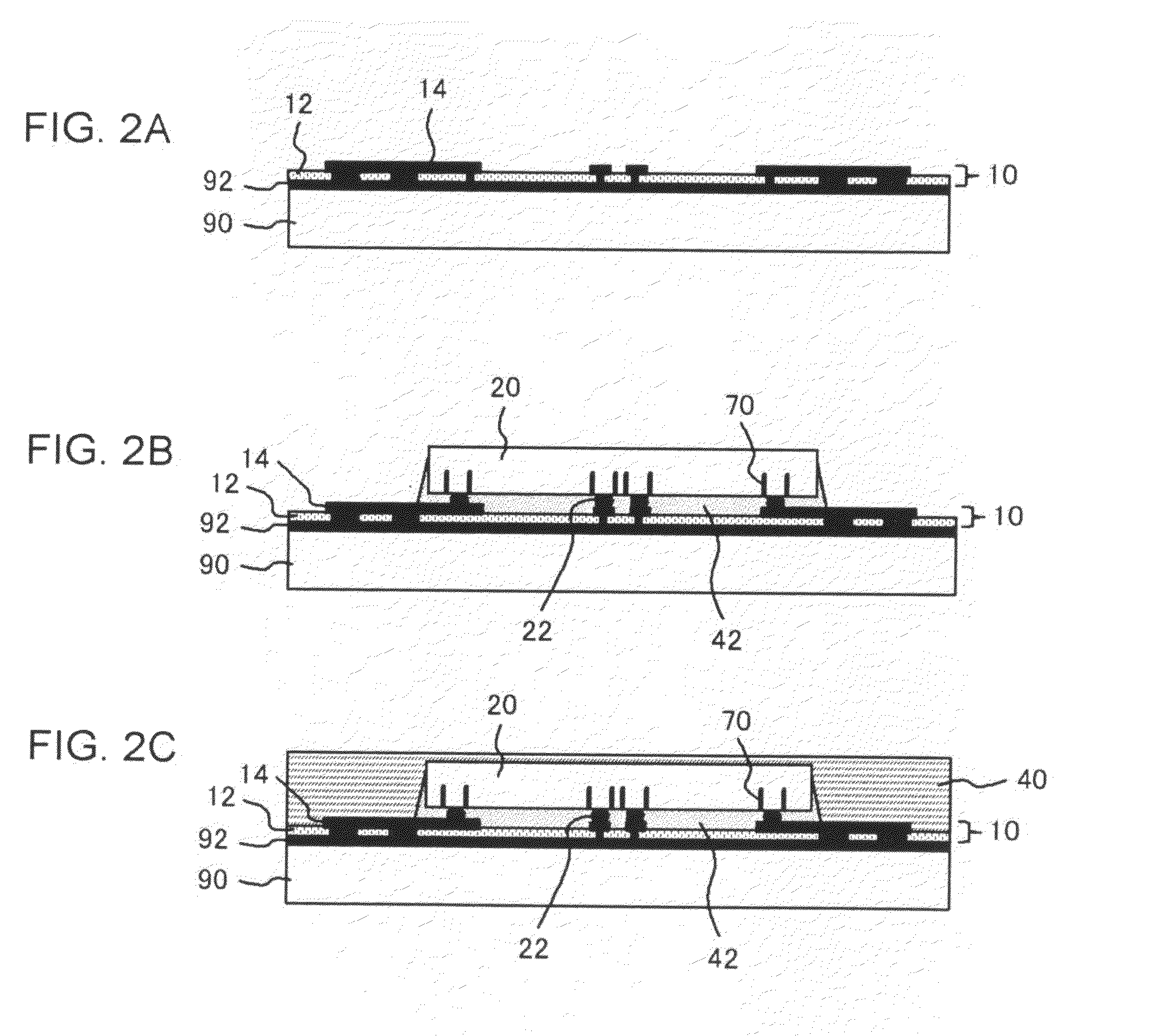

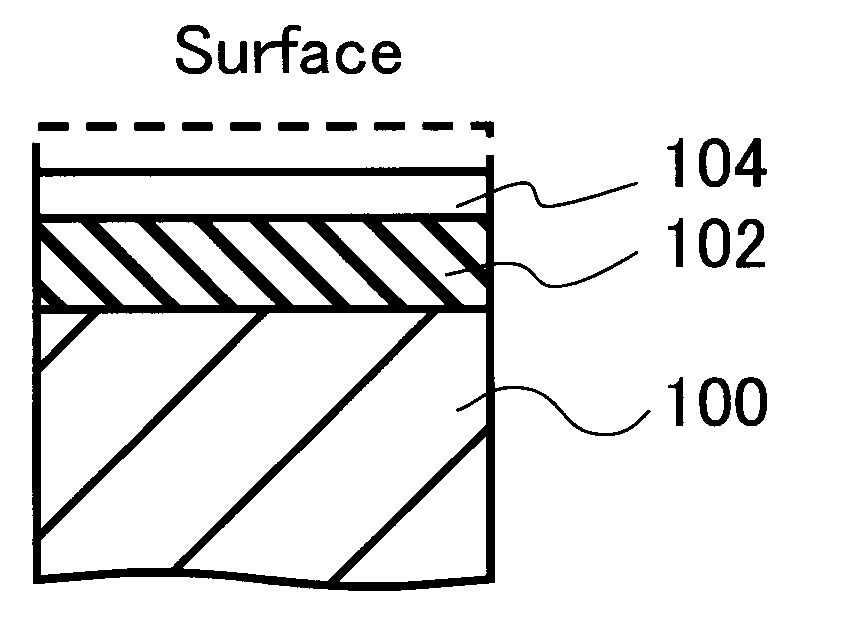

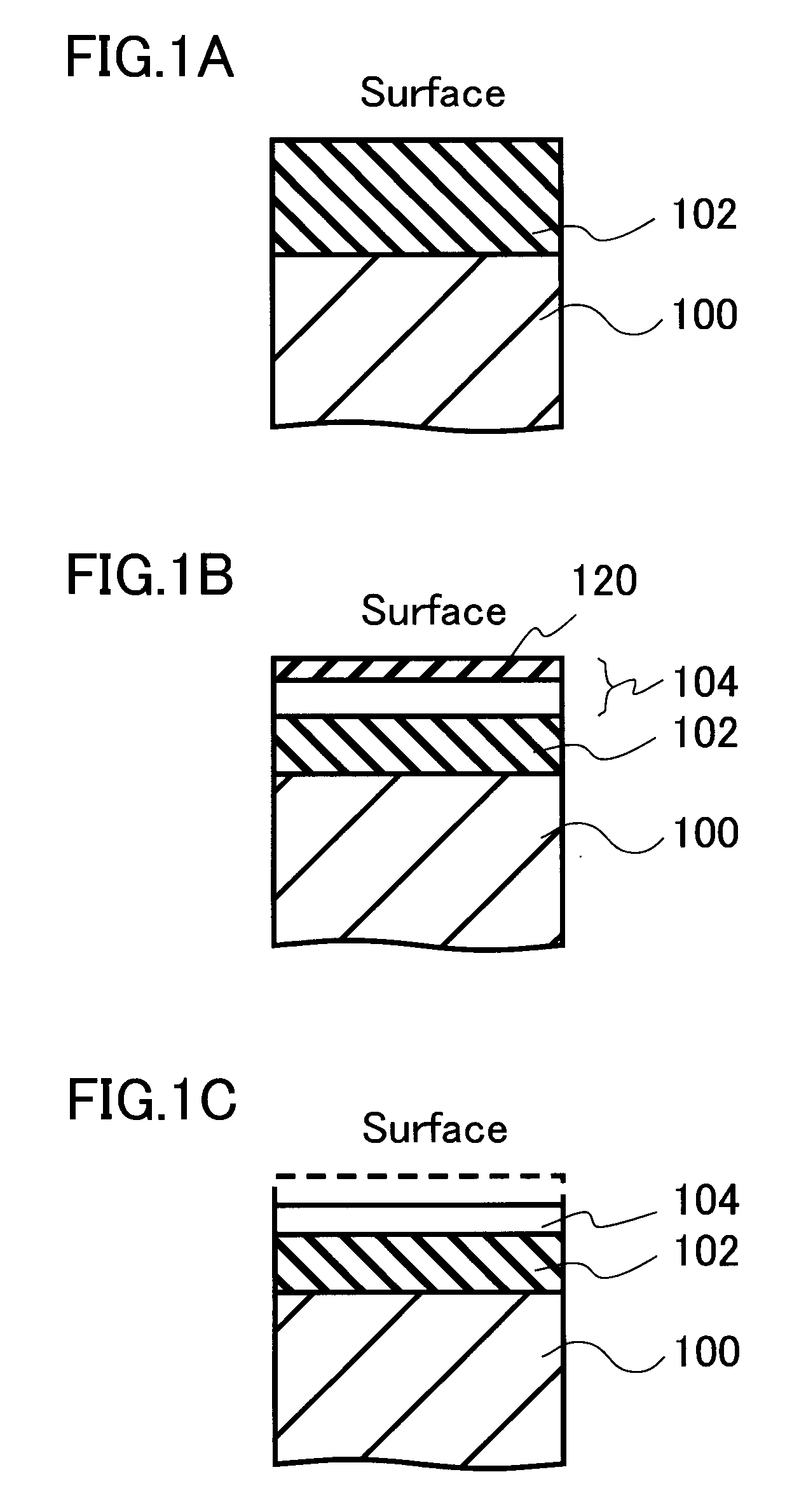

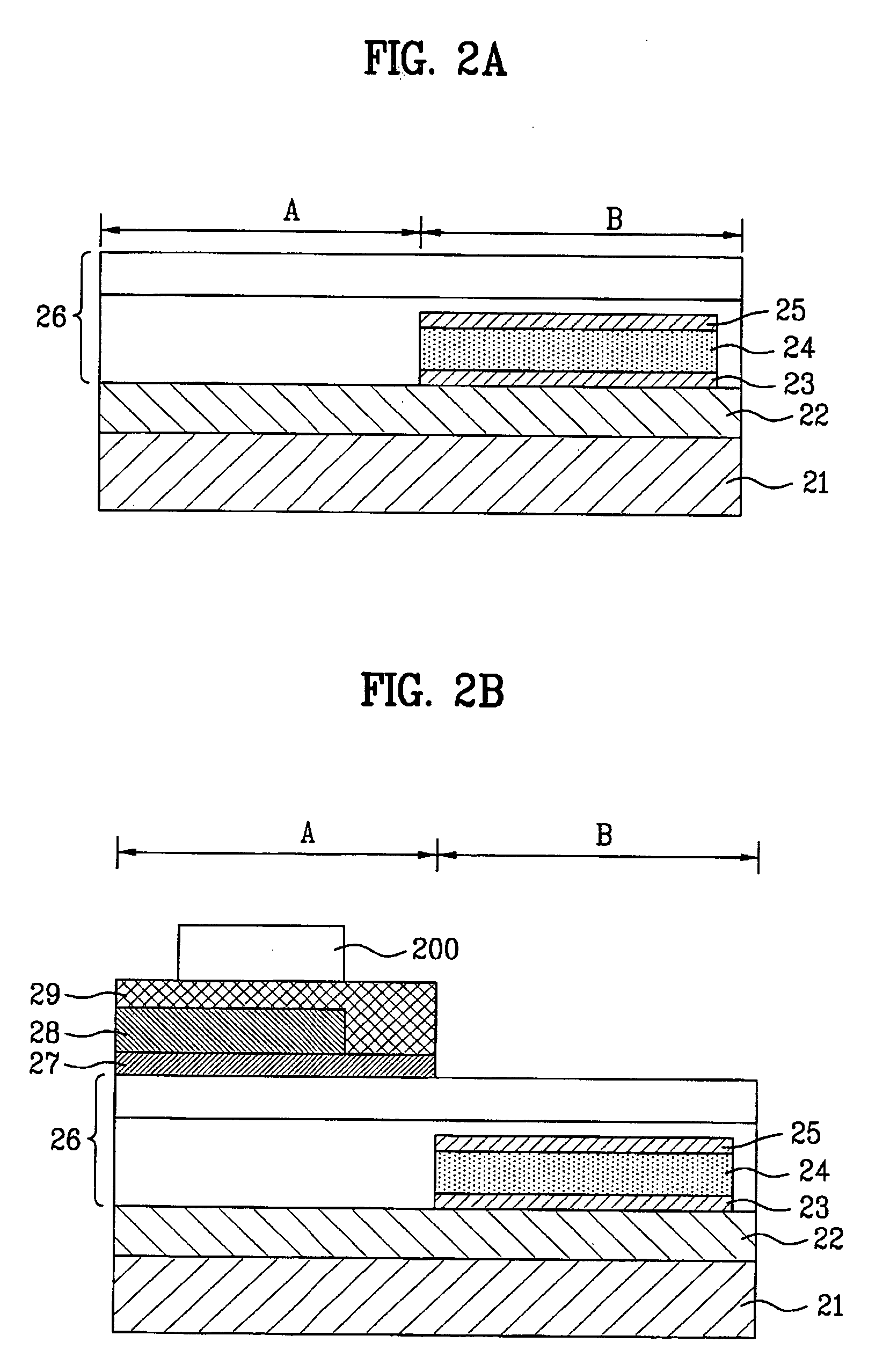

Semiconductor device and method of manufacturing the same

ActiveUS20100144091A1Reduce path lengthRun at high speedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A method of manufacturing a semiconductor device includes forming an interconnect member, mounting a first semiconductor chip having a semiconductor substrate in a face-down manner on the interconnect member, forming a resin layer on the interconnect member to cover a side surface of the first semiconductor chip, thinning the first semiconductor chip and the resin layer, forming an inorganic insulating layer on a back surface of the first semiconductor chip so as to be in contact with the back surface and to extend over the resin layer, and forming a through electrode so as to penetrate the inorganic insulating layer and the semiconductor substrate.

Owner:RENESAS ELECTRONICS CORP

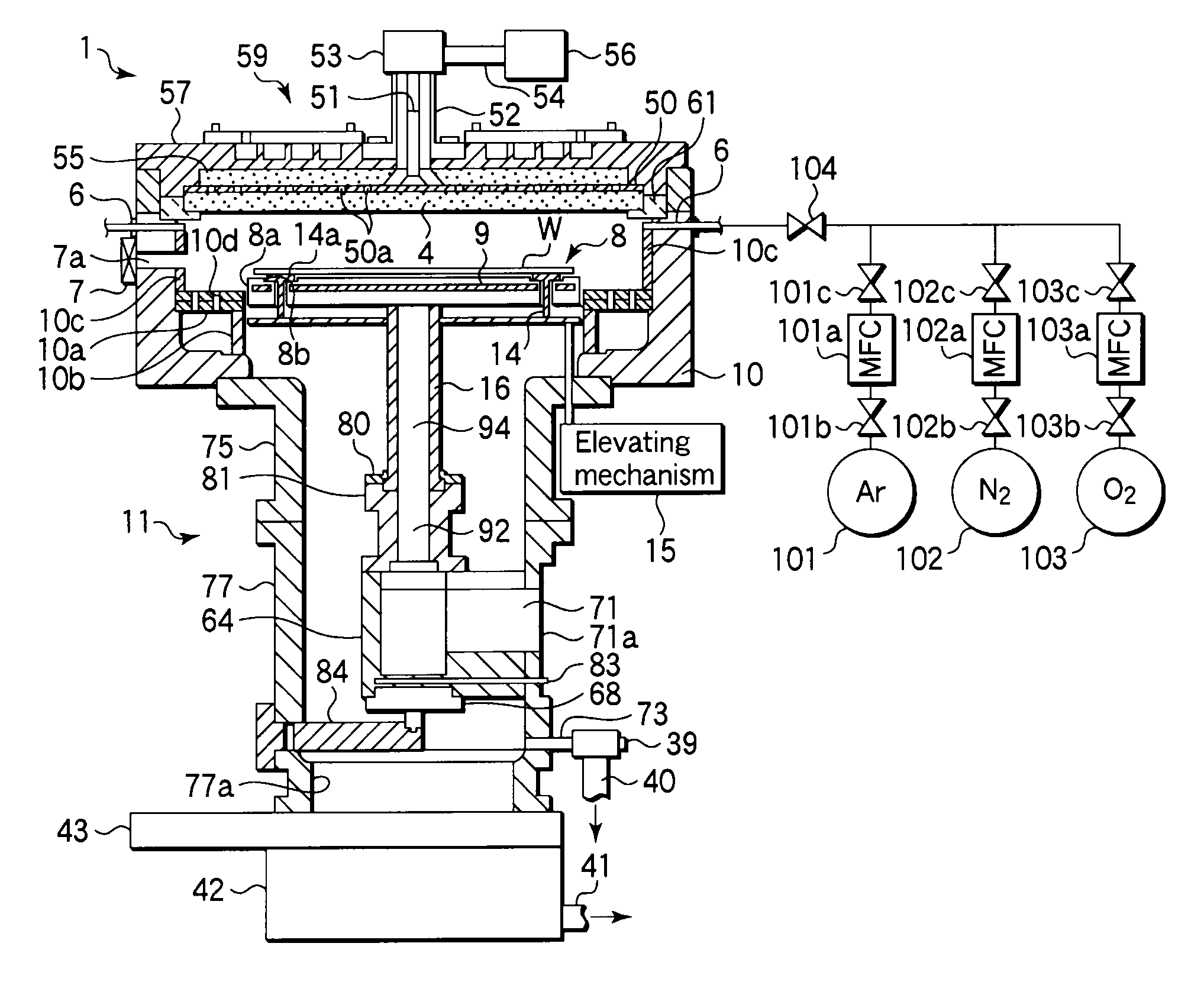

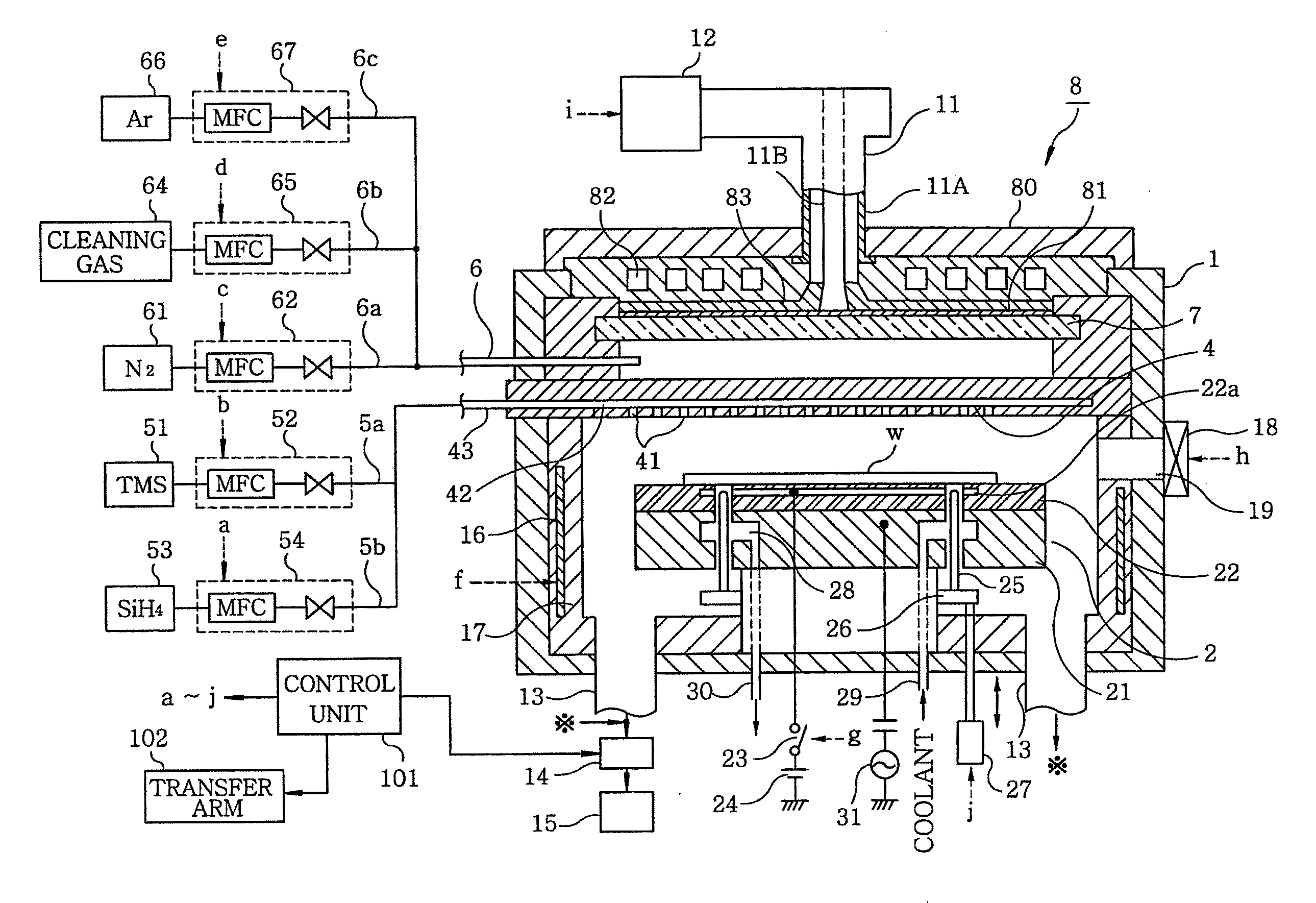

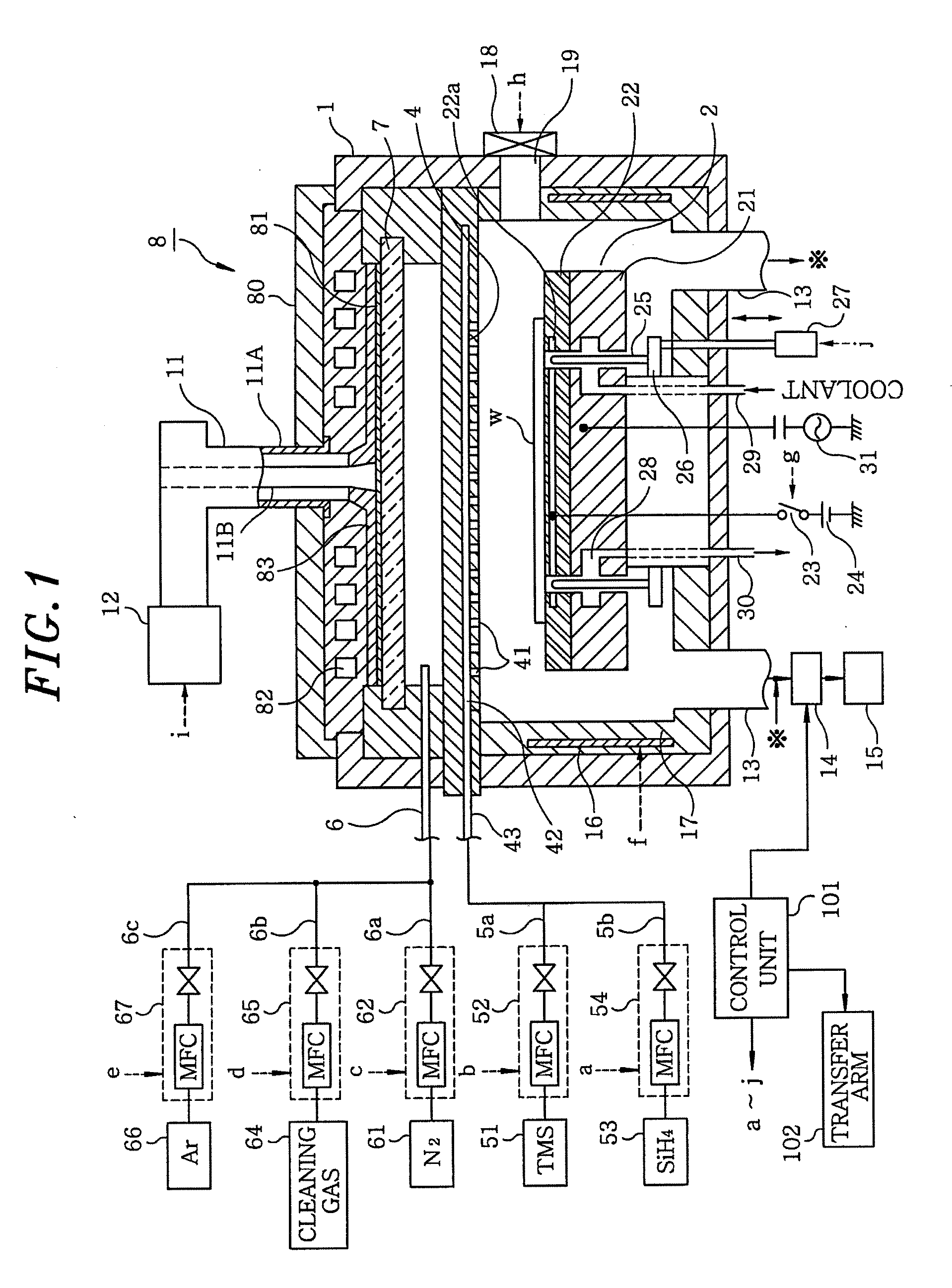

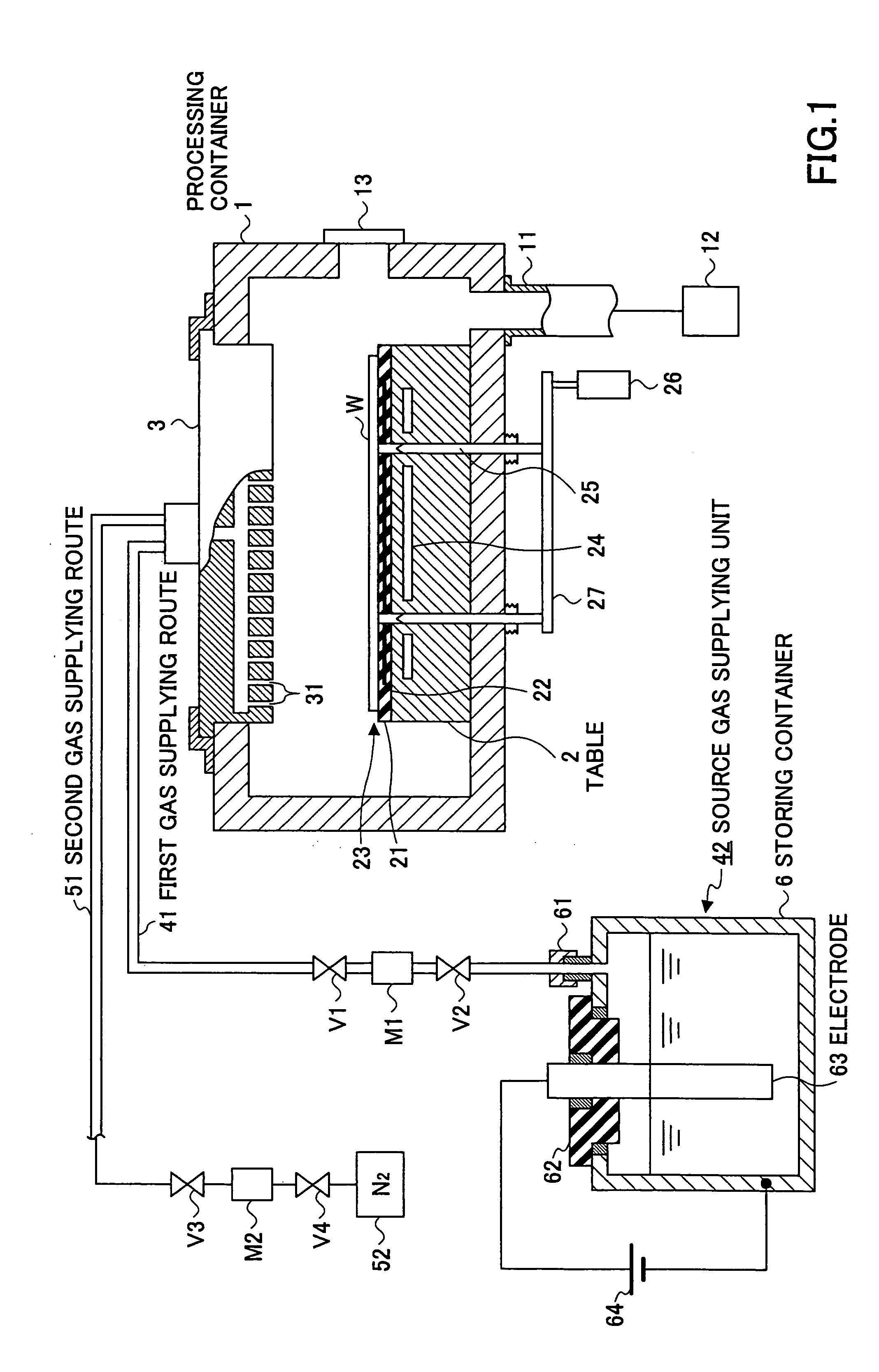

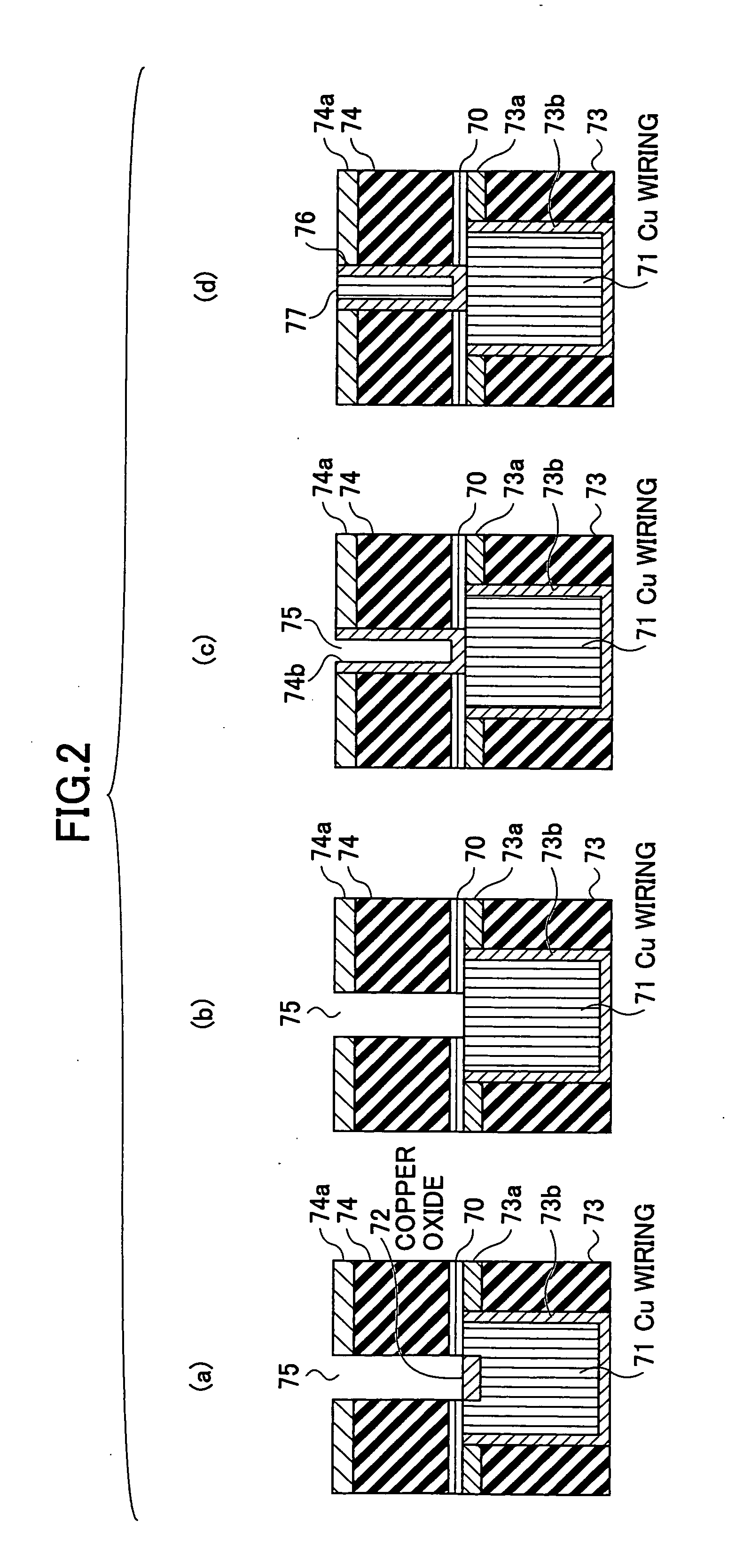

Film forming method and film forming apparatus

InactiveUS20090061092A1Avoid Metal ContaminationReduce probabilityLiquid surface applicatorsVacuum evaporation coatingSilanesPre treatment

A film forming method is characterized in that the method is provided with a step of introducing a processing gas including inorganic silane gas into a processing chamber, in which a mounting table composed of ceramics including a metal oxide is arranged, and precoating an inner wall of the processing chamber including a surface of the mounting table with a silicon-containing nonmetal thin film; a step of mounting a substrate to be processed on the mounting table precoated with the nonmetal thin film; and a step of introducing a processing gas including organic silane gas into the processing chamber, and forming a silicon-containing nonmetal thin film on a surface of the substrate mounted on the mounting table.

Owner:TOKYO ELECTRON LTD

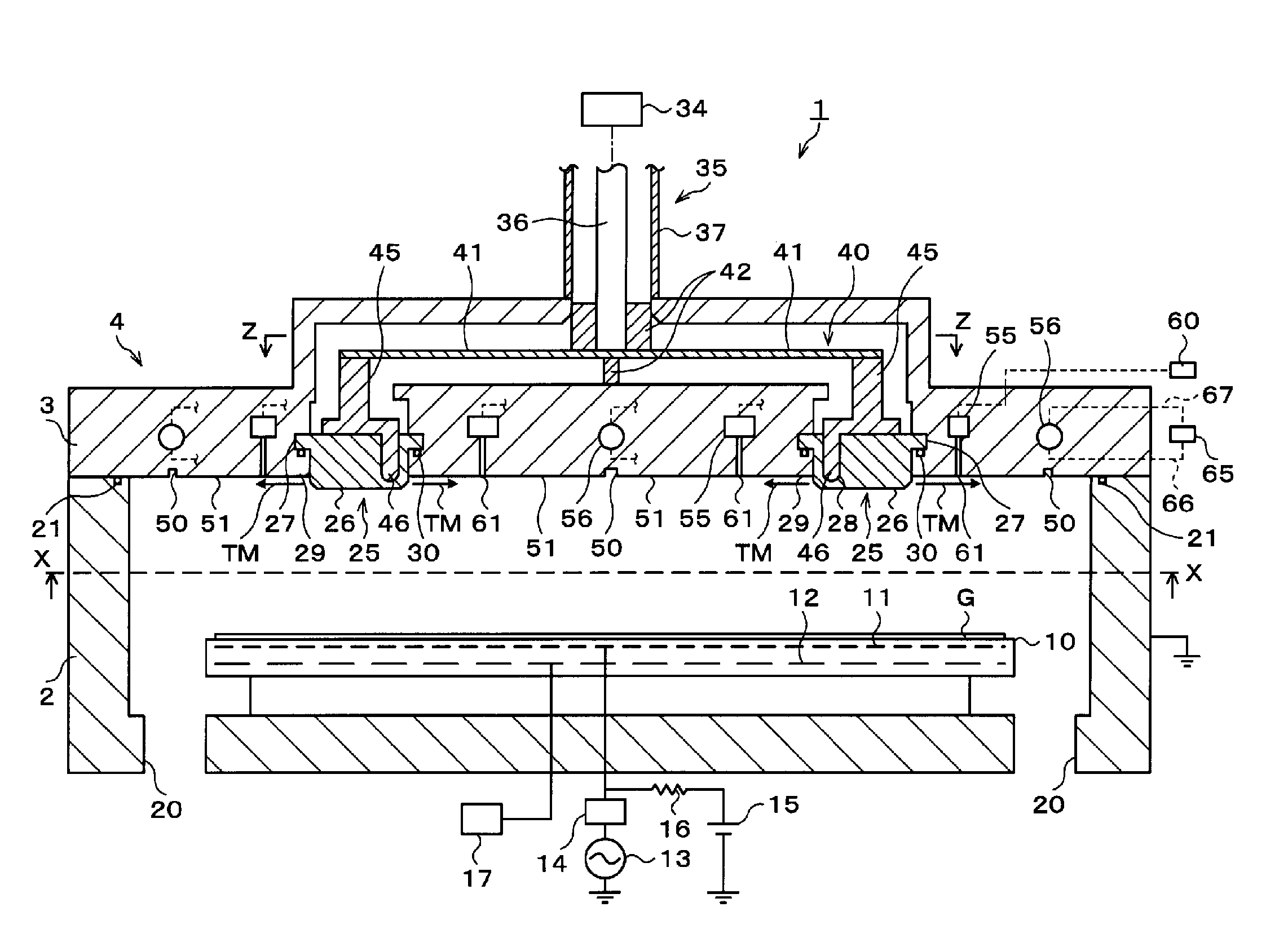

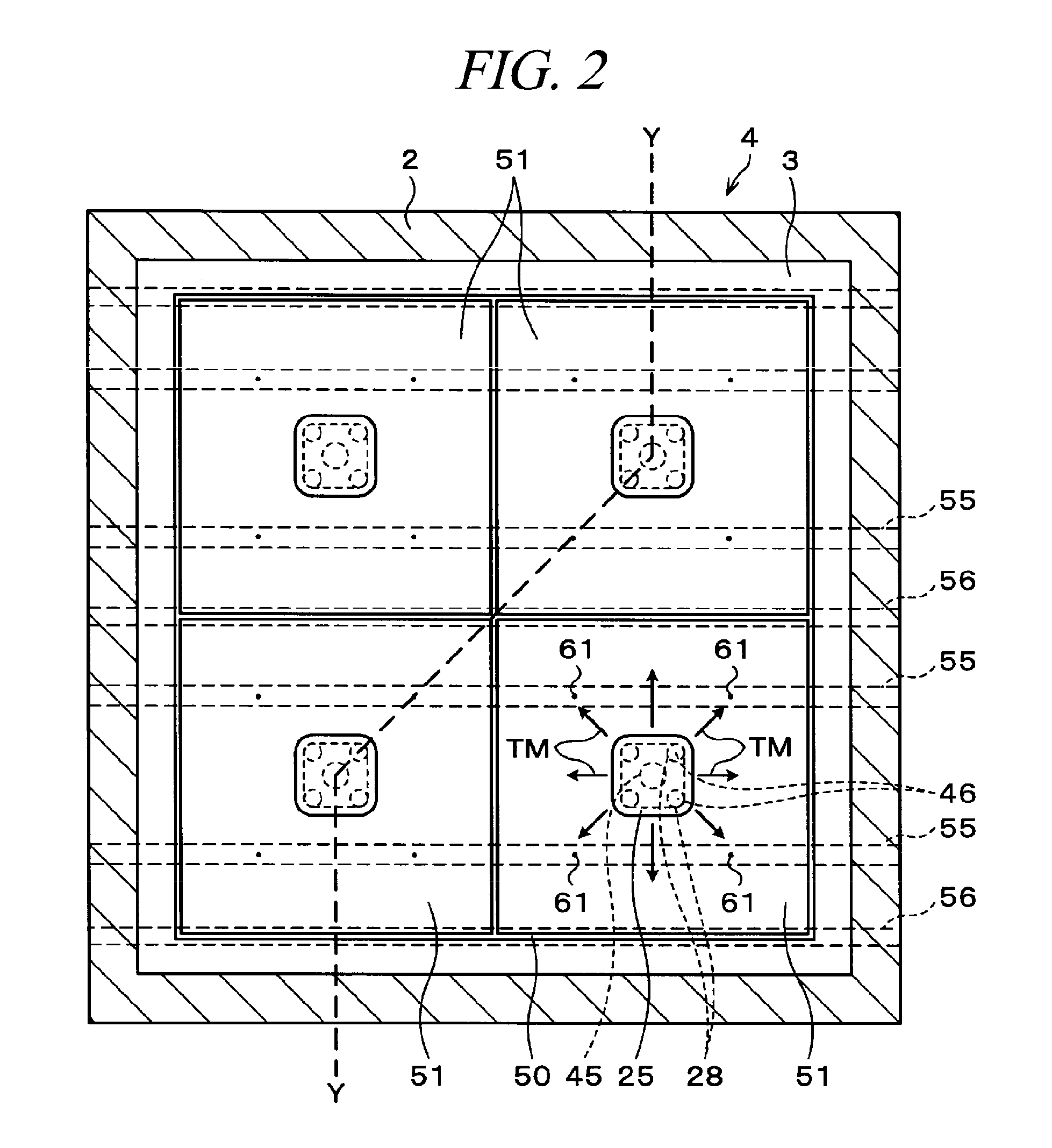

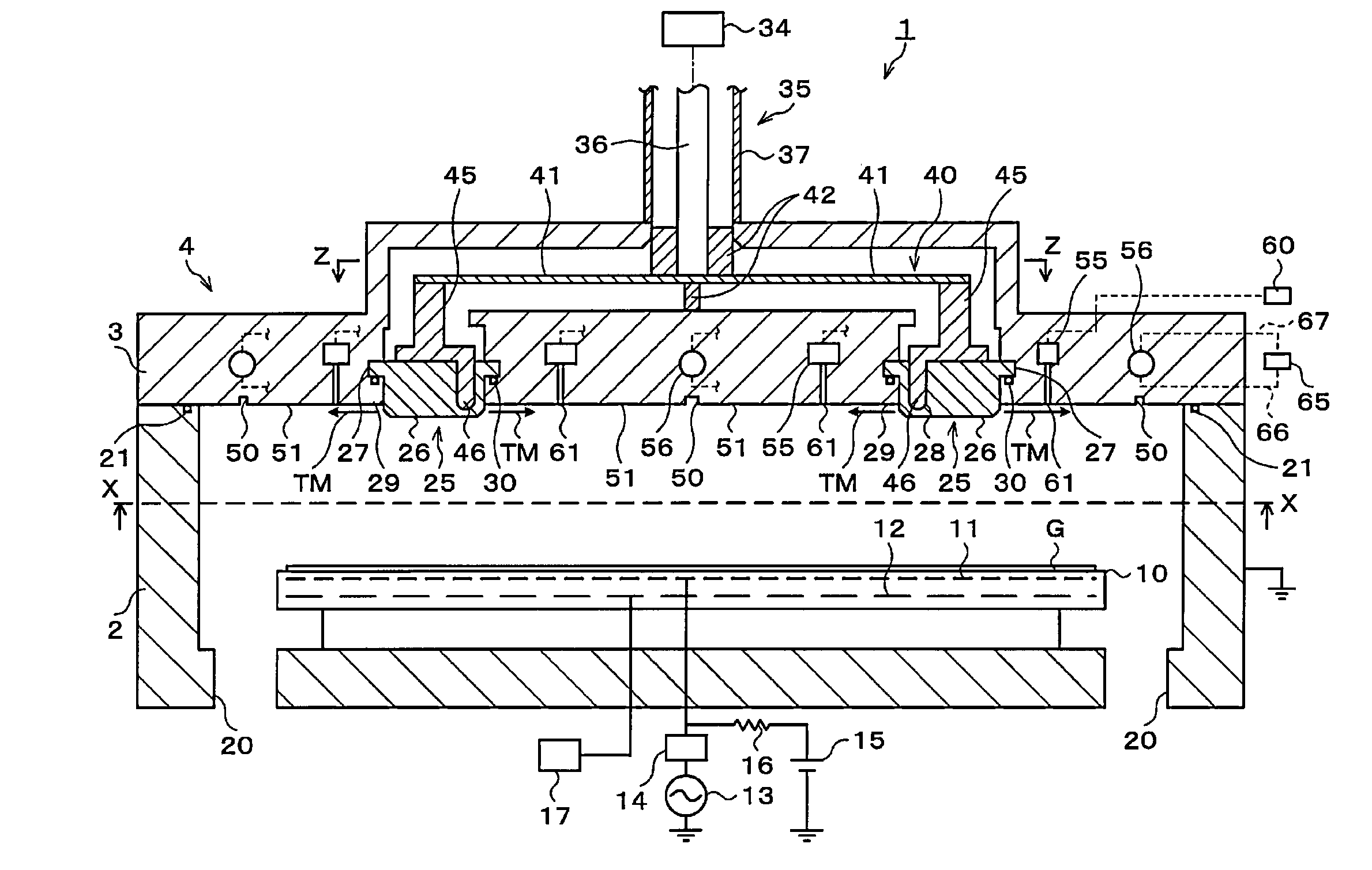

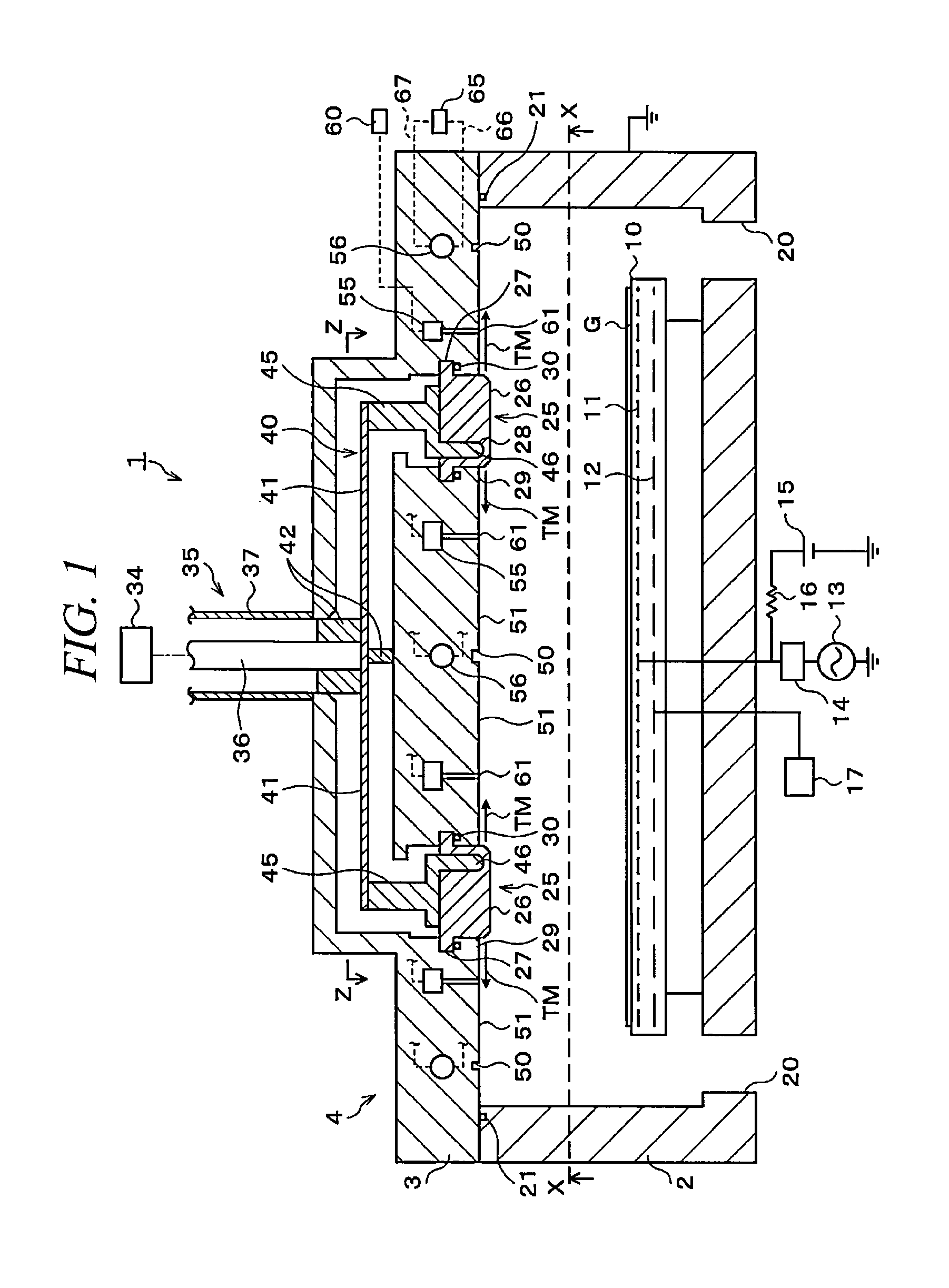

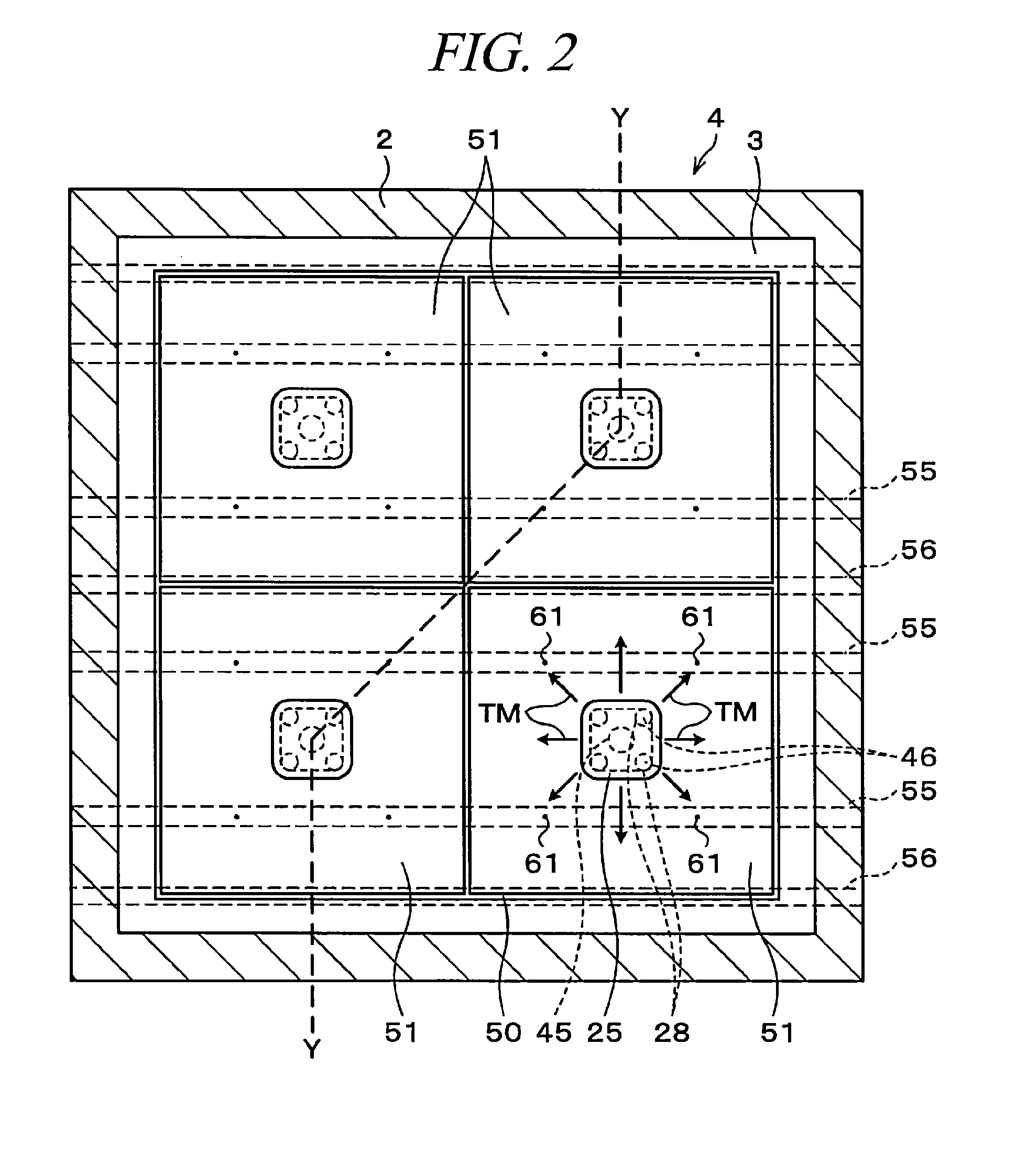

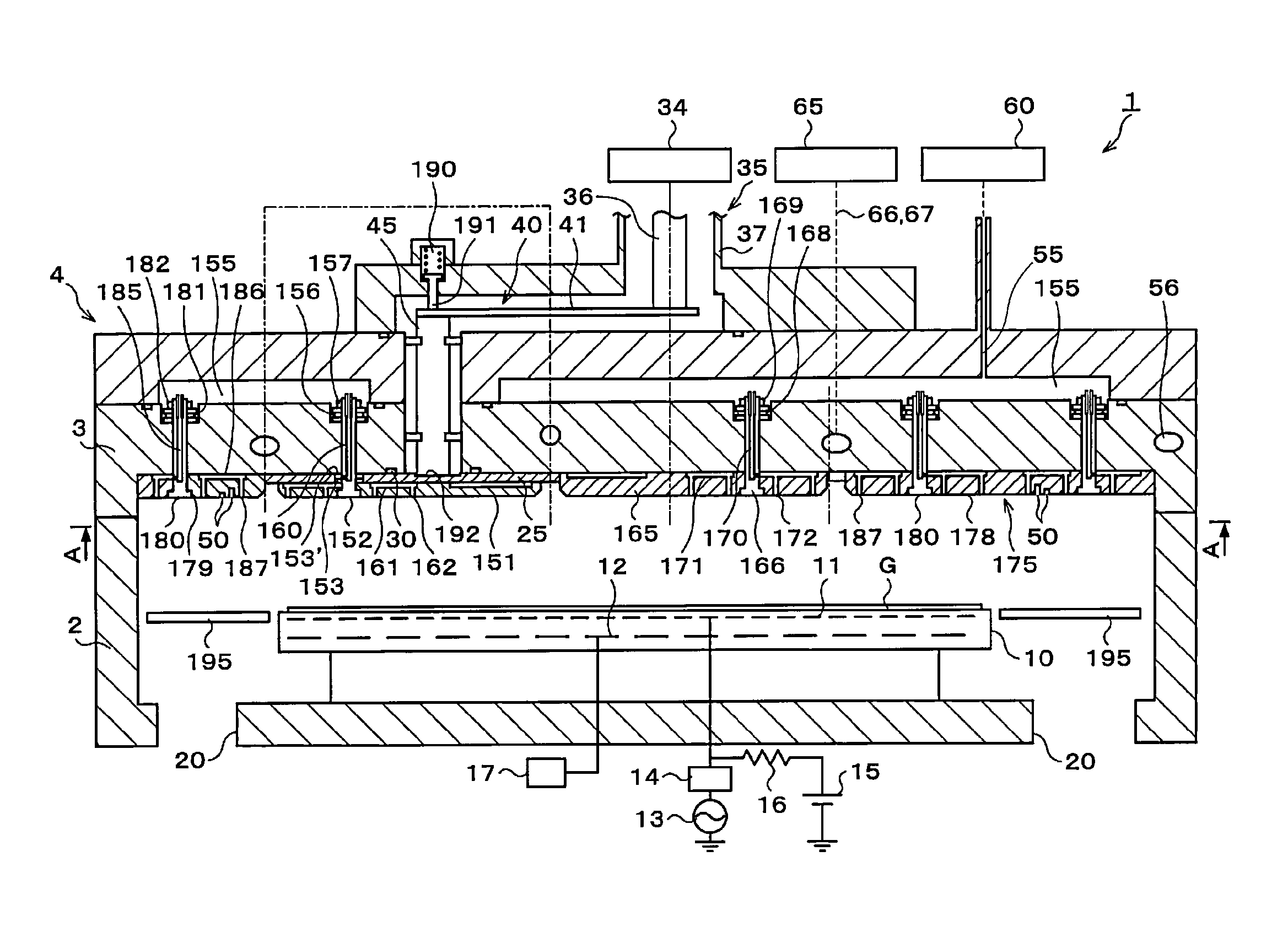

Plasma processing apparatus and plasma processing method

InactiveUS20100183827A1Well formedProduct qualityLiquid surface applicatorsElectric discharge tubesDielectricElectromagnetic electron wave

A plasma processing apparatus capable of reducing the use amount of a dielectric member is provided. The plasma processing apparatus 1 includes a metal processing chamber 4 configured to accommodate therein a substrate G to be plasma-processed; an electromagnetic wave source 34 that supplies an electromagnetic wave necessary to excite plasma in the processing chamber 4; one or more dielectric members 25 provided on a bottom surface of a cover 3 of the processing chamber 4 and configured to transmit the electromagnetic wave supplied from the electromagnetic wave source 34 into the inside of the processing chamber 4, a portion of each dielectric member 25 being exposed to the inside of the processing chamber 4; and a surface wave propagating section 51 installed adjacent to the dielectric member 25 and configured to propagate the electromagnetic wave along a metal surface exposed to the inside of the processing chamber 4.

Owner:TOKYO ELECTRON LTD +1

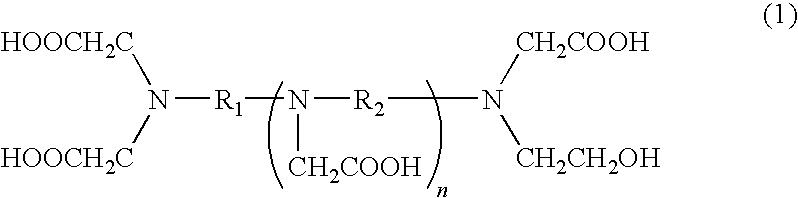

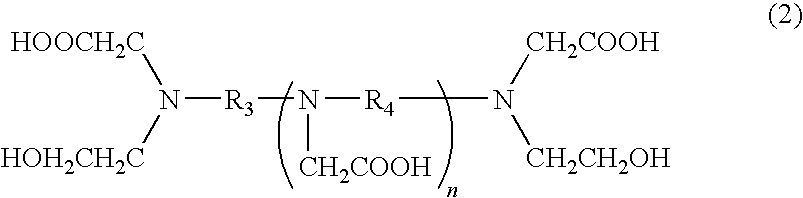

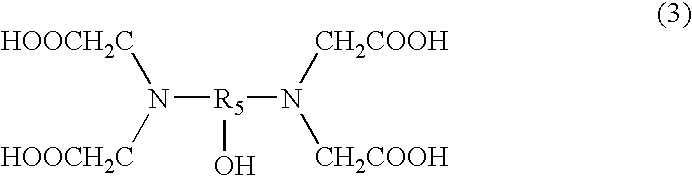

Polishing Composition for Silicon Wafer

InactiveUS20090127501A1Avoid Metal ContaminationHigh removal rateOther chemical processesSemiconductor/solid-state device manufacturingWaferingCopper contamination

The present invention relates to a polishing composition for silicon wafer comprising silica, a basic compound, a polyaminopolycarboxylic acid compound having hydroxy group, and water. The polishing composition can prevent metal contamination by nickel, chromium, iron, copper or the like, particularly copper contamination in polishing of silicon wafer.

Owner:NISSAN CHEM IND LTD

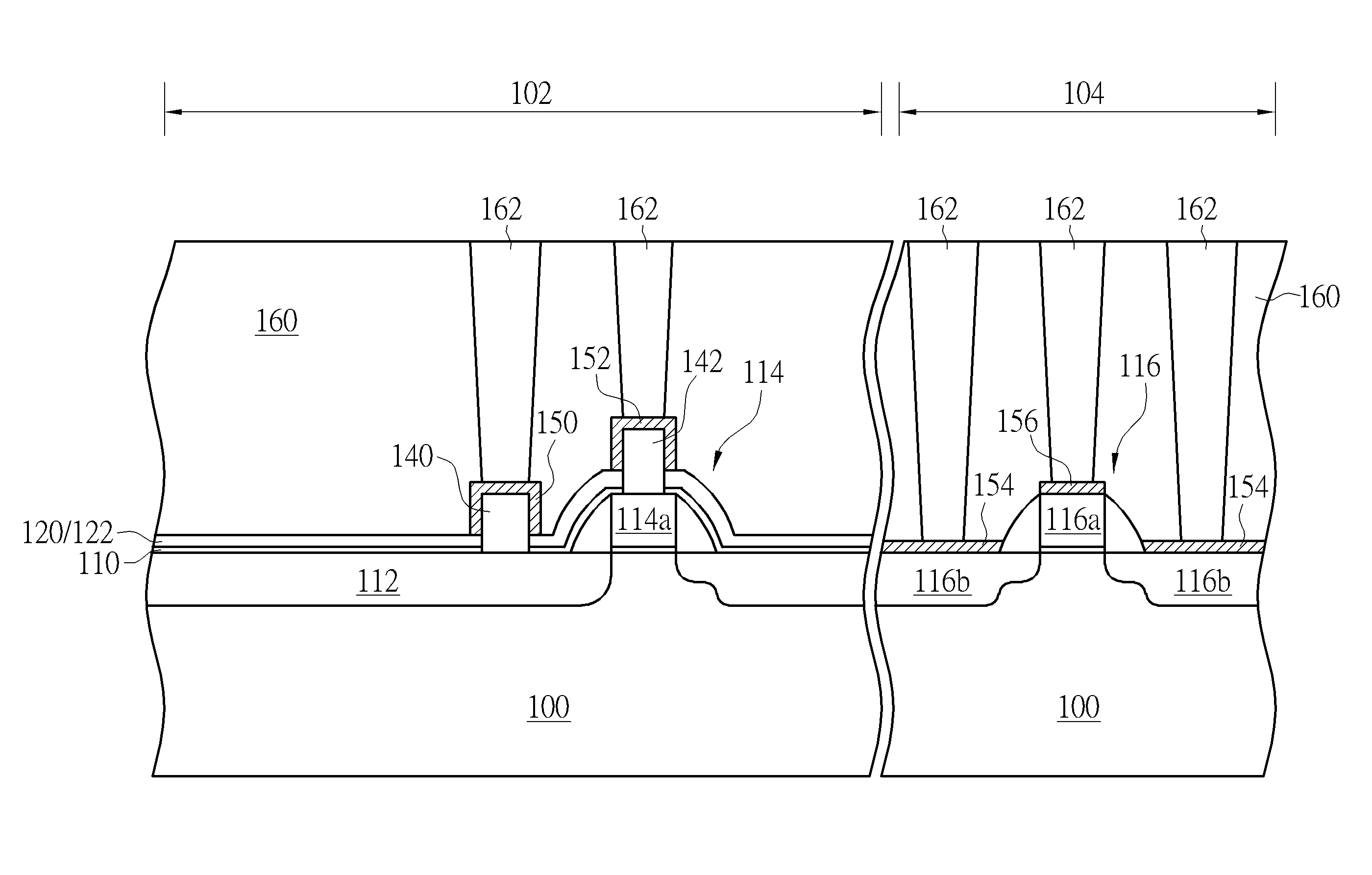

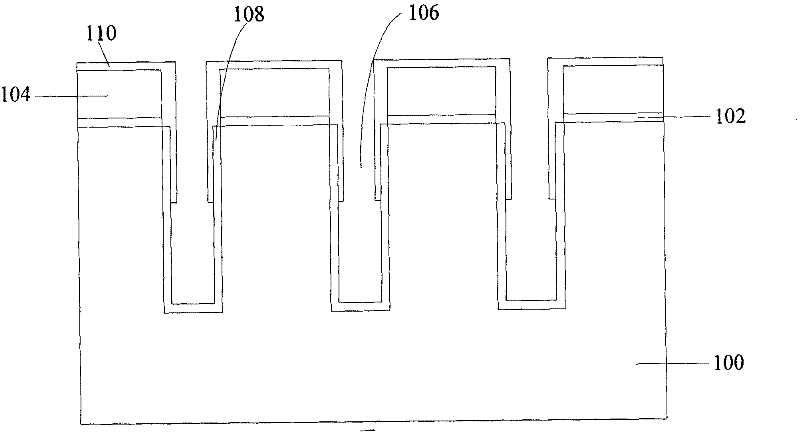

Integrated circuit device and method of manufacturing the same

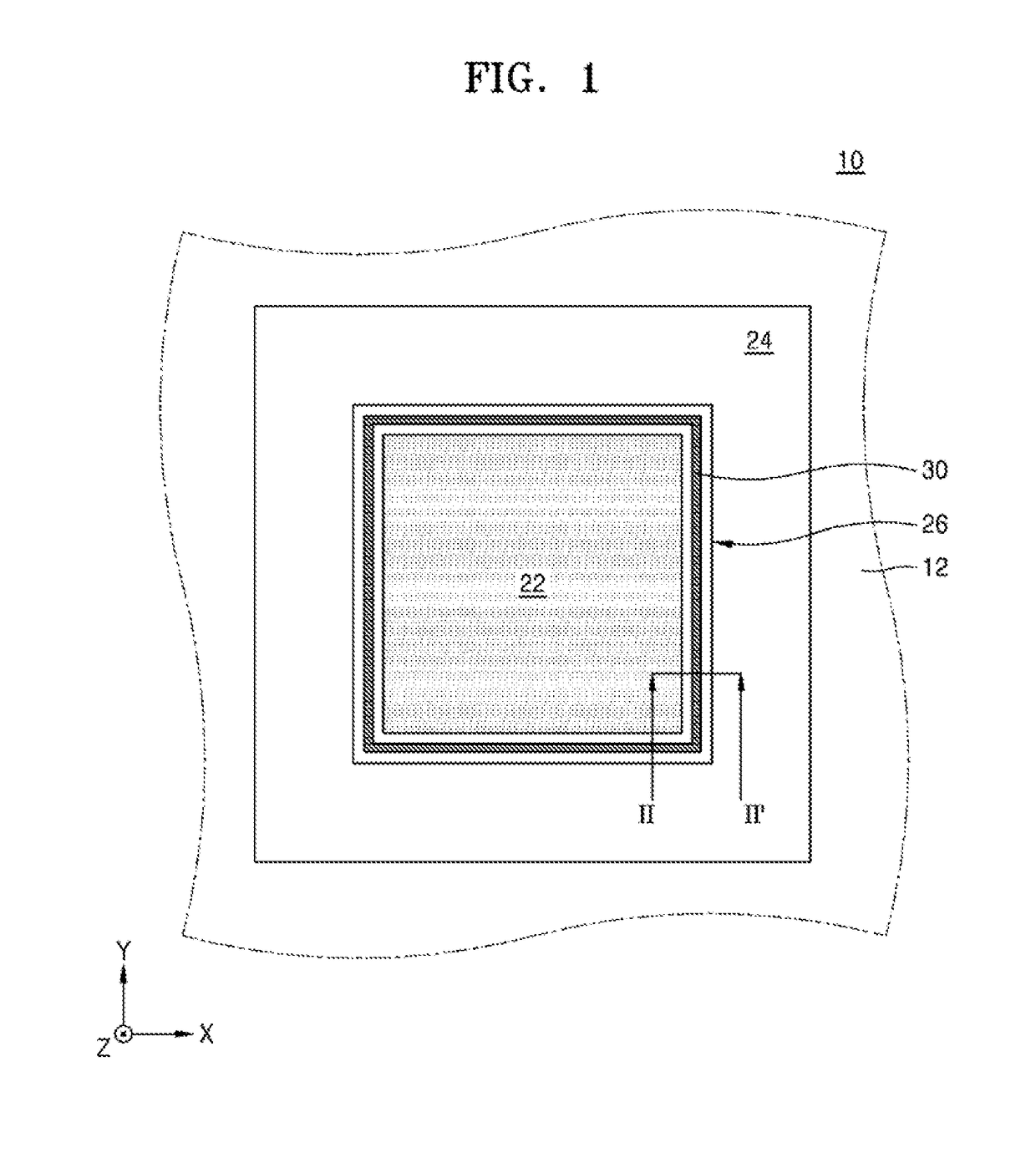

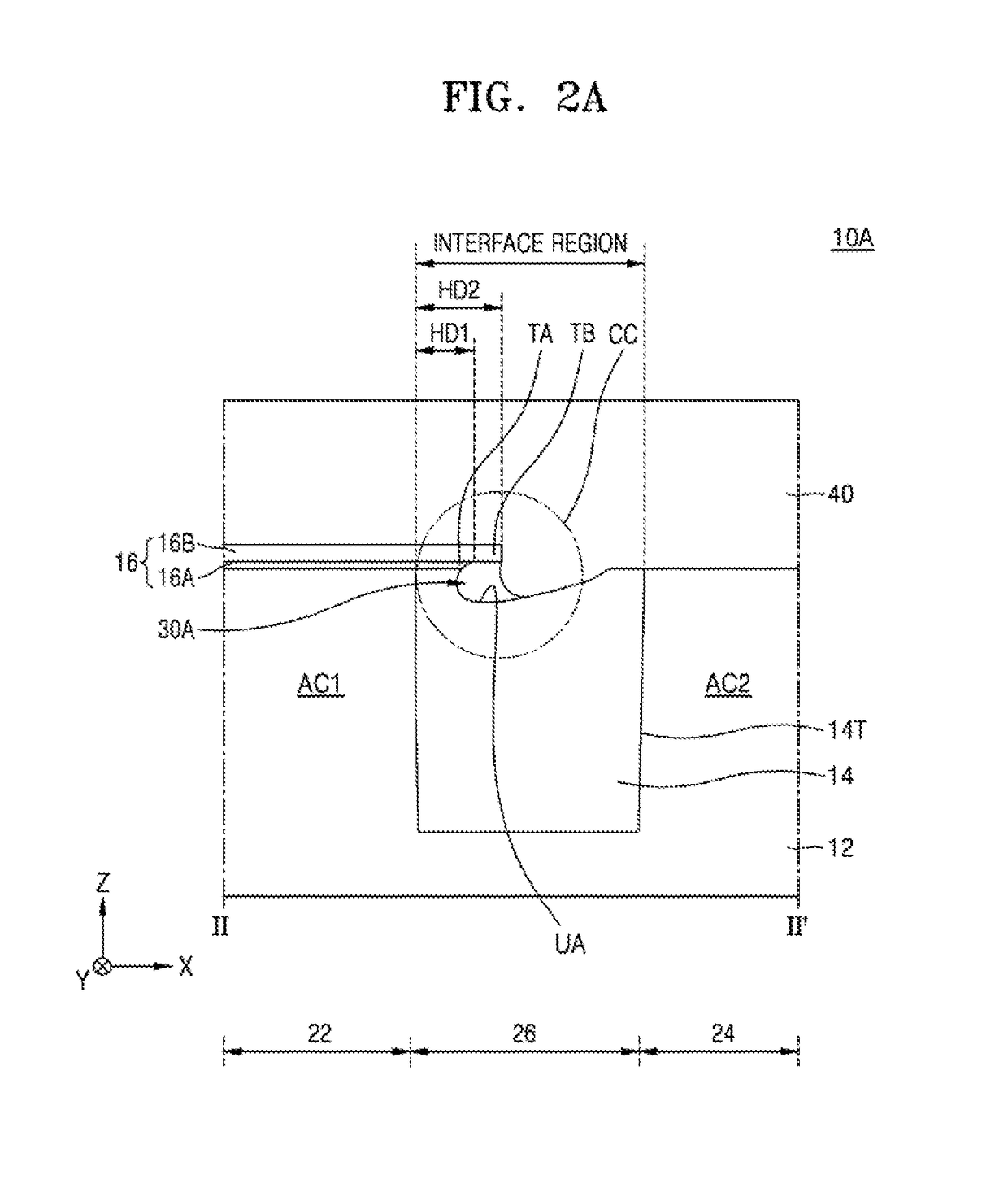

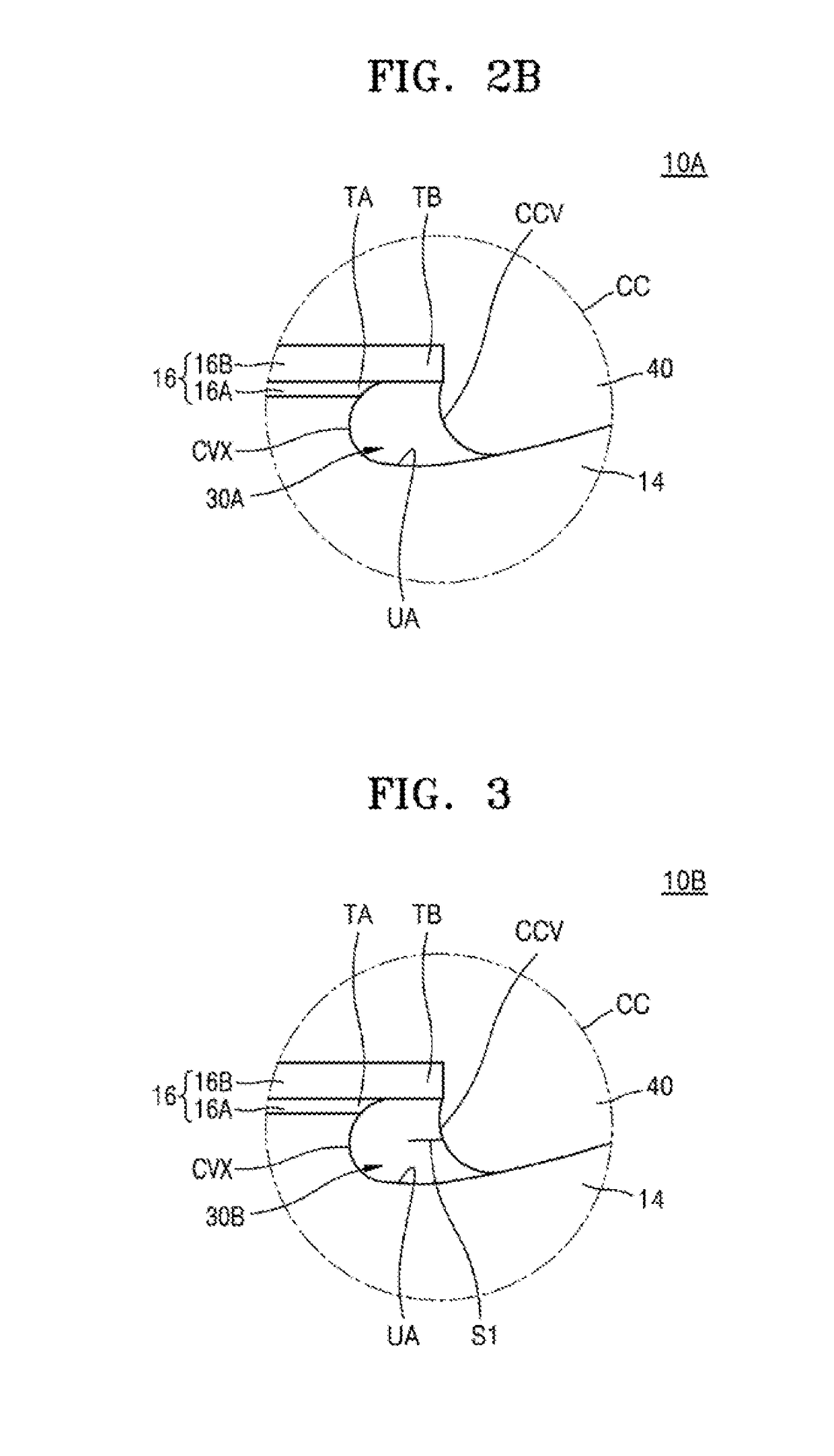

An integrated circuit device includes a substrate having a first region and a second region separated from each other along a direction parallel to an upper surface of the substrate. An interface device isolation layer fills an interface trench in an interface region between the first region and the second region and defines a portion of a first active area positioned in the first region and a portion of a second active area positioned in the second region. An insulation pattern extends from the first region to an upper portion of the interface device isolation layer. The insulation pattern covers the first active area and at least a portion of the interface device isolation layer. The insulation pattern defines an undercut area on an upper surface of the interface device isolation layer. A buried pattern substantially fills the undercut region.

Owner:SAMSUNG ELECTRONICS CO LTD

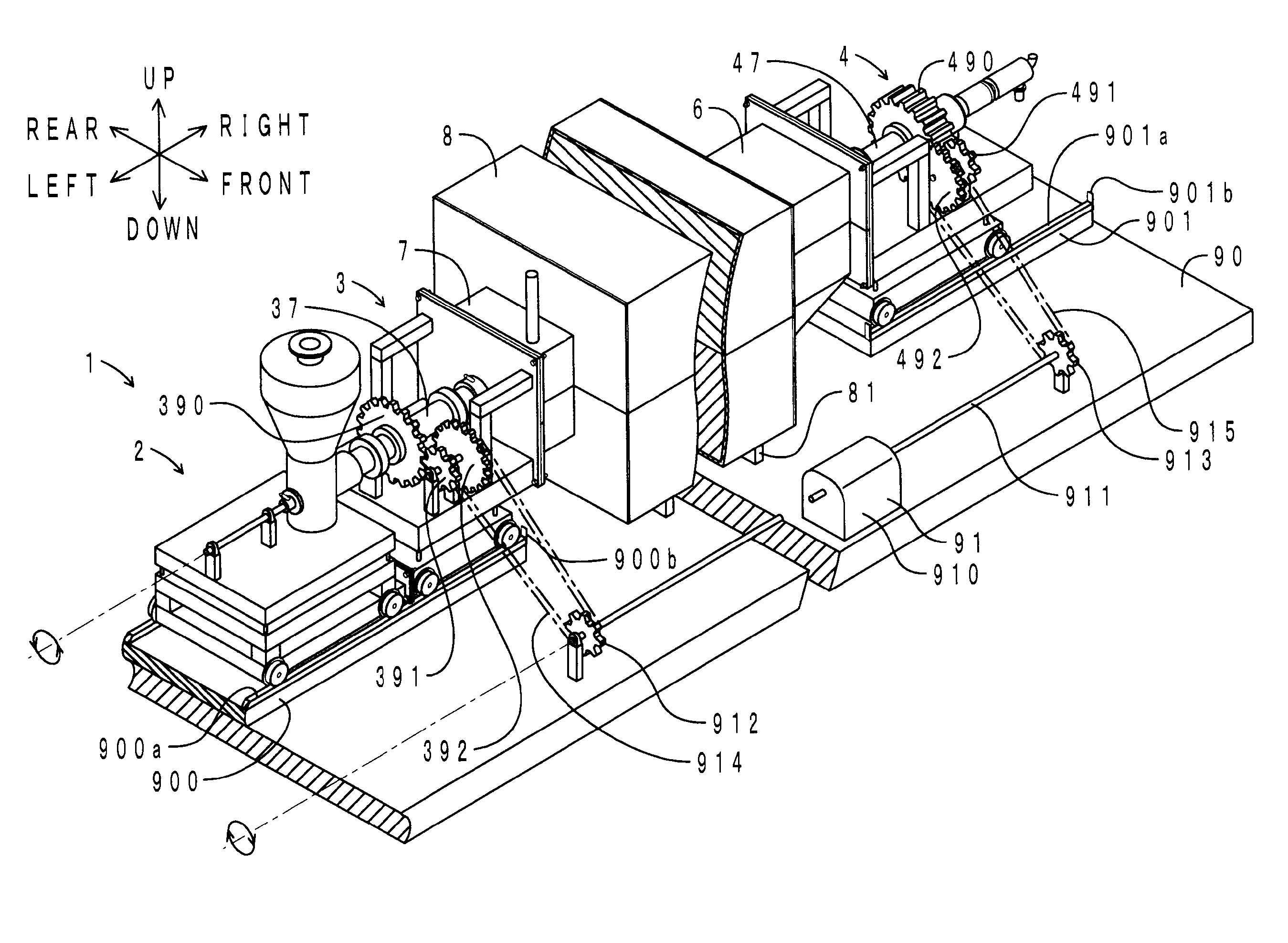

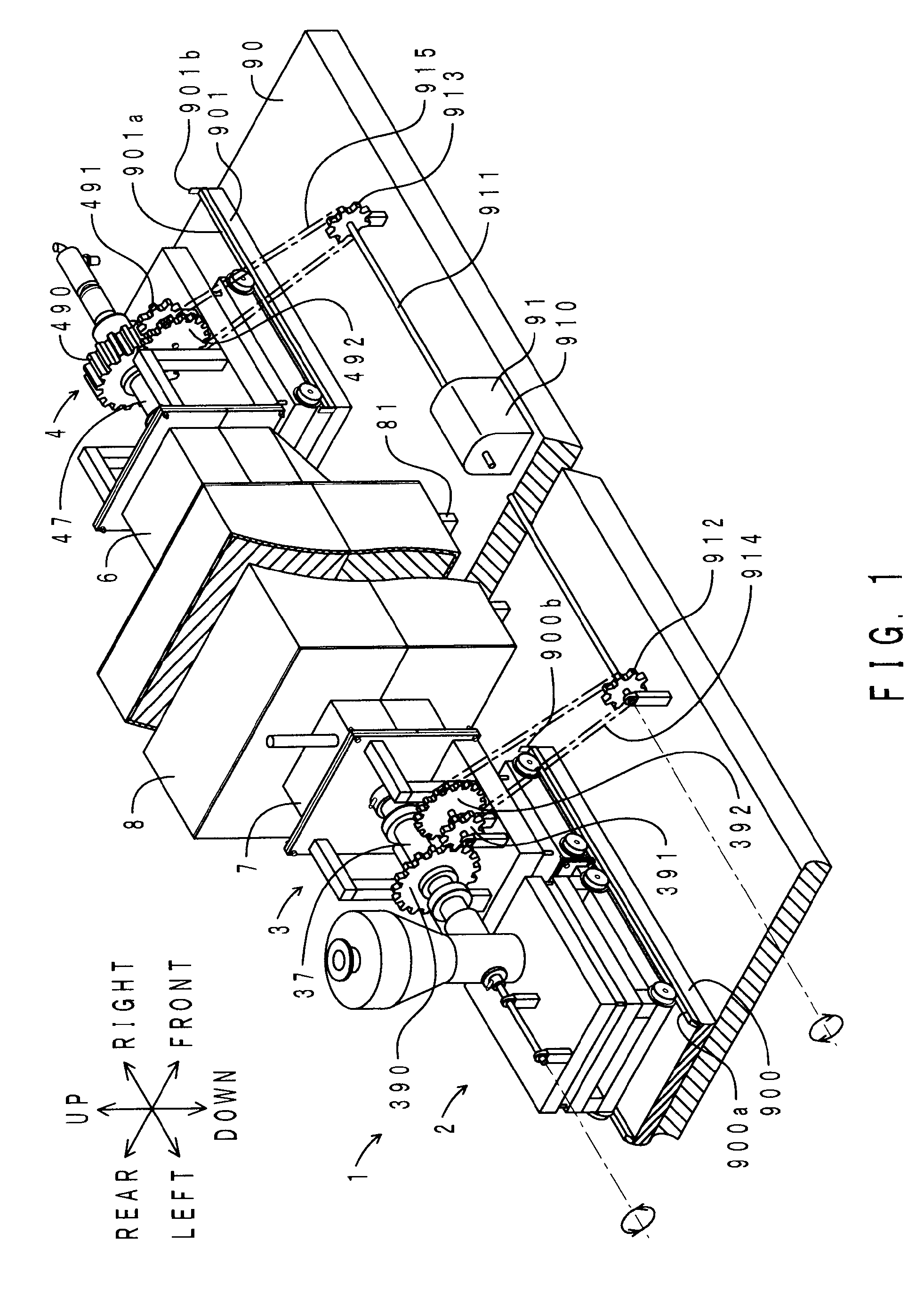

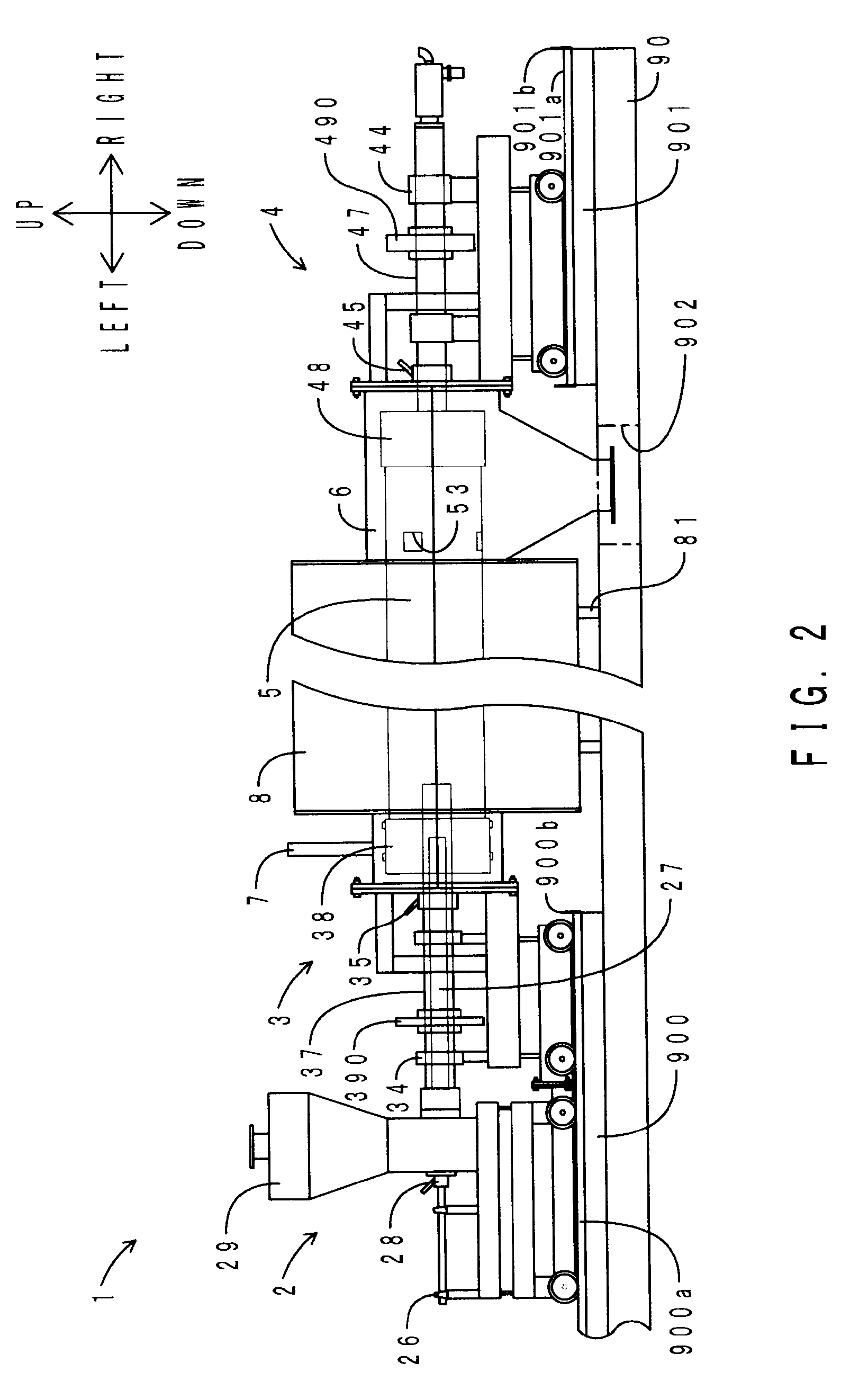

Substrate processing apparatus and substrate processing method

InactiveUS20050178503A1Avoid Metal ContaminationReduce consumptionDecorative surface effectsPreparing sample for investigationSpray nozzleMetal contamination

A substrate processing apparatus for supplying a treatment liquid onto the surface of a substrate to treat the same. This apparatus is provided with: a spin chuck for holding and rotating a substrate; a nozzle for supplying a treatment liquid to the substrate held by the spin chuck; a circulating passage arranged such that the treatment liquid supplied to the substrate from the nozzle and used for substrate treatment is circulated to the nozzle and reutilized for substrate treatment; a metal contamination amount measuring device for measuring the metal contamination amount in the treatment liquid passing through the circulating passage; and a judgment processing unit for judging whether or not the value measured by the metal contamination amount measuring device has exceeded a predetermined set value.

Owner:DAINIPPON SCREEN MTG CO LTD

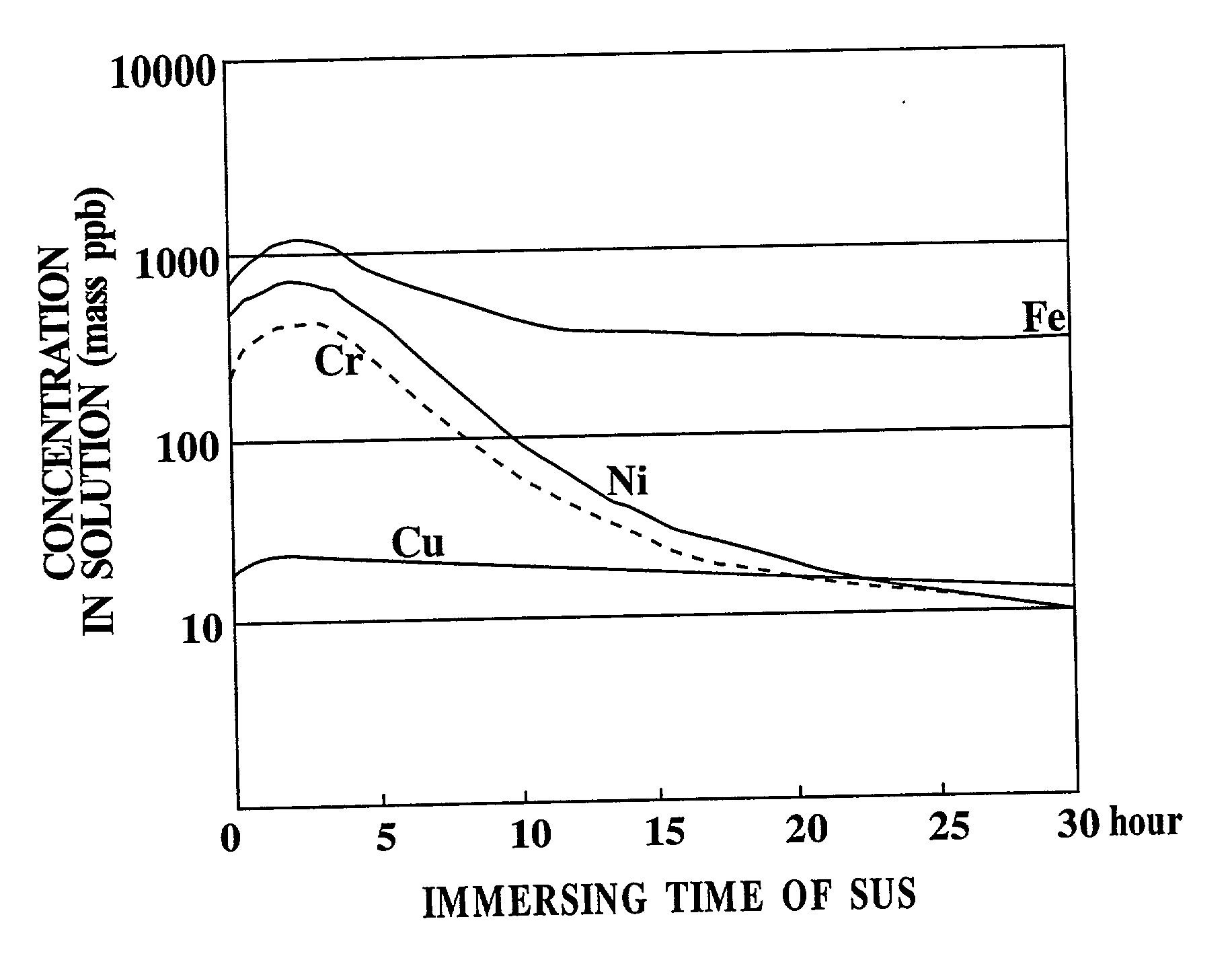

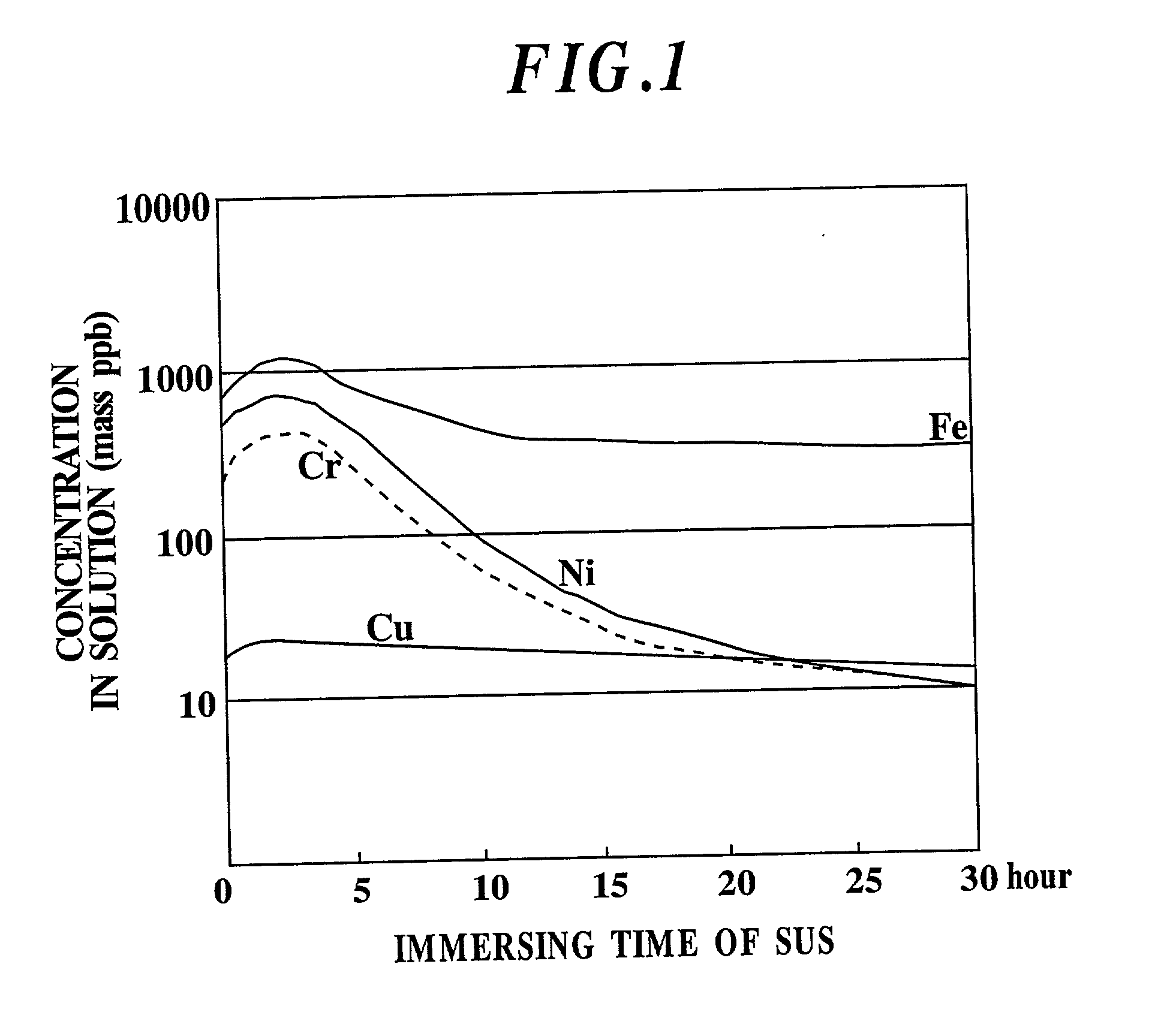

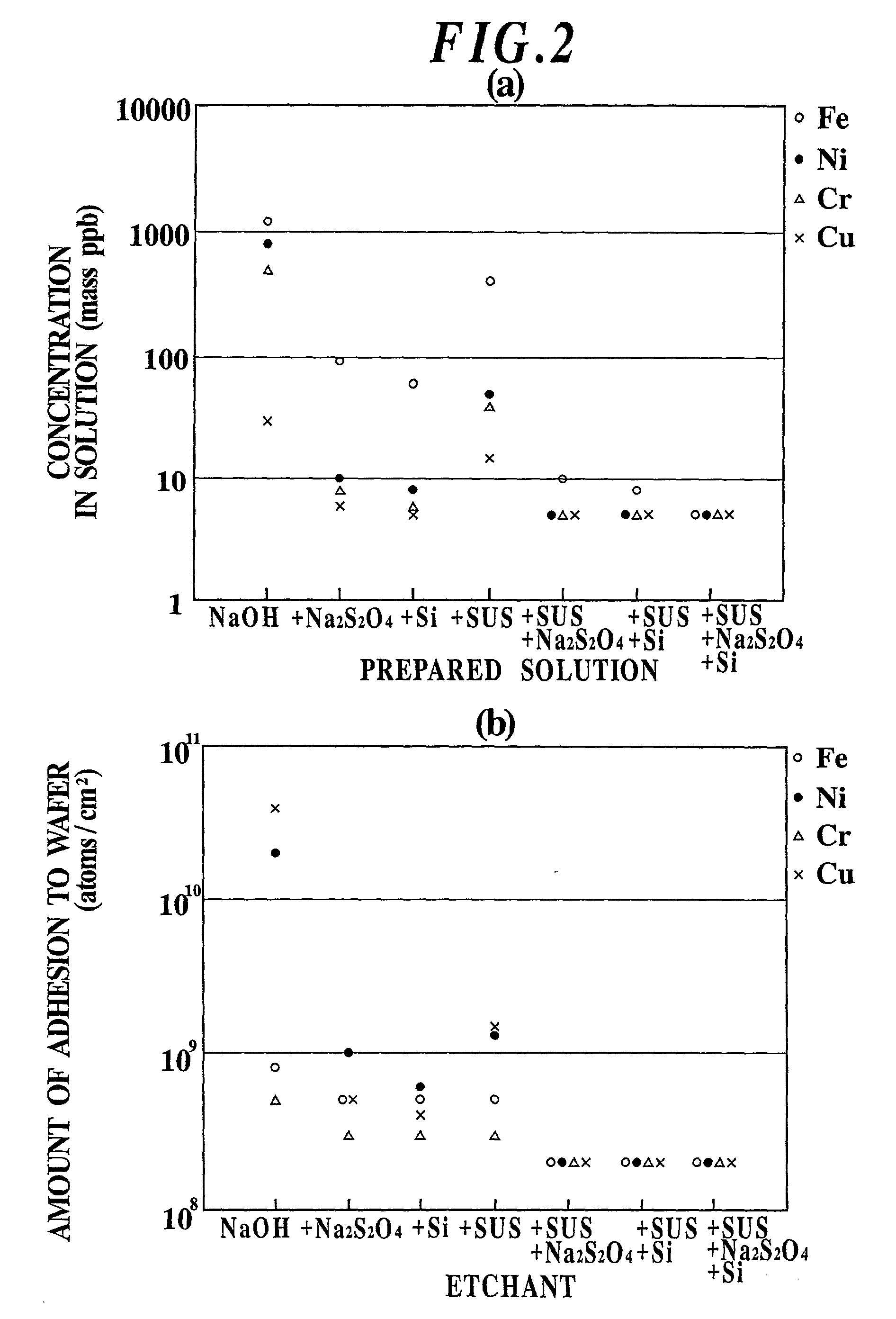

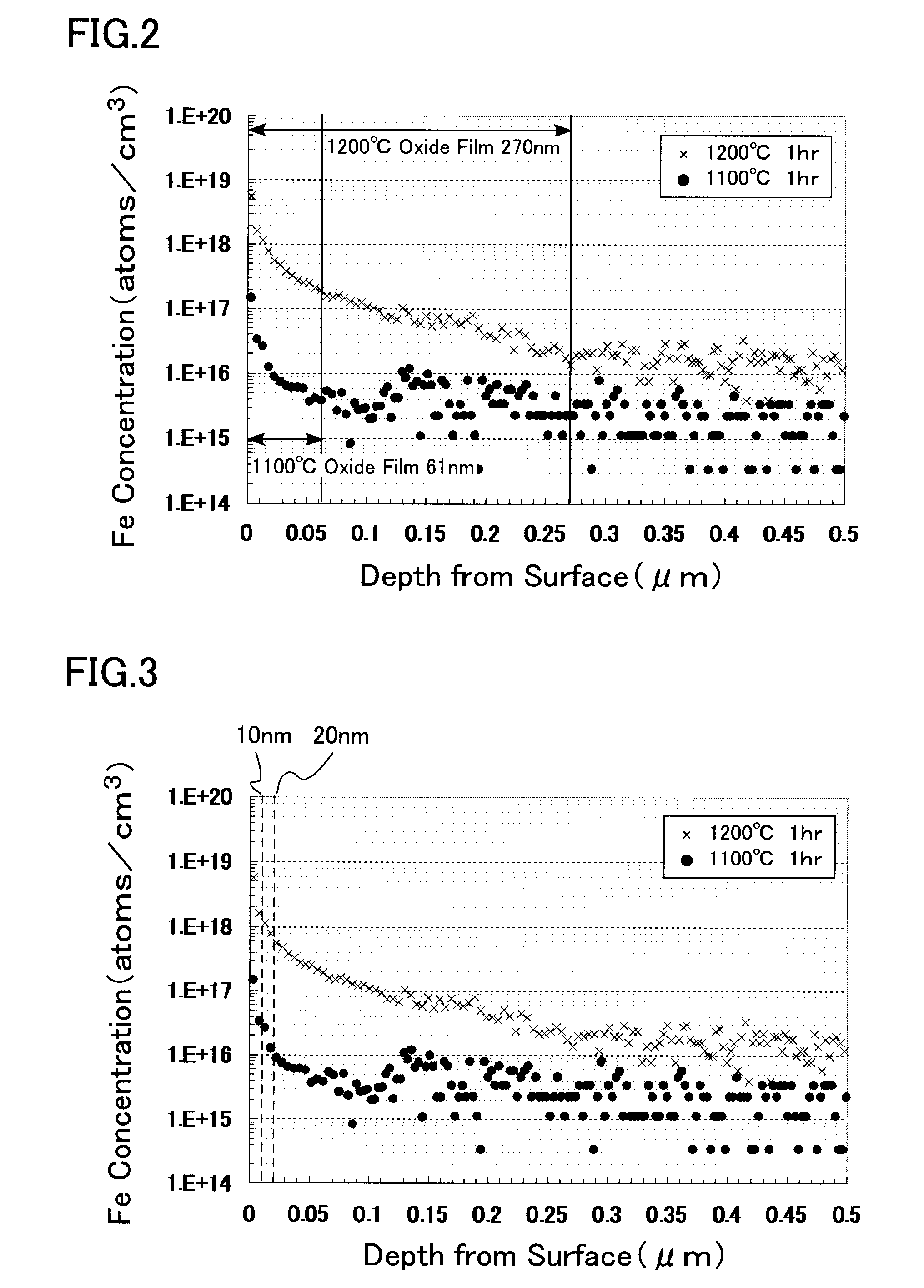

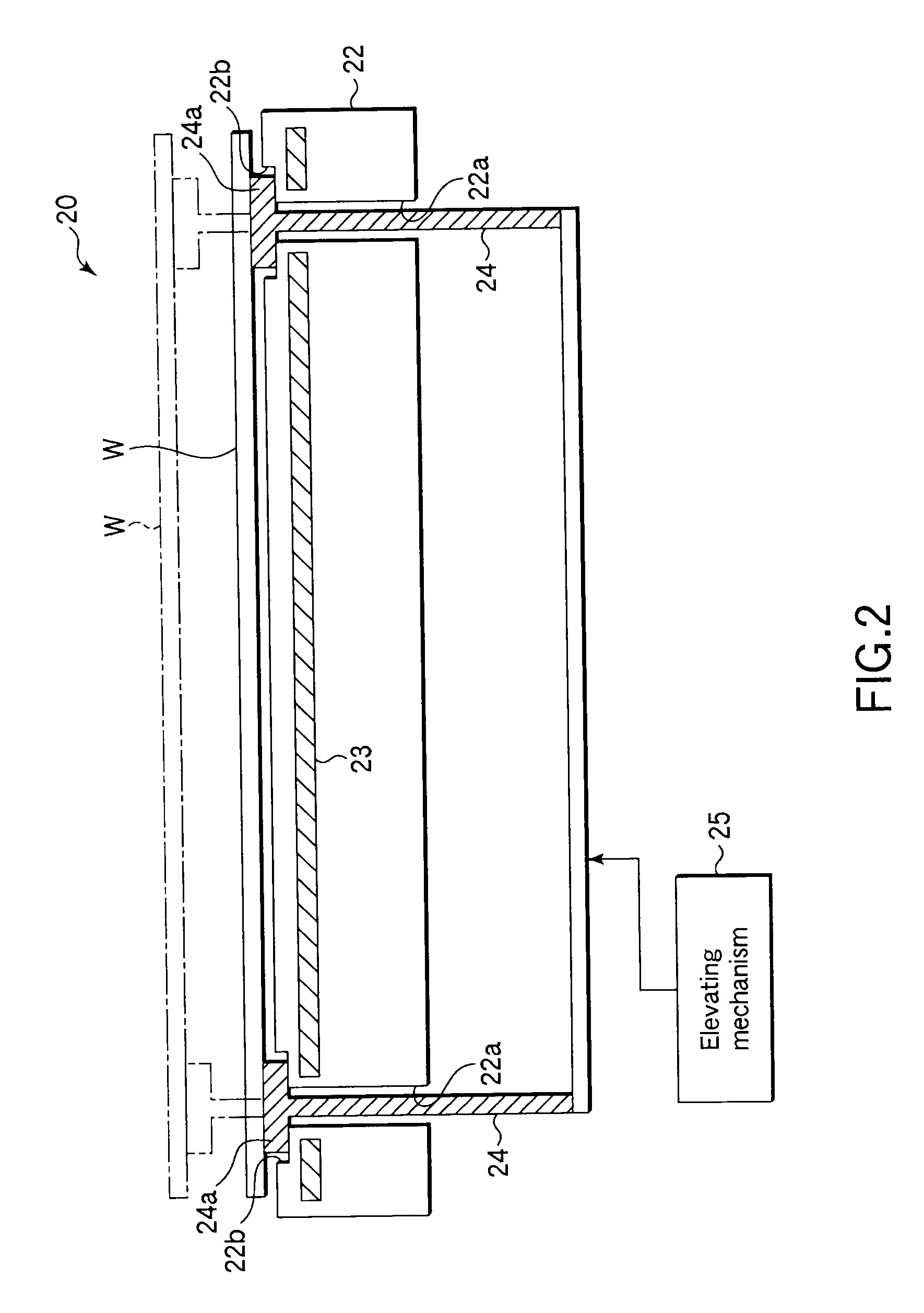

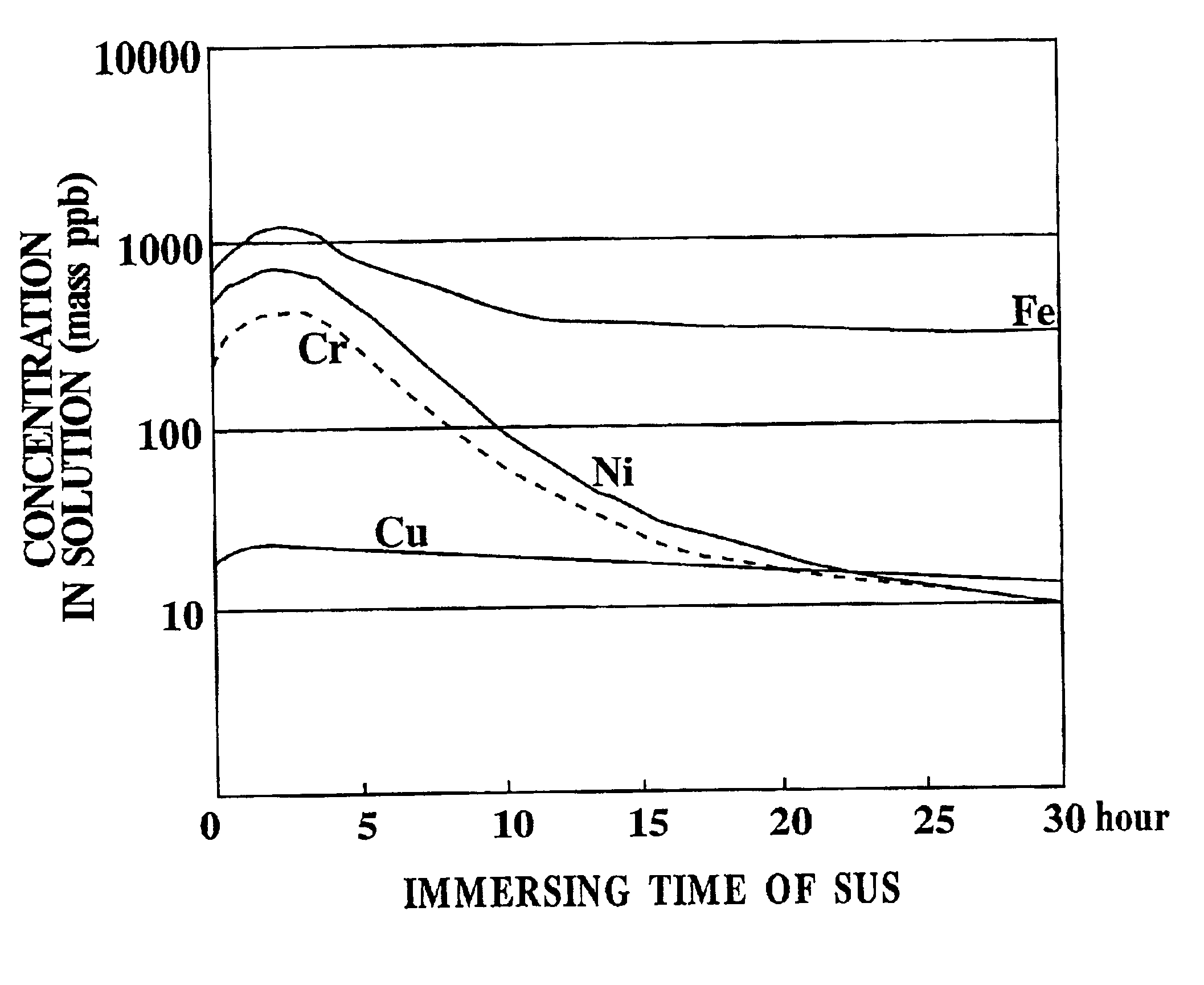

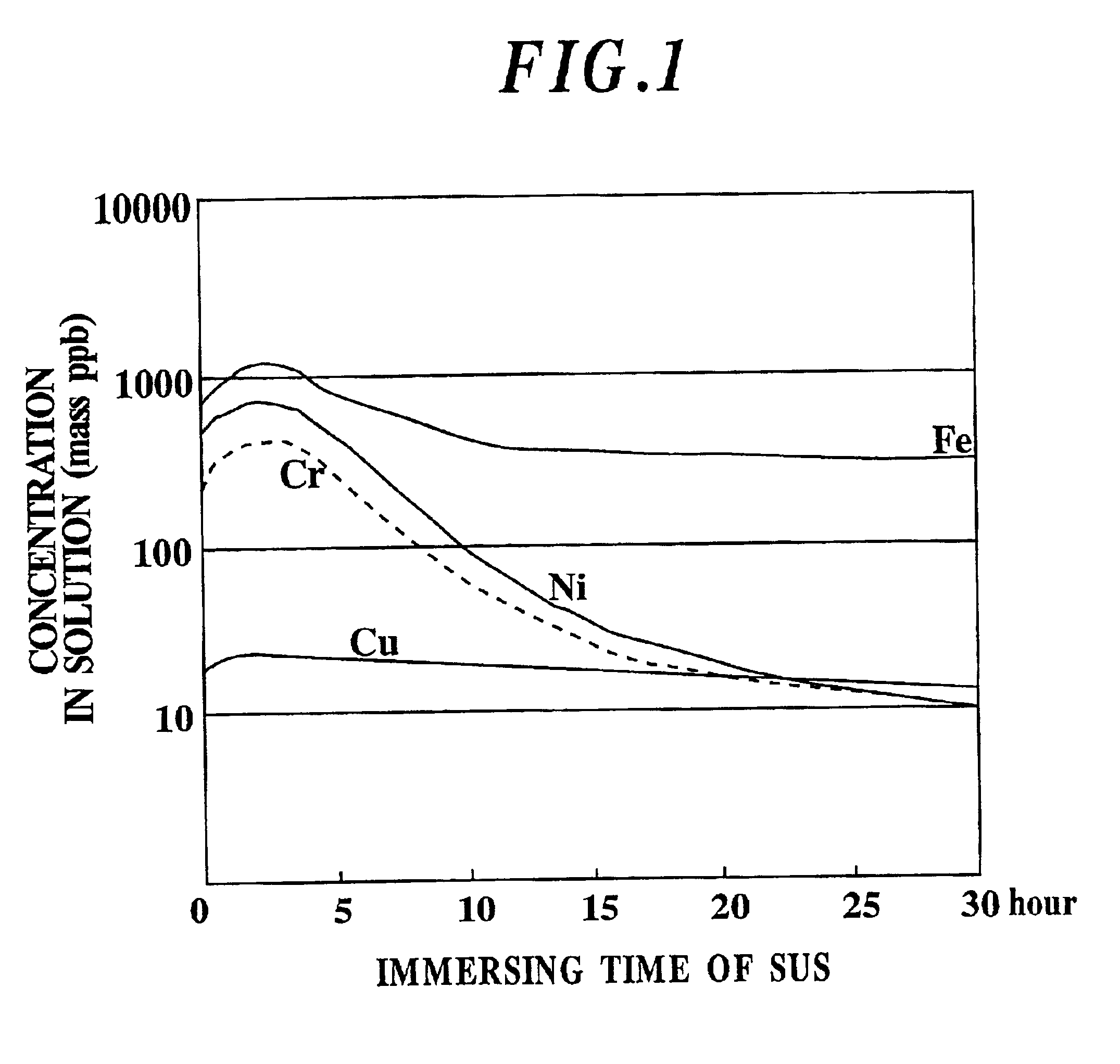

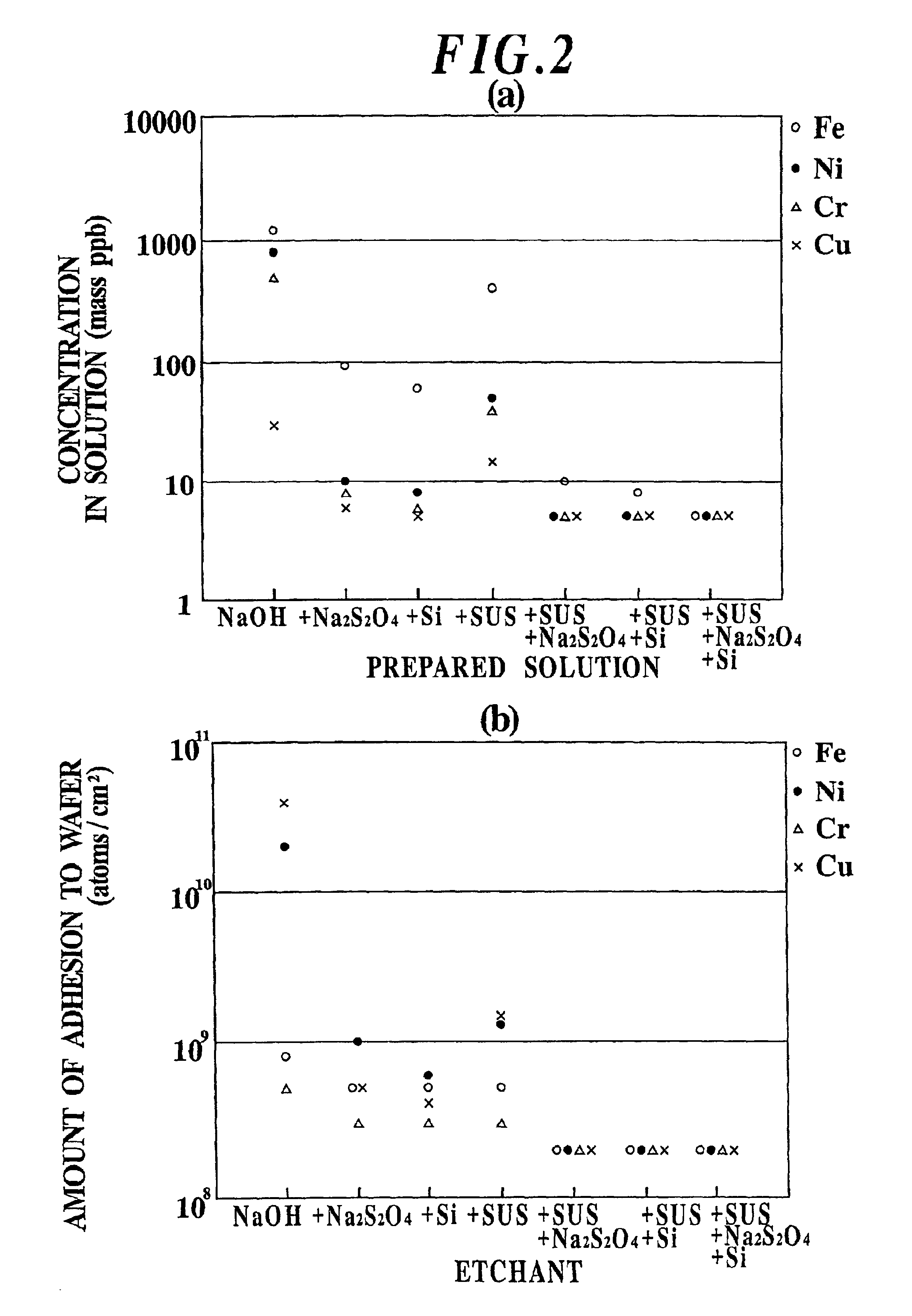

Etchant, etching method and semiconductor silicon waffer

InactiveUS20030008504A1Reduce metal pollutionReduce concentrationPolycrystalline material growthAfter-treatment detailsMetal contaminationAqueous solution

An etchant and an etching method that contribute to prevention of metal contamination of a semiconductor silicon wafer, and a semiconductor silicon wafer in which metal contamination is extremely reduced, are provided. The etchant according to the present invention is prepared by immersing stainless steel in an alkali aqueous solution for not less than 10 hours. In the etching method according to the present invention, a semiconductor silicon wafer is etched by using the etchant. Thereby, the semiconductor silicon wafer according to the present invention, in which metal contamination is extremely reduced, is obtained.

Owner:SHIN-ETSU HANDOTAI CO LTD

Solid base adsorption agent for treating processes of deacidification in use for liquid matter in esters of organic acid

InactiveCN101049550AImprove adsorption capacityMaintain active stabilityOrganic compound preparationOther chemical processesOrganic acidAlkaline earth metal

An alkaline solid adsorbent for deacidifying and refining the liquid esters of organic acid is prepared from the oxide and hydroxide of alkali-earth in IIA family and alumina through wetting, mixing, kneading, extruding to become strips, drying and high-temp calcining. It has high specific surface area, adsorptive volume and mechanical strength.

Owner:WEIFANG BAILI CHEM

Multi-gate field effect transistor and method for manufacturing the same

ActiveUS7781274B2Avoid Metal ContaminationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringField-effect transistor

Owner:KIOXIA CORP

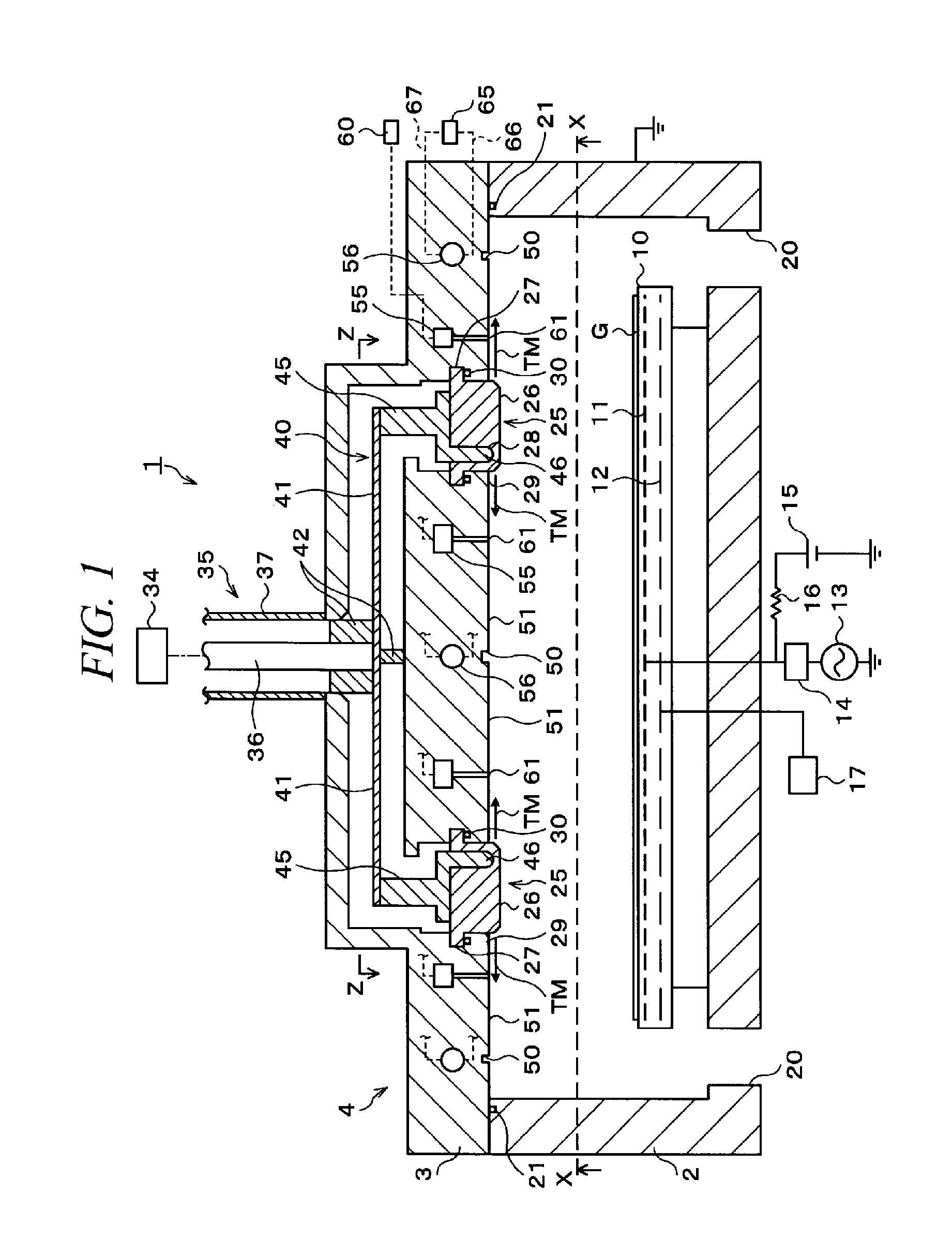

Plasma processing apparatus

ActiveUS20130112352A1Well formedReduce usageLiquid surface applicatorsElectric discharge tubesDielectricSusceptor

A plasma processing apparatus includes: a processing chamber produced from a metal; a susceptor configured to mount a substrate; an electromagnetic wave source that supplies an electromagnetic wave; one or more dielectric member provided at an inner wall of the processing chamber, and configured to transmit the electromagnetic wave into an inside of the processing chamber; one or more metal electrode, wherein each metal electrode is installed on a bottom surface of each dielectric member such that a part of the each dielectric member is exposed to the inside of the processing chamber; and a surface wave propagating section which is a metal surface facing the susceptor, the surface wave propagating section being installed adjacent to the dielectric member and being exposed to the inside of the processing chamber. The surface wave propagating section and a bottom surface of the metal electrode are positioned on the same plane.

Owner:TOKYO ELECTRON LTD +1

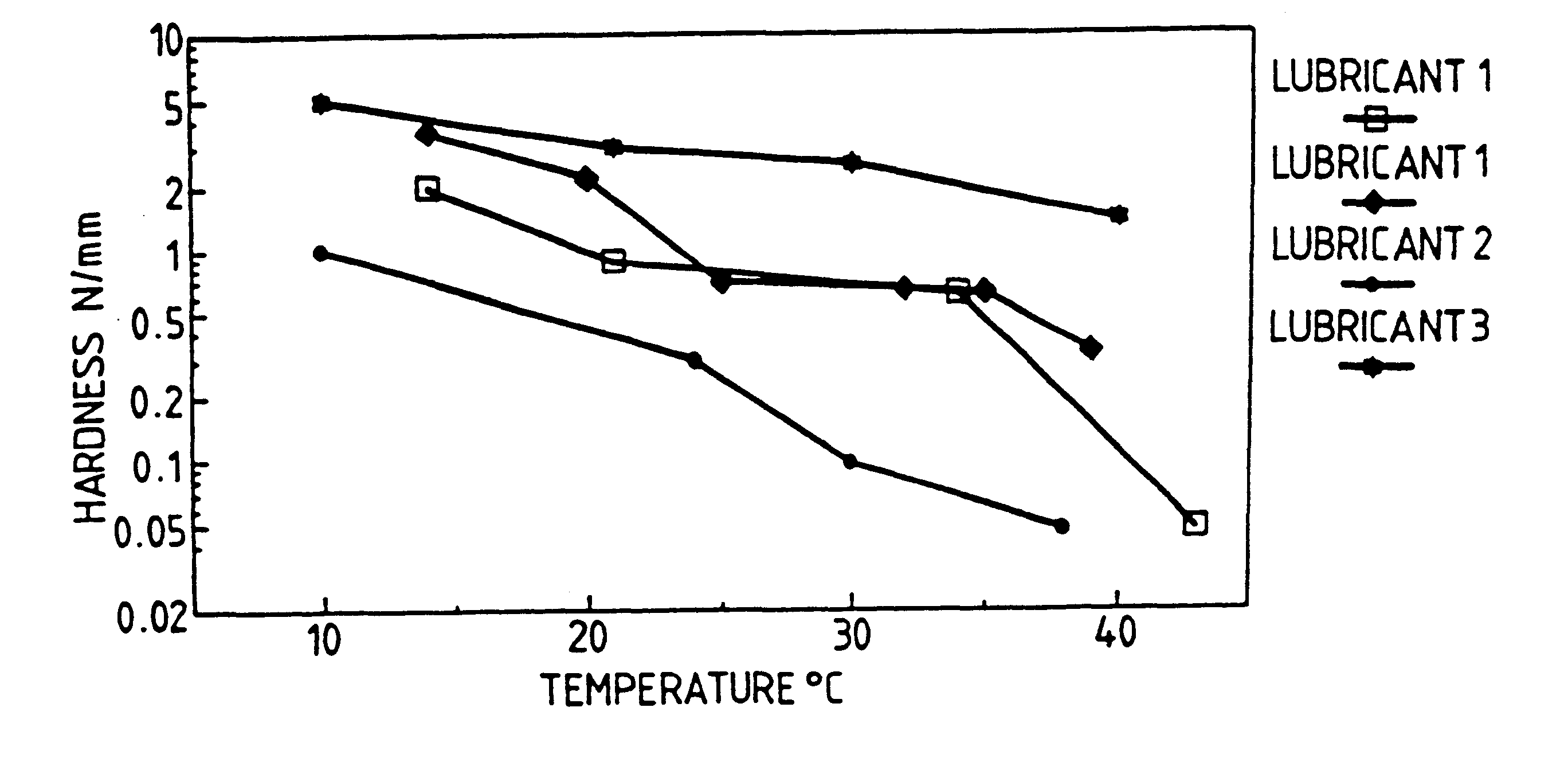

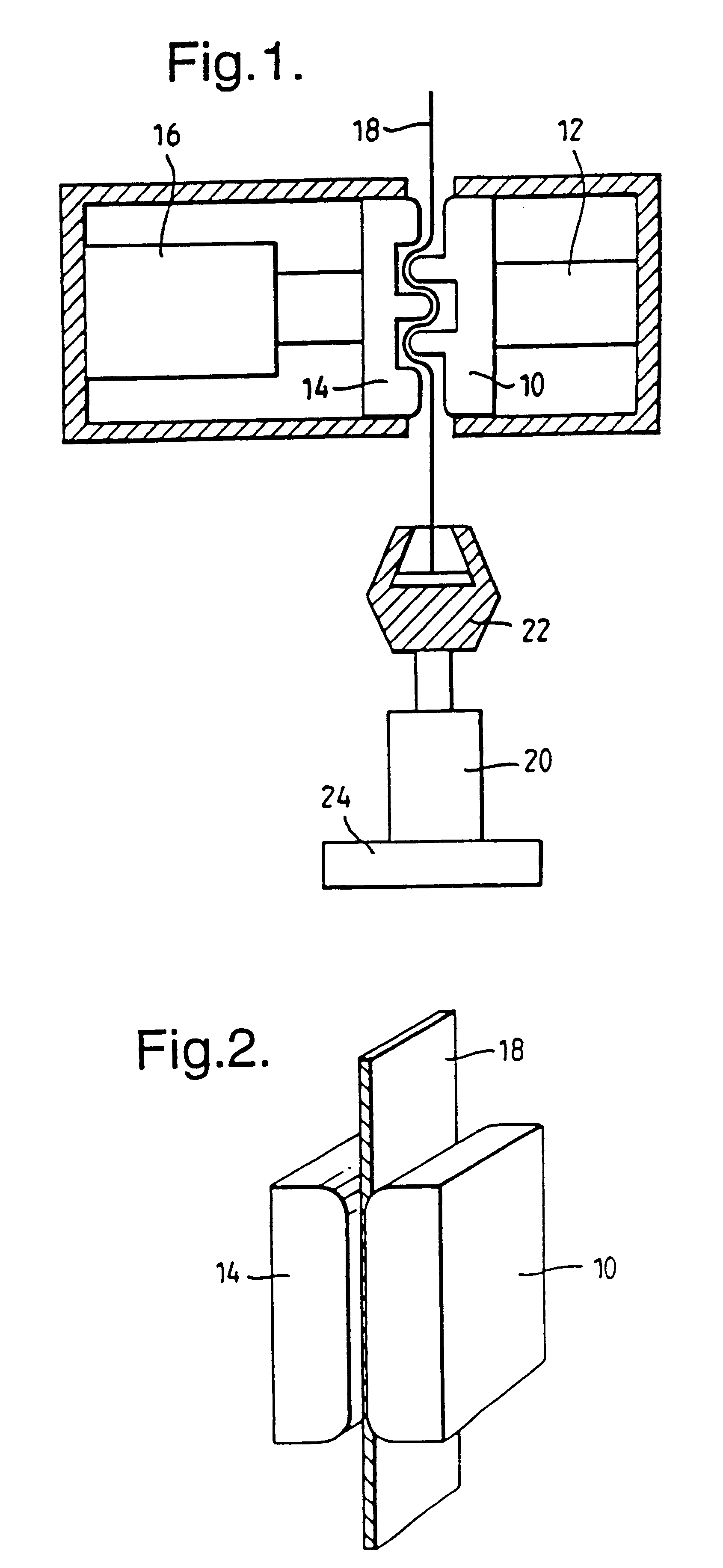

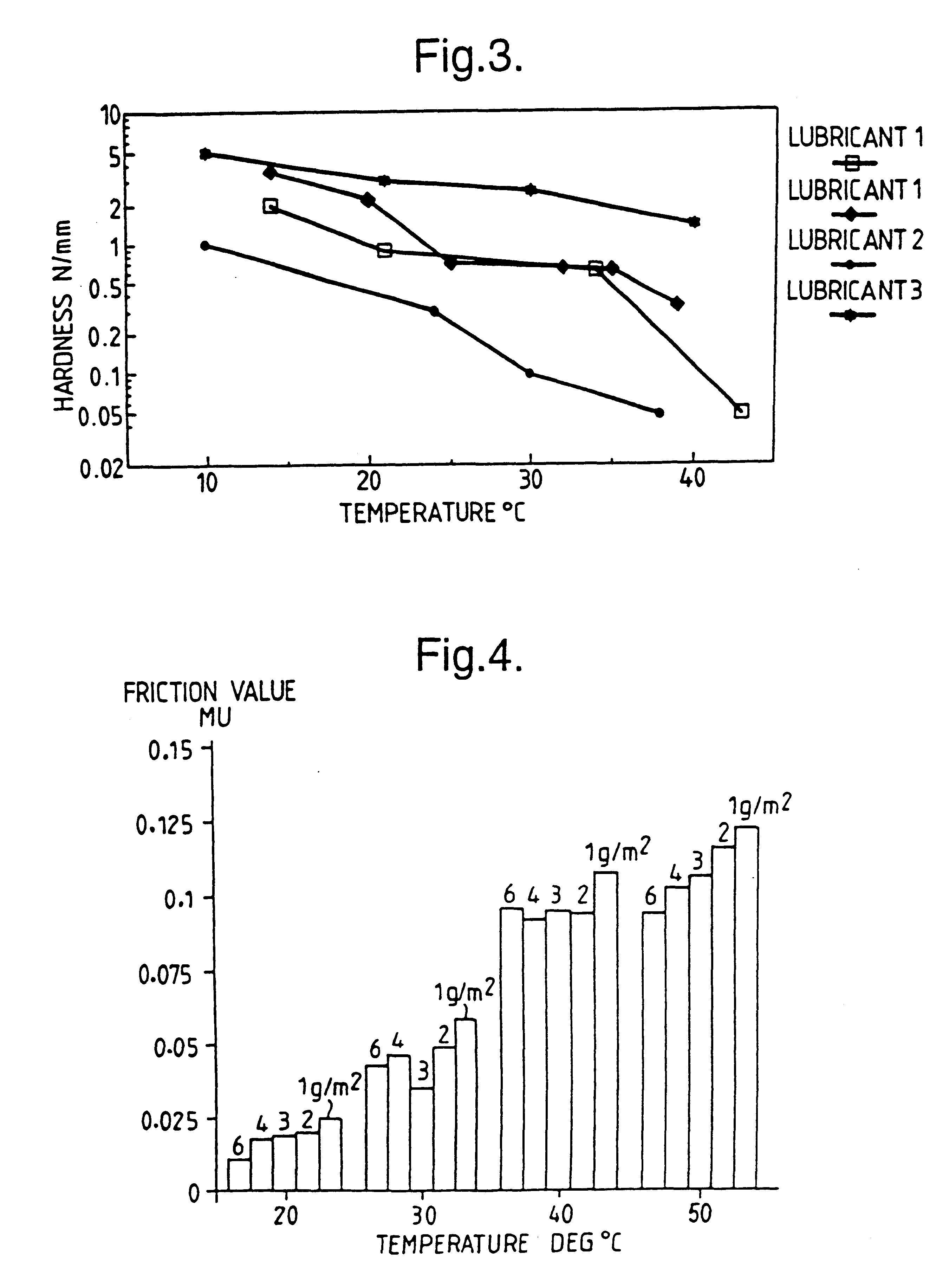

Lubricated metal workpiece and method

InactiveUS6329329B1Satisfactory viscosityFreeze fastWork treatment devicesAdditivesHardnessStearic acid

A lubricant is provided which has a hardness in the range 0.1-10 N / mm at all temperatures in the range 15-40° C. The lubricant consists of at least one full ester of a glycol with a fatty acid, e.g. ethylene glycol dilaurate, optionally mixed with a minor amount of a fatty acid such as stearic acid, and / or a minor amount of a partial ester of a glycol with a fatty acid. The lubricant is useful in the production of press-formed components, and particularly in techniques for converting aluminium sheet to adhesively bonded aluminium structures.

Owner:NOVELIS INC

Surface cleaning method of semiconductor wafer heat treatment boat

InactiveUS20080237190A1Efficiently and easily removing metallic contaminationKeep down production timeDecorative surface effectsSurface treatment compositionsSurface cleaningCleaning methods

A surface cleaning method of a semiconductor wafer heat treatment boat that can prevent metallic contamination to semiconductor wafers and keep down a production time and manufacturing costs of semiconductor wafers by efficiently and easily removing metallic impurities in an oxide film on an SiC boat surface is provided. A surface cleaning method of a semiconductor wafer heat treatment boat according to an embodiment of the present invention is a surface cleaning method of a semiconductor wafer heat treatment boat whose surface is formed of SiC, includes oxidizing the surface of the heat treatment boat by thermal oxidation and etching a portion of the oxide film formed after oxidation is removed.

Owner:COVALENT MATERIALS CORP

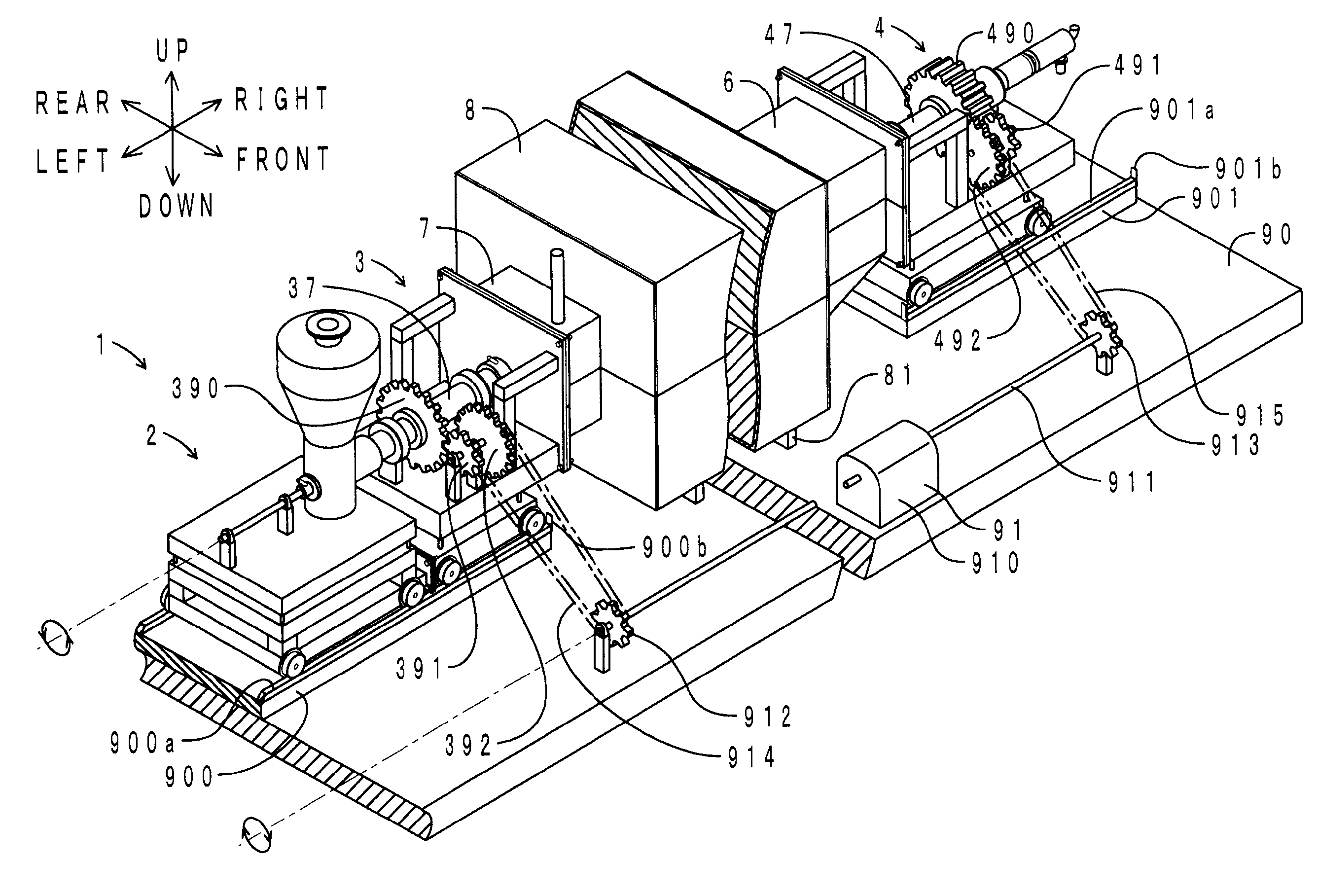

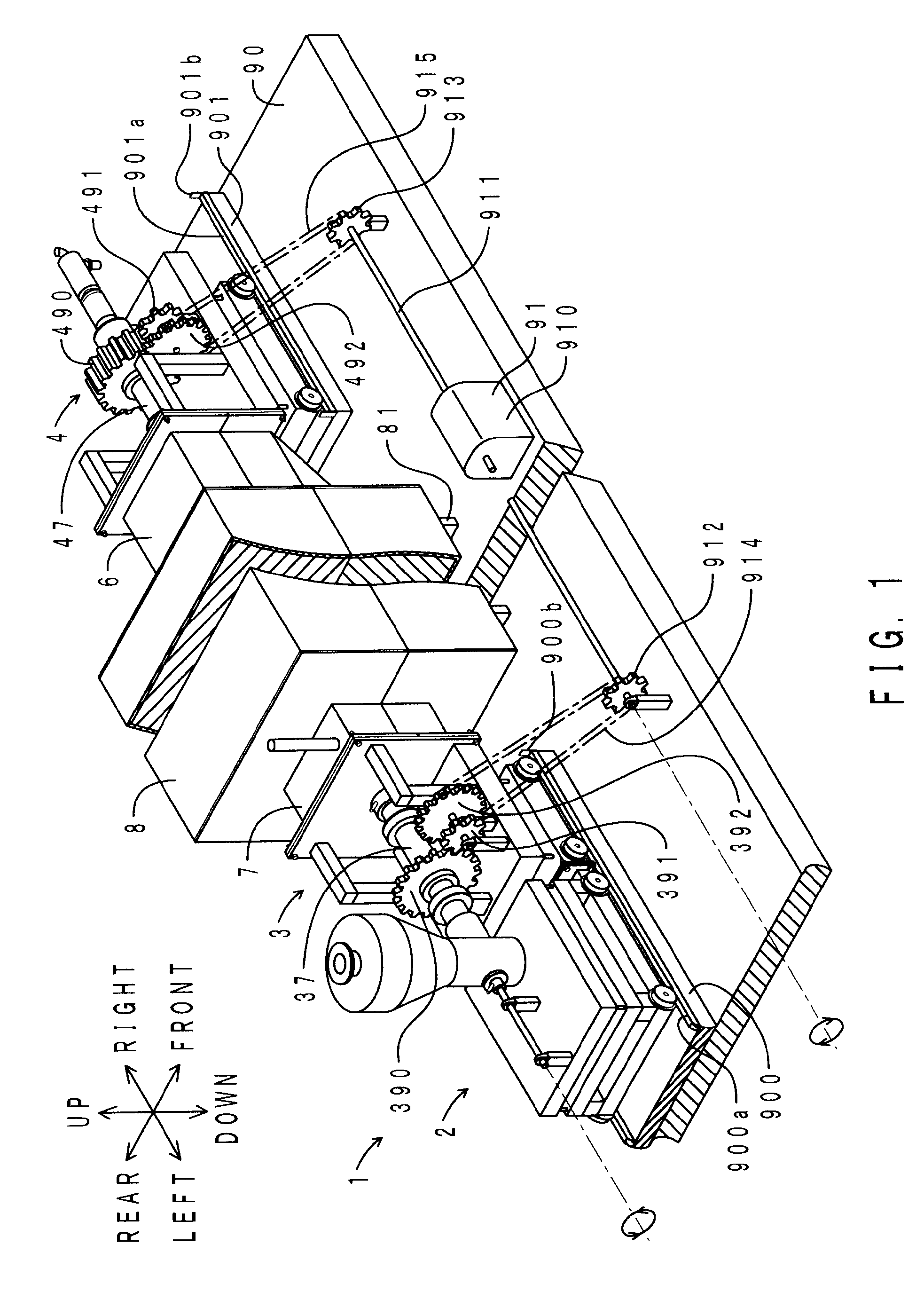

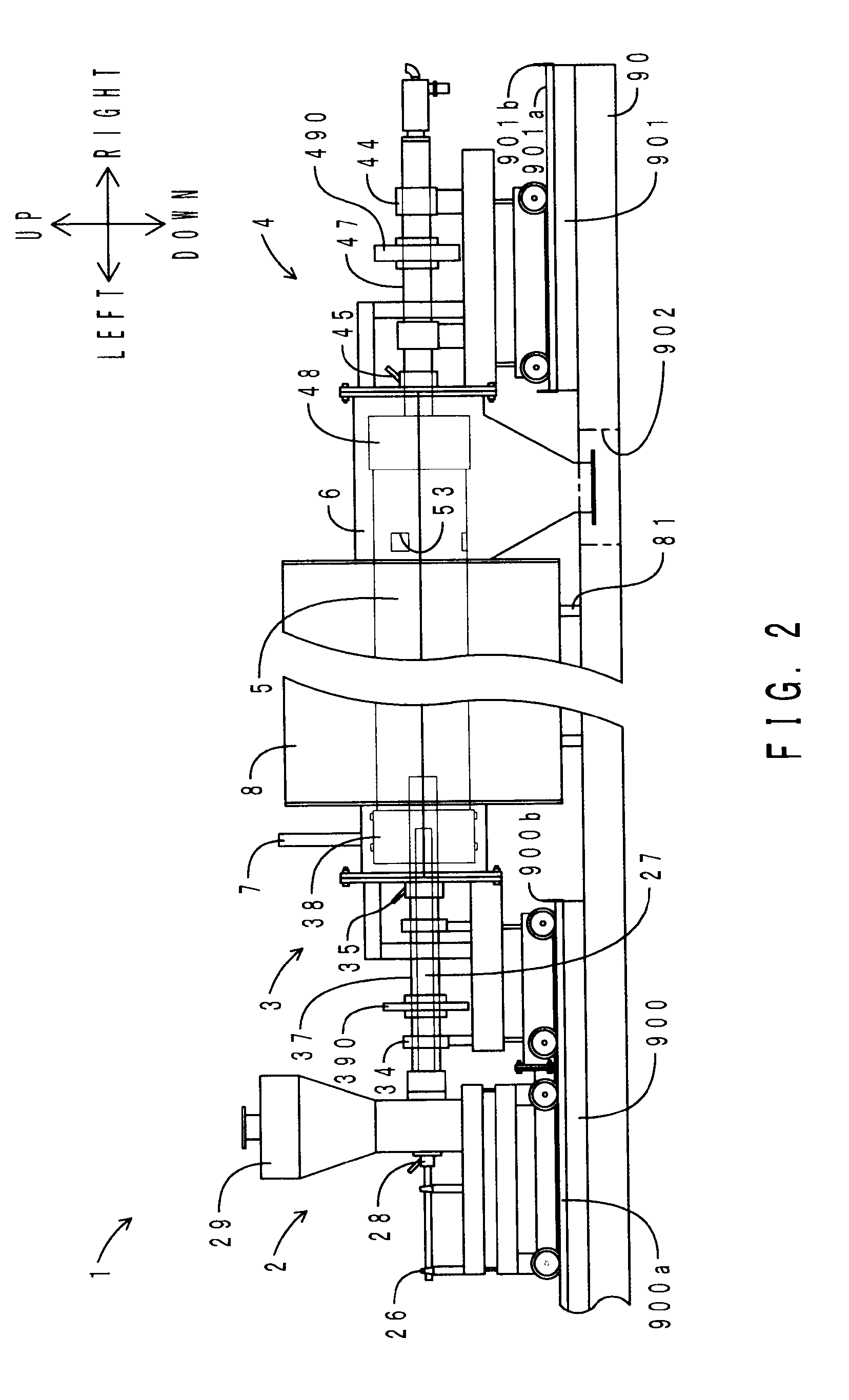

Rotary kiln and battery material manufactured by the rotary kiln

InactiveUS20110065005A1Pollution suppressionContamination of scaleRotary drum furnacesCharge manipulationMechanical engineeringContamination

A rotary kiln includes a cylindrical shell that rotates about its own axis and that has a heat treatment chamber provided radially inward of the shell. In the rotary kiln, a heat treatment is performed on a process material in the heat treatment chamber to manufacture a battery material. The shell is made of a carbon material. Since the shell is made of a carbon material, the rotary kiln can suppress contamination of metal scale, which adversely affects the battery material, into the battery material.

Owner:TAKASAGO IND

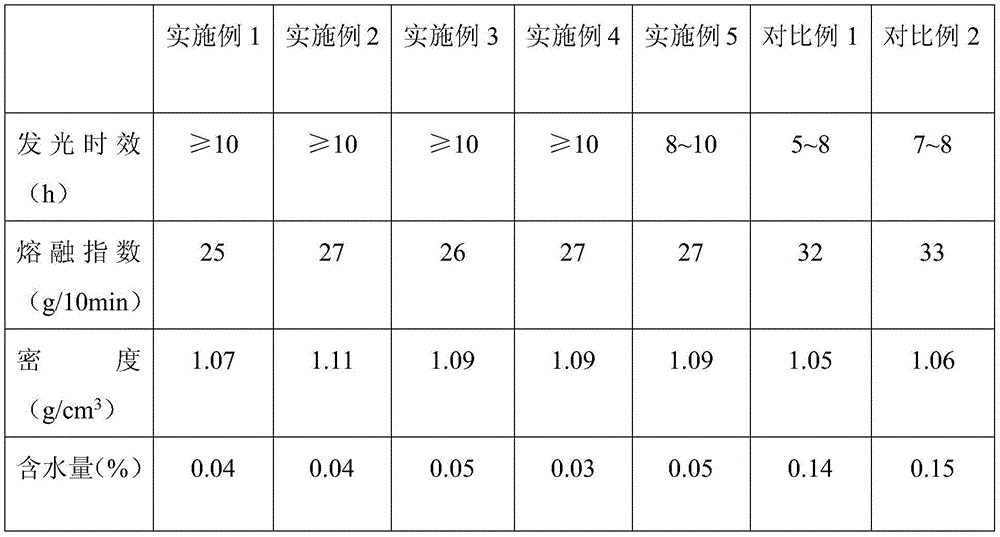

ABS noctilucent masterbatches and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to ABS noctilucent masterbatches and a preparation method thereof. The ABS noctilucent masterbatches comprise the following components in percentage by mass: 50 to 75 percent of ABS, 5 to 10 percent of dispersant, and 20 to 40 percent of noctilucent powder, wherein the dispersant is dimethyl silicon oil and / or polyethylene wax. The ABS noctilucent masterbatches and the preparation method thereof have the benefits that the abrasion of a machine caused by noctilucent powder during a production process is reduced and the blackening phenomenon of noctilucent powder is avoided by the improvements, such as extruding through a single screw, reducing extruding rate, raising processing temperature, mixing materials in a plastic material barrel at a low speed, of process conditions; the processing temperature is risen, the coating capacity of melt to the noctilucent powder is improved, and the ABS noctilucent masterbatches with higher concentration are prepared by mixing ABS powdery matrix resin and ABS particular matrix resin; the interference to the luminance caused by the color of the matrix resin is reduced by using a suitable amount of dispersant; the ABS noctilucent masterbatches prepared by the preparation method has the advantages of high concentration, long-acting luminescence, large molecular weight of ABS, low abrasion to the machine, uniform dispersion, no chromatic aberration, wide application range and the like.

Owner:DALIAN CRYSTAL COLOR MASTERBATCH CO LTD

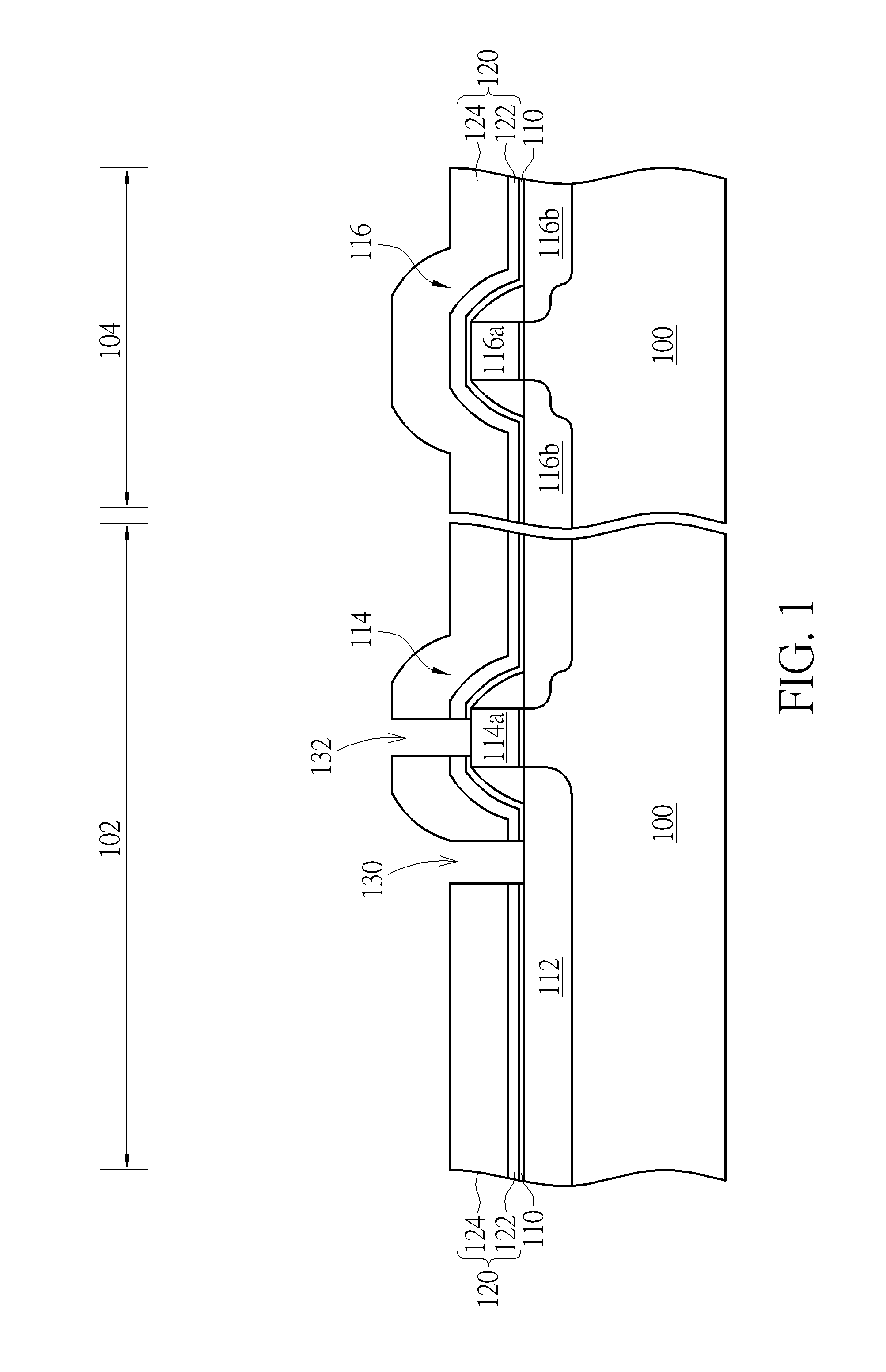

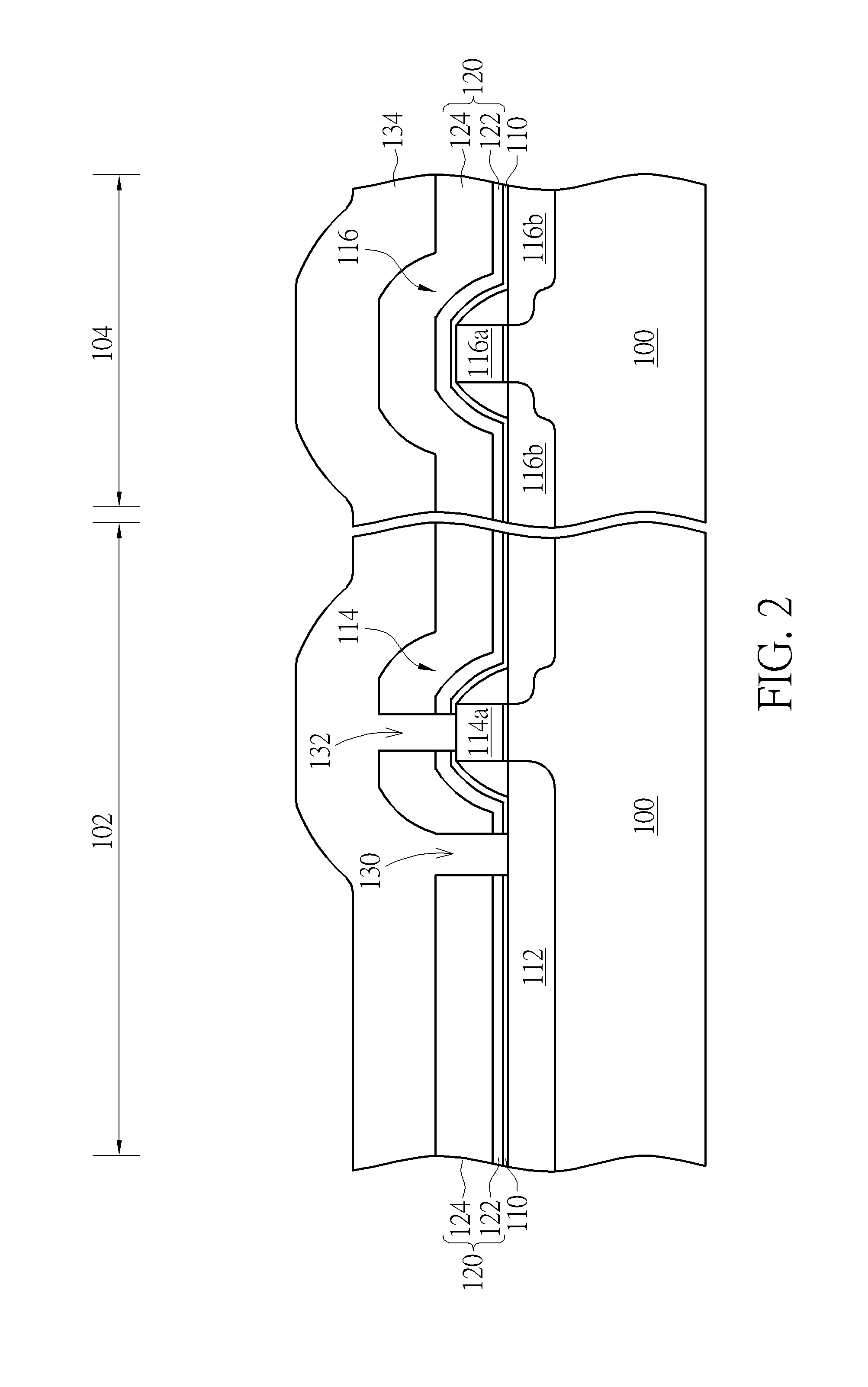

Complementary metal-oxide-semiconductor image sensor and manufacturing method thereof

ActiveUS9537040B2Improve electrical performanceAvoid Metal ContaminationSolid-state devicesDiodeSalicideEngineering

A method for manufacturing semiconductor devices includes following steps. A substrate having a pixel region and a periphery region defined thereon is provided, and at least a transistor is formed in the pixel region. A blocking layer is formed on the substrate, and the blocking layer includes a first opening exposing a portion of the substrate in the pixel region and a second opening exposing a portion of the transistor. A first conductive body is formed in the first opening and a second conductive body is formed in the second opening, respectively. The first conductive body protrudes from the substrate and the second conductive body protrudes from the transistor. A portion of the blocking layer is removed. A first salicide layer is formed on the first conductive body and a second salicide layer is formed on the second conductive body, respectively.

Owner:UNITED MICROELECTRONICS CORP

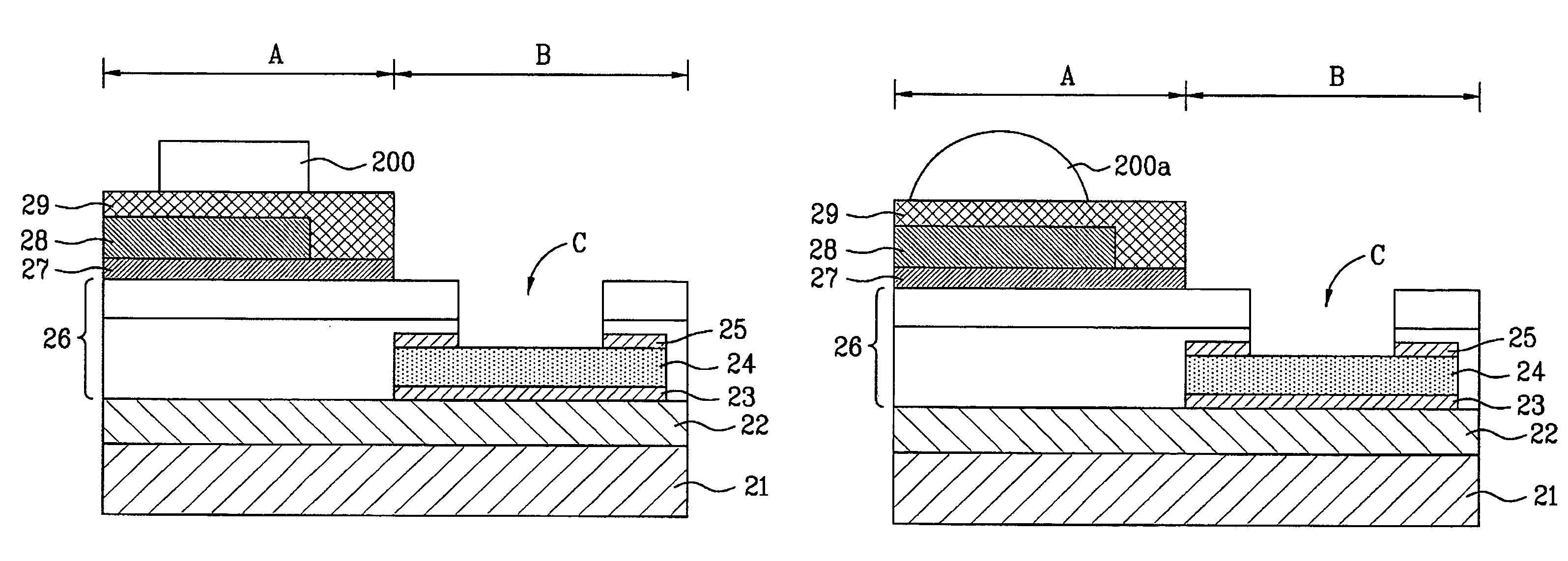

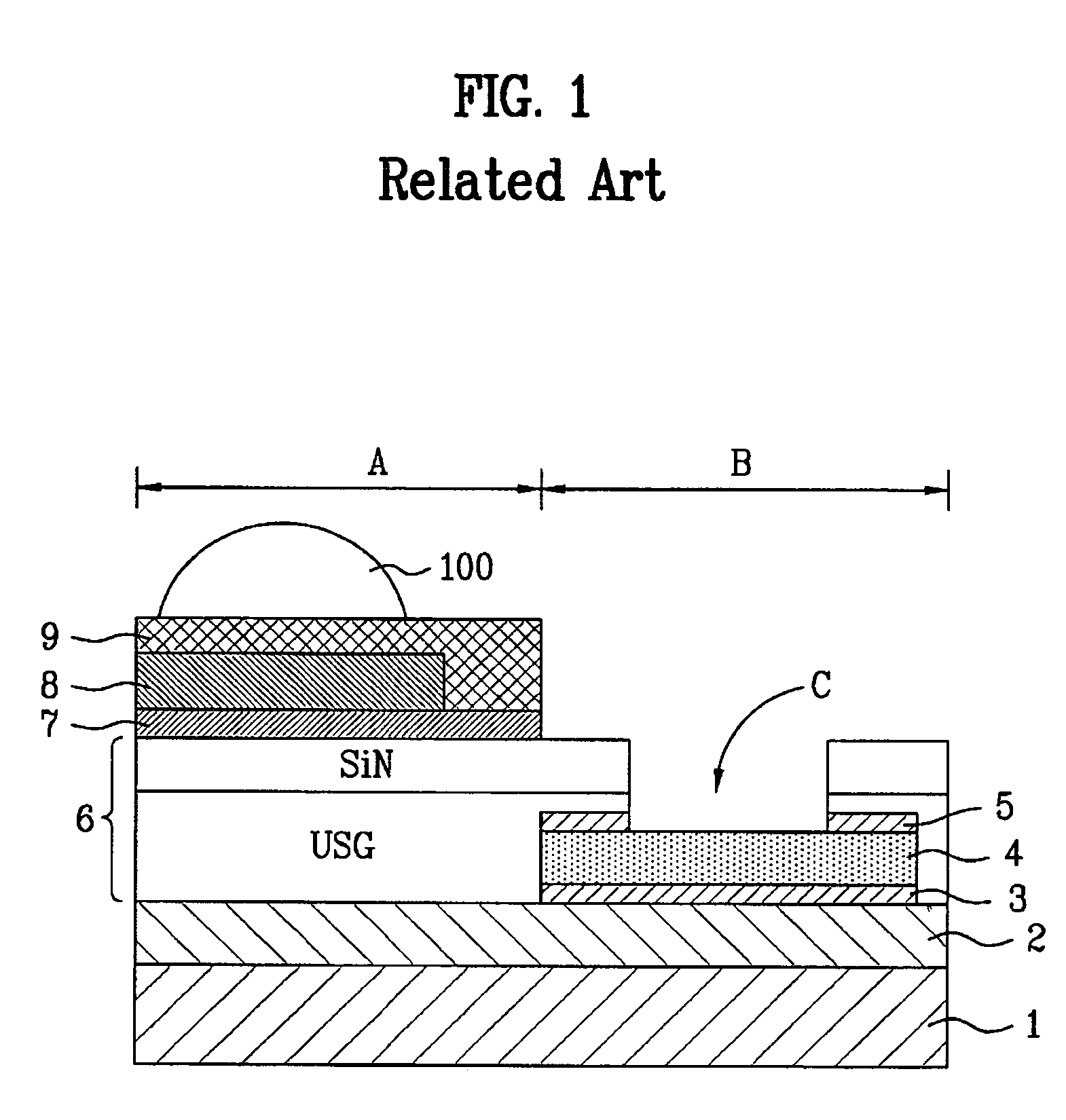

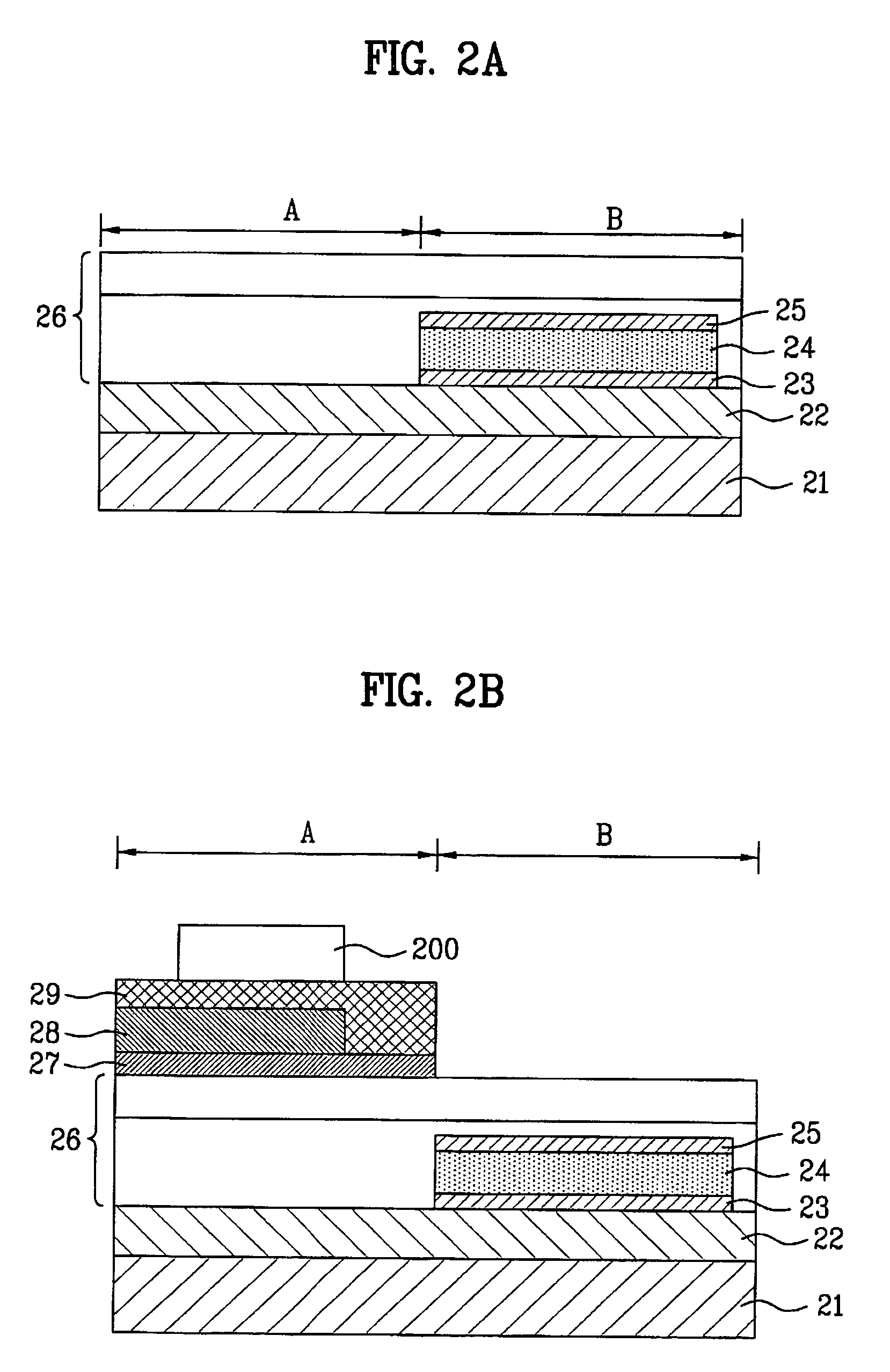

Method for fabricating CMOS image sensor

InactiveUS7435615B2Avoid Metal ContaminationImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingCMOSEngineering

A method for fabricating a CMOS image sensor improves the characteristics of device by preventing a pad from being contaminated without damaging a micro-lens. The method includes steps of forming a device protection layer on a semiconductor substrate including at least one photo-sensing device and at least one metal pad disposed in a logic circuit area corresponding to the at least one photo-sensing device, the device protection layer covering the at least one metal pad; forming each of a first planarization layer, a color filter layer, and a second planarization layer in sequence on the device protection layer in correspondence with the at least one photo-sensing device; forming on the second planarization layer a material layer for micro-lens formation; exposing a predetermined portion of the metal pad by selectively etching the device protection layer; and forming a micro-lens for directing incident light onto the at least one photo-sensing device by reflowing, after the exposing step, the material layer for micro-lens formation.

Owner:DONGBU ELECTRONICS CO LTD

Method for dyeing fabric with plant dye

InactiveCN109577031AAvoid Metal ContaminationPrevent the production of carcinogensDyeing processMetal pollutionPre treatment

The invention discloses a method for dyeing a fabric with plant dye. In the method, dye mother liquor extracted from natural plants is used as dye liquor, a pretreated fabric is soaked in the dye liquor, a dyeing additive is added into the dye liquor, no dye mordant is added, ultrasonic dyeing is conducted according to the bath ratio of 1:3-10 and at the temperature of 30-50 DEG C, and finally dyed fabric meeting the demand for firmness is obtained. According to the obtained method for dyeing the fabric with the plant dye, the common dyeing additive is used for preparing the natural plant dyeliquor without usage of toxic dye mordant, ultrasonic dyeing with the low bath ratio is conducted, and finally the dyed fabric which meet the demand for dyeing firmness and is environmentally friendlyis obtained; in the method, during dyeing, the dyeing bath ratio can be decreased greatly, water used for production is further saved, more importantly, the amount of wastewater is reduced, there isno metal pollution in the wastewater, there are no cancerogenic substances, and the meaning of environmental protection is remarkable.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for fabricating CMOS image sensor

InactiveUS20060019425A1Avoid Metal ContaminationImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingCMOSEngineering

A method for fabricating a CMOS image sensor improves the characteristics of device by preventing a pad from being contaminated without damaging a micro-lens. The method includes steps of forming a device protection layer on a semiconductor substrate including at least one photo-sensing device and at least one metal pad disposed in a logic circuit area corresponding to the at least one photo-sensing device, the device protection layer covering the at least one metal pad; forming each of a first planarization layer, a color filter layer, and a second planarization layer in sequence on the device protection layer in correspondence with the at least one photo-sensing device; forming on the second planarization layer a material layer for micro-lens formation; exposing a predetermined portion of the metal pad by selectively etching the device protection layer; and forming a micro-lens for directing incident light onto the at least one photo-sensing device by reflowing, after the exposing step, the material layer for micro-lens formation.

Owner:DONGBU ELECTRONICS CO LTD

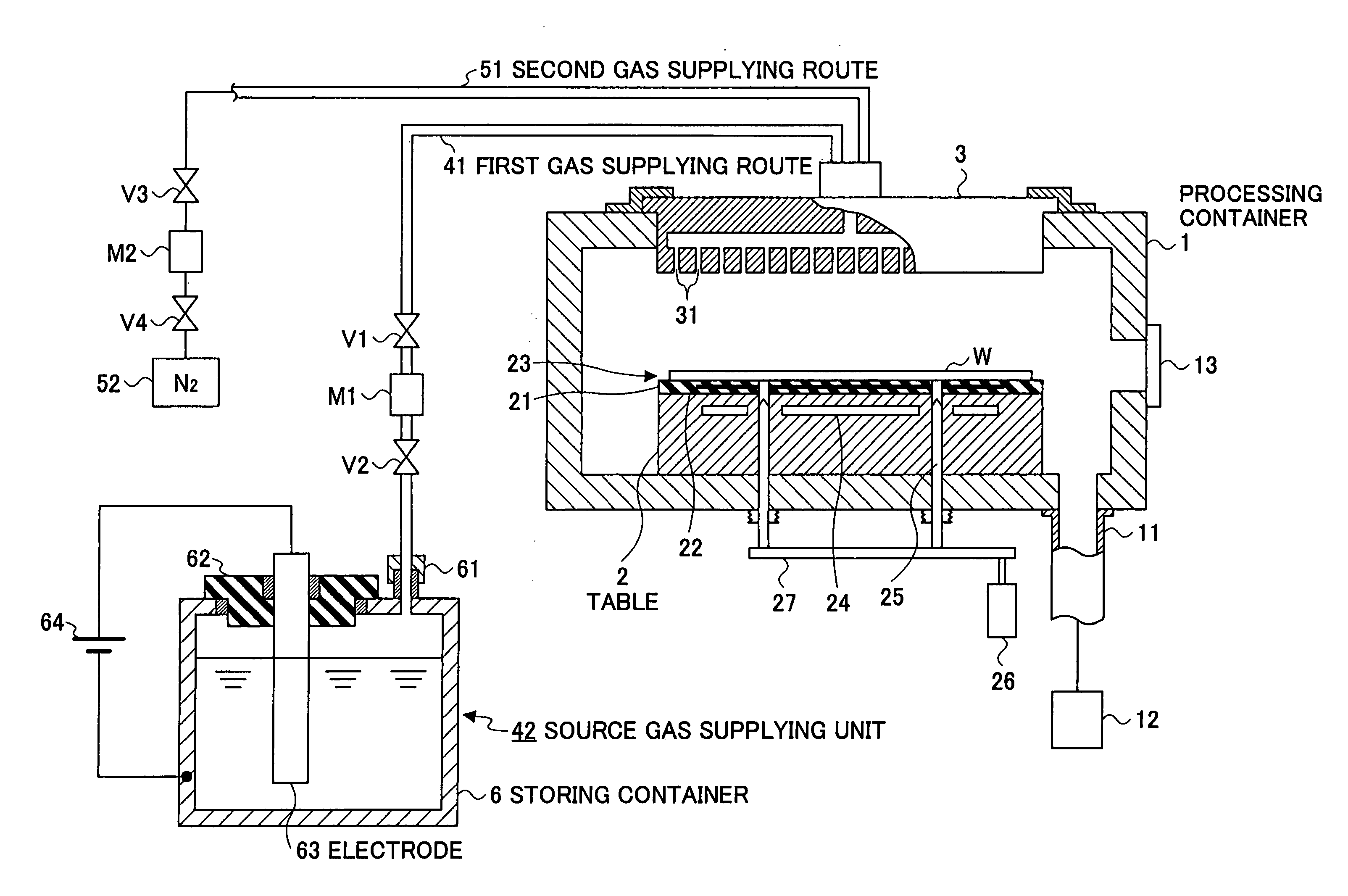

Semiconductor device manufacturing apparatus and operating method thereof

InactiveUS20060289297A1Avoid pollutionNot to damageSemiconductor/solid-state device manufacturingCleaning processes and apparatusDevice materialManufactured apparatus

A semiconductor device manufacturing apparatus is disclosed. The semiconductor device manufacturing apparatus applies a process to a semiconductor wafer by supplying a vapor of a corrosive liquid source to a processing container. An electrode is immersed in a storing container which stores the corrosive liquid source. The main material of the electrode is a metal whose ionization tendency is less than that of a metal of the storing container, and a protection current is applied between them by a DC power source. Or another electrode is used. The main material of the electrode is a metal whose ionization tendency is greater than that of the metal of the storing container and the metal of the electrode does not damage the semiconductor wafer. A protection current is applied between the storing container and the electrode by utilizing the difference of the ionization tendency between them.

Owner:TOKYO ELECTRON LTD

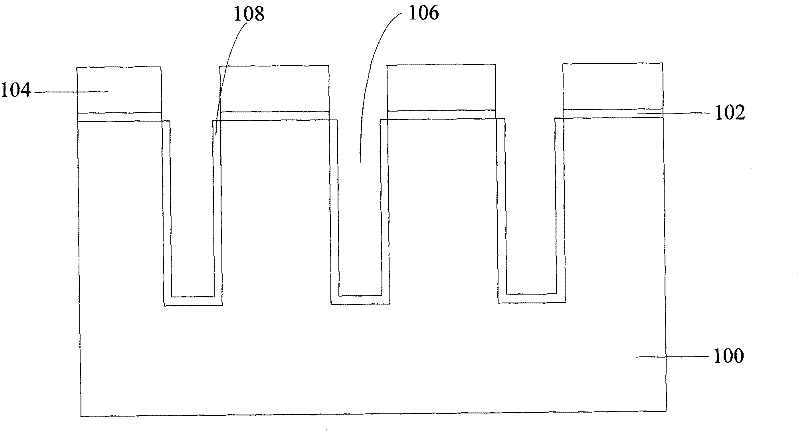

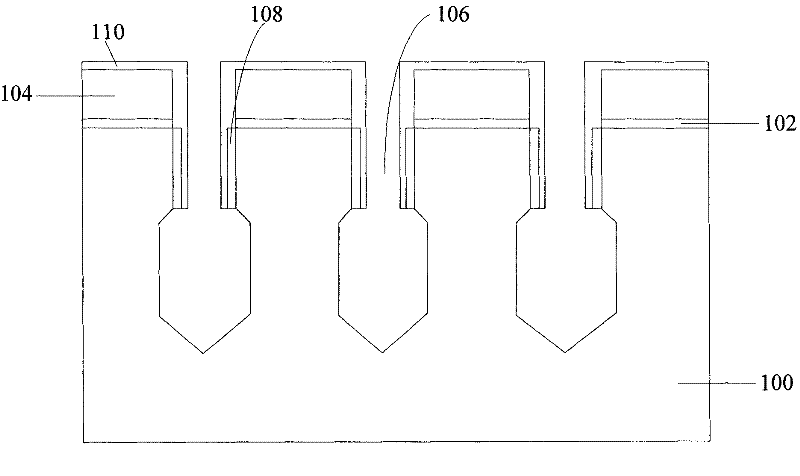

How to make a capacitor

InactiveCN102270567AAvoid Metal ContaminationGuard electrodeSemiconductor/solid-state device manufacturingMetal contaminationOxide

The present invention proposes a method for manufacturing a capacitor, comprising: providing a semiconductor substrate in which several trenches are formed; forming a lining oxide layer on the sidewall and bottom of the trench; forming a covering part on the sidewall of the trench The nitride layer lining the oxide layer; using the nitride layer as a mask, etching the lining oxide layer and semiconductor substrate exposed in the trench to form an area with increased area; the sidewall and bottom of the area with increased area in the trench The first electrode is formed; after removing the nitride layer, a dielectric layer and a second electrode are sequentially formed on the first electrode and the sidewall of the trench. The invention avoids metal pollution to the electrode, effectively protects the electrode, and improves the quality of the electrode and the subsequently formed capacitor.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Substrate processing apparatus for performing plasma process

InactiveUS20110253311A1Reduce generationAvoid Metal ContaminationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon membraneProcess engineering

A substrate processing apparatus for performing a plasma process on a target substrate includes a process container configured to accommodate the target substrate. The apparatus includes a gas feed passage configured to supply a process gas into the process container and an exhaust passage configured to exhaust gas from inside the process container. The apparatus further includes a plasma generation mechanism configured to generate plasma of the process gas inside the process container and a metal component to be exposed to plasma inside the process container. The metal component is provided with a silicon film that coats at least a portion thereof to be exposed to plasma and to suffer an intense electric filed generated thereabout.

Owner:TOKYO ELECTRON LTD

Etching method for semiconductor silicon wafer

InactiveUS6844269B2Reduce metal pollutionReduce concentrationPolycrystalline material growthAfter-treatment detailsMetal contaminationAqueous solution

An etchant and an etching method that contribute to prevention of metal contamination of a semiconductor silicon wafer, and a semiconductor silicon wafer in which metal contamination is extremely reduced, are provided. The etchant according to the present invention is prepared by immersing stainless steel in an alkali aqueous solution for not less than 10 hours. In the etching method according to the present invention, a semiconductor silicon wafer is etched by using the etchant. Thereby, the semiconductor silicon wafer according to the present invention, in which metal contamination is extremely reduced, is obtained.

Owner:SHIN-ETSU HANDOTAI CO LTD

Rotary kiln and battery material manufactured by the rotary kiln

InactiveUS8500444B2Pollution suppressionContamination of scaleRotary drum furnacesCharge manipulationEngineeringMechanical engineering

A rotary kiln includes a cylindrical shell that rotates about its own axis and that has a heat treatment chamber provided radially inward of the shell. In the rotary kiln, a heat treatment is performed on a process material in the heat treatment chamber to manufacture a battery material. The shell is made of a carbon material. Since the shell is made of a carbon material, the rotary kiln can suppress contamination of metal scale, which adversely affects the battery material, into the battery material.

Owner:TAKASAGO IND

Plasma processing apparatus

ActiveUS8733281B2Well formedReduce usageLiquid surface applicatorsElectric discharge tubesDielectricSusceptor

A plasma processing apparatus includes: a processing chamber produced from a metal; a susceptor configured to mount a substrate; an electromagnetic wave source that supplies an electromagnetic wave; one or more dielectric member provided at an inner wall of the processing chamber, and configured to transmit the electromagnetic wave into an inside of the processing chamber; one or more metal electrode, wherein each metal electrode is installed on a bottom surface of each dielectric member such that a part of the each dielectric member is exposed to the inside of the processing chamber; and a surface wave propagating section which is a metal surface facing the susceptor, the surface wave propagating section being installed adjacent to the dielectric member and being exposed to the inside of the processing chamber. The surface wave propagating section and a bottom surface of the metal electrode are positioned on the same plane.

Owner:TOKYO ELECTRON LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com