Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Maintain active stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

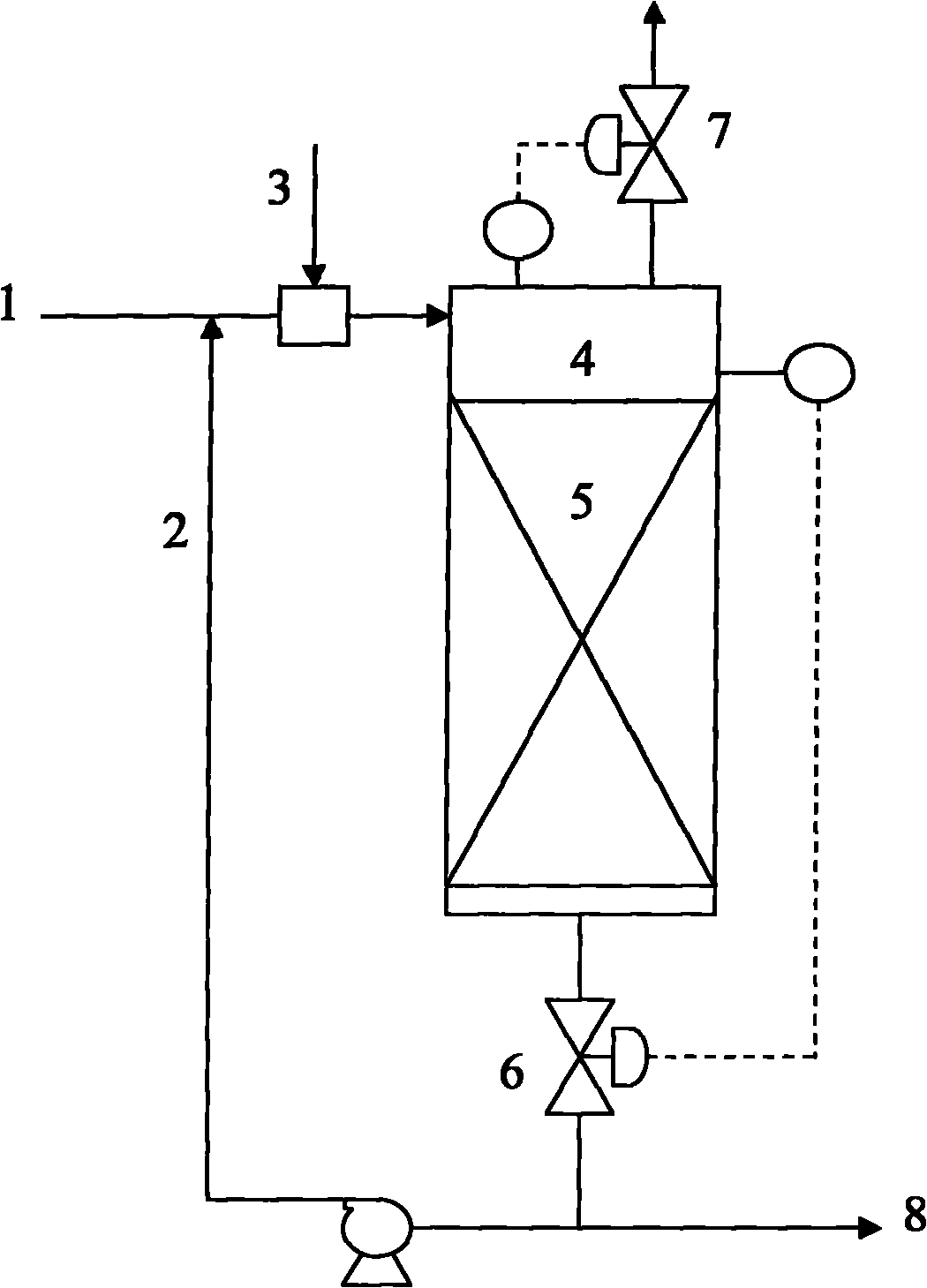

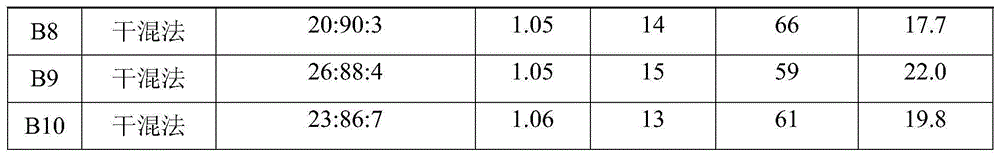

Method and reaction system for liquid phase cycling hydrotreatment

ActiveCN101993721AMaintain active stabilityImprove effective utilizationHydrocarbon oils treatment control/regulationTreatment with hydrotreatment processesGas phaseControl system

The invention discloses a method and a reaction system for liquid phase cycling hydrotreatment. In the method, part of a liquid phase product after the hydrotreatment is mixed with fresh raw oil in a cycling mode to form a liquid phase material; hydrogen is mixed into the liquid phase material; the hydrogen mixed amount is 1 to 20 times that of the dissolved hydrogen which makes the reaction system saturated under a reaction condition; the liquid phase material mixed and dissolved with the hydrogen is put into a reactor; a hydrogenation catalyst bed is arranged in the reactor and is immersed in the liquid phase material; the upper part of the reactor is provided with a gas phase space; a pressure control system communicated with the gas phase space is arranged on the reactor and controls the pressure in the reactor by controlling the gas exhaust quantity; and the liquid phase material dissolved with the hydrogen is put into the hydrogenation catalyst bed of the reactor to perform hydrogenation reaction. Compared with the prior art, the method ensures that the liquid phase cycling hydrotreatment can be controlled and operated stably, and obtain an ideal reaction effect.

Owner:CHINA PETROLEUM & CHEM CORP +2

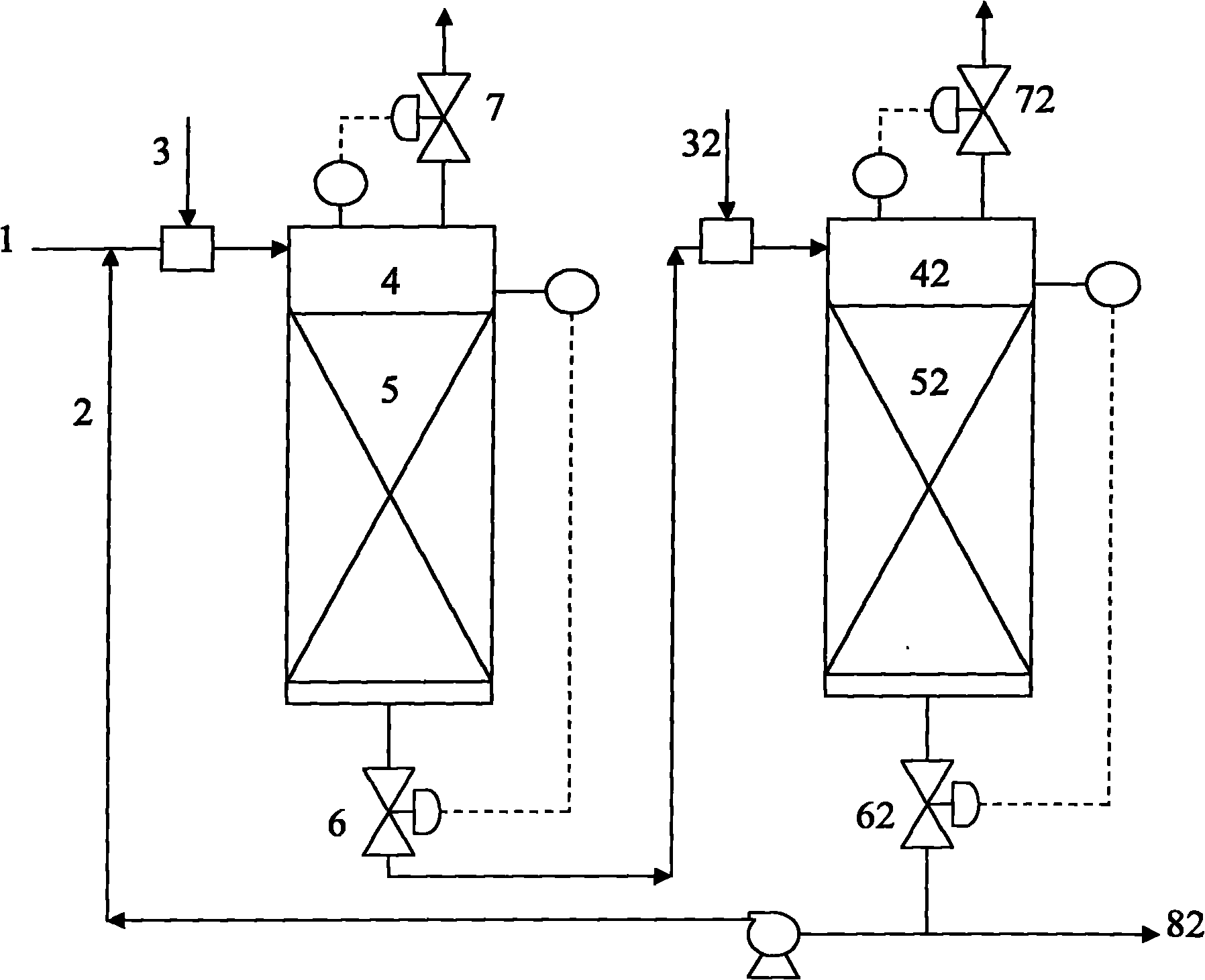

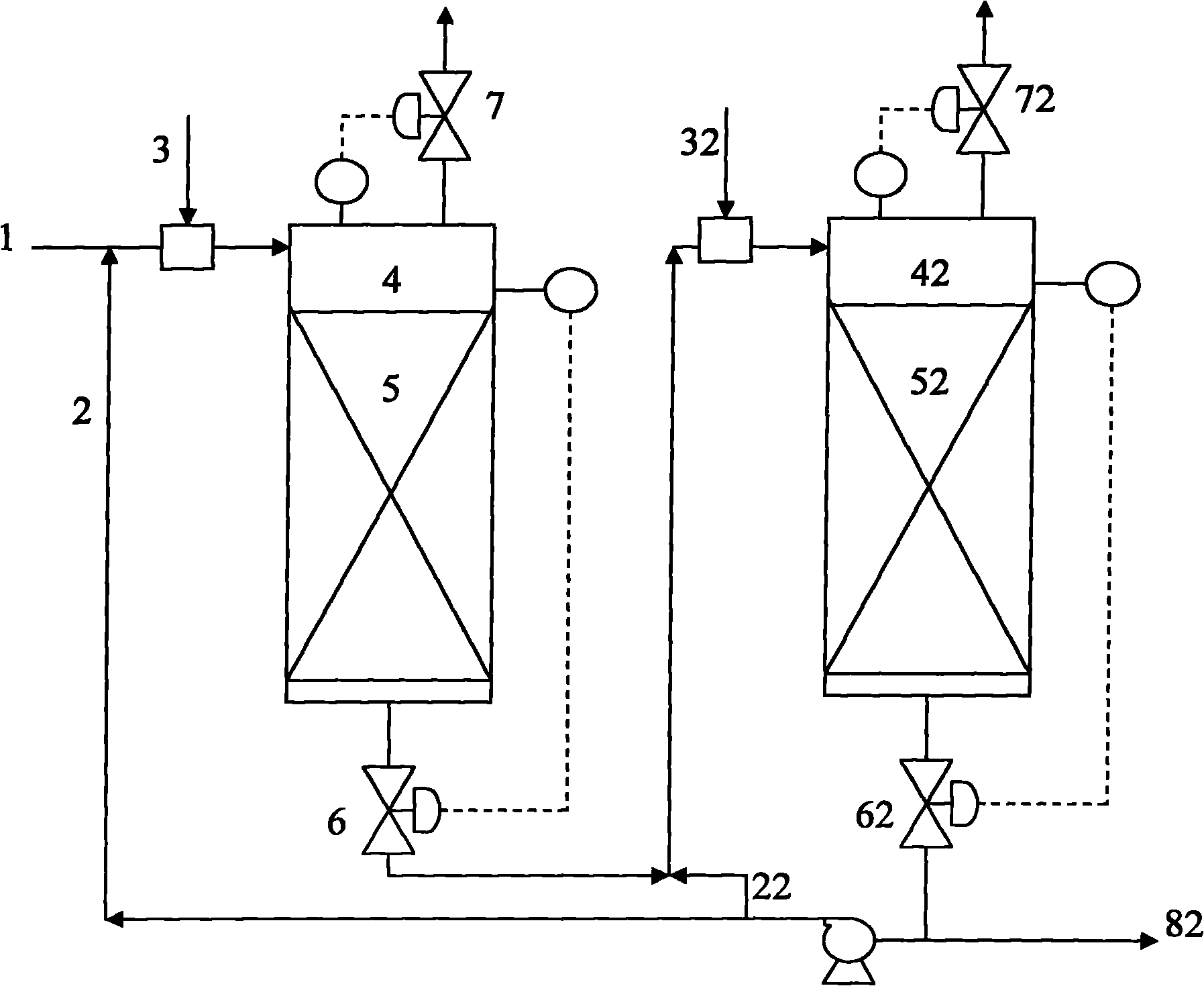

Method for removing olefins from reformate through liquid phase circulation selective hydrogenation

ActiveCN102911721AGood dispersionImprove hydrogenation activityTreatment with hydrotreatment processesReaction temperatureHydrogenation process

The invention relates to a method for removing olefins from reformate through liquid phase circulation selective hydrogenation. The method is characterized in that performing hydrogen saturation in a pipeline to form a raw material / hydrogenation product / hydrogen liquid phase mixture, and adding the liquid phase mixture to a multistage conventional hydrogenation reactor in sections under the hydrogenation condition; and entering a catalyst bed area in sections for reaction, wherein part of reaction products discharged from the bottom of the reactor circulate and are mixed with fresh raw materials, and part of reaction products discharged from the reaction system enter a follow-up separating device, the ratio of the circulation volume and the raw materials in the circulating liquid hydrogenation products is 1: (1-5): 1 by volume, the hydrogenation process conditions include that the reaction temperature is 80-180 DEG C, the pressure is 1.5-2.0MPa, and the fresh feed volume space velocity is 2.0-4.0hr-1.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hydrotreating method of product circulation

ActiveCN102029128AMaintain active stabilityImprove utilization efficiencyChemical/physical processesRefining to eliminate hetero atomsHydrogenation reactionLifting gas

The invention discloses a hydrotreating method of product circulation. One part of circulation of a hydrotreated liquid phase product is mixed with a raw material into a liquid phase material, and the liquid phase material enters the upper part of a reactor. The hydrotreating method of product circulation is characterized in that the upper part of the reactor is provided with at least one air-lift tray of which the lower part is introduced with hydrogen; the hydrogen and the liquid phase material contact on the air-lift tray for the air lift of hydrogen sulfide and ammonia in the liquid phase material; meanwhile, hydrogen is further dissolved in the liquid phase material; the air-lift liquid phase material enters a catalyst bed on the lower part of the reactor for hydrotreating reaction; and air-lift gas containing hydrogen sulfide and ammonia is discharged from the top of the reactor. The reactor adopted by the invention simultaneously has the action of catalytic hydrotreating reaction and the action on causing products H2S, NH3 and the like to be discharged out of a reaction system by air lift, thus greatly improving hydrotreating reaction efficiency and enhancing technology flexibility and raw material adaptability.

Owner:CHINA PETROLEUM & CHEM CORP +1

CO sulfur resistant transformation catalyst and its preparation method

InactiveCN1429763AHigh strengthImprove stabilityHydrogenBulk chemical productionWater vaporHigh activity

An isothermal S-resistant conversion catalyst used for the isothermal conversion process where CO reacts on water vapor to generate H2 and CO2 for preparing synthetic ammonia gas, H2, city gas and synthetic carbonyl gas is prepared from the composite carrier containing TiO2, MgO, Al2O3 and cement and non-alkali metal as promoter through improved kneading and dipping. Its advantages are high activity, high mechanical strength, adaptability to high space velocity, good resistance to hydration, and no environmental pollution.

Owner:QILU PETRO CHEM - SINOPEC

Liquefied gas hydrogenating, olefin content decreasing and desulfurizing catalyst and preparation method thereof

InactiveCN102500403AGood activity at low temperature and low pressureIncrease dispersionPhysical/chemical process catalystsHydrocarbon oils treatmentComposite oxideAmount of substance

The invention provides a liquefied gas hydrogenating, olefin content decreasing and desulfurizing catalyst and a preparation method thereof. The catalyst comprises a carrier and activated substances, the carrier adopts F-modified Al2O3-TiO2 composite oxides, activated substances comprise molybdenum, nickel and cobalt, the molybdenum is a main component, and the nickel and the cobalt are auxiliary components. The preparation method of the catalyst comprises a process for preparing a modified Al2O3-TiO2 compound oxide carrier and a process for preparing the liquefied gas hydrogenating, olefin content decreasing and desulfurizing catalyst by a co-impregnation method. The liquefied gas hydrogenating, olefin content decreasing and desulfurizing catalyst has the advantages of double functions of resisting to sulfur-poisoning and hydrogenating, olefin content decreasing and desulfurizing of a traditional molybdenum catalyst, simultaneously, low-temperature and low-pressure activity is good, deeply hydrogenating saturability is high, and activity is stable.

Owner:WUHAN KELIN FINE CHEM

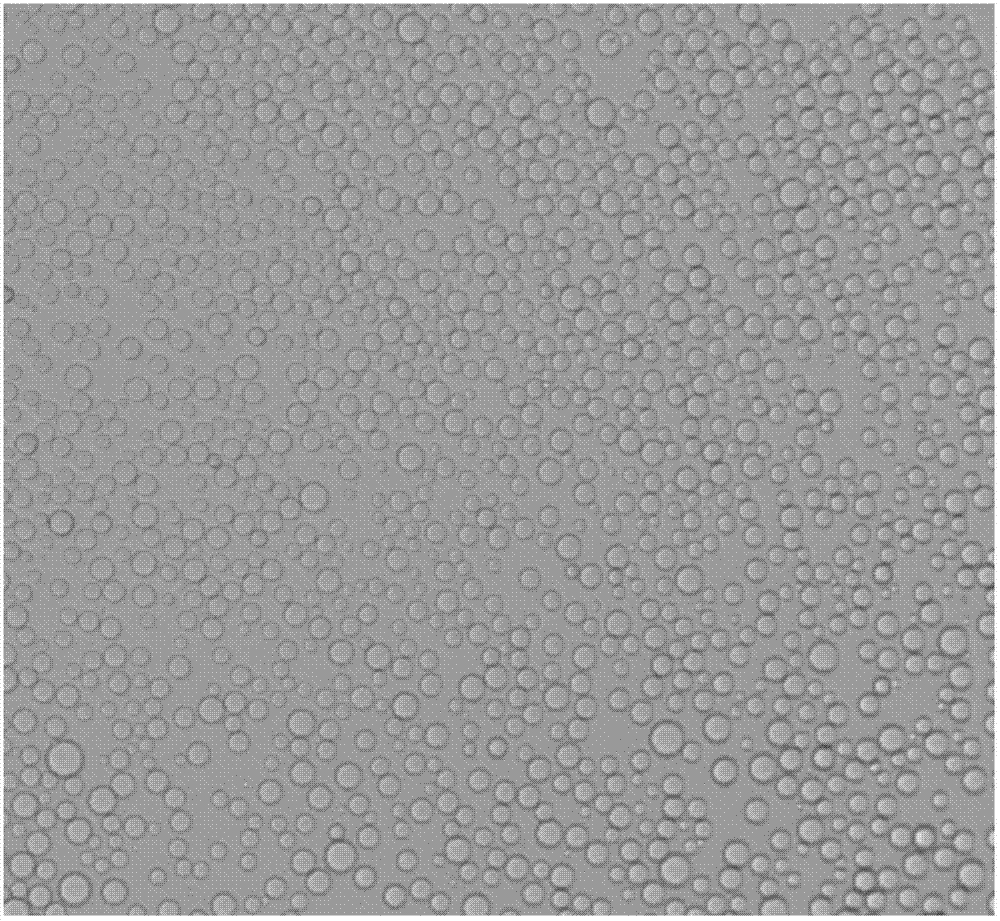

Uniform-sized konjak gulcomannan microspheres and preparation method thereof

ActiveCN103194008AHigh mechanical strengthEasy to separateEssential-oils/perfumesPharmaceutical non-active ingredientsMicrosphereParticle-size distribution

The invention relates to uniform-sized konjak gulcomannan microspheres. The average particle size of the microspheres is less than 10 mu m; the content of the konjak gulcomannan in the microspheres is greater than 20% (w / w); the particle size is uniform; and the particle size distribution coefficient Span value is less than 0.9. The invention further provides a preparation method of the microspheres. According to the invention, the problems that the konjak gulcomannan microspheres of which the particle size is less than 10 mu m are hard to prepare by using the conventional method and the prepared microspheres are not uniform in particle size are solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low-cost hydrogenation process method

InactiveCN101724444ALess excessMaintain active stabilityRefining to eliminate hetero atomsGas phaseHydrogenation process

The invention discloses a low-cost hydrogenation process method, which comprises the following steps of: mixing base oil with hydrogen; allowing the mixture to pass through a catalyst bed under the condition of a hydrogenation process; and mixing and recycling partial hydrotreating products without setting a hydrogen circulating system, wherein the using amount of the hydrogen is 1 to 10 times that of the hydrogen which is dissolved by a reaction system under the condition of adding a reaction condition based on the chemical hydrogen consumption during the reaction. The low-cost hydrogenation process method is a hydrogenation process of gas, liquid and solid phases with a low hydrogen-oil ratio; due to the low hydrogen-oil ratio, the hydrogen circulating system in the conventional hydrogenation process can be removed to greatly reduce the equipment investment and the operation cost; the reaction can be ensured to perform successfully by properly maintaining a little gas-phase hydrogen; and proper hydrotreating product circulation can ensure that the operation is stably performed for a long-time circle.

Owner:CHINA PETROLEUM & CHEM CORP +1

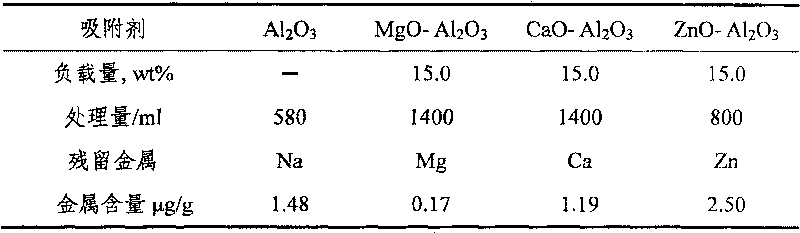

Solid base adsorption agent for treating processes of deacidification in use for liquid matter in esters of organic acid

InactiveCN101049550AImprove adsorption capacityMaintain active stabilityOrganic compound preparationOther chemical processesOrganic acidAlkaline earth metal

An alkaline solid adsorbent for deacidifying and refining the liquid esters of organic acid is prepared from the oxide and hydroxide of alkali-earth in IIA family and alumina through wetting, mixing, kneading, extruding to become strips, drying and high-temp calcining. It has high specific surface area, adsorptive volume and mechanical strength.

Owner:WEIFANG BAILI CHEM

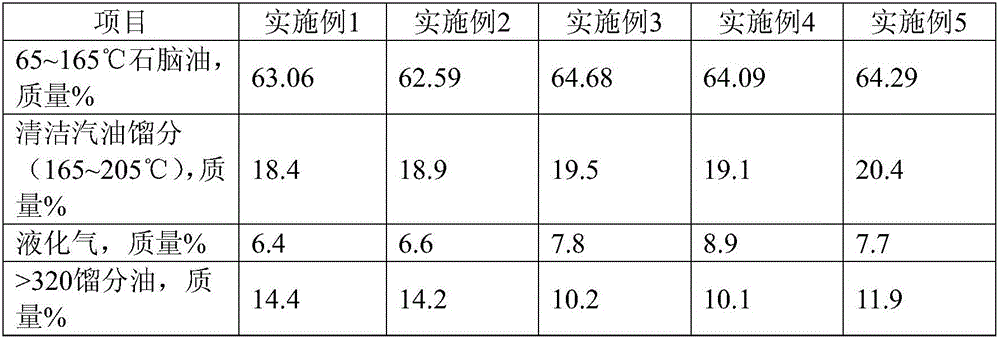

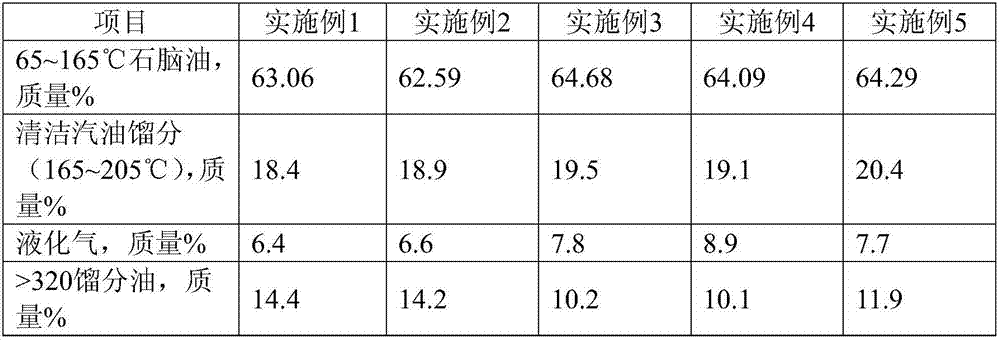

Method for producing naphtha and clean gasoline by catalytic cracking diesel oil

ActiveCN105694966AMeet the feed requirementsLight distillationTreatment with hydrotreatment processesHydrocarbon oils treatment productsCatalytic reformingNaphtha

The invention provides a method for producing naphtha and clean gasoline by catalytic cracking diesel oil. The method comprises the following steps of mixing the catalytic cracking diesel oil and hydrogen gas; enabling the mixture to enter the middle part of a reverse sequence filling hydrocracking reactor-hydrofining reactor to be mixed with cracking products from the hydrocracking reactor; enabling the mixture to enter the hydrofining reactor to perform a hydrofining reaction so as to remove impurities such as sulfur and nitrogen; performing an olefin saturated reaction and arene hydrogenation saturation; performing cutting processing on products after the hydrofining; using distillate oil below 165 DEG C as a naphtha product to be used as a raw material for a catalytic reforming unit; using distillate oil being 165 to 205 DEG C as a clean gasoline conditioning ingredient; returning distillate oil being 205 to 320 DEG C into the top of the reverse sequence filling hydrocracking reactor-hydrofining reactor; performing hydrocracking and hydrofining reactions; returning distillate oil being higher than 320 DEG C into a catalytic cracking device for further cracking, or enabling the distillate oil being higher than 320 DEG C to enter other hydrogenation devices for processing treatment. The method has the advantages that high yield of naphtha products is taken as the goal; the clean gasoline can be produced at the same time.

Owner:CHINA NAT OFFSHORE OIL CORP +3

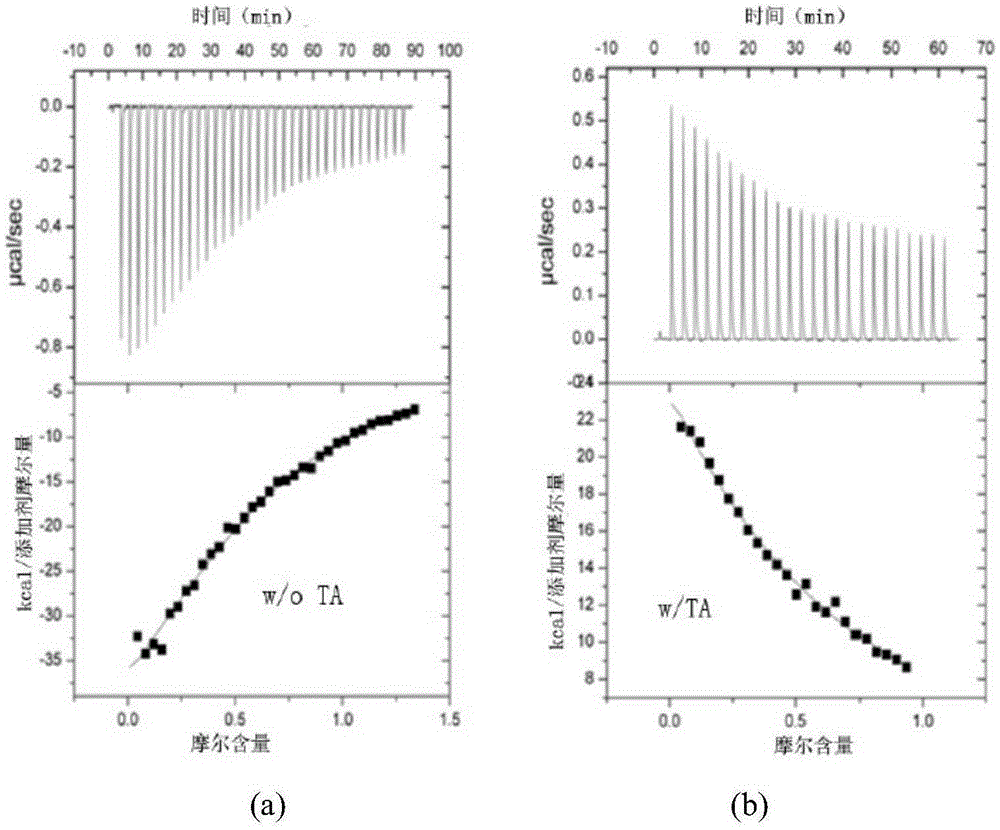

Application of triterpene compound and Parkinson's disease treatment medicine

ActiveCN106581006ANeuroprotectiveGood effectOrganic active ingredientsNervous disorderTormentic acidMedicine

The invention provides application of a triterpene compound and a Parkinson's disease treatment medicine. The application comprises blocking of mutual combination between autophagy skeleton protein Beclin1 and an autophagy inhibiting factor Bcl-2 so as to induce nerve cell autophagy, and preparation of a Parkinson's disease treatment medicine. The triterpene compound is any one or a mixture of two of maslinic acid and tormentic acid. The Parkinson's disease treatment medicine provided by the invention comprises a pharmaceutically acceptable auxiliary material as well as an effective dosage of any one or a mixture of two of the maslinic acid and the tormentic acid. The triterpene compounds, namely the maslinic acid and the tormentic acid, are capable of directly blocking mutual combination between the autophagy skeleton protein Beclin1 and the autophagy inhibiting factor Bcl-2, so that the triterpene compounds have the function of promoting autophagy in nerve cells, and have a nerve protection function on Parkinson's disease cells. Therefore, the maslinic acid and the tormentic acid can be directly adopted to prepare the Parkinson's disease treatment medicine, and the Parkinson's disease treatment medicine is endowed with good medicinal effect.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST +1

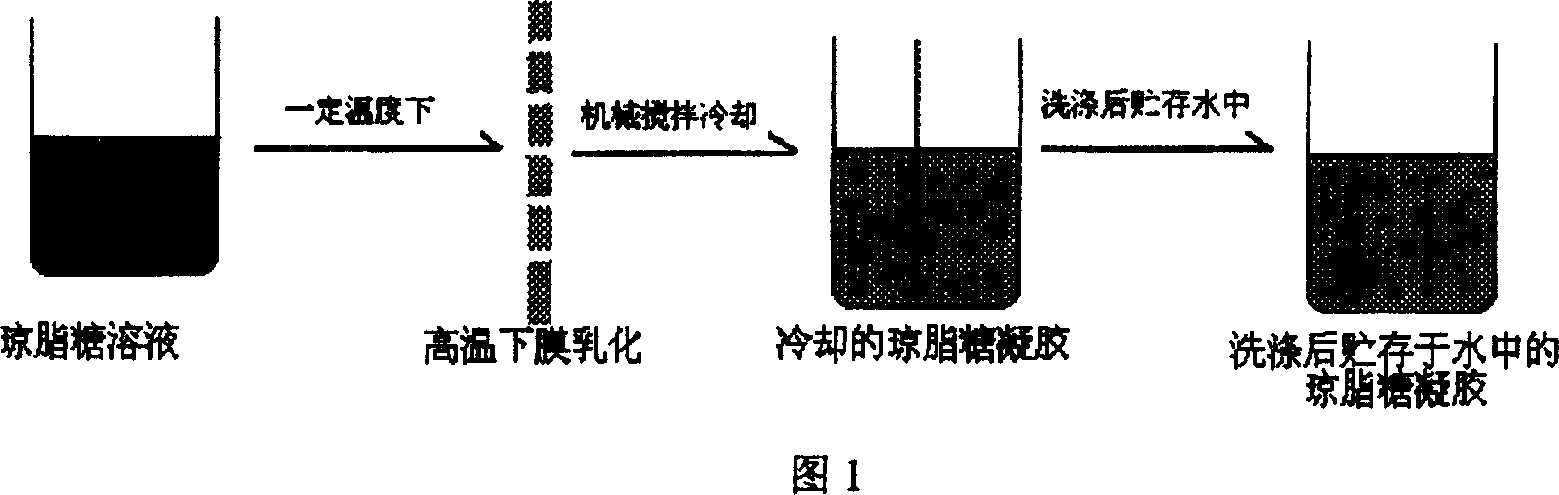

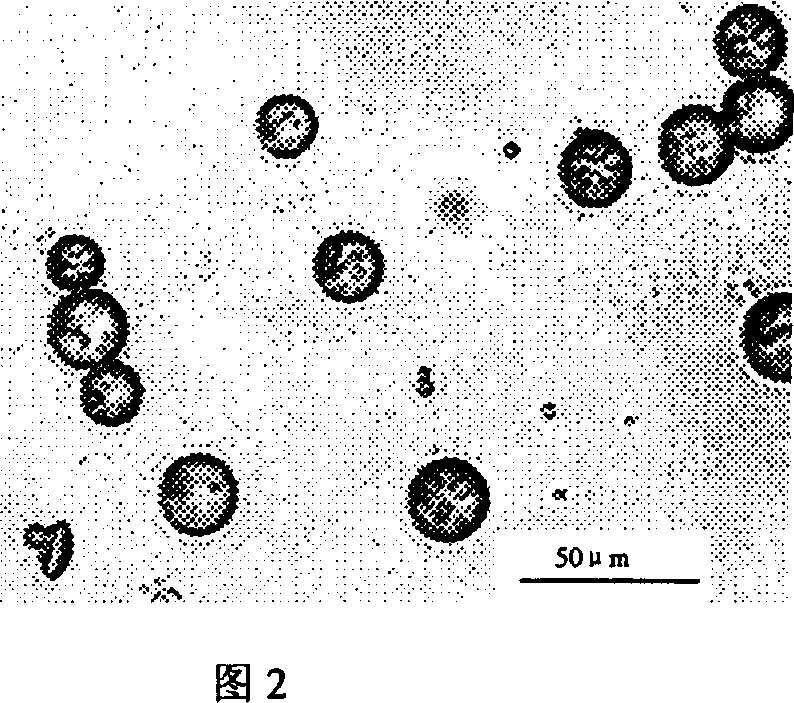

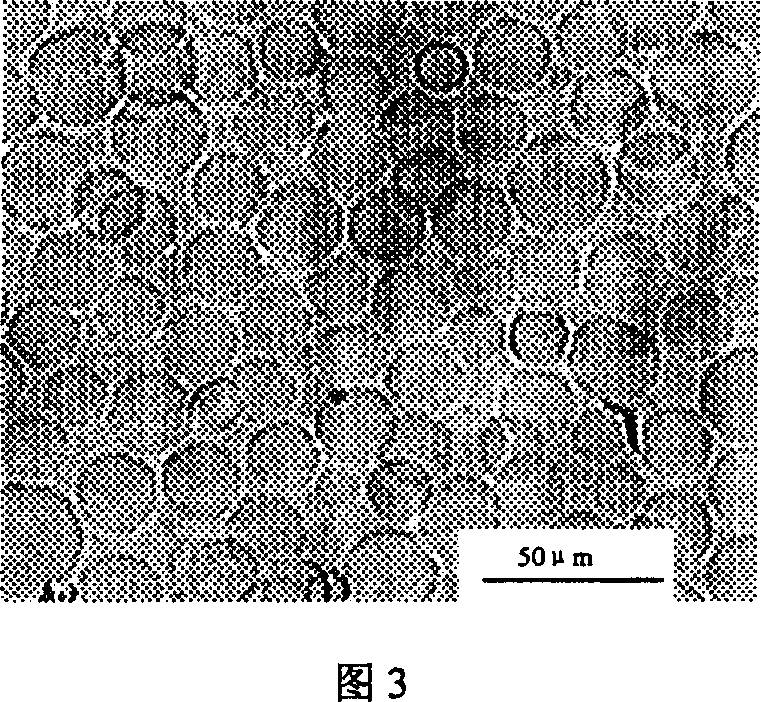

Size-uniform agarose gel microball and its preparing method

ActiveCN1304101CEasy to separateEvenly packedMicroballoon preparationMicrocapsule preparationMicrosphereOil phase

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

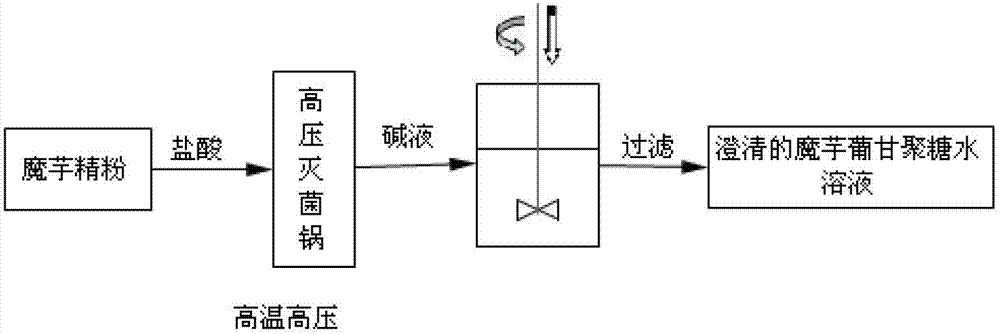

Preparation method of konjac glucomannan gel microspheres

ActiveCN106215819AMaintain active stabilityMaintain biological stabilityMicroballoon preparationMicrocapsule preparationMicrosphereOil phase

The invention discloses a preparation method of konjac glucomannan gel microspheres. The preparation method includes: (1), adding konjac glucomannan into a water solution containing certain alcohol, and stirring to obtain a dispersion; (2), adding the dispersion into an oil phase, adding an emulsifier and alkaline substance, and stirring to obtain an emulsion; (3), adding an acidic solution and glutaraldehyde into the emulsion, and stirring for reaction to obtain gel microspheres; (4), using cyclohexane, alcohol and purified water to wash the gel microspheres to be neutral, and lyophilizing to obtain the konjac glucomannan gel microspheres. By the method, the konjac glucomannan gel microspheres which are uniform in grain size can be prepared and have porous structure. The method can be used for preparing media used for biochemical fine separation and gel microspheres serving as a drug conveying carrier, is expected to be capable of maintaining bioactivity and biostability of drugs and can be used for essence adsorption and controlled-release carriers. Due to small grain size, the konjac glucomannan gel microspheres can be dispersed in media well and are free of settling after being placed for a long time.

Owner:SOUTHWEAT UNIV OF SCI & TECH

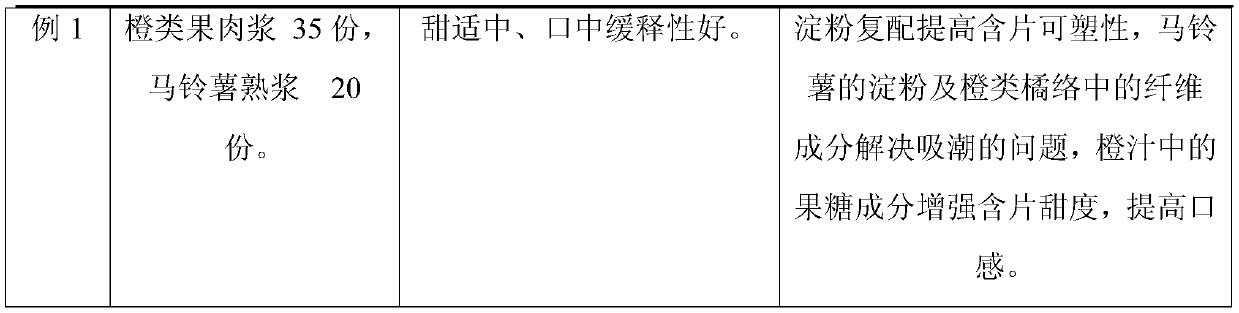

Catalyst for poor diesel hydrotreatment and preparation method

ActiveCN102284300BEvenly distributedLarge hole volumePhysical/chemical process catalystsRefining to eliminate hetero atomsMischmetalAlkaline earth metal

The invention relates to a catalyst for poor diesel hydrotreatment and a preparation method. In the catalyst, W-Mo-Ni-P is used as an active component; alkali metal, alkaline earth metal or rare-earth metal is used as an auxiliary; silicon-aluminum is used as a carrier; according to weight percentage, the alkali metal, alkaline earth metal or rare-earth metal accounts for 2 to 9 percent, WO3 accounts for 5 to 25 percent, MoO3 accounts for 8 to 20 percent, NiO accounts for 2 to 9 percent, P accounts for 1.0 to 5 percent, and the balance is the silicon-aluminum oxide carrier. The catalyst is used for evaluating mixed oil with raw material oils of catalytic cracking diesel and coked diesel, performs excellent reaction activity and stability in condition and stability tests, and can remove more than 90 percent of sulfur and nitrogen in the poor mixed diesel.

Owner:PETROCHINA CO LTD

Hydrocracking method for increasing production of high-quality middle distillates

ActiveCN102807898AHigh selectivityAvoid secondary crackingTreatment with hydrotreatment processesNaphthaChemistry

The invention relates to a hydrocracking method for increasing production of high-quality middle distillates. The method comprises the following steps that: fresh feedstock oils are simultaneously introduced into a hydrofining reactor and a hydrocracking reactor in a co-current flow way; the hydrofining reactor is sequentially filled with a hydrofining catalyst and an amorphous hydrocracking catalyst; the hydrocracking reactor is sequentially filled with a hydrofining catalyst and a zeolite hydrocracking catalyst; a reaction effluent from the hydrofining reactor is separated to obtain light naphtha fractions and tail oil fractions; and all or part of the tail oil fractions are introduced into the hydrocracking reactor, and a reaction effluent from the hydrocracking reactor and part of the feedstock oils are introduced into the hydrofining reactor together. According to the method provided by the invention, the heavy distillates can be treated, and the maximum production of the middle distillates can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

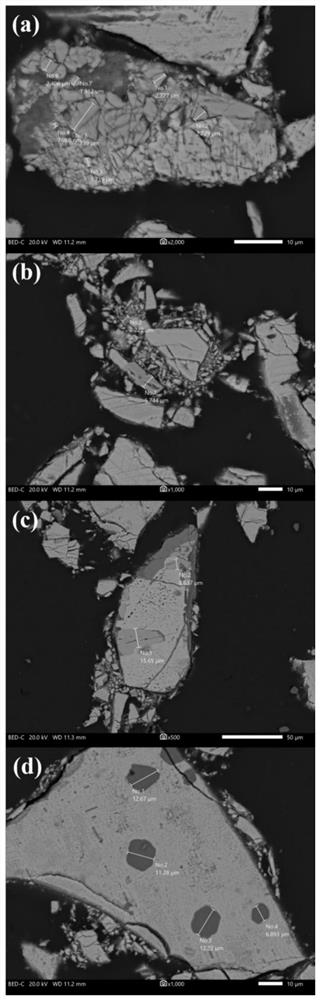

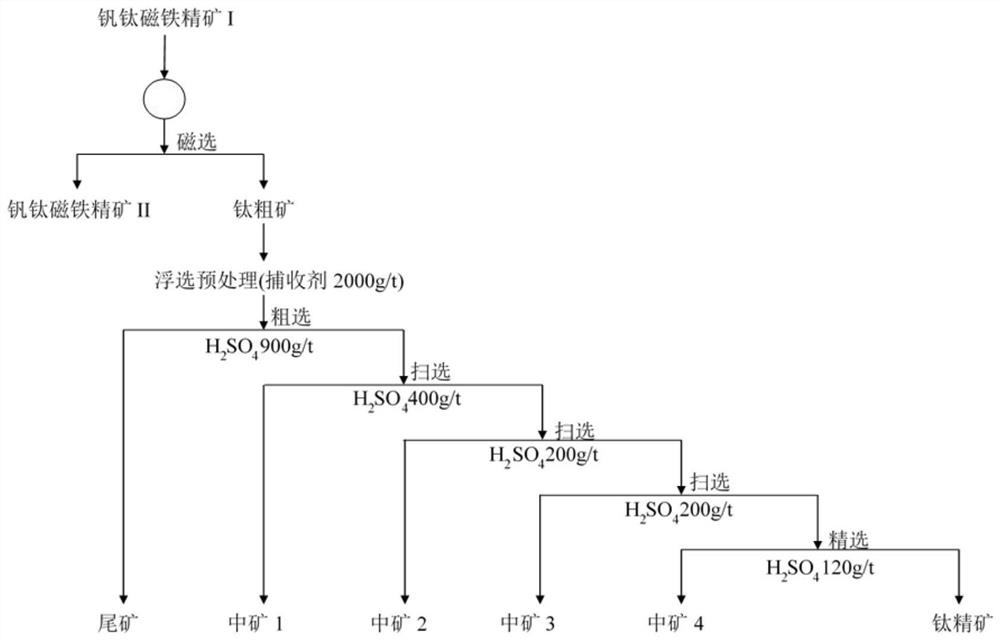

Beneficiation method of vanadium-titanium magnetite concentrate

ActiveCN113560030AAchieve dissociationSolve the difficult problem of substantive sortingProcess efficiency improvementGrain treatmentsMagnetiteTitanium

The invention belongs to the field of mineral separation, and particularly relates to a beneficiation method of vanadium-titanium magnetite concentrate. The beneficiation method comprises the following steps: (1) mixing vanadium-titanium magnetite concentrate I and an aqueous solution dissolved with a dispersing agent to prepare ore pulp; (2) carrying out wet ball milling treatment on the ore pulp, and controlling the proportion of fine ore with the granularity being minus 15 microns after ball milling to be 95% or above; and (3) carrying out magnetic separation on the ground fine ore to obtain iron-rich vanadium-titanium magnetite concentrate II and titanium-rich coarse titanium ore after separation. The magnetic field intensity in the magnetic separation process is 0.1-1.3 T. In addition, the invention further relates to a method for carrying out pretreatment-flotation on the obtained coarse titanium ore, and through combined control over the ore grinding process and conditions, efficient separation of iron and titanium can be achieved based on an ore grinding mechanism.

Owner:CENT SOUTH UNIV

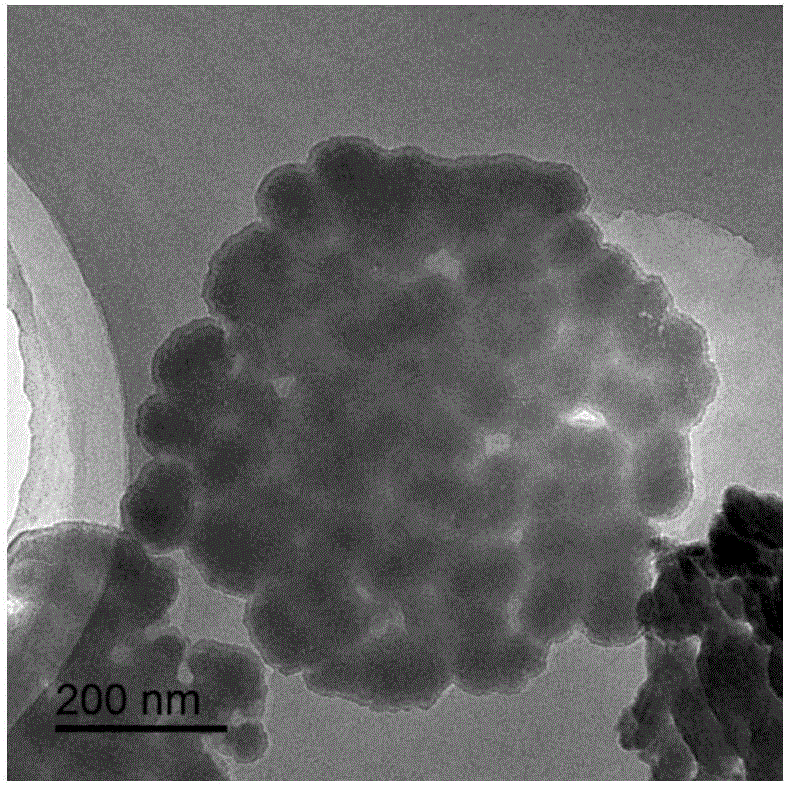

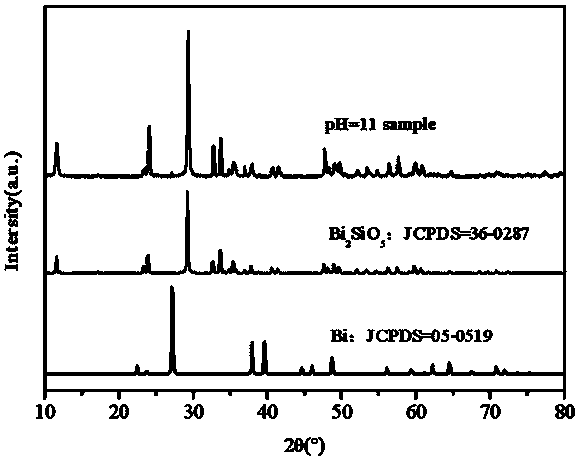

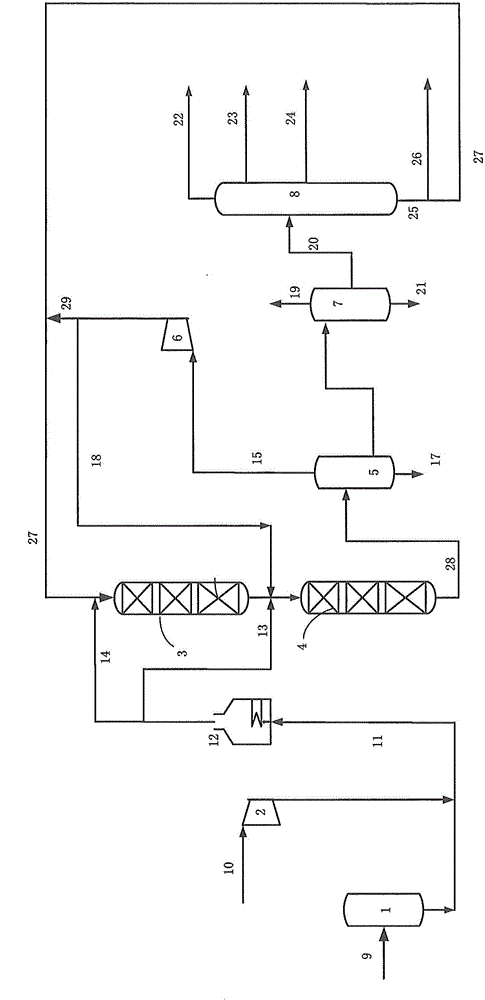

Preparation method and application of Bi/Bi2SiO5 photocatalyst

ActiveCN110586067AThe preparation method is simple and controllableImprove abilitiesCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsSolventIon

The invention relates to a preparation method and application of a Bi / Bi2SiO5 photocatalyst, belongs to the fields of controllable preparation of a Bi / Bi-based photocatalytic material composite system, CO2 reduction resource conversion and utilization and artificial photosynthesis, and solves the problems of narrow light response range of Bi2SiO5, high photoelectron-hole combination rate and the like. In the preparation method, Bi(NO3)3.5H2O and Na2SiO3.9H2O are respectively taken as a bismuth source and a silicon source, ethylene glycol and deionized water are taken as solvents, a NaOH solution is taken as a pH value regulator, a one-step hydrothermal method is utilized, the pH value of a reaction solution is adjusted to be 9-14 by regulating the concentration of the NaOH solution, and the high-purity Bi / Bi2SiO5 photocatalyst can be obtained. Finally, activity, selectivity and stability of Bi2SiO5 for photocatalytic reduction of CO2 are improved, and a new method and a new applicationare provided for preparation of a high-efficiency novel elemental Bi / Bi-based photocatalytic material composite system.

Owner:TAIYUAN UNIV OF TECH

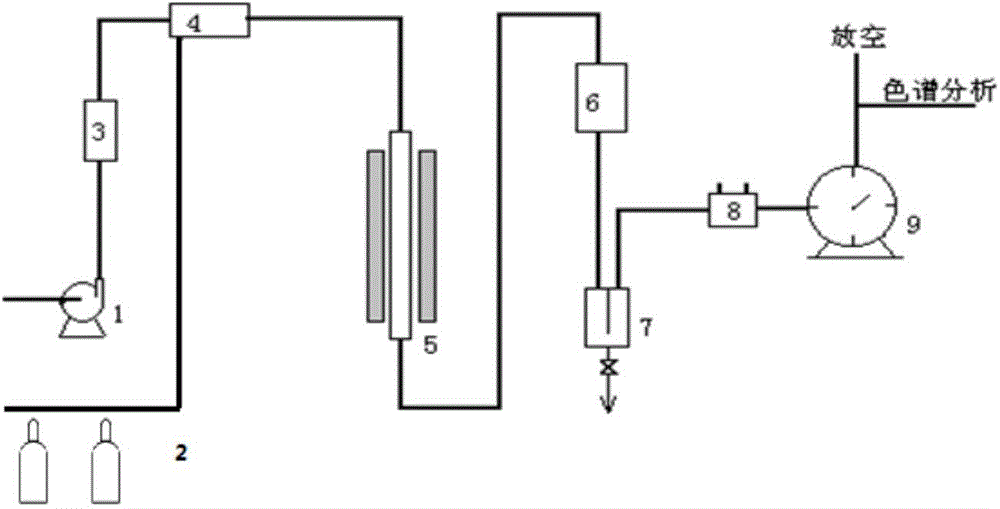

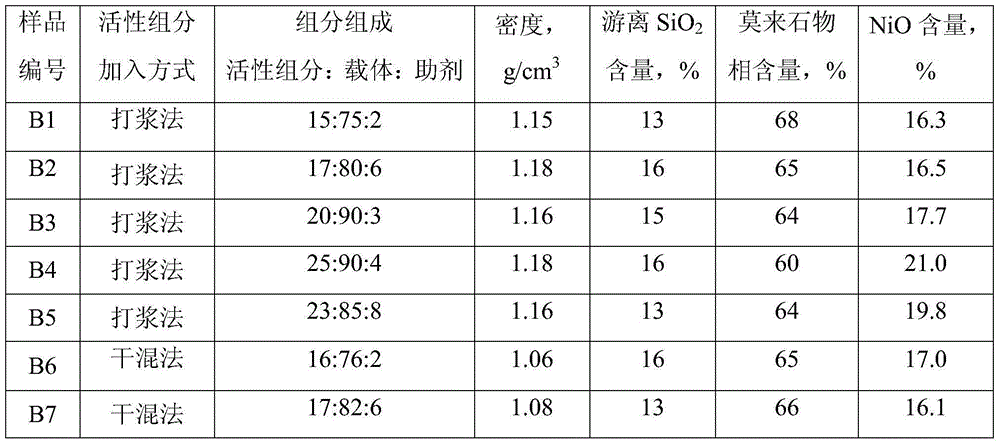

Gaseous hydrocarbon self-heating conversion catalyst and preparation method thereof

ActiveCN104549284AIncrease active metal dispersionGuaranteed catalyst activityMetal/metal-oxides/metal-hydroxide catalystsHydrogen productionOxide

The invention belongs to the technical field of gaseous hydrocarbon conversion catalysts, and relates to a catalyst for the field of synthesis gas produced by gaseous hydrocarbon self-heating conversion or hydrogen production and a preparation method of the catalyst. According to the catalyst disclosed by the invention, nickel is used as an active component; SiO2 at free state and 3Al2O3*2SiO2 of a mullite structure are used as carriers; MgO and / or a rare earth metal oxide are used as auxiliaries. The preparation method comprises the following steps: adopting a pulping method or a dry mixing method to prepare a semi-finished product, and then molding and baking the semi-finished product to obtain the finished product catalyst. The catalyst is high in anti-carbon deposition performance, good in strength and strength stability, and good in reactive metal dispersion effect, effectively avoids the reactive metal crystal grain aggregation in the using process, ensures the activity stability of the catalyst, and facilitates large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

Method for producing industrial grade white oil

ActiveCN1318549CMaintain active stabilityReduce viscosity dropTreatment with hydrotreatment processesChemistryNickel

The industrial white oil producing process includes the following steps: 1. catalytically dewaxing hydrocracked tail oil as material oil under the action of shape selecting catalyst; 2. fractioning in fractionating tower and leading out side oils of different viscosities from different side lines; and 3. feeding side oils to corresponding fixed bed reactors with hydrorefining reducing nickel metal catalyst to produce industrial white oils in corresponding grades via one section of hydrorefining. The present invention has reduced reaction temperature, reduced viscosity lowering of the hydrorefined material, capacity of reaching the saturated aromatic hydrocarbon level, flexible operation and high market adaptability.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A kind of small particle size konjac glucomannan microspheres with uniform size and preparation method thereof

ActiveCN103194008BHigh mechanical strengthEasy to separateEssential-oils/perfumesPharmaceutical non-active ingredientsMicrosphereParticle-size distribution

The invention relates to uniform-sized konjak gulcomannan microspheres. The average particle size of the microspheres is less than 10 mu m; the content of the konjak gulcomannan in the microspheres is greater than 20% (w / w); the particle size is uniform; and the particle size distribution coefficient Span value is less than 0.9. The invention further provides a preparation method of the microspheres. According to the invention, the problems that the konjak gulcomannan microspheres of which the particle size is less than 10 mu m are hard to prepare by using the conventional method and the prepared microspheres are not uniform in particle size are solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Hydrocracking method for increasing production of high-quality middle distillates

ActiveCN102807898BHigh selectivityAvoid secondary crackingTreatment with hydrotreatment processesNaphthaChemistry

The invention relates to a hydrocracking method for increasing production of high-quality middle distillates. The method comprises the following steps that: fresh feedstock oils are simultaneously introduced into a hydrofining reactor and a hydrocracking reactor in a co-current flow way; the hydrofining reactor is sequentially filled with a hydrofining catalyst and an amorphous hydrocracking catalyst; the hydrocracking reactor is sequentially filled with a hydrofining catalyst and a zeolite hydrocracking catalyst; a reaction effluent from the hydrofining reactor is separated to obtain light naphtha fractions and tail oil fractions; and all or part of the tail oil fractions are introduced into the hydrocracking reactor, and a reaction effluent from the hydrocracking reactor and part of the feedstock oils are introduced into the hydrofining reactor together. According to the method provided by the invention, the heavy distillates can be treated, and the maximum production of the middle distillates can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

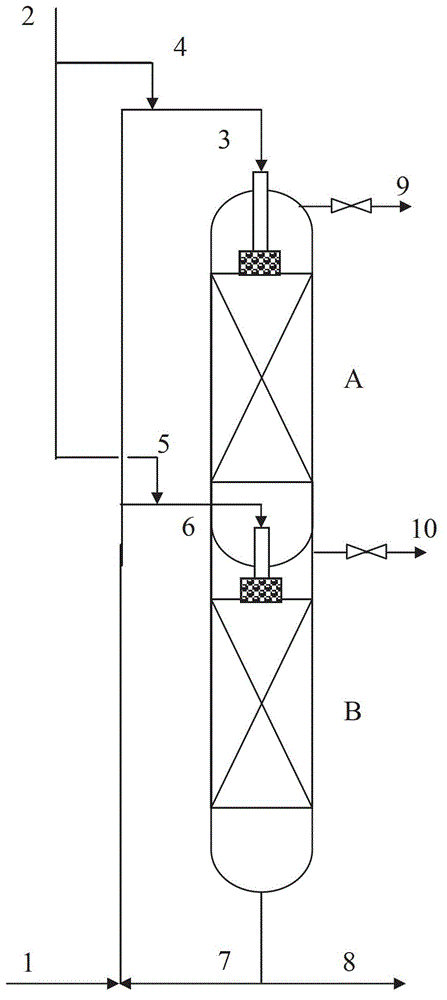

Method for producing clean fuel by hydroprocessing

ActiveCN101724445AReduce loadMaintain active stabilityRefining to eliminate hetero atomsSingle stageHydrogenation reaction

The invention discloses a method for hydroprocessing a static bed. The method is characterized in that raw material oil is mixed with hydrogen to pass through a hydroprocessing region with a catalyst bed layer under hydroprocessing technique condition, wherein the hydroprocessing region comprises a single-stage or multi-stage internal cross-flow reactor, and a part of hydrogenation products are mixed with the raw material oil for recycling. By using the method, the volume of hydrogen oil is smaller, thereby the apparatus investment and operating cost are greatly reduced; the used internal cross-flow reactor simultaneously has functions of catalyzing the hydrogenation reaction and extracting gases of reaction by-products such as H2S, NH3 and the like from a reaction system, thereby greatlyimproving the efficiency of the hydrogenation reaction. The invention not only can be used for distillate of gas, coal, diesel fuel and the like for hydrodesulphurization, hydrodenitrogenation and hydrodearomatization to refine, but also for distillate such as VGO raw material moderating the hydrocracking to produce clean fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

a bi/bi 2 sio 5 Preparation method and application of photocatalyst

ActiveCN110586067BThe preparation method is simple and controllableImprove abilitiesCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsSolventArtificial photosynthesis

Owner:TAIYUAN UNIV OF TECH

Preparation method of multi-element transition metal composite environment restoration material

PendingCN114538594AEfficient degradationMaintain active stabilityWater treatment compoundsWater contaminantsSilicic acidFiltration

The invention discloses a preparation method of a multi-element transition metal composite environment restoration material, which comprises the following steps: stirring CuSO4. 5H2O and FeCl3. 6H2O according to a ratio to completely dissolve CuSO4. 5H2O and FeCl3. 6H2O in deionized water; dropwise adding a NaOH solution and a Na2CO3 solution to carry out coprecipitation reaction, keeping the temperature at 60 DEG C for 4 hours, and then carrying out suction filtration, washing and vacuum drying to obtain a blue gray solid; putting the blue gray solid into a muffle furnace for calcining to obtain CuFe2O4 nanoparticles, adding the CuFe2O4 nanoparticles into a mixed solution of water, ethanol, cetyltrimethylammonium bromide and tetraethyl silicate, dropwise adding ammonia water, further stirring a reaction mixture, and then filtering, washing and vacuum drying; the CuFe2O4 / SiO2 composite environmental remediation material prepared by the preparation method disclosed by the invention can efficiently degrade various organic pollutants in water in a relatively wide pH range, can be applied to various water treatment processes and water environmental remediation engineering practices in various modes, and is high in activity stability of repeated use.

Owner:SHANGHAI INST OF TECH

A method for producing naphtha and clean gasoline from catalytic cracking diesel oil

ActiveCN105694966BMeet the feed requirementsLight distillationTreatment with hydrotreatment processesHydrocarbon oils treatment productsCatalytic reformingNaphtha

The invention provides a method for producing naphtha and clean gasoline by catalytic cracking diesel oil. The method comprises the following steps of mixing the catalytic cracking diesel oil and hydrogen gas; enabling the mixture to enter the middle part of a reverse sequence filling hydrocracking reactor-hydrofining reactor to be mixed with cracking products from the hydrocracking reactor; enabling the mixture to enter the hydrofining reactor to perform a hydrofining reaction so as to remove impurities such as sulfur and nitrogen; performing an olefin saturated reaction and arene hydrogenation saturation; performing cutting processing on products after the hydrofining; using distillate oil below 165 DEG C as a naphtha product to be used as a raw material for a catalytic reforming unit; using distillate oil being 165 to 205 DEG C as a clean gasoline conditioning ingredient; returning distillate oil being 205 to 320 DEG C into the top of the reverse sequence filling hydrocracking reactor-hydrofining reactor; performing hydrocracking and hydrofining reactions; returning distillate oil being higher than 320 DEG C into a catalytic cracking device for further cracking, or enabling the distillate oil being higher than 320 DEG C to enter other hydrogenation devices for processing treatment. The method has the advantages that high yield of naphtha products is taken as the goal; the clean gasoline can be produced at the same time.

Owner:CHINA NAT OFFSHORE OIL CORP +3

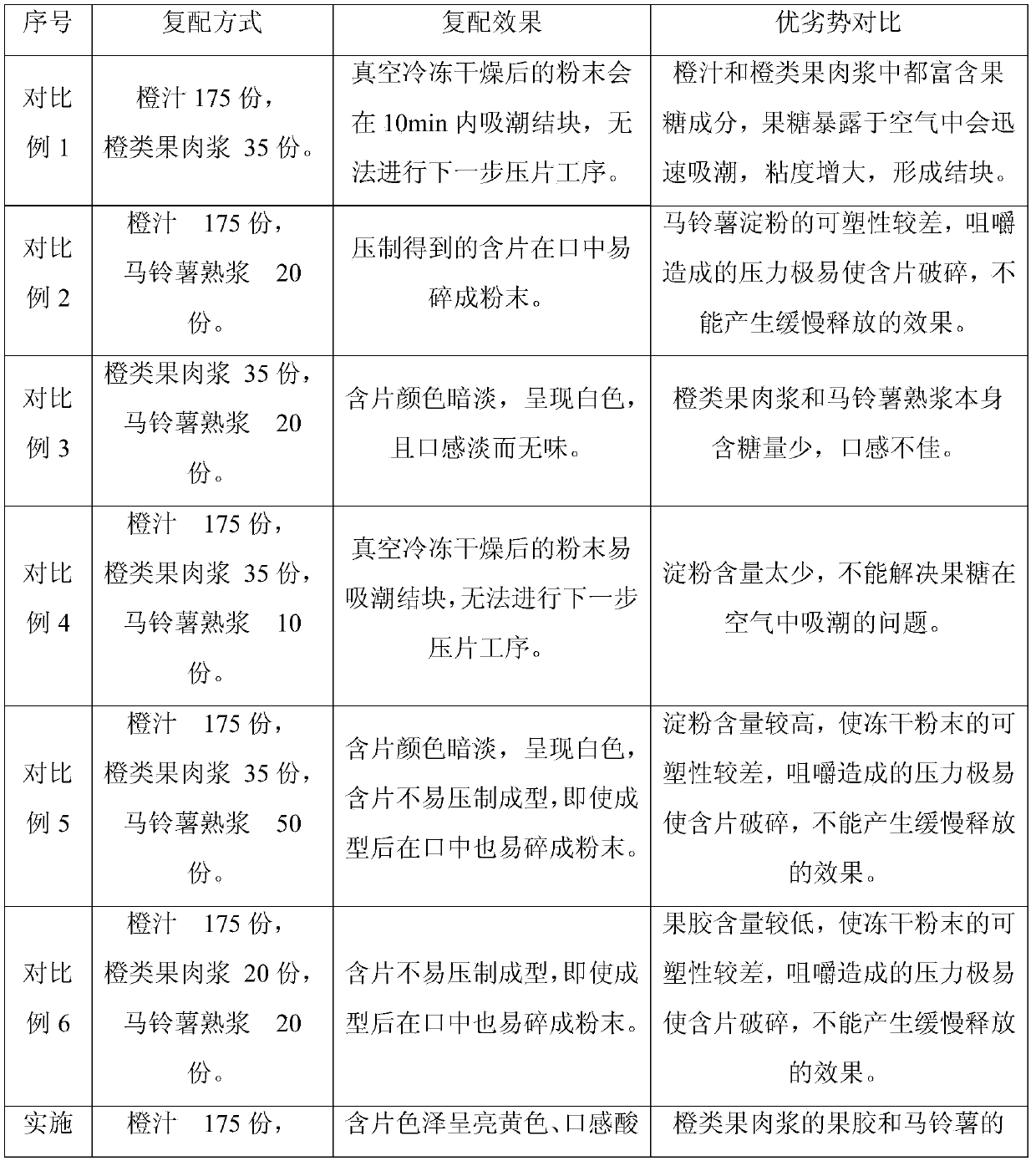

Zero-additive composite nutritional fruit and vegetable lozenge and preparation method thereof

PendingCN111513272AEliminate peeling processNutrient rich and completeFruits/vegetable preservation by irradiation/electric treatmentFood ingredient as colourOrange juiceChemistry

The invention discloses a zero-additive composite nutritional fruit and vegetable lozenge and a preparation method thereof. The zero-additive composite nutritional fruit and vegetable lozenge comprises the following raw material components in parts by mass: 175-240 parts of orange juice, 35-40 parts of orange pulp and 20-30 parts of cooked potato pulp. The preparation method comprises the following steps: mixing the orange juice, the orange pulp and the cooked potato pulp, carrying out micronizing, vacuum freeze drying, crushing, and tabletting to obtain the product. The zero-additive composite nutritional fruit and vegetable lozenge does not contain any sweetening agent, excipient, preservative, pigment, essence and other food additives. The pure natural compound fruit and vegetable lozenge which is sweet, sour, palatable and delicate in taste is prepared by utilizing the complementarity and color similarity of the raw materials, and the lozenge has the characteristics of nutrition, health care and wide range of people suitable for eating.

Owner:HUNAN AGRI PRODS PROCESSING INST

A deoxidizing and desulfurizing double-functional fine desulfurizer and its preparation method

ActiveCN104624197BAvoid generatingSolubility product is smallGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsManganeseAntimony

The invention discloses a deoxygenating and desulfurization double-function fine desulfurization agent and a preparation method thereof. The structure of the fine desulfurization agent is aAxOy.bGO.mDxOy.nMO3, wherein A is iron or manganese; G is calcium or magnesium; D is one of copper, zinc, antimony, lead and silver; and M is molybdenum or tungsten. The deoxygenating and desulfurization double-function fine desulfurization agent comprises the following components according to the total mass of the catalyst: 40%-65% of AxOy, 25%-40% of GO, 5%-10% of DxOy and 5%-10% of MO3. The catalyst can be used for purifying coke oven gas and raw gas for producing methanol by converter gas, and has the advantages of good deoxygenating and desulfurization activity, no byproducts including mercaptan and the like, stable activity and the like.

Owner:WUHAN KELIN FINE CHEM

Solid base adsorption agent for treating processes of deacidification in use for liquid matter in esters of organic acid

InactiveCN101049550BImprove adsorption capacityMaintain active stabilityOther chemical processesOrganic compound preparationOrganic acidAlkaline earth metal

An alkaline solid adsorbent for deacidifying and refining the liquid esters of organic acid is prepared from the oxide and hydroxide of alkali-earth in IIA family and alumina through wetting, mixing,kneading, extruding to become strips, drying and high-temp calcining. It has high specific surface area, adsorptive volume and mechanical strength.

Owner:WEIFANG BAILI CHEM

Hydrogels and Protein Drugs

ActiveCN109627463ANo biological toxicityMaintain active stabilityPeptide/protein ingredientsAerosol deliverySide effectIn vivo

The invention provides a hydrogel and a protein drugs. The hydrogel comprises the following raw materials in parts by weight: 1 to 50 parts of chitosan, 0.1 to 20 parts of a crosslinking agent and 10to 100 parts of water; the crosslinking agent is prepared by combining a non-degradable raw material A and a degradable raw material B to form a block copolymer, and connecting a raw material C at thetail end of the block copolymer. The hydrogel is injectable, coatable and degradable in vivo, can well maintain the biological activity of the drug protein, and has no toxic or side effect on the hydrogel and degradation products thereof. The protein drug adopts the hydrogel to carry and disperse the drug protein, so that the biological activity and the functional stability of the drug protein can be well maintained.

Owner:深圳普洛美康材料有限公司

Method for producing propylene from methanol or dimethyl ether

ActiveCN101811923BAvoid Burnout SituationsRealize continuous regenerationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The invention relates to a method for producing propylene from methanol or dimethyl ether, and mainly solves the problems that a catalyst is easily inactivated due to short reaction residence time and the reaction conditions are frequently fluctuated and the operation is unstable caused by frequent switch and reproduction in the prior art. The method for producing the propylene from the methanol or the dimethyl ether comprises the following steps of: a) making oxygen-containing compounds and a diluent enter a fluid bed reactor from the bottom; b) performing contact reaction on the raw materials and a ZSM-5 molecular sieve catalyst at the temperature of between 400 and 550 DEG C under the pressure of between 0.02 and 0.5 MPa; c) separating gas-phase material flow out of the top of the fluid bed reactor to obtain the propylene; d) extracting the reaction heat by using a heat exchanger; e) controlling the inactivated catalyst with a sliding valve and feeding the catalyst into a regenerator through a catalyst spending inclined tube, reacting the inactivated catalyst with air at the temperature of between 480 and 700 DEG C to burn off carbon deposit, and exhausting waste gas; and f) controlling the regenerated catalyst by using the sliding valve and feeding the regenerated catalyst to the upper part of the fluid bed reactor for circulation through a catalyst regenerating inclined tube. The technical scheme of the invention better solves the problems, and can be applied to the industrial production of the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inferior gasoline hydrotreating catalyst and preparation method and application thereof

ActiveCN102872891BMaintain active stabilityHydrodesulfurization is goodPhysical/chemical process catalystsRefining to eliminate hetero atomsLithiumActive component

The invention relates to an inferior gasoline hydrotreating catalyst and a preparation method and application thereof. The catalyst comprises the following active components in percentage by mass: 19 to 22 percent of WO3, 4 to 5 percent of NiO, 2 to 3 percent of P (on the basis of the mass of P2O5), 10 to 13 percent of MoO3, 1 to 2 percent of lithium or lanthanum (on the basis of oxides) and the balance of silicon-aluminum carrier. According to the preparation method, catalytic gasoline of which the mixed volume ratio is 3:1 and coker gasoline are hydrotreated under the action of the catalyst to remove sulfur and nitrogen, wherein the sulfur content of the mixed gasoline is 2,854 ug.g<-1>, the nitrogen content is 760 ug.g<-1>, the removal rate of the sulfur and the nitrogen is over 95 mass percent, and the content of the sulfur and the nitrogen in treated products is less than 50 ug.g<-1>.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com