Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Evenly packed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

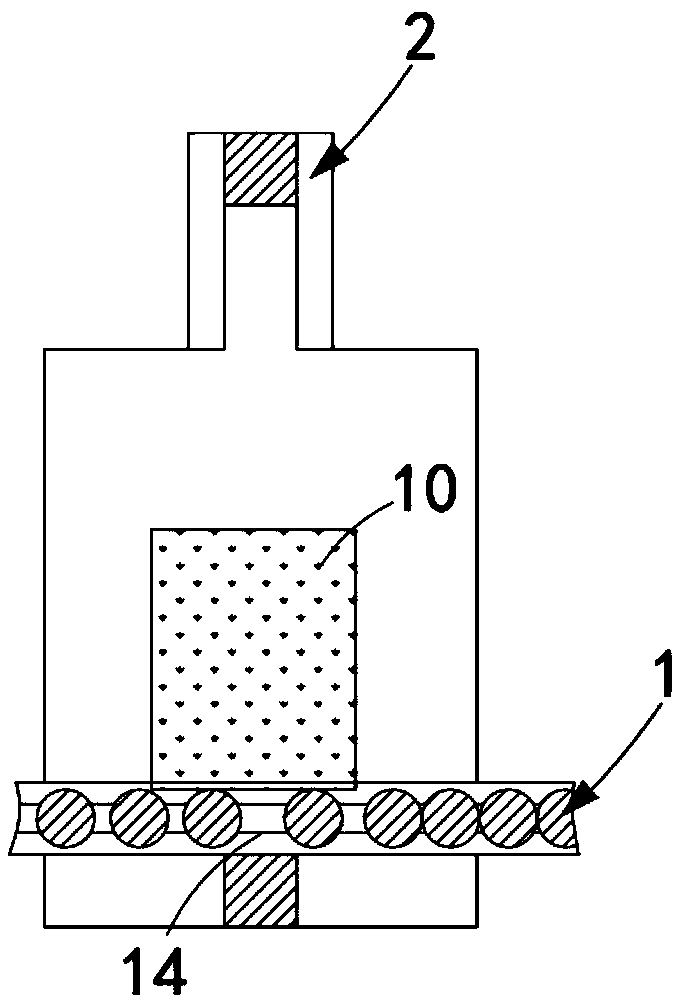

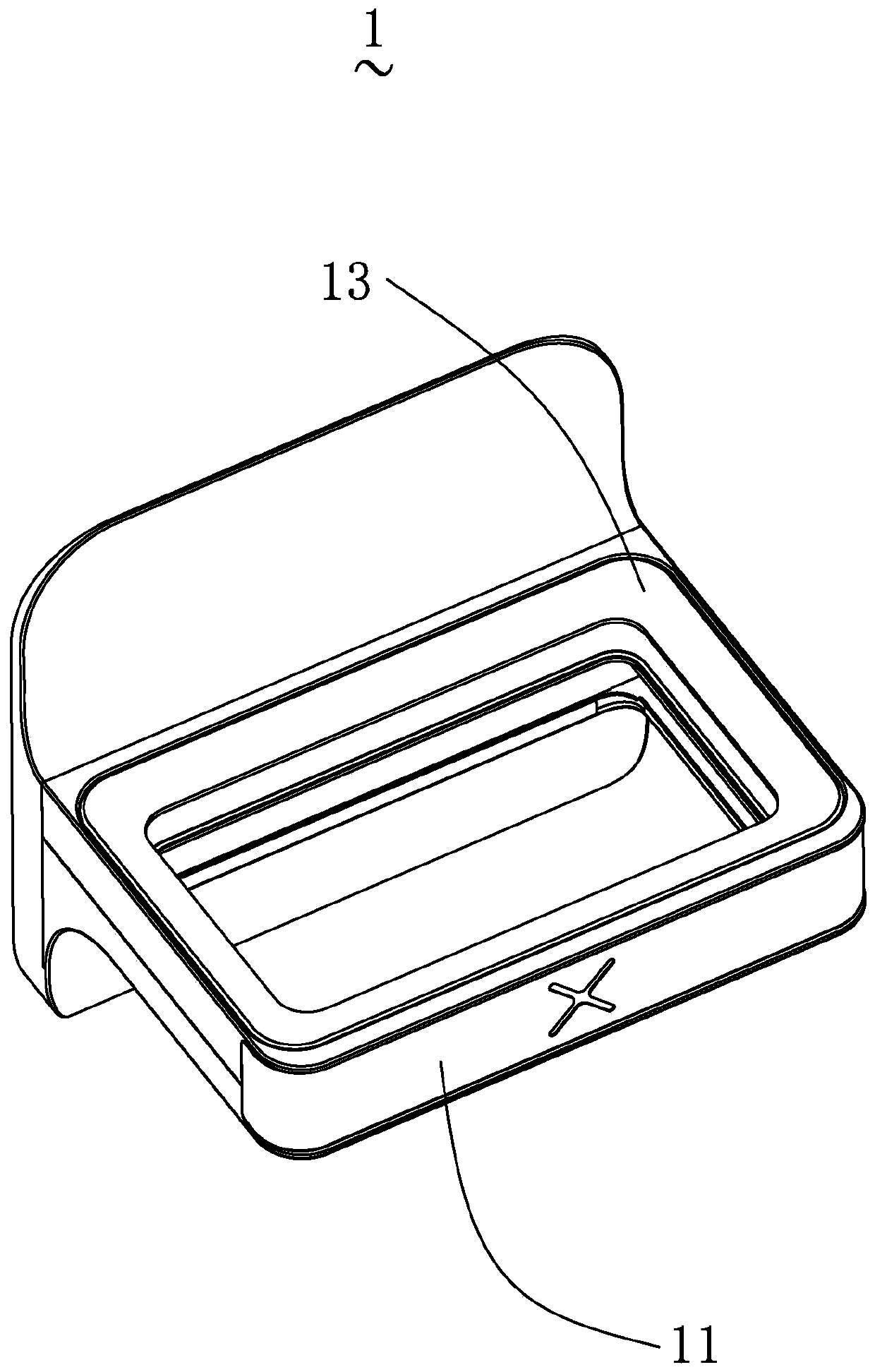

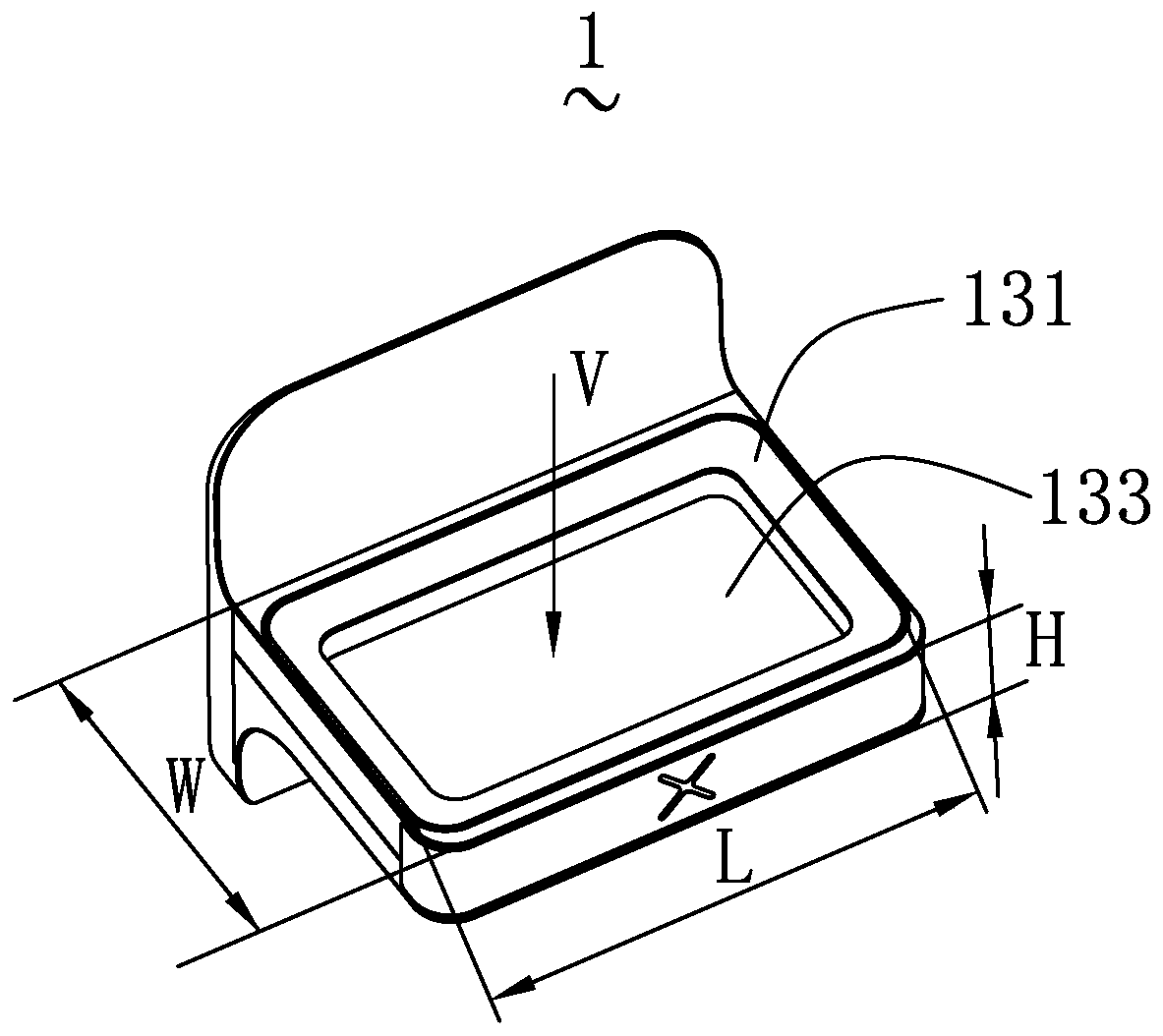

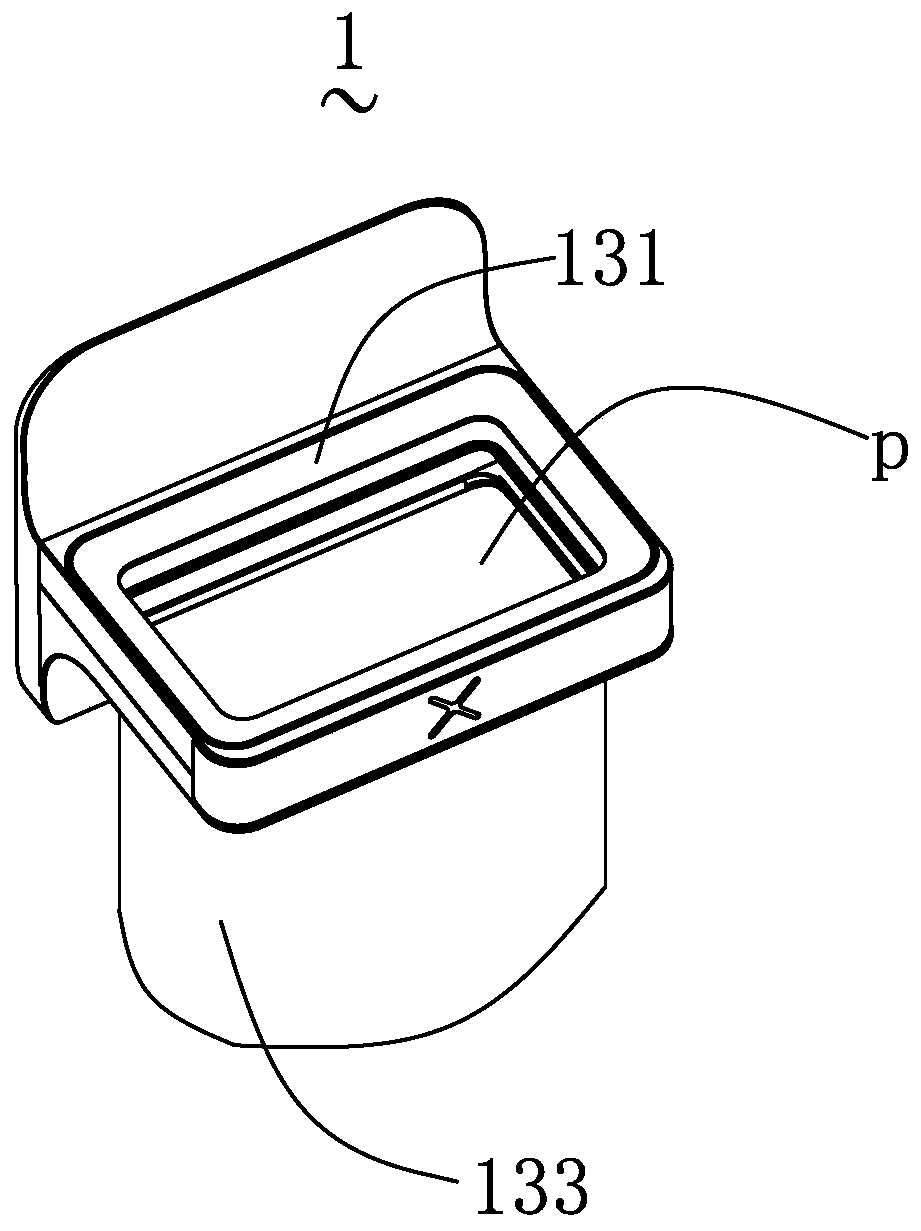

Lithium ion rechargeable cell

InactiveUS20100227216A1Small sizeReduce capacityCell seperators/membranes/diaphragms/spacersFinal product manufactureLithiumRechargeable cell

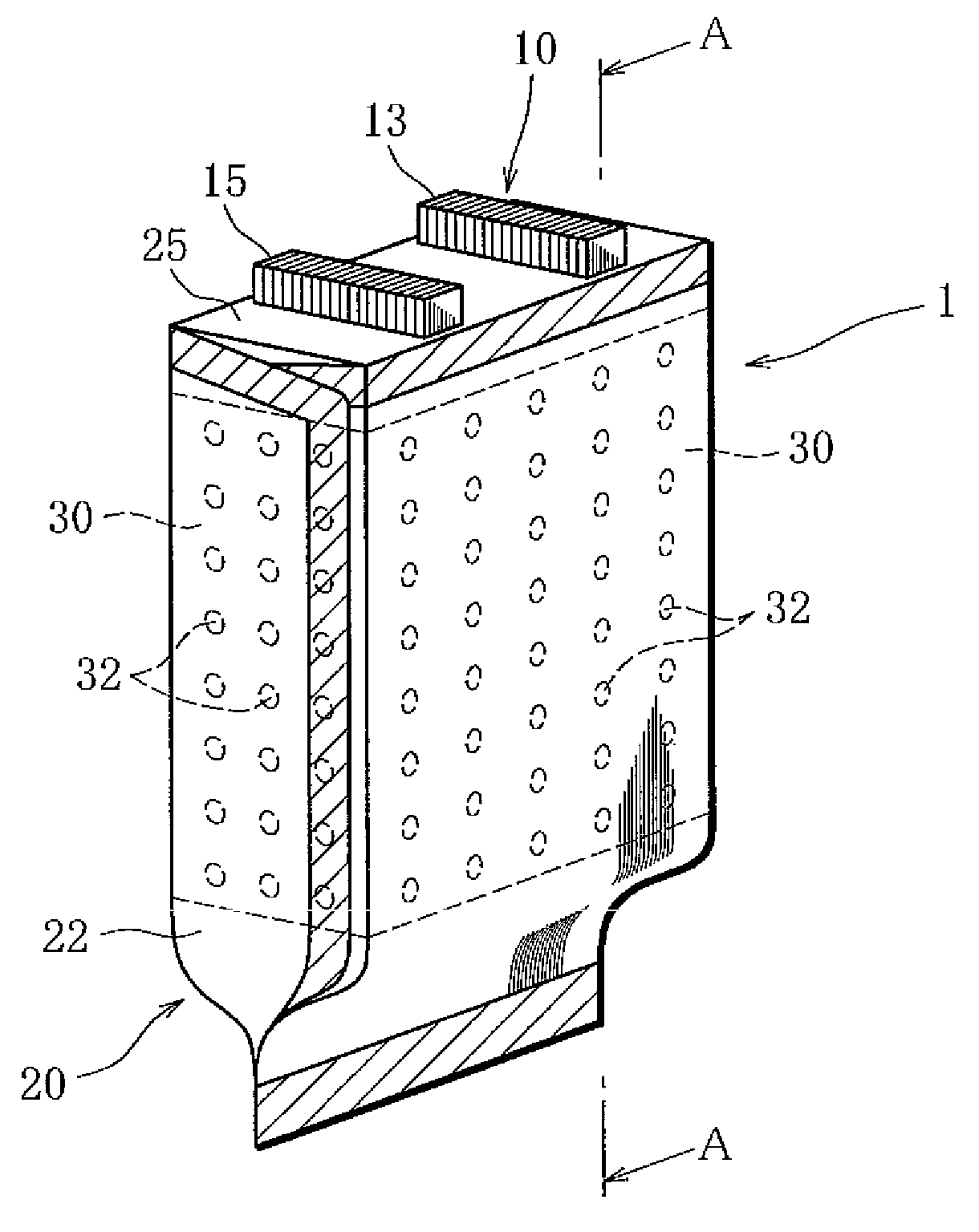

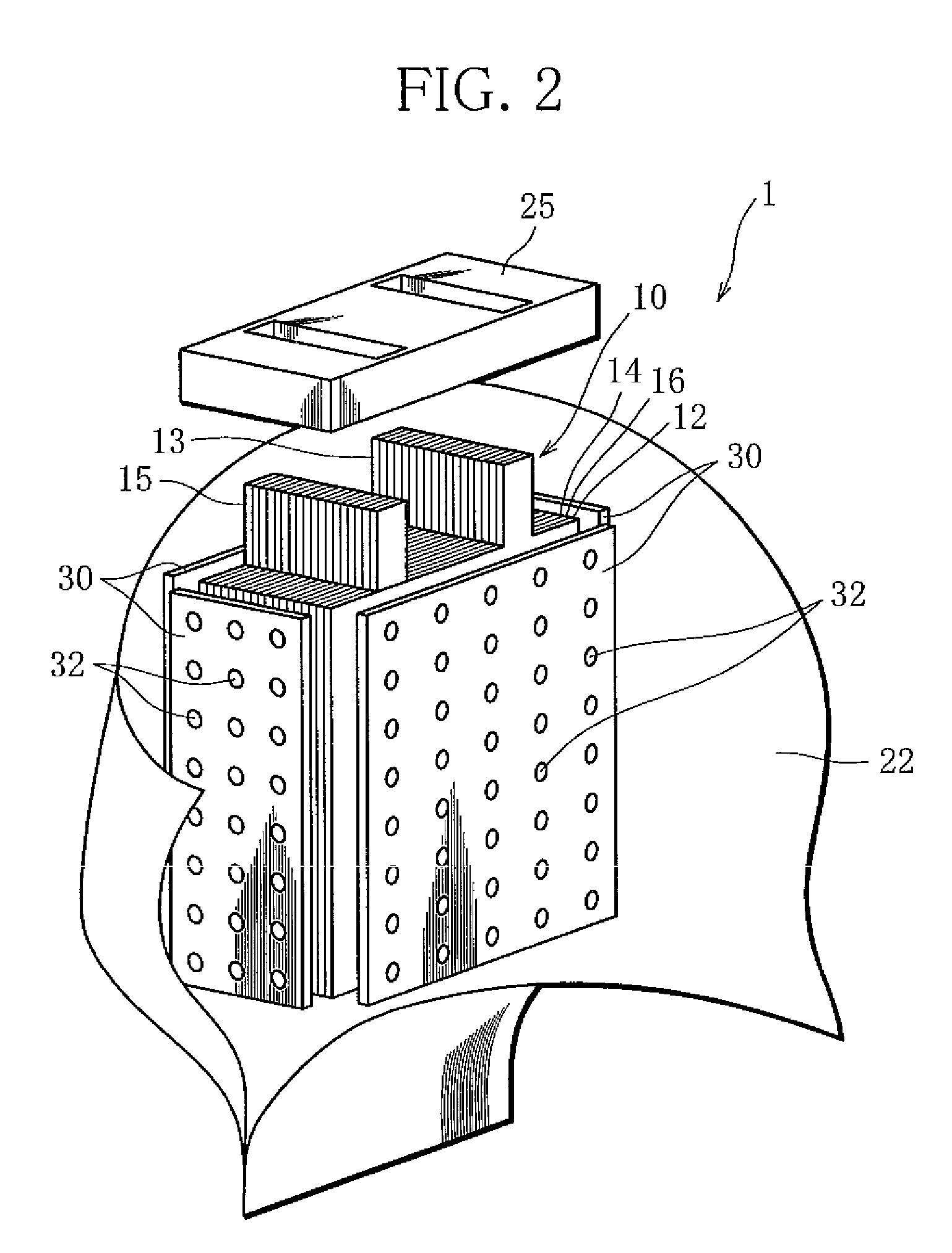

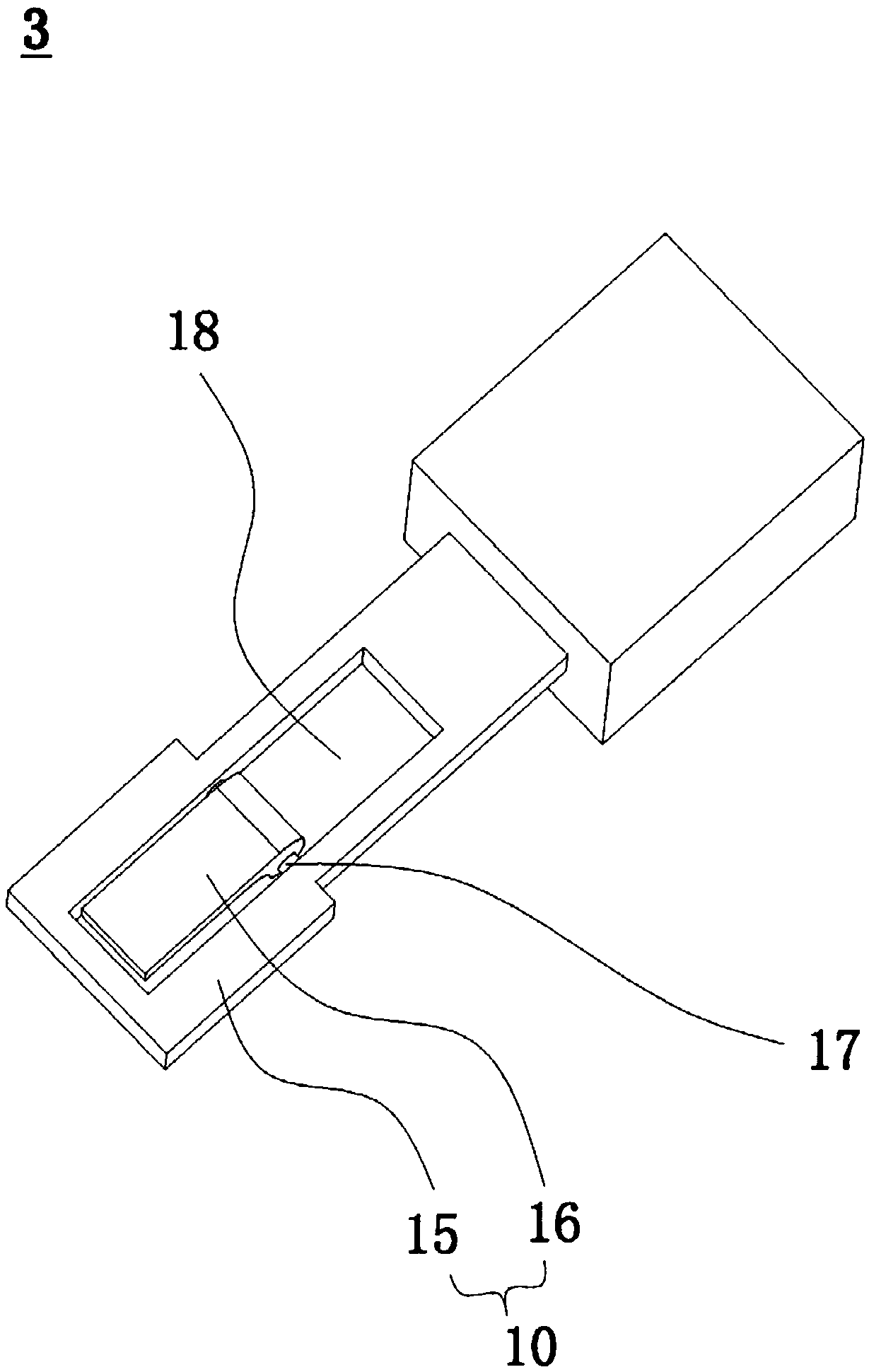

A lithium ion rechargeable cell that is constructed by the steps of forming a cell unit (1) by packing an electrode group (10), in which plate-like positive and negative electrodes (12 and 14) and a plate-like separator (16) are superposed in layers, in a cell case (20) and sealing the electrode group together with an electrolyte; and forming a module by aligning and packing a plurality of cell units in a module case. The cell case is made of a laminated film (22). A porous spacer (30) made of insulating material is interposed in between the entire circumferential surface or partial surface of the electrode group and the laminated film.

Owner:MITSUBISHI MOTORS CORP

Novel food packaging mechanical equipment

ActiveCN107902149ASave adjustment timeIncrease productivitySolid materialIndividual articlesEngineeringMechanical equipment

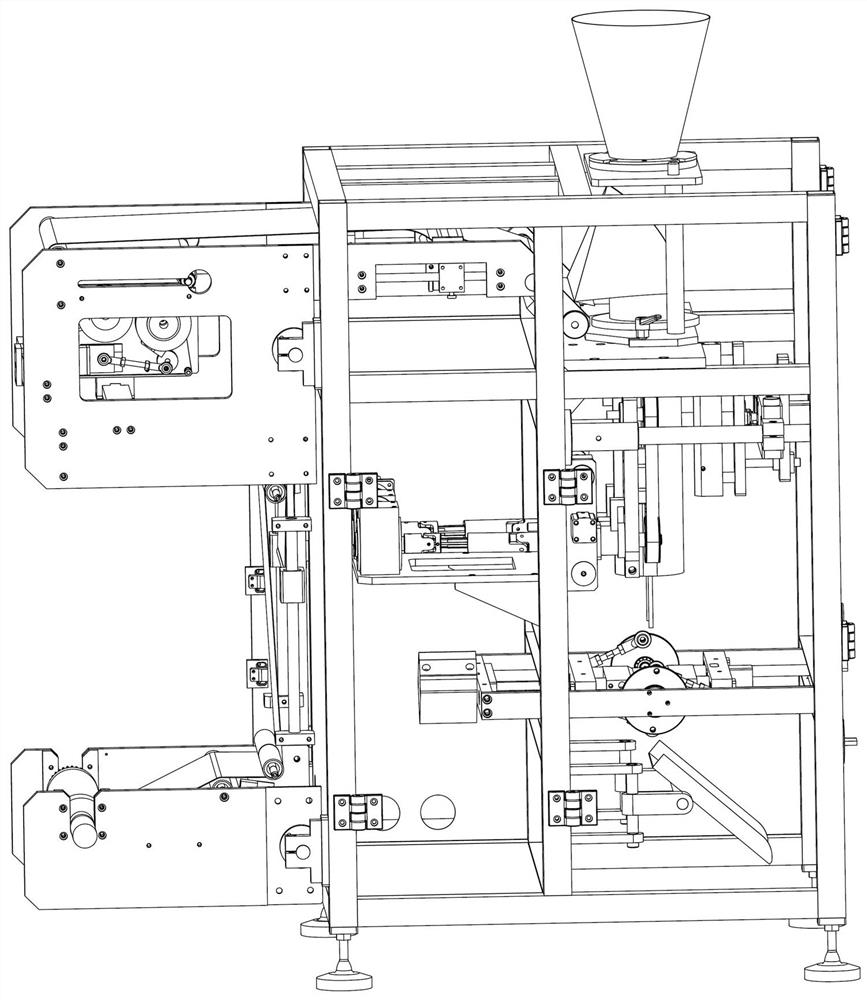

The invention relates to novel food packaging mechanical equipment. The novel food packaging mechanical equipment comprises a conveying track, a fixing supporting plate, a material feeding hopper, a package bag, a package case, a conveying belt and a hydraulic telescoping rod; two horizontal supporting rods are arranged on the conveying track; the fixing supporting plate is arranged at one ends ofthe horizontal supporting rods and a movable supporting plate is arranged at the other ends of the horizontal supporting rods; and sliding grooves are formed in the horizontal supporting rods. According to the equipment, the food packaging, sealing and casing are combined into an integration, so that the adjusting time between original steps can be effectively shortened, the production efficiencycan be greatly improved and the production cost can be lowered; meanwhile, magnets and electromagnets are taken as a fixing device of the package bag, so that the installation is greatly convenient,the operation difficulty of workers can be reduced and thus the working efficiency of the workers can be improved; moreover, the package bag can be completely opened up by the repulsion between the magnets and the electromagnets during material feeding, so that the food can be conveniently fed into the package bag and the possibility of material falling can be reduced.

Owner:汕头市昆士达食品包装机械有限公司

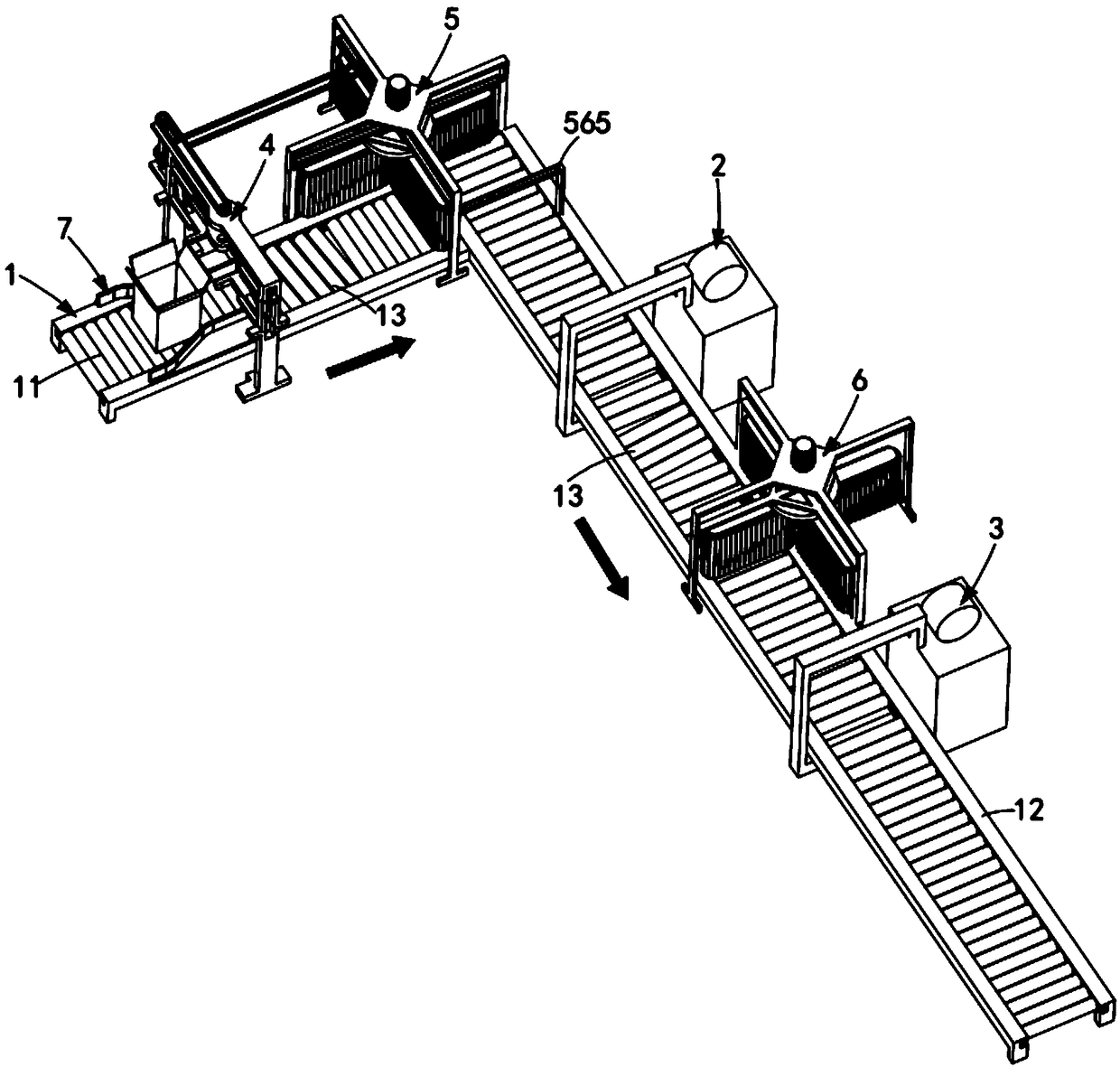

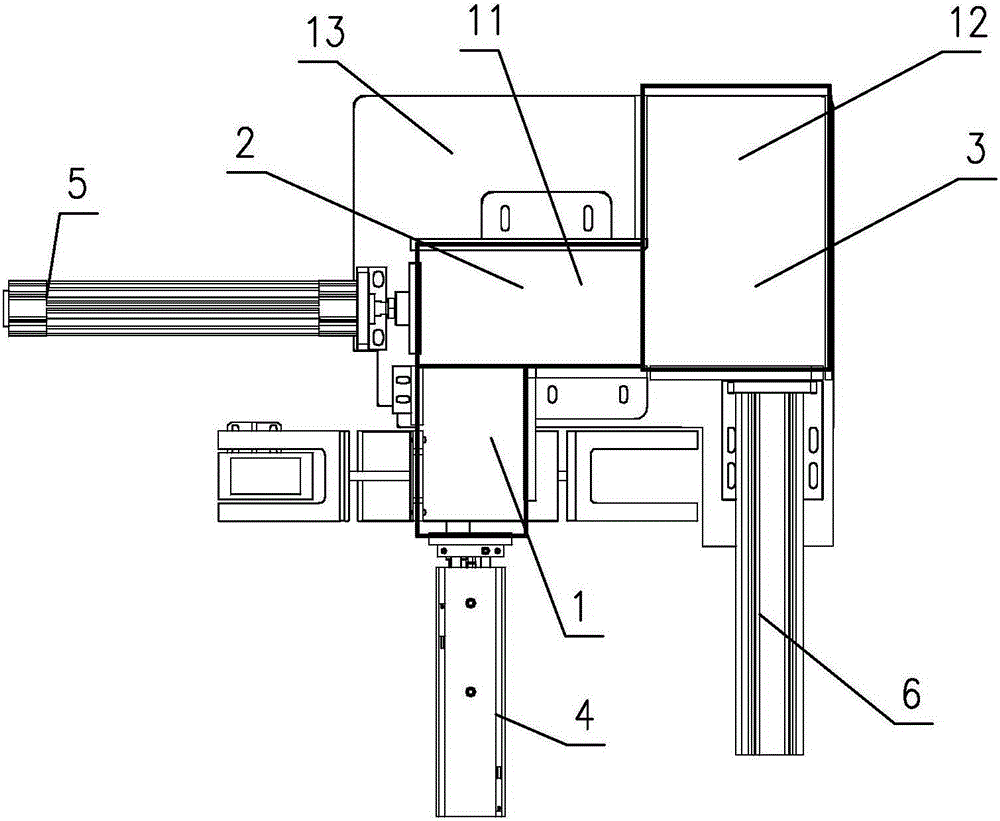

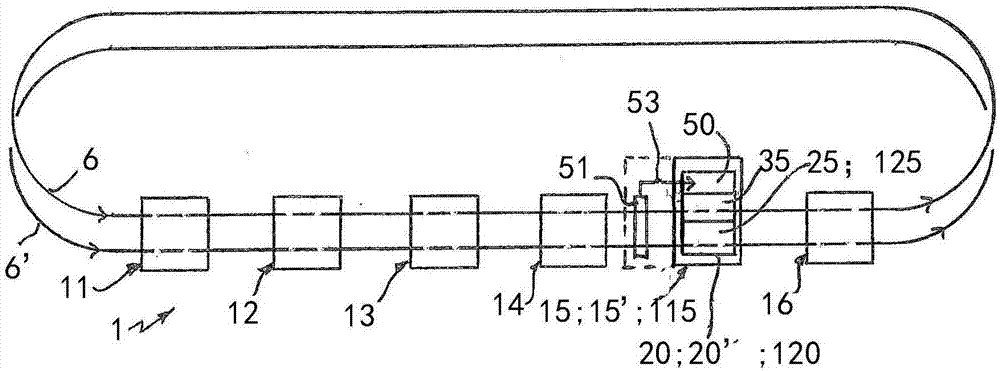

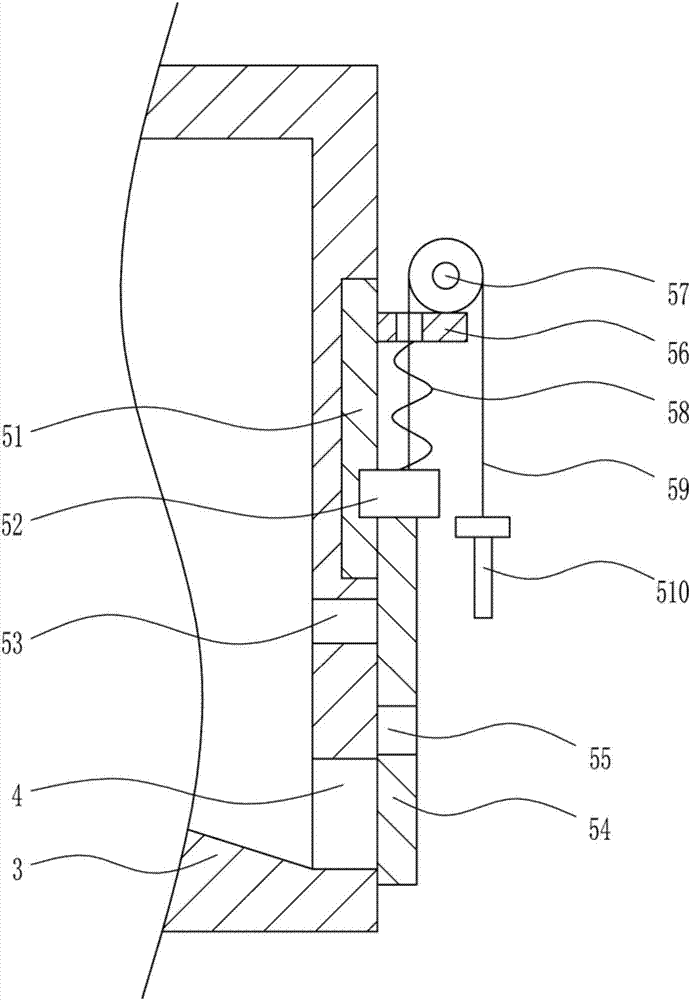

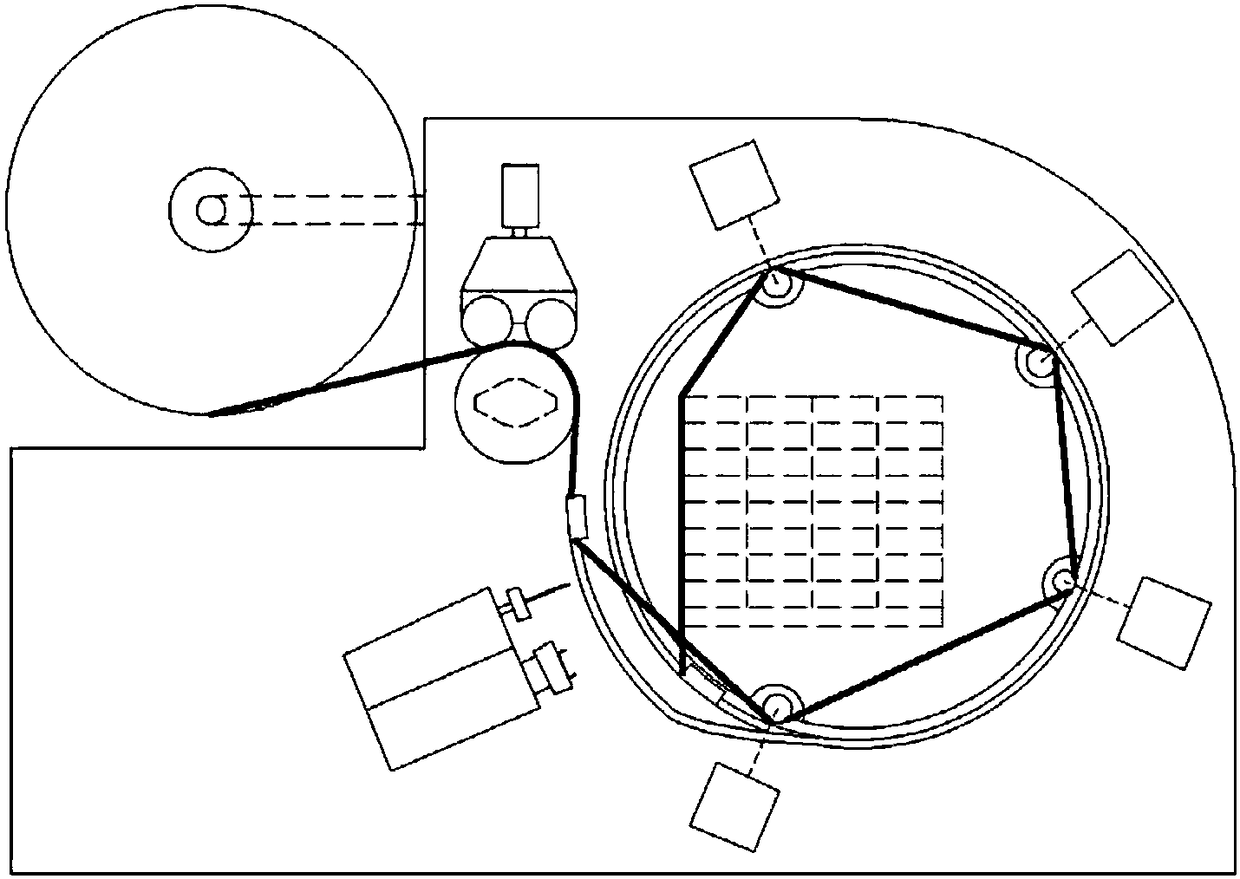

Automatic reversing lateral packaging system for lead acid battery packaging box

ActiveCN109292131AQuick automatic changeoverNo detachment from the packaging conveyor linePackagingCardboardBiochemical engineering

The invention provides an automatic reversing lateral packaging system for a lead acid battery packaging box. The automatic reversing lateral packaging system for the lead acid battery packaging box comprises a folding mechanism, a first reversing mechanism, a first packaging machine, a second reversing mechanism and a second packaging machine which arearranged sequentially in the conveying direction of a packaging conveyor line. The lead acid battery packaging box is rotated and reversed by using the first reversing mechanism and the second reversing mechanism, the lead acid battery packagingbox is subjected to frictional restriction by using the autorotation of a conveyor belt in the process of reversing, and the lead acid battery packaging box is prevented from being separated from thepackaging conveyor line in the process of reversing due to the centrifugal force; and the reversing problem of the lead acid battery packaging box in the process of packaging is solved, andin the process of packaging the lead acid battery packaging box, the condition that the first reversing mechanism is used for driving the folding mechanism to fold paperboardsat the top of the lead acid batterypackaging box is achieved.

Owner:赵娟

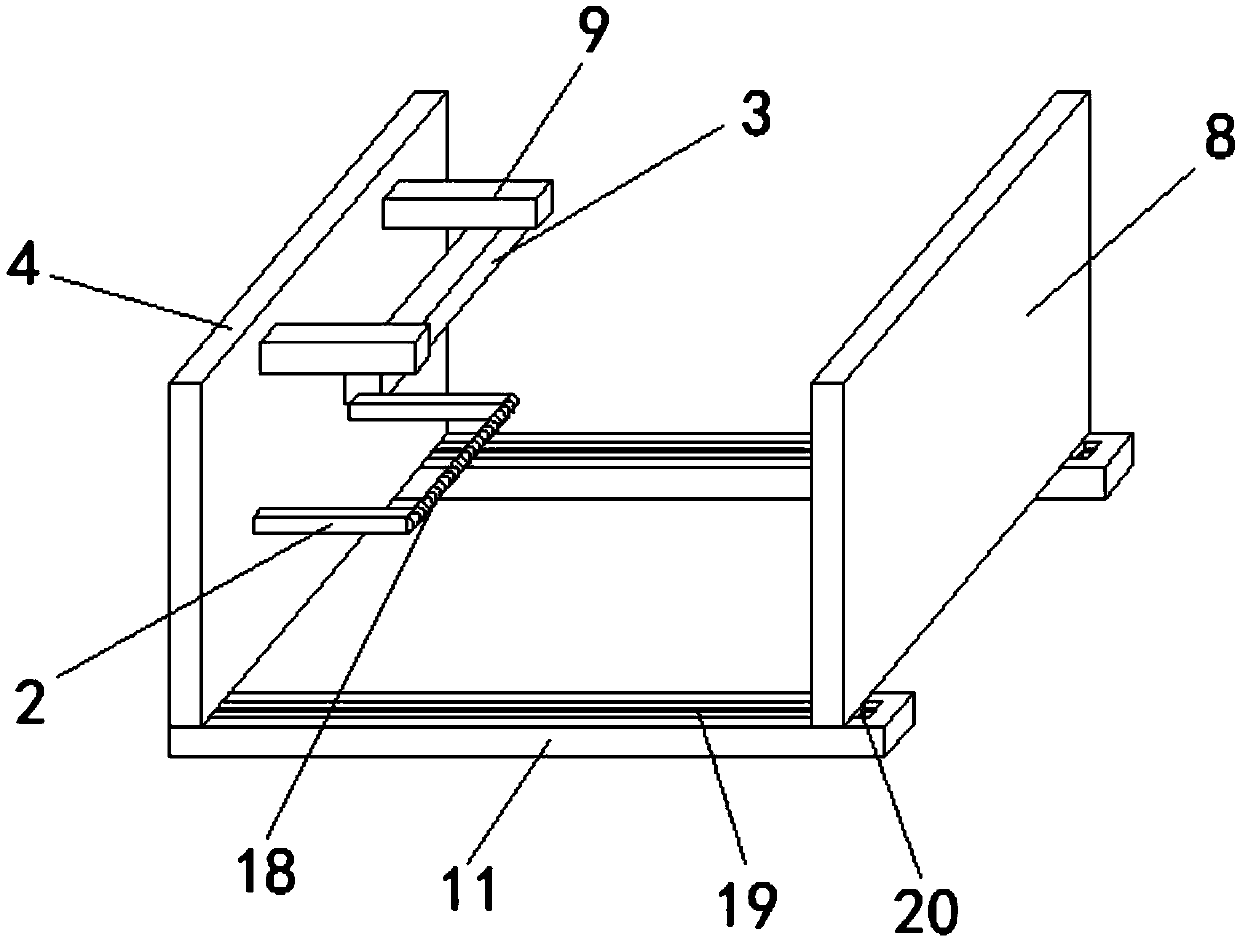

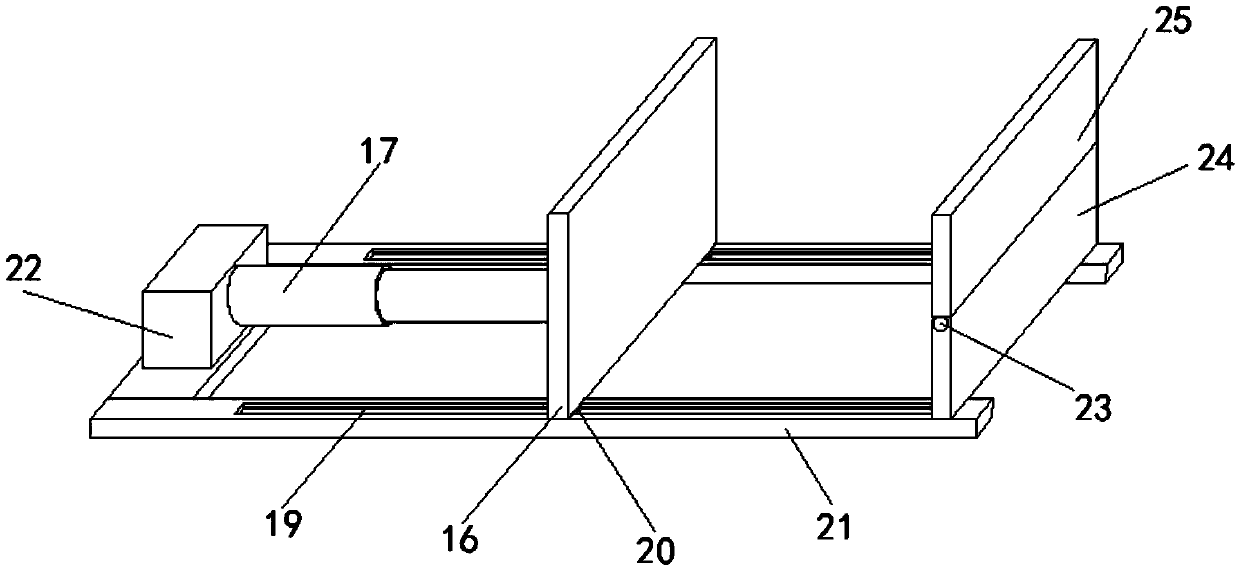

Automatic arranging combination device for connected bags

The invention discloses an automatic arranging combination device for connected bags. The automatic arranging combination device comprises an electric control gear, a first pushing channel, a second pushing channel, a third pushing channel, a first pushing mechanism, a second pushing mechanism, a third pushing mechanism and an overturning mechanism; an outlet of the first pushing channel is communicated with an inlet of the second pushing channel, and an outlet of the second pushing channel is communicated with an inlet of the third pushing channel; the first pushing mechanism is located at the inlet of the first pushing channel and can push the connected bags along the first pushing channel, the second pushing mechanism is located at the inlet of the second pushing channel and can push the connected bags along the second pushing channel, and the third pushing mechanism is located at the inlet of the third pushing channel and can push the connected bags along the third pushing channel; and the overturning mechanism is located in front of the inlet of the first pushing channel. The automatic arranging combination device is simple and compact in structure, a plurality of connected bags folded into the S shape are automatically arranged and combined, the automation is achieved, a large amount of time and a large amount of manpower are saved, the manual cost is greatly reduced, and meanwhile the production efficiency is greatly improved.

Owner:广州紫怡机电有限公司 +1

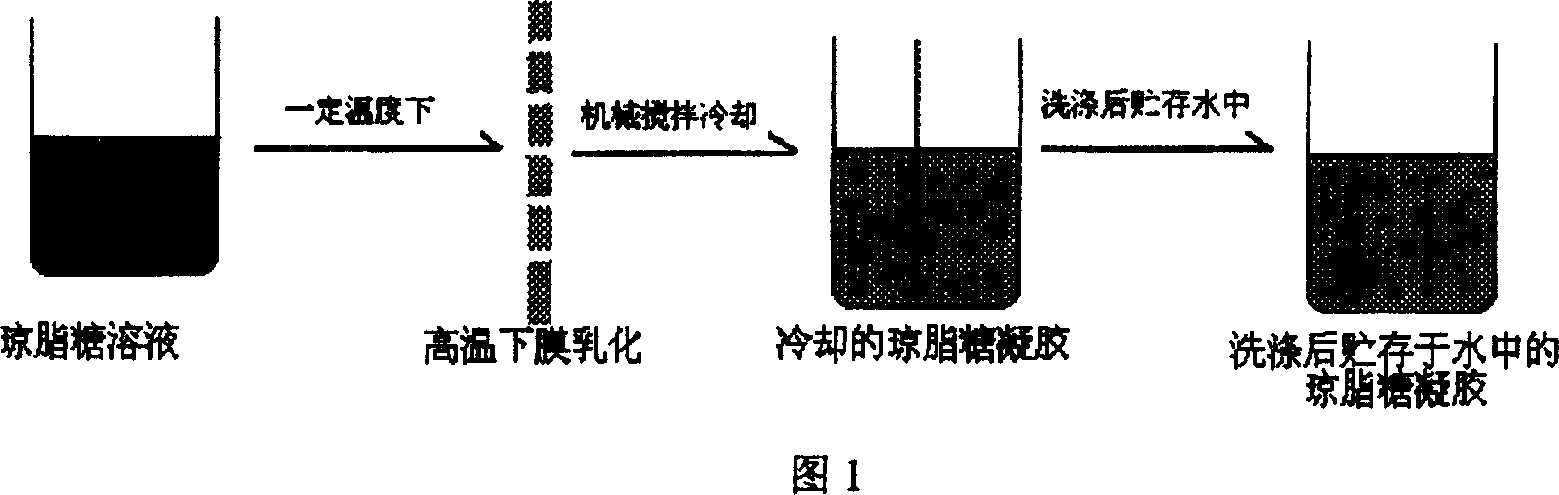

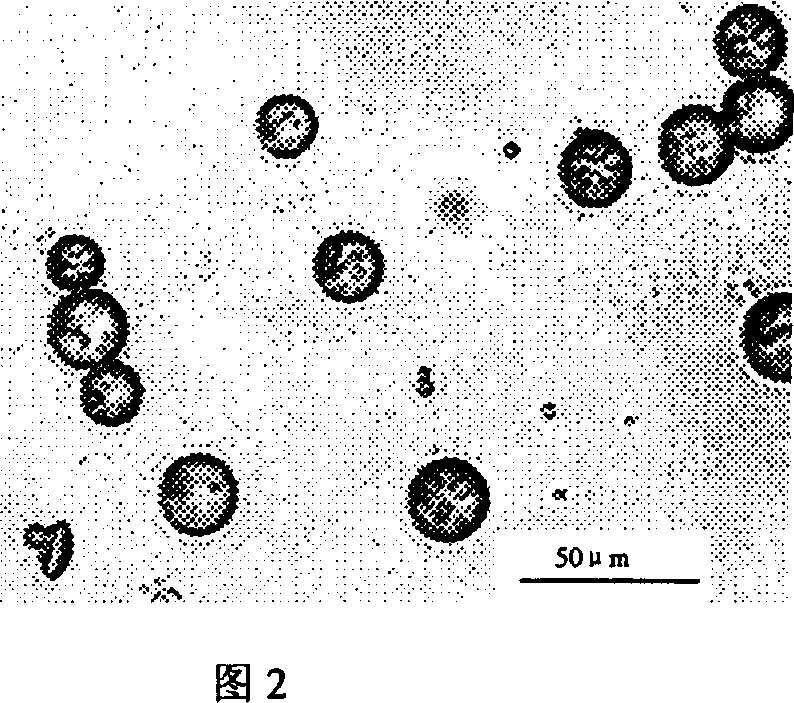

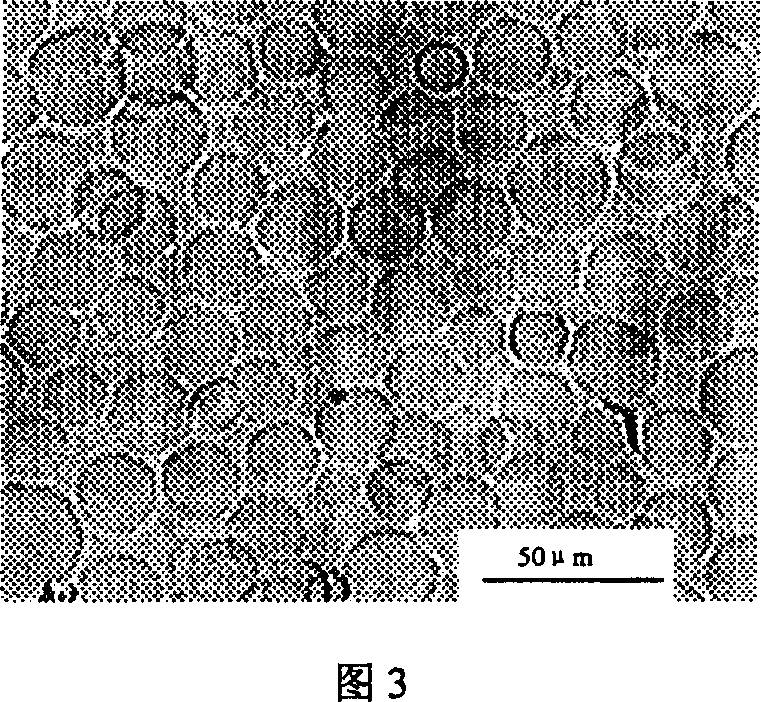

Size-uniform agarose gel microball and its preparing method

ActiveCN1304101CEasy to separateEvenly packedMicroballoon preparationMicrocapsule preparationMicrosphereOil phase

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Stripping of a dip-mouled glove from a former

A glove stripping apparatus (15) for fully stripping a partially stripped elastomeric dip-moulded glove (2) from a hand-shaped dip-moulding former(4) comprises a gripping device (25) relatively movable with respect to a downwardly hanging cuff end portion (10), a gripping actuator (32),a stripping actuator (35) and a controller for controlling the operation of the actuators. The relative movement of the gripping device and the downwardly hanging cuff end portion is driven by the stripping actuator. The gripping device has first and second gripping members (24, 26) movable relative to each other by the gripping actuator. The gripping members provide opposed gripping surfaces (34, 36) for gripping the cuff end portion. The first gripping member and the second gripping member initially provide a horizontally extending gap between the gripping surfaces which receives the cuff end portion. The gripping members are moved to reduce the gap (40') until the cuff end portion is restrained between the gripping surfaces with a beaded cuff end (3) of the glove being below the gap. The gripping members are moved downwardly (46) together towards the beaded cuff end so that the cuff end portion moves upwards relative to the gap until the beaded cuff end (3) is caught by the gap (40'). The downward movement is then continued until the glove is fully stripped from the dip-moulding former.

Owner:SAFEDON

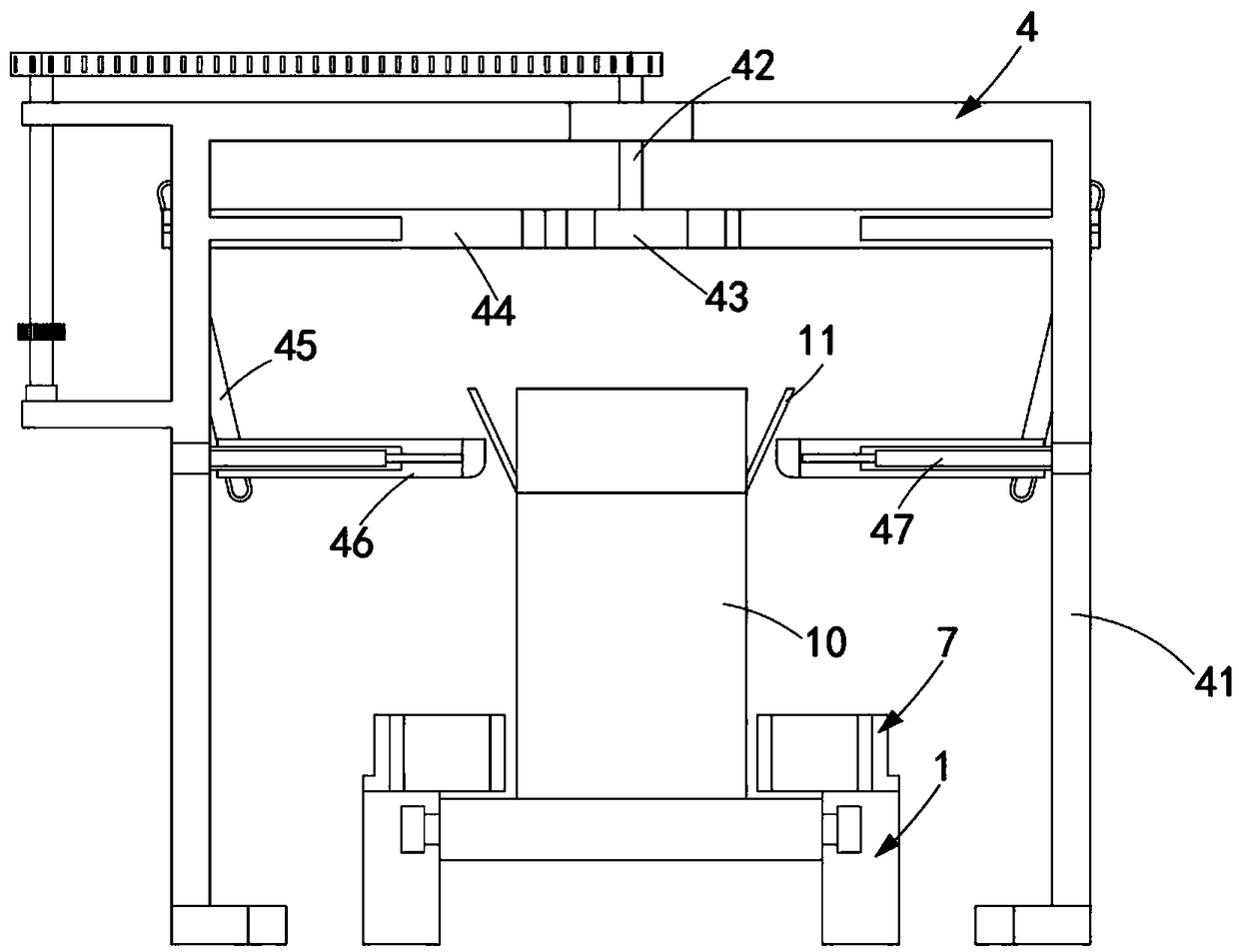

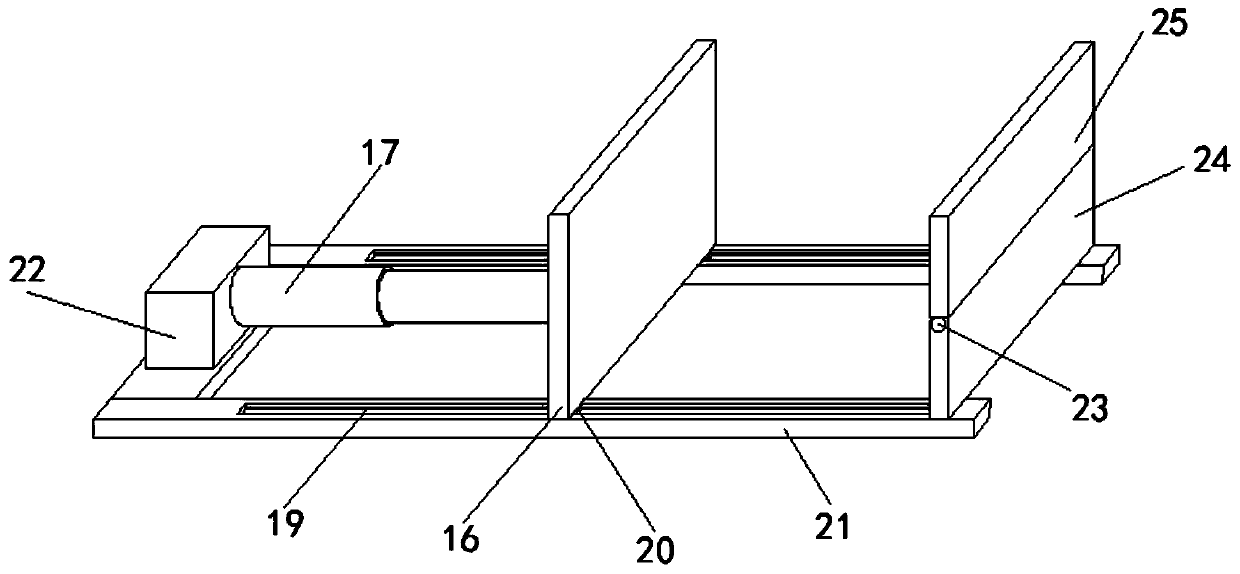

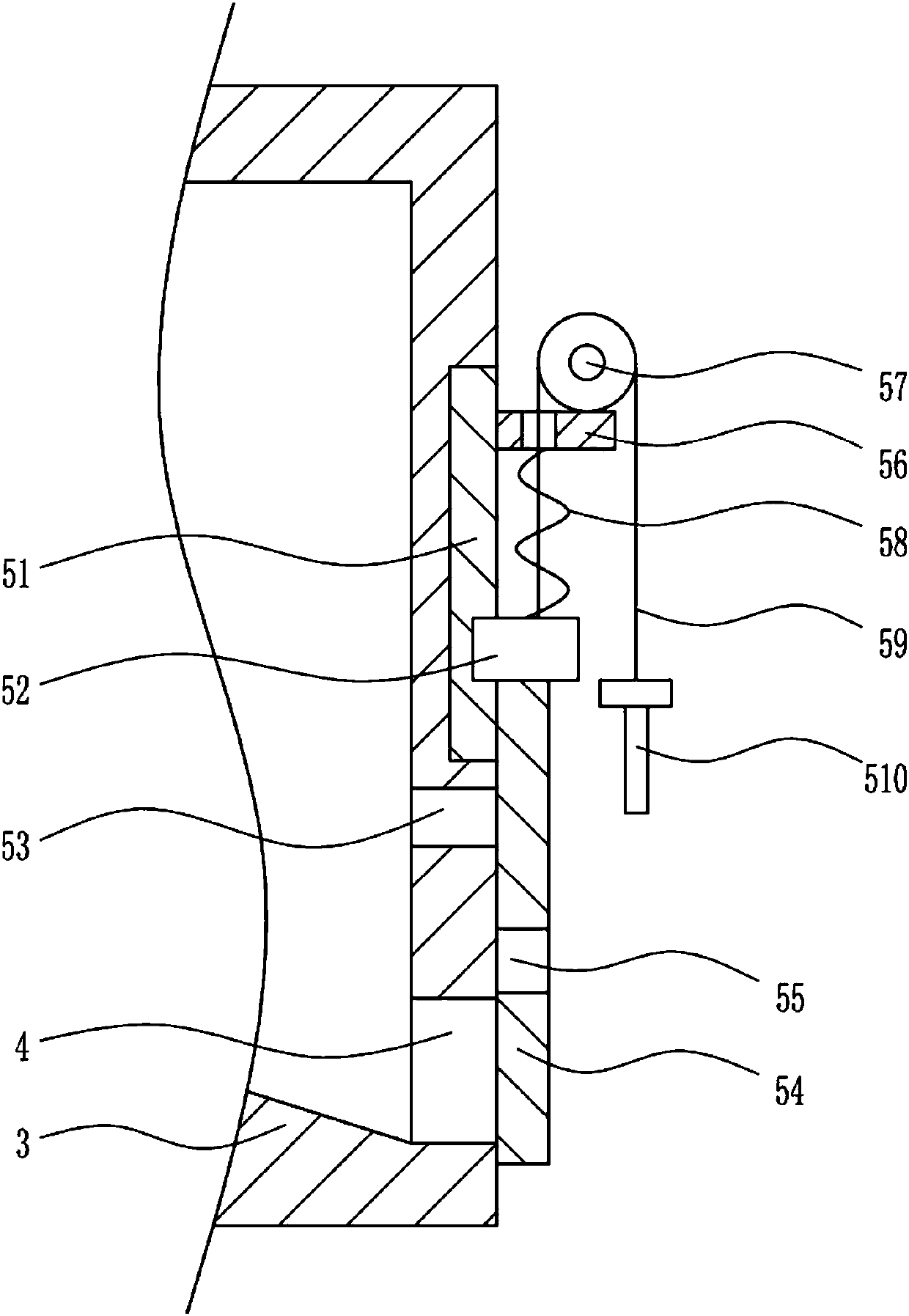

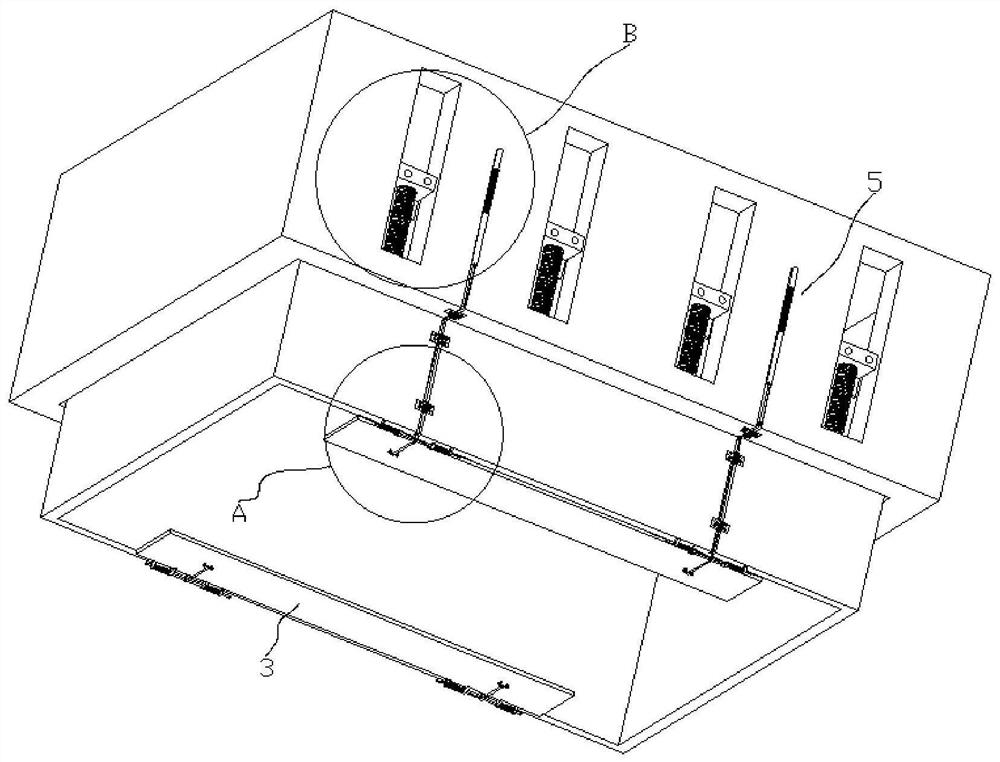

Equipment capable of uniformly packing discarded batteries

InactiveCN107963244AEasy to operateReduce the burden onPackaging automatic controlSolid materialEngineeringLoudspeaker

The invention relates to packing equipment, in particular to equipment capable of uniformly packing discarded batteries. The invention aims at providing the packing equipment for discarded battery landfill treatment, which can carry out uniform packing and has high packing speed. The equipment capable of uniformly packing discarded batteries comprises a bottom plate and the like, and the left sideof the top of the bottom plate is connected with a supporting rod. A frame is arranged at the top of the supporting rod, a first through hole is formed in the lower part of the inner right wall of the frame, and a feeding device is arranged at the lower part of the right side of the frame. The left side of the inner top of the frame is hinged with a cover plate, a handle is arranged at the lowerpart of the left side of the cover plate. A containing device is arranged at the center of the top of the bottom plate. Through the feeding device, feeding can be better controlled, packing of the discarded batteries is facilitated through the containing device, and through cooperation of a loudspeaker and a switch, the weight of each package can be further controlled, and packing is more uniform.

Owner:吴敏

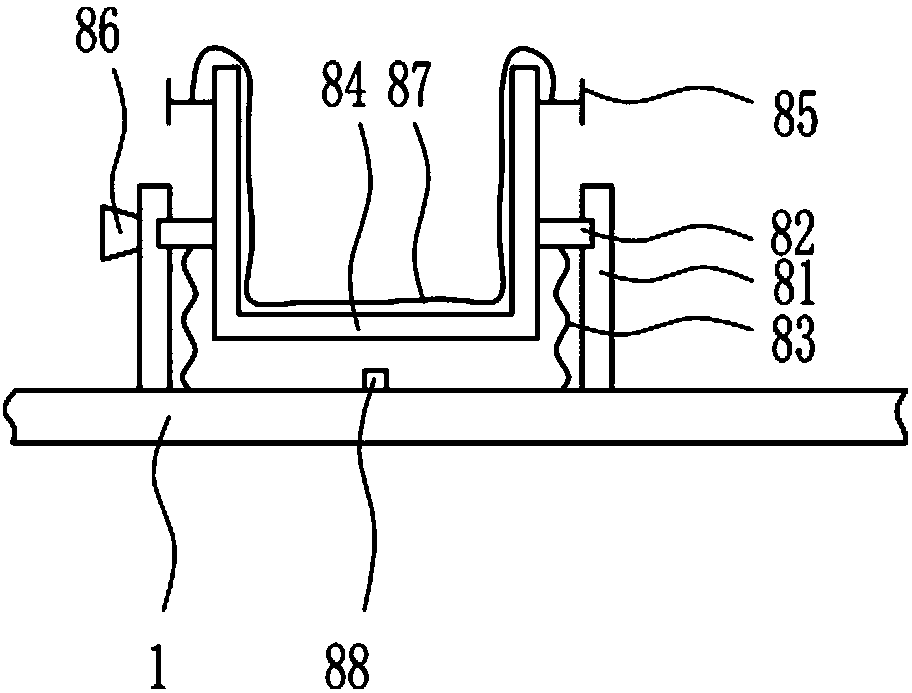

Quantitative packing device for organic fertilizer

The invention relates to the technical field of organic fertilizer processing, and discloses a quantitative packing device for organic fertilizer. The quantitative packing device for the organic fertilizer comprises a rack, wherein the rack is fixedly provided with a material storage cabin, a stepping motor, a first telescopic cylinder and two second telescopic cylinders; the bottom of the material storage cabin is provided with a material outlet; the material outlet is in sliding connection with a first baffle and a second baffle used for covering the material outlet; the second baffle is fixedly connected with a limiting block; the first baffle and the output end of the first telescopic cylinder are fixedly connected with a first spring; the rack below the material outlet is hinged to two U-shaped frames; the second telescopic cylinders are used for pushing the U-shaped frames; each U-shaped frame is fixedly provided with a heat sealing head, a first switch used for controlling the heat sealing head to be electrified, a second switch used for controlling the stepping motor, a third switch used for controlling the first telescopic cylinder, and a fourth switch used for controllingthe corresponding second telescopic cylinder; a packaging film driven by the stepping motor is laid above a charging mechanism. According to the quantitative packing device, the working efficiency oforganic fertilizer packaging can be improved, and production cost is reduced.

Owner:重庆铜梁三丰生物肥料有限公司

Used battery packaging landfill equipment capable of reducing arm loads

The invention relates to packaging equipment, in particular to used battery packaging landfill equipment capable of reducing arm loads. According to the technical aims of the used battery packaging landfill equipment capable of reducing the arm loads, even packaging can be achieved, and the packaging speed is high. In order to achieve the above technical aims, the used battery packaging landfill equipment capable of reducing the arm loads comprises a base plate and the like. A strut is connected to the left side of the top of the base plate, a frame is arranged at the top of the strut, a firstthrough hole is formed in the lower portion of the right wall of the interior of the frame, a discharging device is arranged at the lower portion of the right side of the frame, a cover plate is connected to the left side of the top of the interior of the frame in a hinged manner, a pull handle is arranged at the lower portion of the left side of the cover plate, and an emptying device is arranged in the center of the top of the base plate. By means of the discharging device, discharging can be better controlled; and by means of the emptying device, packaging can be more convenient, and a horn can be matched with a switch.

Owner:吴敏

Garbage packing device, cleaning equipment and packing method

PendingCN114572477AEvenly stackedEvenly packedWaste collection and transferRefuse receptaclesEngineeringStructural engineering

The invention relates to the technical field of garbage treatment, and provides a garbage packing device, cleaning equipment and a packing method. The garbage packaging device comprises a machine body and a packaging mechanism, the machine body comprises a garbage bin, a cover body and a first driving assembly, the cover body is used for sleeving a garbage bag, the cover body is rotatably connected to the top of the garbage bin, a containing cavity is defined by the cover body and the garbage bin, the cover body is provided with a garbage input opening communicating with the containing cavity, and the first driving assembly is used for driving the cover body to rotate; the packaging mechanism is installed on the cover body and used for packaging the garbage bags. Wherein the first driving assembly drives the cover body to rotate upwards before the packaging mechanism carries out packaging, so that the garbage bag sleeved on the cover body is driven to be lifted upwards, the height of a bag opening of the garbage bag is increased to the position higher than the garbage stacking height, garbage can be poured into the bottom of the garbage bag, and the interior of the garbage bag is filled more uniformly; the garbage bag packing success rate is guaranteed, and the technical problem that garbage bag packing of existing cleaning equipment is likely to fail is solved.

Owner:SHENZHEN PUDU TECH CO LTD

Square tube packing equipment

InactiveCN109533428AWon't fall offGuaranteed packaging qualityWrapping material feeding apparatusWrapping with article rotationEngineeringMechanical engineering

The invention provides square tube packing equipment. The square tube packing equipment comprises a bottom plate, a conveying device, a square tube, a packing device and an auxiliary chain, wherein the conveying device is mounted at the upper end of the front side of the bottom plate, the square tube is mounted on the conveying device, the packing device is mounted in the middle of the bottom plate, and the auxiliary chain is mounted on the bottom plate located at the rear end of the packing device. The square tube packing equipment can solve the problems as follows that a, the surface of thesquare tube is partially exposed and the square tube is easily scratched in a transporting process due to non-uniform packing of conventional equipment; b, a packing strap on the surface of the squaretube is prone to falling off due to non-firm packing of the conventional equipment; and c, the packing equipment on the market has low efficiency and low automation degree, cannot meet the actual production demand and the like; the square tube packing equipment can realize the function of automatically packing the square tube, and has the advantages of uniform and firm packing and high packing efficiency.

Owner:合肥巍华钢结构有限公司

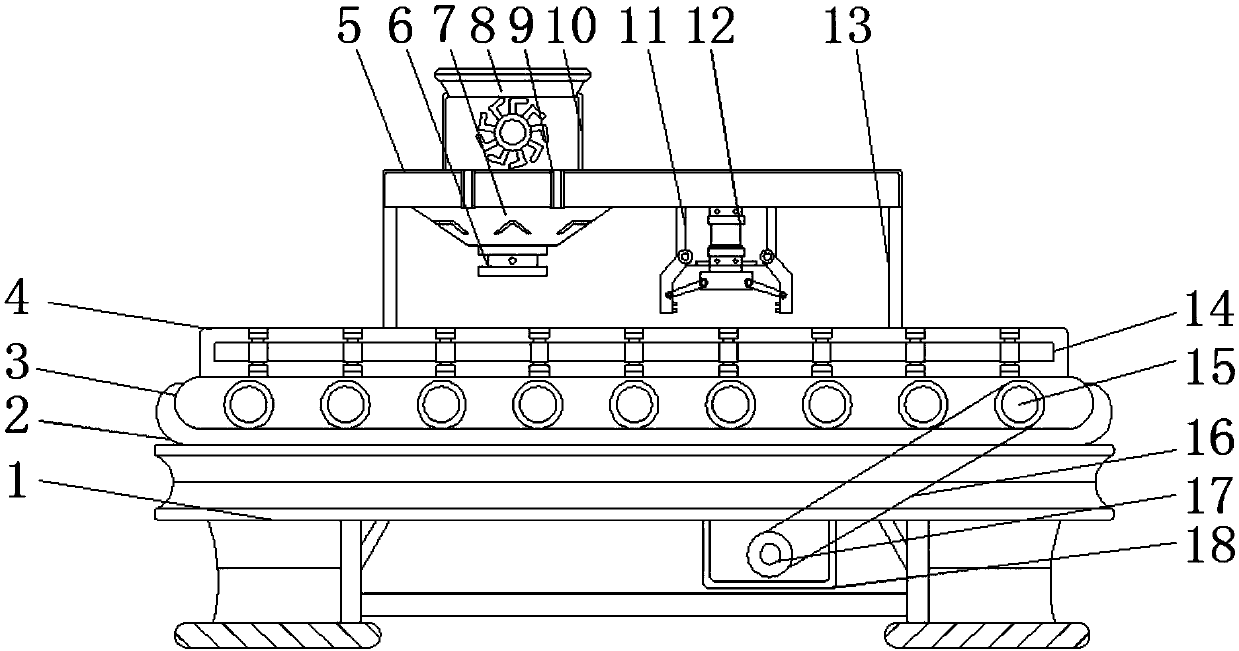

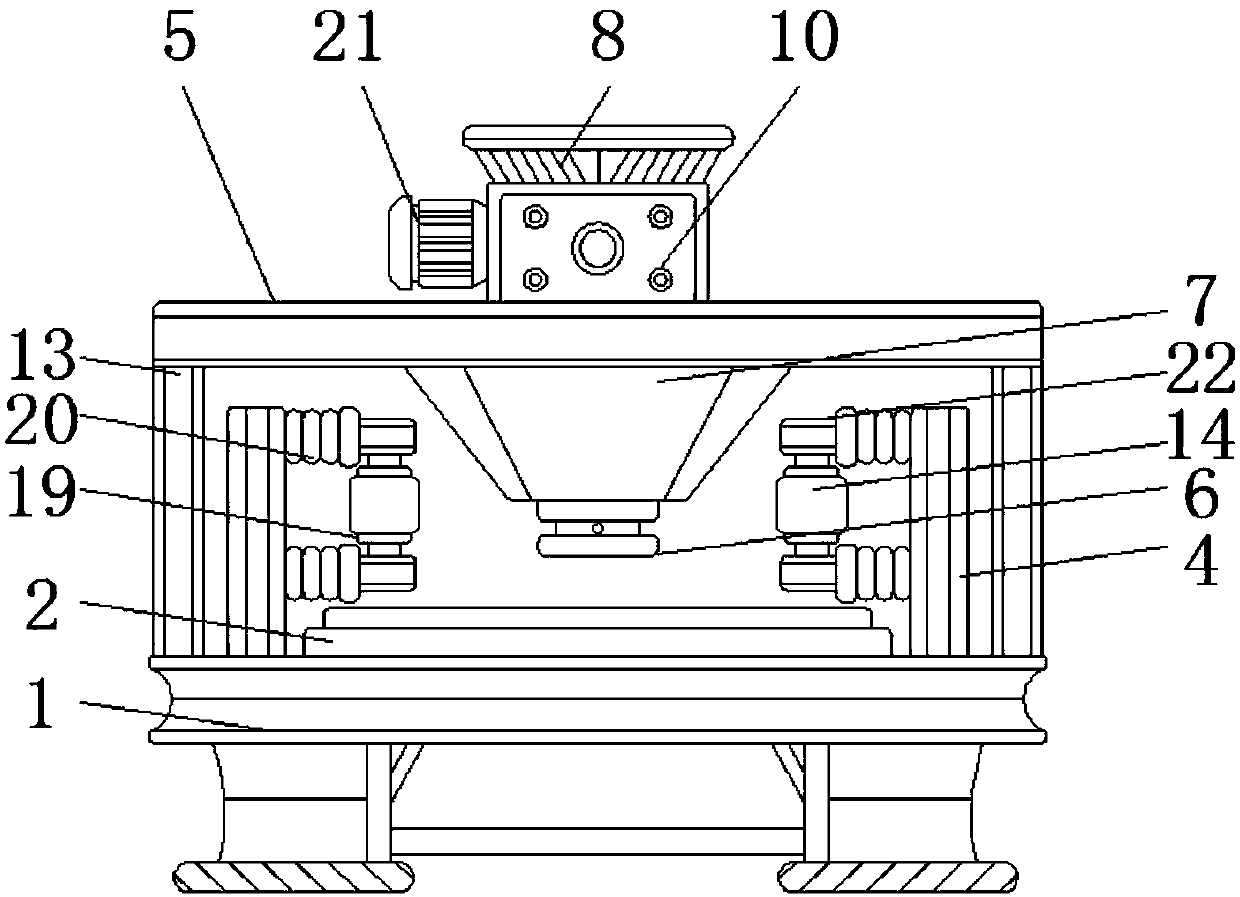

Automatic packaging equipment

InactiveCN107902112AEvenly packedSlow down the feeding speedConveyorsSolid materialMotor shaftPulley

The invention discloses an automatic packaging equipment, which comprises a frame body, a mounting plate, a fixing plate, a support plate and a material distribution bin. The mounting plate is installed at the middle position above the frame body, and a first motor is installed at the lower end. , the inside of the installation plate is equipped with a roller, and the outside of the roller is installed with a conveyor belt, the output end of the first motor is installed with a rotating shaft, and the rotating shaft is connected to the roller through a pulley mechanism, and the fixed plate is installed close to Springs are evenly installed above and below one side of the plate, and fixed blocks are installed on the ends of the springs far away from the fixed plate, and rotating rollers are installed on the inner sides of the fixed blocks. The invention is equipped with a second motor, a rotating rod and a material distribution block. The second motor drives the material distribution block to rotate through the rotating rod, which can not only delay the speed of tea blanking, but also make the tea blanking more uniform, so that each tea leaves There is less variation in the quality of tea added to the box and more uniform packaging.

Owner:徐素香

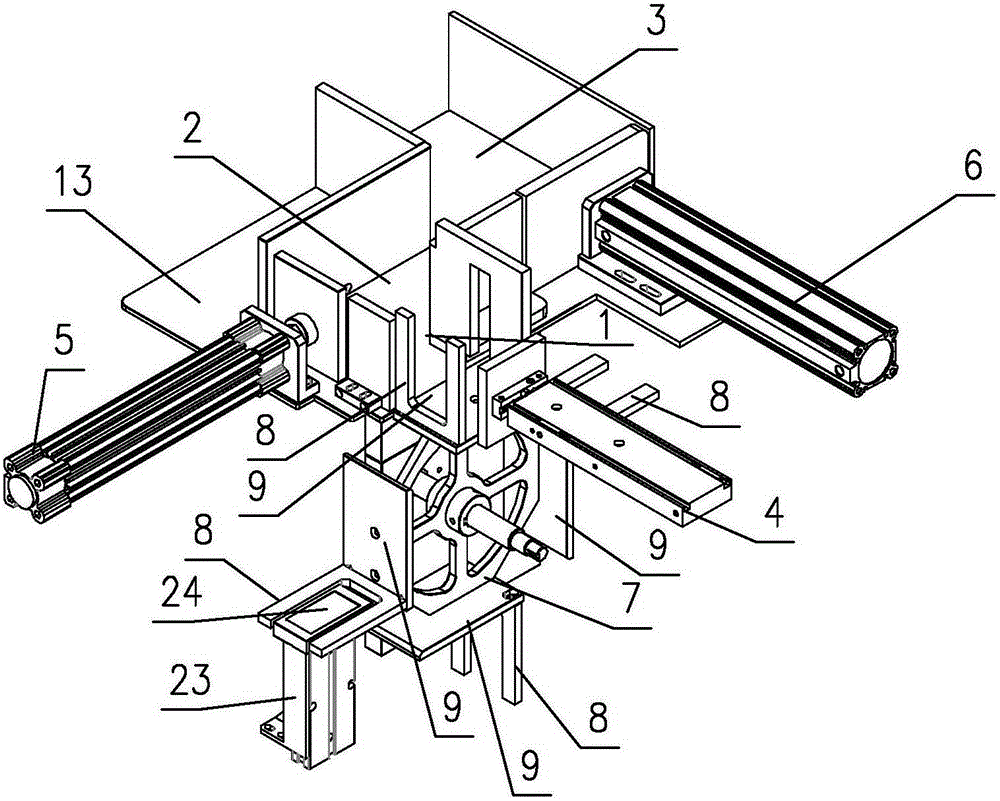

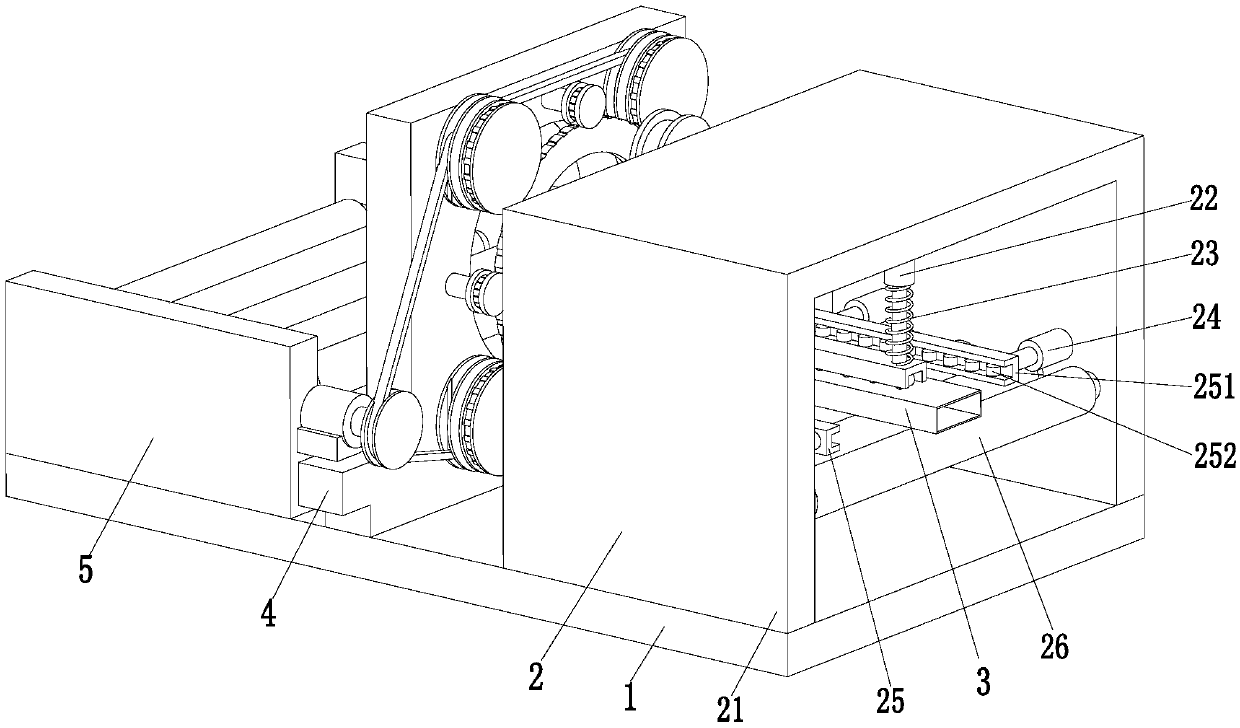

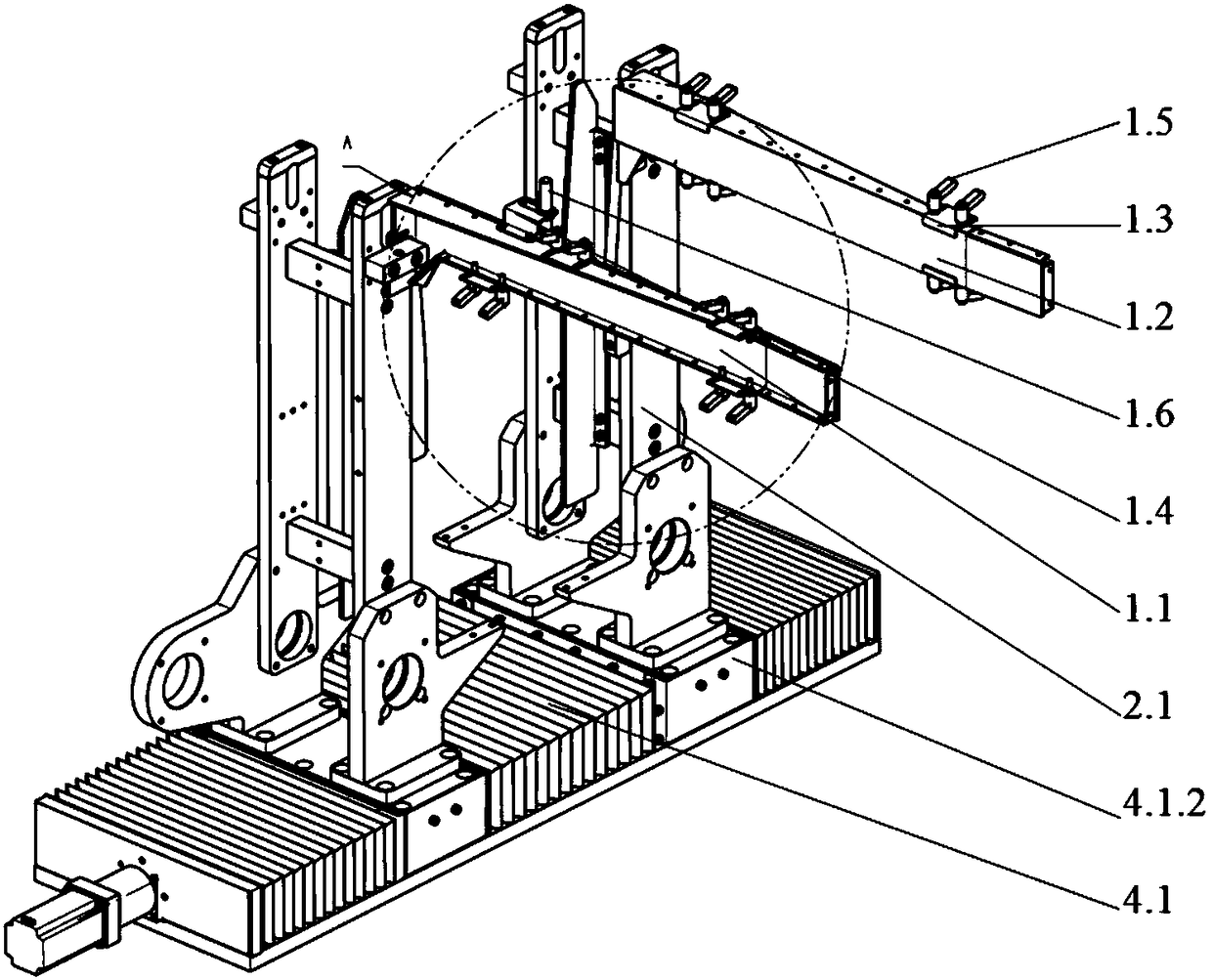

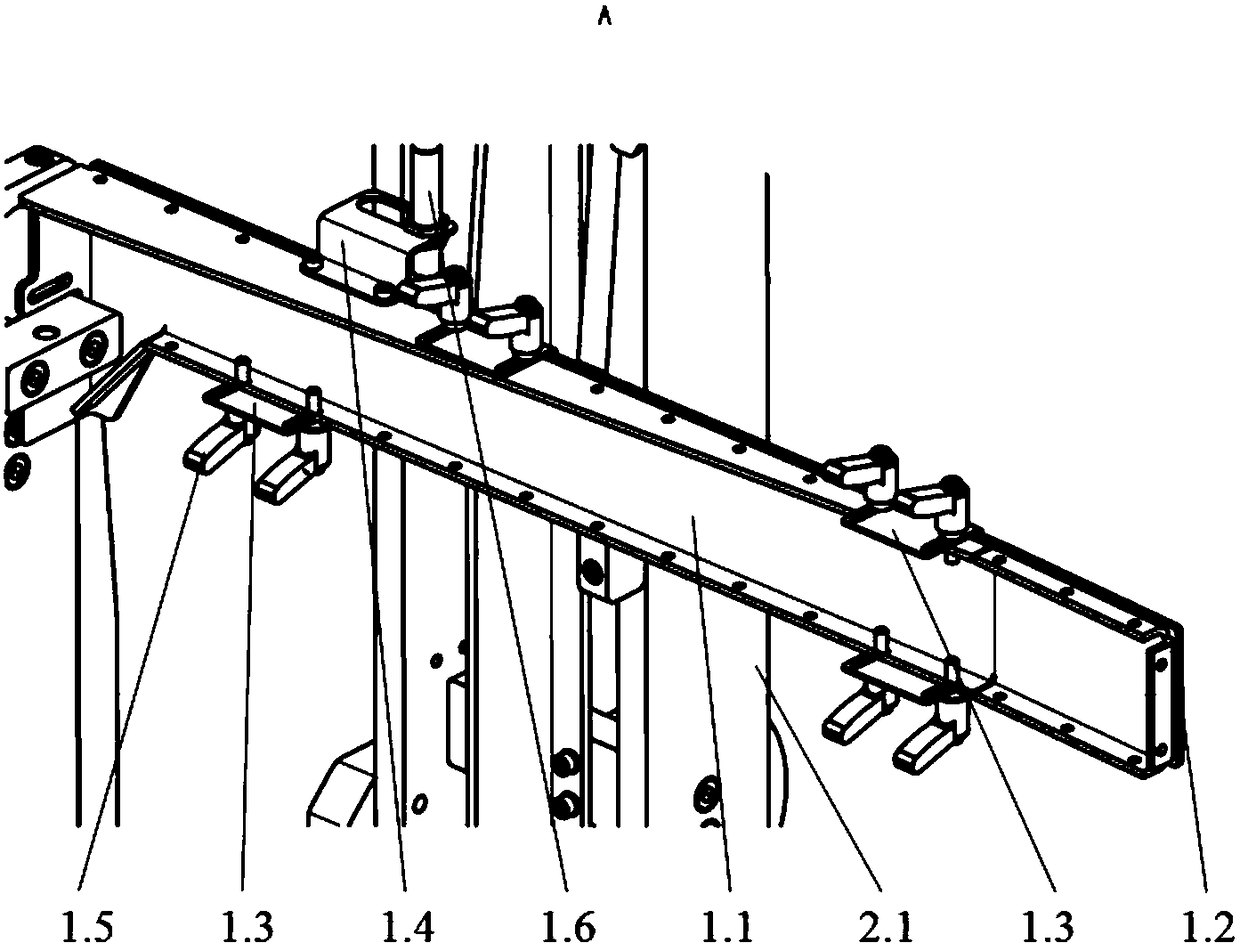

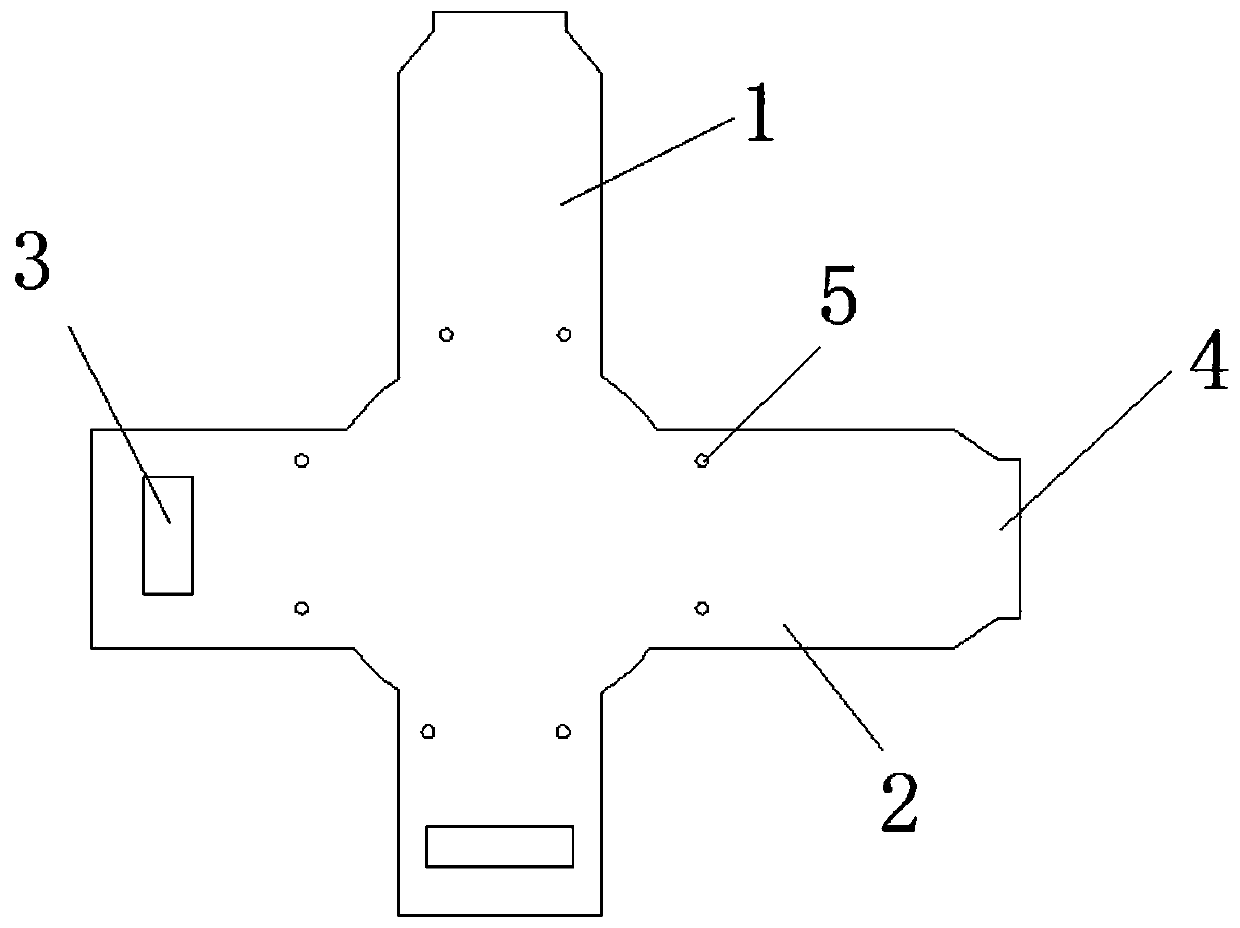

Rapid boxing mechanism of ceramic tile stacking-boxing arrangement machine and working method of rapid boxing mechanism

ActiveCN108100344AImprove uniformityImprove finishing efficiencyPackaging automatic controlShock-sensitive articlesBrickCarton

The invention discloses a rapid boxing mechanism of a ceramic tile stacking-boxing arrangement machine and a working method of the rapid boxing mechanism. The rapid boxing mechanism comprises a ceramic tile conveying-out mechanism, a paper box supporting mechanism and center alignment supporting plates. The ceramic tile conveying-out mechanism is arranged on the rear side of a conveying-out rollerway of the ceramic tile stacking-boxing arrangement machine and fixed to a base. The paper box supporting mechanism is mounted on a continuous tile stacking mechanism. The two center alignment supporting plates are in a set and are used in cooperation and formed by machining metal plates, one center alignment supporting plate is an inclined face, the other center alignment supporting plate is a straight face, and the two center alignment supporting plates are fixed to two supporting frames, located on the left side and the right side of the conveying-out roller way, of the paper box supporting mechanism correspondingly in bilateral symmetry. The two center alignment supporting plates are located on the front side of a tile stacking frame of the ceramic tile stacking-boxing arrangement machine, and a tile feeding channel is formed by the two center alignment supporting plates, wherein a horn mouth of the tile feeding channel faces a horn closing segment on one side of the tile stackingframe and is combined with a straight segment. The rapid boxing mechanism can adapt to the arrangement requirements of multiple ceramic tile specifications and has the advantages of being high in adaptability, easy to operate, high in automation degree and ceramic tile arrangement efficiency and the like.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Automatic folding machine for scarf production

InactiveCN113071764AFold accuratelyGuaranteed to move normallyPackagingHydraulic cylinderStructural engineering

The invention discloses an automatic folding machine for scarf production. The machine comprises a folding table, supporting legs are oppositely arranged at the bottom of the folding table, a first conveying assembly, a second conveying assembly and a third conveying assembly are sequentially arranged above the folding table, and the two sides of the second conveying assembly are each provided with two first mounting plates. A first folding plate is rotationally arranged between the two first mounting plates on the same side, two first hydraulic cylinders are hinged to the folding table, the ends of piston rods of the two first hydraulic cylinders are hinged to the bottoms of the two first folding plates correspondingly, two first vertical plates are oppositely arranged on the folding table, and a first transverse plate is connected to the upper portions of the two first vertical plates. Two second hydraulic cylinders are arranged on the first transverse plate, a first lifting plate is arranged at the bottom ends of piston rods of the second hydraulic cylinders, a third hydraulic cylinder is arranged on the back face of the first lifting plate, and a first L-shaped pressing rod is arranged at the end of a piston rod of the third hydraulic cylinder. Compared with the prior art, the machine has the advantages that the labor intensity of workers is relieved, and the working efficiency is high.

Owner:长兴东振纺织股份有限公司

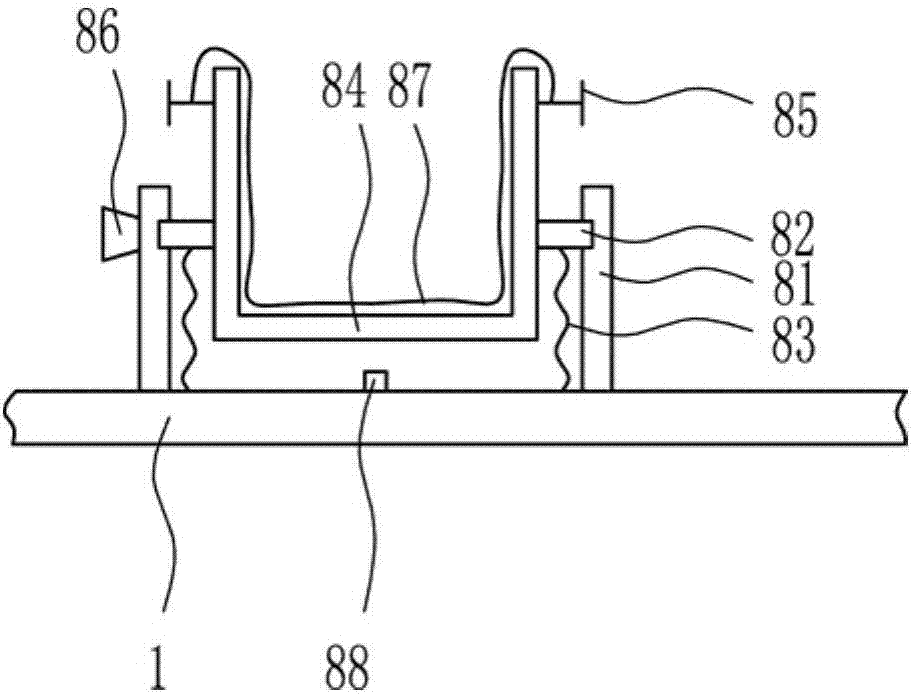

Lithium ion rechargeable cell

InactiveUS7998614B2Small sizeReduce capacityCell seperators/membranes/diaphragms/spacersFinal product manufactureLithiumRechargeable cell

A lithium ion rechargeable cell that is constructed by the steps of forming a cell unit (1) by packing an electrode group (10), in which plate-like positive and negative electrodes (12 and 14) and a plate-like separator (16) are superposed in layers, in a cell case (20) and sealing the electrode group together with an electrolyte; and forming a module by aligning and packing a plurality of cell units in a module case. The cell case is made of a laminated film (22). A porous spacer (30) made of insulating material is interposed in between the entire circumferential surface or partial surface of the electrode group and the laminated film.

Owner:MITSUBISHI MOTORS CORP

Continuous packaging equipment for Chinese yam slices

PendingCN112278444AHigh degree of automationEasy to operateWrapping material feeding apparatusWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to continuous packaging equipment for Chinese yam slices, comprising a frame, an electric box, a film conveying assembly, a forming assembly, a pressing and sealing assembly anda material receiving assembly. The sealing and pressing assembly comprises a longitudinal pressing mechanism and a transverse sealing mechanism; the forming assembly comprises a transition hopper, a former, a charging barrel and guide feet; the film conveying assembly comprises a film passing mechanism and a film feeding mechanism; the electric box is arranged on the right side of the frame; the forming assembly is arranged at the uppermost end of the frame; the longitudinal pressing mechanism and the transverse sealing mechanism are sequentially located below the frame; and the receiving assembly is located at the lowermost end of the frame. A packaging film is arranged on the film passing mechanism and penetrates through the former through code printing and photoelectric induction; the charging barrel is fed by the film feeding mechanism and penetrates out of the guide feet; Chinese yam slices located on a discharge portion enter the packaging film under the guide of the charging barrel; the packaging film is longitudinally sealed and pressed by a vertical pressing and longitudinal sealing mechanism; the packaging film is transversely sealed and pressed by the transverse sealingmechanism; and the packaging film cut by the transverse sealing mechanism enters the material receiving assembly to complete bag making and packaging. According to the continuous packaging equipment,the operation is simple and convenient, and the production efficiency is improved.

Owner:RUICHANG YURUI IND CO LTD

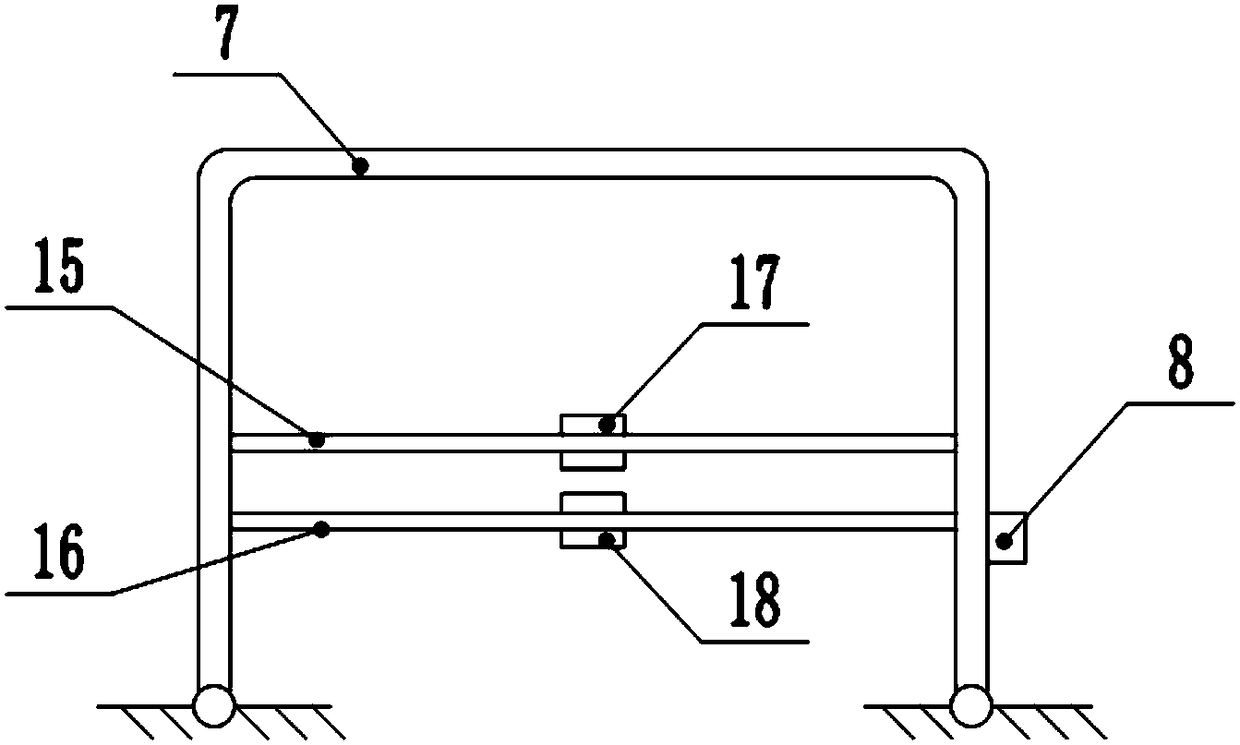

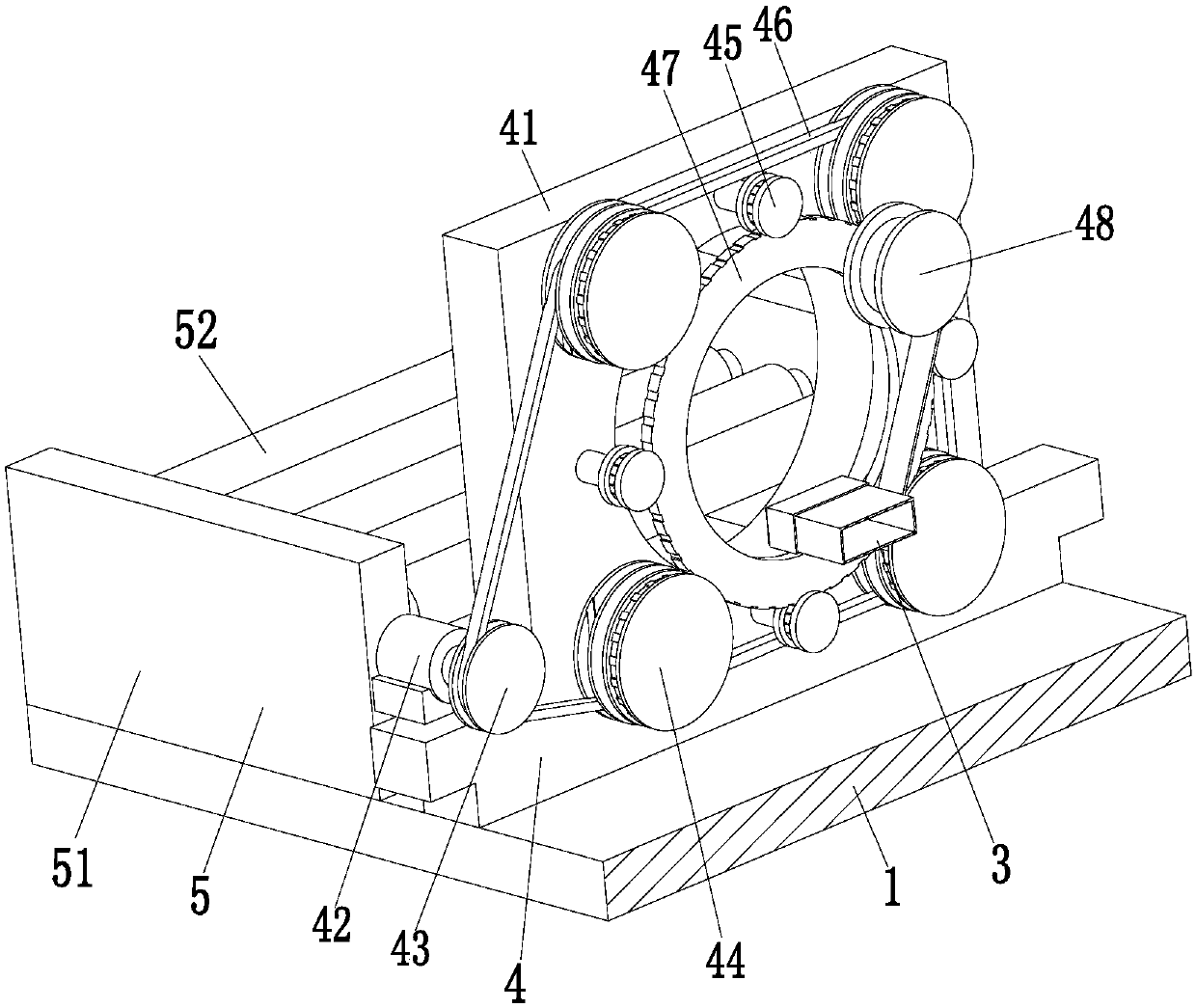

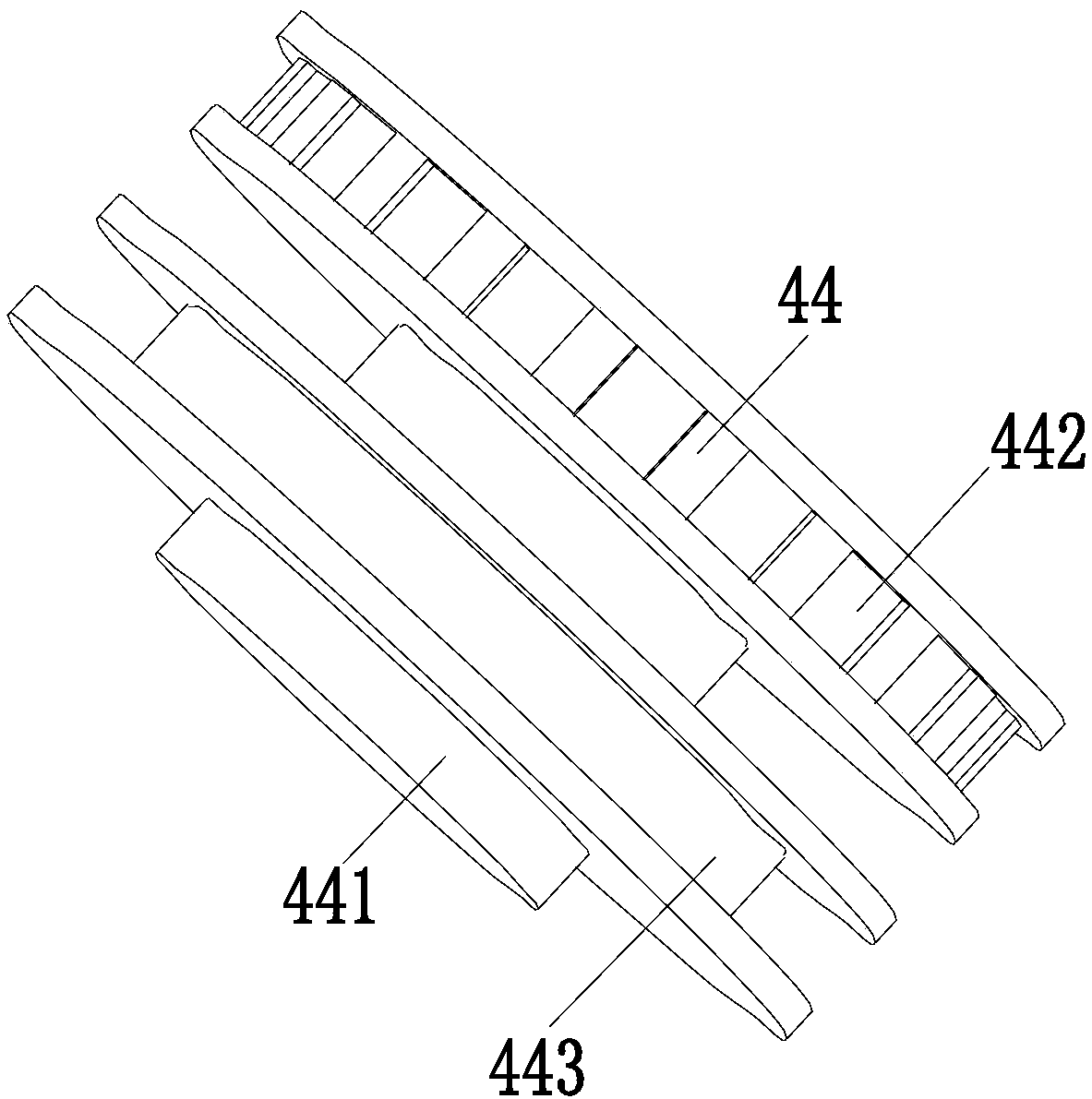

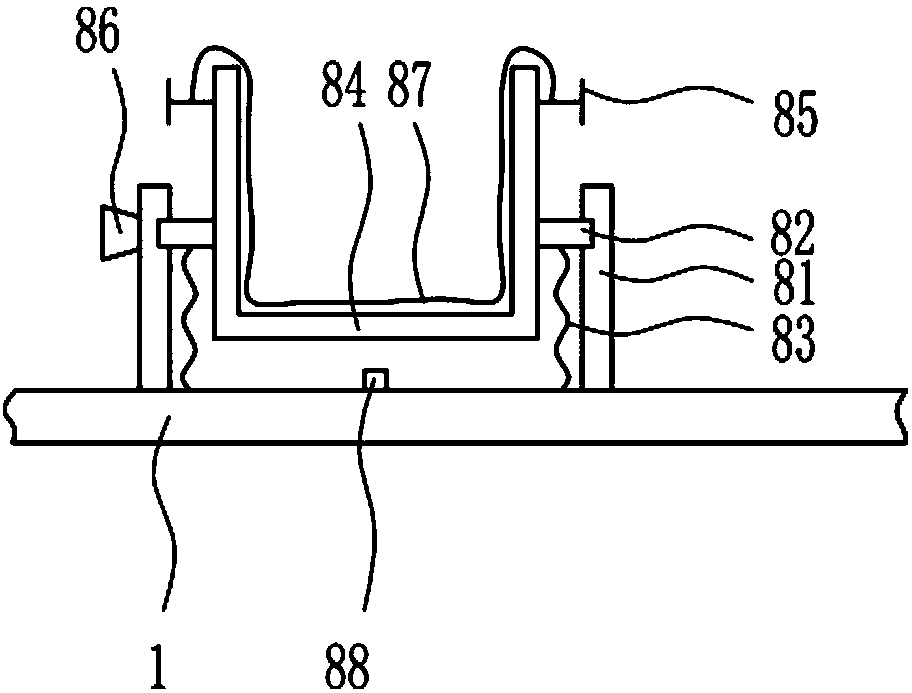

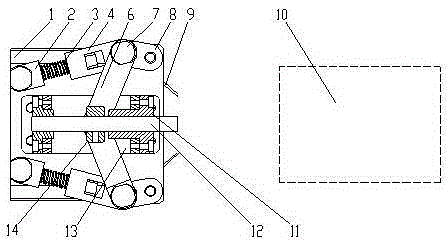

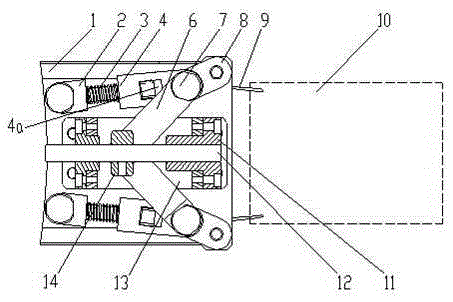

Belt winding device for block packing machine and belt winding method thereof

ActiveCN108438295AEvenly packedTied up firmlyBuilding material packagingBinding material applicationStops deviceEngineering

The invention provides a belt winding device for a block packing machine and a belt winding method thereof, belongs to the technical field of construction material production, and solves such problemsas discontinuous packing of a belt winding device of a traditional block packing machine. The belt winding device comprises a packing device; the packing device comprises a belt loading device, a belt clamping device, a belt stop device, a belt return device, a buckling device and a belt cutting device; a belt winding rail is arranged on the packing device; the belt clamping device can move alongthe belt winding rail; the belt stop device is arranged along the belt winding rail; the belt loading device outputs binding belts; the belt clamping device clamps the binding belts, moves along thebelt winding rail, and hangs the binding belts on the belt stop device; the belt return device reversely transmits the binding belts; the buckling device buckles the binding belts; the belt cutting device cuts off the binding belts; the packing device is provided with a belt clamping rail; the belt clamping rail is connected with the belt winding rail; the belt clamping device comprises two belt clamping heads; and the belt clamping rail is provided with a belt clamping position and an ending position. The belt winding device has the advantages of continuous packing and the like.

Owner:杭州径缘新型墙体材料有限公司

An automatic reversing device for packing boxes

ActiveCN109279063BTroubleshoot technical problems with flippingReduce usagePackagingControl engineeringPaperboard

The invention provides an automatic reversing device of a packaging box. The automatic reversing device comprises a packaging conveying line, a support, a driving motor, a main shaft, a friction mechanism, a self-rotation mechanism, a turnover mechanism and an auxiliary turnover mechanism, wherein the driving motor is installed at the top of the support, the main shaft is driven by the driving motor to rotate, the friction mechanism is installed on the main shaft, the self-rotation mechanism is used for driving the friction mechanism to rotate. A driving motor is used for driving a friction assembly to rotate by the automatic reversing device, self-rotation of a friction roller is utilized in a revolution process of the friction assembly, friction limitation is carried out on the packagingbox, so that the packaging box is prevented from being separated from a packaging conveying line due to centrifugal force in a direction turning process; meanwhile, rolling wheels are driven to rotate by means of autorotation of the friction roller, so that a paper board of the packaging box can be folded and reinforced; the technical problem that the paper board at the top of the packaging box is turned over in the reversing process is solved, the use of a group of turnover paper board device can be reduced, so that the structure of equipment is optimized; and meanwhile, the paper board is automatically turned over in the process of conveying the packaging box, so that the working efficiency is improved.

Owner:NANTONG SHENGYANG METAL PROD CO LTD

Seedling block moisturizing seedling disc for hand-operated rice transplanter

InactiveCN106612796AMoisturize evenlySmooth hydrationSelf-acting watering devicesTransplantingGraduated cylinderWater storage tank

A seedling block moisturizing seedling disc for a hand-operated rice transplanter comprises a seedling disc and a liquid storage tank arranged on the back of the seedling disc. A horizontally arranged spraying pipe is arranged on the front side of the upper portion of the seedling disc, and the spraying pipe extends from one side to the other side of the seedling disc, a plurality of spraying holes are formed side by side in the spraying pipe opposite to the seedling disc along the axis of the pipe, the spraying holes are sequentially formed from one end to the other end of the spraying pipe, nozzles are arranged at the positions of the spraying holes, the middle of the spraying pipe is provided with a liquid inlet pipe, a quantification barrel for measuring the spraying amount is arranged below the liquid storage tank, a float valve is arranged at the position of a liquid inlet of the quantification barrel, a water pump is arranged at the position of a liquid outlet of the quantification barrel, the liquid inlet pipe of the spraying pipe is connected with the water pump, a control mechanism for controlling the float valve and the water pump is arranged on one side of the liquid storage tank, and the top of the water storage tank is provided with a starting switch of the control mechanism. The spraying pipe supplements water evenly, the water supplementing amount is calculated through the quantification barrel, an appropriate amount of moisture is supplemented to seedling blocks, and the seedling transplanting quality is improved while it is ensured that the seedling blocks are encased smoothly.

Owner:孙成军

Discarded battery packaging device capable of increasing packaging speed

InactiveCN107933984AEasy to operateReduce the burden onSolid materialPackaging automatic controlEngineeringLoudspeaker

The invention relates to packaging equipment, in particular to a discarded battery packaging device capable of increasing the packaging speed, and aims at achieving the technical purpose of providingpackaging equipment for waste battery landfill treatment, wherein the packaging equipment is capable of conducting uniform packaging and high in packaging speed. To achieve the above technical purpose, the discarded battery packaging device capable of increasing the packaging speed is provided and comprises a bottom plate and the like. A support rod is connected to the left side of the top of thebottom plate, a frame is arranged on the top of the support rod, a first through hole is formed in the lower portion of the right wall in the frame, and a discharging device is arranged at the lower portion of the right side of the frame. A cover plate is connected to the left side of the top in the frame through a hinge connection manner. A handle is arranged at the lower portion of the left sideof the cover plate, and an emptying device is arranged at the center of the top of the bottom plate. Discharging can be better controlled through the discharging device, packaging is more convenientthrough the emptying device, and a loudspeaker can be matched with a switch.

Owner:吴敏

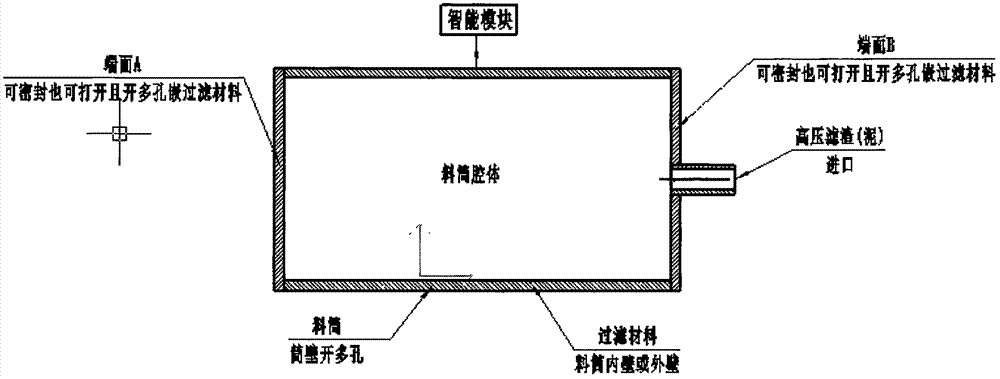

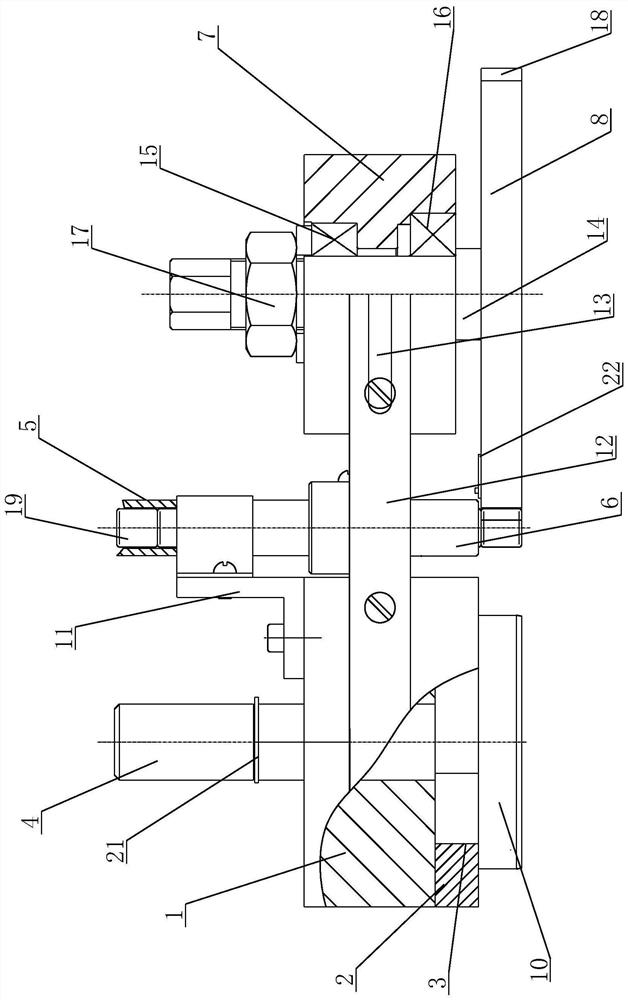

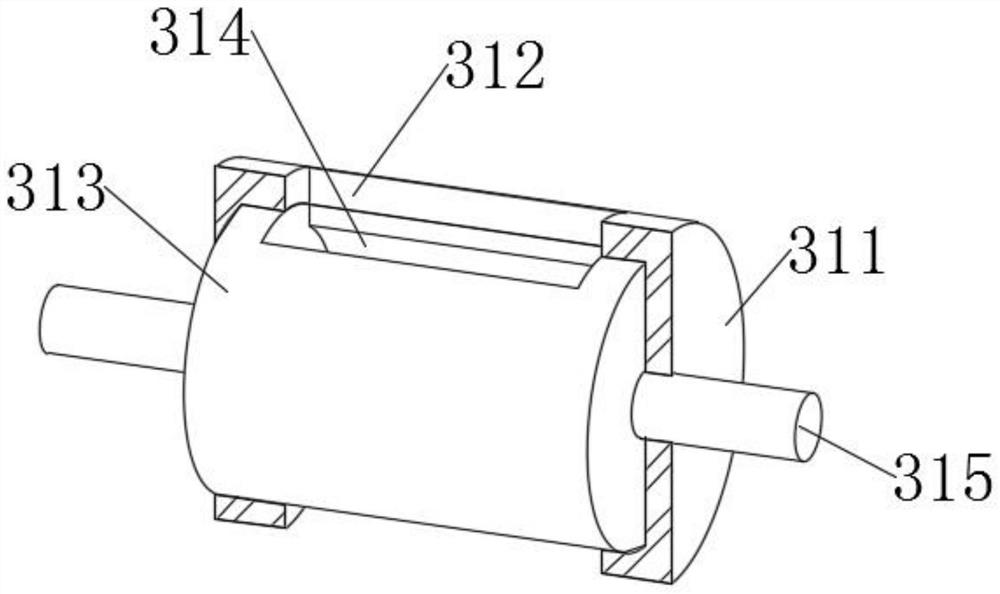

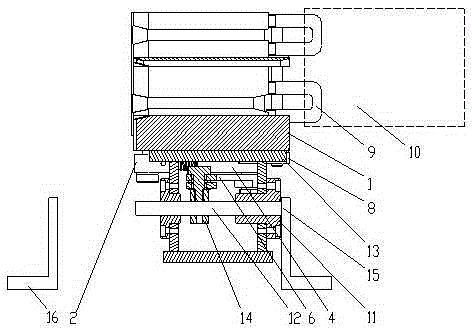

Filter residue (mud) liquid (water) exhaustion briquetting and packing method

InactiveCN106985435ARapid dehydrationEfficient dehydrationPressesPhysical chemistryEnvironmental engineering

The invention provides a filter residue (mud) liquid (water) exhaustion briquetting and packing method. The method comprises an extrusion piston A, an extrusion piston B, a charging barrel, a charging barrel cavity, an intelligent control module and a filter material, or comprises an end surface A, an end surface B, a charging barrel, a charging barrel cavity, an intelligent control module, and a filter material. The charging barrel cavity is fully filled with filter residues (mud) with high liquid (water) content; under the effect of the extrusion piston A, the extrusion piston B or high pressure, the filter residues (mud) with high liquid (water) content in the charging barrel cavity are extruded, and liquid (water) inside is extruded for removal through the filter material to form a massive material with low liquid (water) content and compressive strength; and the intelligent control module is added to realize automatic briquetting and packing of filter residue (mud) liquid (water) exhaustion. Compared with the prior art, the method increases the liquid recovery rate in previous procedures, reduces the transportation quantity and the stacking place, prevents the environmental pollution from the material, needs no airing and baking, saves the energy consumed by drying, and reduces the cost.

Owner:林和军 +4

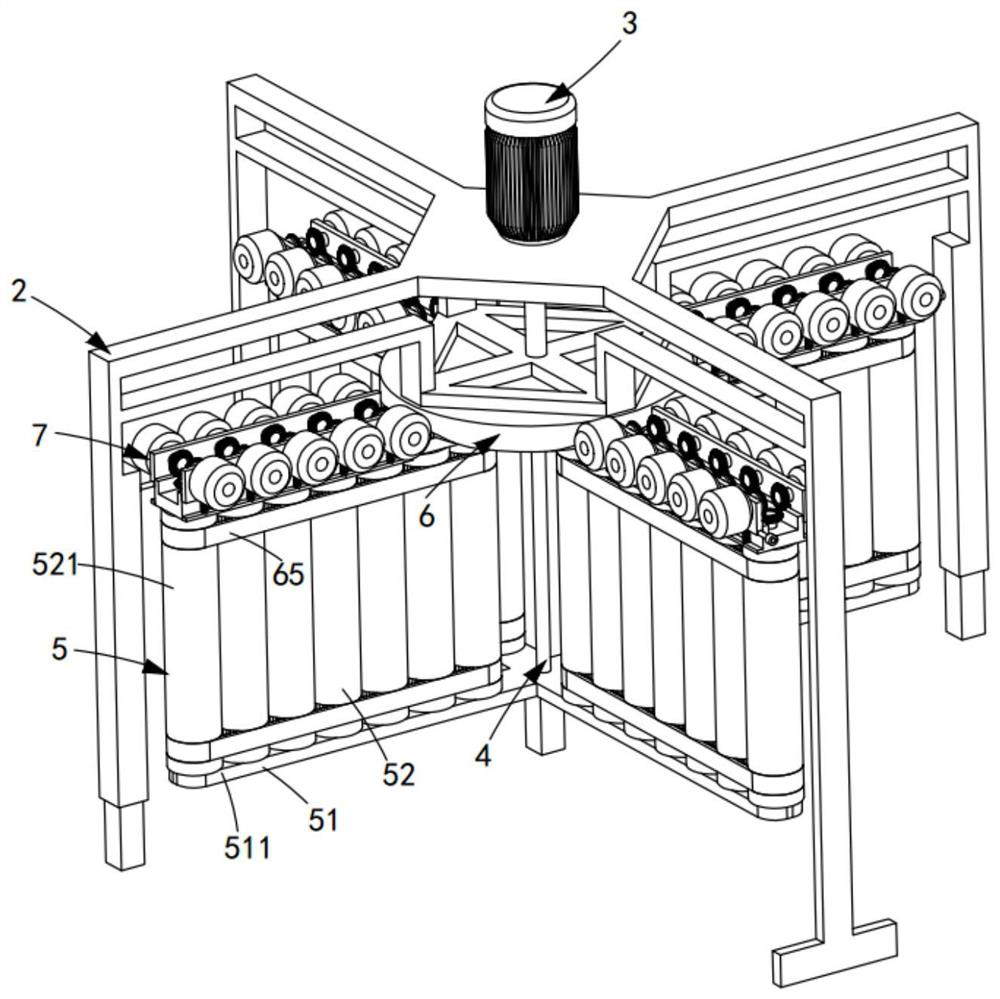

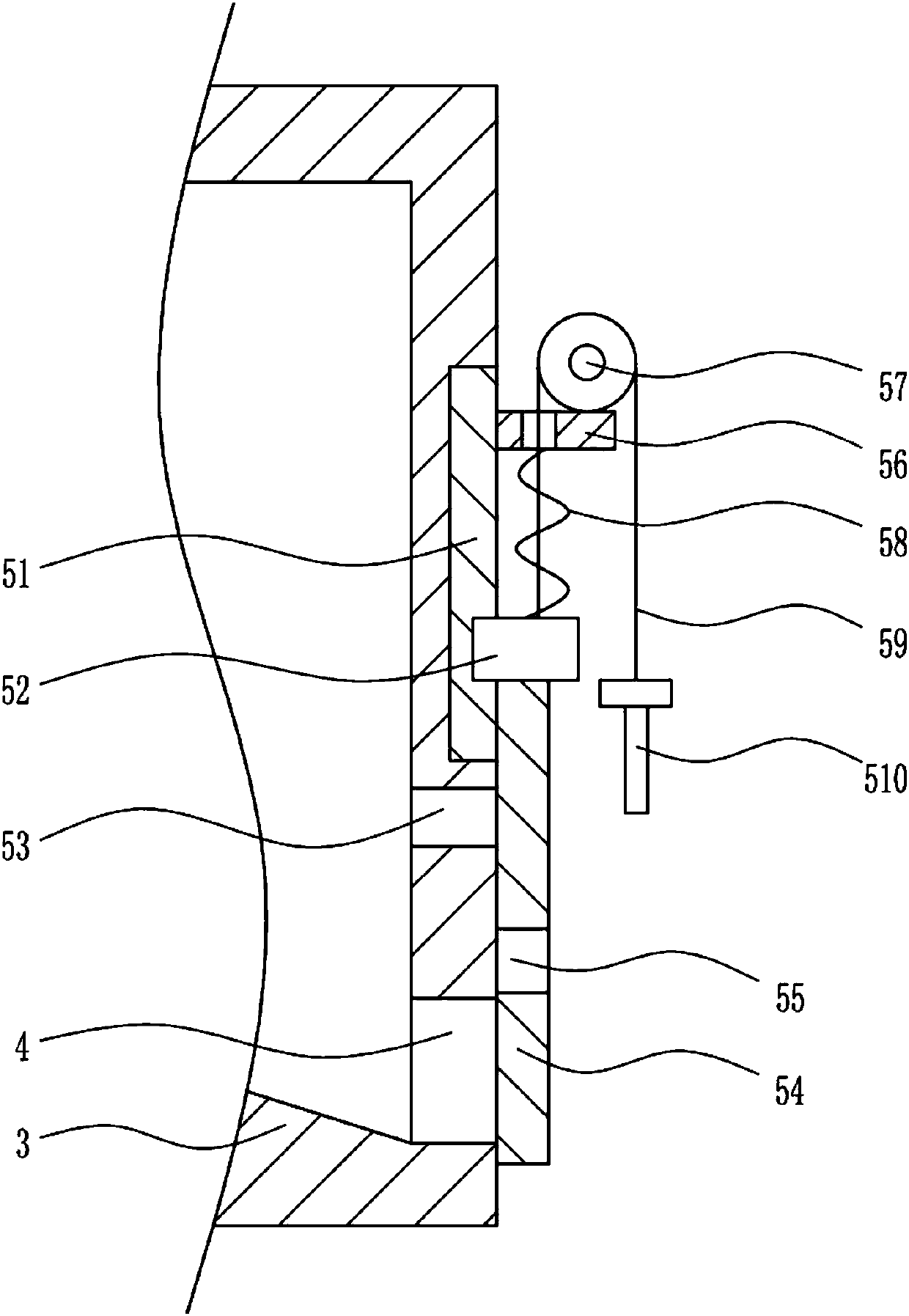

Efficient close-packed feeding mechanism for grinding roller end faces

PendingCN114833717AImprove close packing efficiencyReduce labor intensityGrinding feedersRotational axisEngineering

The efficient close-packed feeding mechanism comprises a positioning seat assembly, a blanking pipe, a blanking adapter pipe, a rotating part and a blanking groove disc, the positioning seat assembly is arranged on a grinding disc, the blanking pipe is vertically fixed to the positioning seat assembly, the top end of the blanking pipe is connected with a vibration hopper, the blanking adapter pipe is connected to the bottom end of the blanking pipe, and the rotating part is connected with the blanking groove disc. The rotating component is fixedly connected with the positioning seat through a connecting plate, a rotating shaft is vertically and upwards arranged in the center of the falling groove disc, the rotating component can be rotationally assembled on the rotating shaft, a plurality of falling grooves are formed in the outer edge of the falling groove disc, and a bottom end opening of the falling adapter is located over the outer edge of the falling groove disc; and a space for placing a roller is defined by the falling groove and the inner wall of the grinding positioning hole. The efficient close-packed feeding mechanism for grinding the end faces of the rollers is simple in structure and ingenious in design; and moreover, the dense arrangement efficiency of grinding the end faces of the small rollers can be greatly improved, the labor intensity of operators is greatly relieved, and dense arrangement is smoother.

Owner:无锡市新裕滚针轴承有限公司

Full-automatic non-woven fabric packaging machine

InactiveCN112357207AEvenly packedImprove cutting effectWrapping material feeding apparatusSevering textilesWoven fabricEngineering

The invention discloses a full-automatic non-woven fabric packaging machine. The machine comprises a working box; the rear portion of the upper end of the working box is fixedly connected with a blanking device; the front portion of the upper end of the working box is fixedly connected with a conveying mechanism; the left portion and the right portion of the upper end of the working box are jointly and fixedly connected with a traction device; a folding device is fixedly connected to the upper portion of the front end of the working box; a longitudinal heat sealing mechanism is fixedly connected to the middle of the front end of the working box; bases are fixedly connected to the left portion and the right portion of the front end of the working box; conveying rods are connected to the middles of the front ends of the bases through bearings; a slitting device is fixedly connected to the lower portion of the front end of the working box; the slitting device is located under the two setsof conveying rods; a control box is fixedly connected to the upper portion of the left end of the working box; and a plurality of sets of control keys are fixedly connected to the upper portion of the working box at equal intervals. According to the full-automatic non-woven fabric packaging machine, raw materials can be equivalently packaged by the whole device, so that products can be uniformlypackaged, and the packaging quality of the products is improved.

Owner:桐城市鸿江包装有限公司

A guide mechanism for material boxing

The invention discloses a material boxing guide mechanism which consists of a feeding plate (1), a supporting rod (4), a connecting rod (6), a short rod (8), a guide plate (9), a supporting shaft sleeve (11), a telescopic shaft (12), a connecting base (13), a connecting block (14), a front impact plate (15) and a rear impact plate (16). The material boxing guide mechanism is characterized in that the guide plate (9) is arranged on the short rod (8), wherein the guide plate (9) moves to the front impact plate (15) along with the telescopic shaft (12) to open lining paper in a packing box at the front end of a feeding mechanism; the telescopic shaft (12) draws back to the rear impact plate (16) to withdraw the guide plate (9) out of the packing box to complete feeding guide. The material boxing guide mechanism is reasonable in design, simple in mechanism and stable in movement; in a boxing and packing process, the lining paper is reliably unfolded in an inner cavity of the packing box to leave a smooth boxing channel, so that the materials are smoothly filled into the box.

Owner:JOYEA CORP

A new type of food packaging machinery and equipment

ActiveCN107902149BSave adjustment timeIncrease productivitySolid materialIndividual articlesMechanical equipmentFood packaging

Owner:汕头市昆士达食品包装机械有限公司

Device for packaging waste batteries

InactiveCN107933983AEasy to operateReduce the burden onSolid materialPackaging automatic controlElectrical batteryEngineering

The invention relates to packaging equipment and particularly relates to a device for packaging waste batteries. The invention aims at providing packaging equipment with uniform packaging and high packaging speed for the burying treatment of the waste batteries. In order to solve the technical problem, the invention provides the device for packaging the waste batteries, which comprises a bottom plate, wherein the top left side of the bottom plate is connected with a support rod, the top of the support rod is provided with a frame body, a first through hole is formed in the lower part of the inner right wall of the frame body, the right lower part of the frame body is provided with a feeding device, the inner top left side of the frame body is connected with a cover plate in a hinge connecting mode, the left lower part of the cover plate is provided with a handle, and the top center of the bottom plate is provided with a discharging device. Through the feeding device, feeding can be better controlled, and through the discharging device, packaging is more conveniently carried out through the cooperation of a horn and a switch.

Owner:吴敏

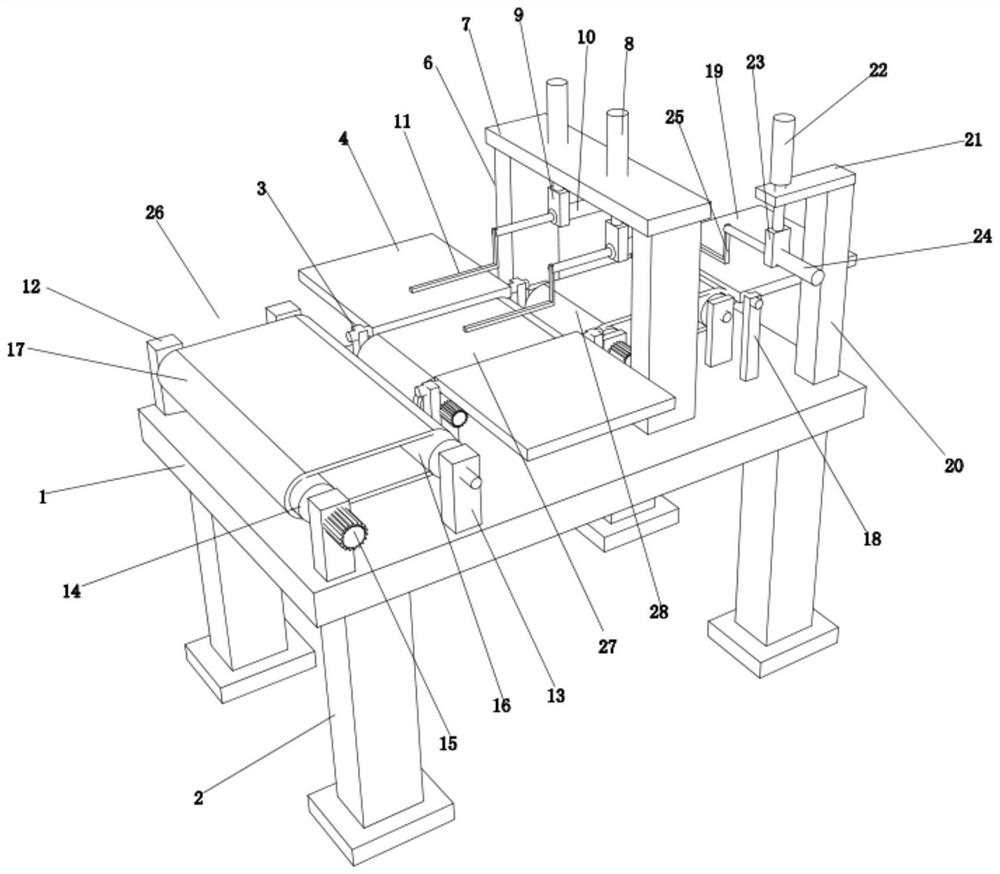

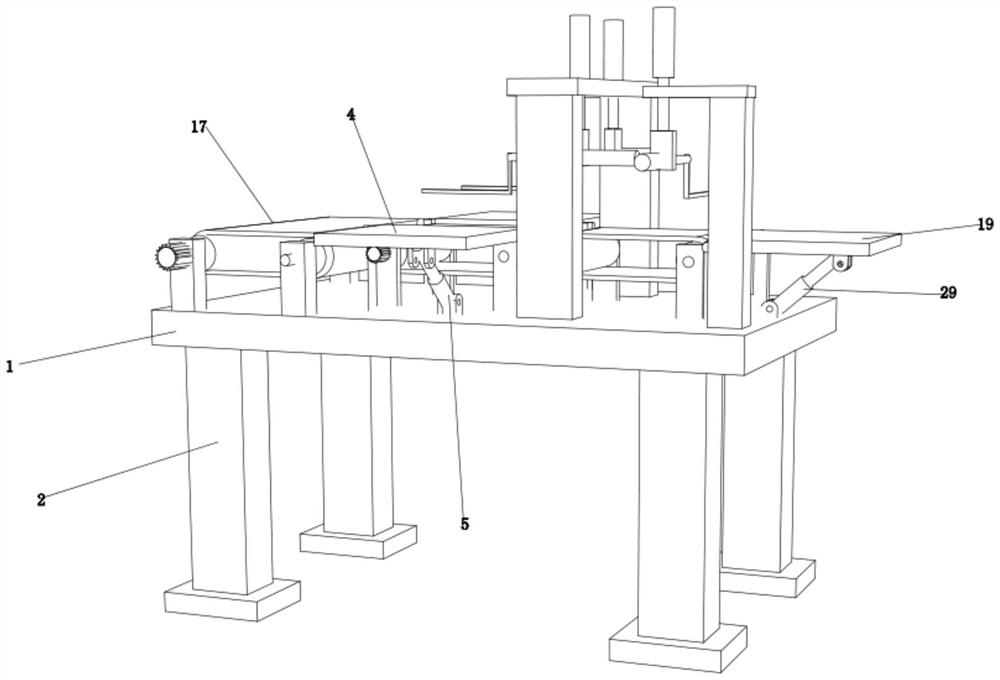

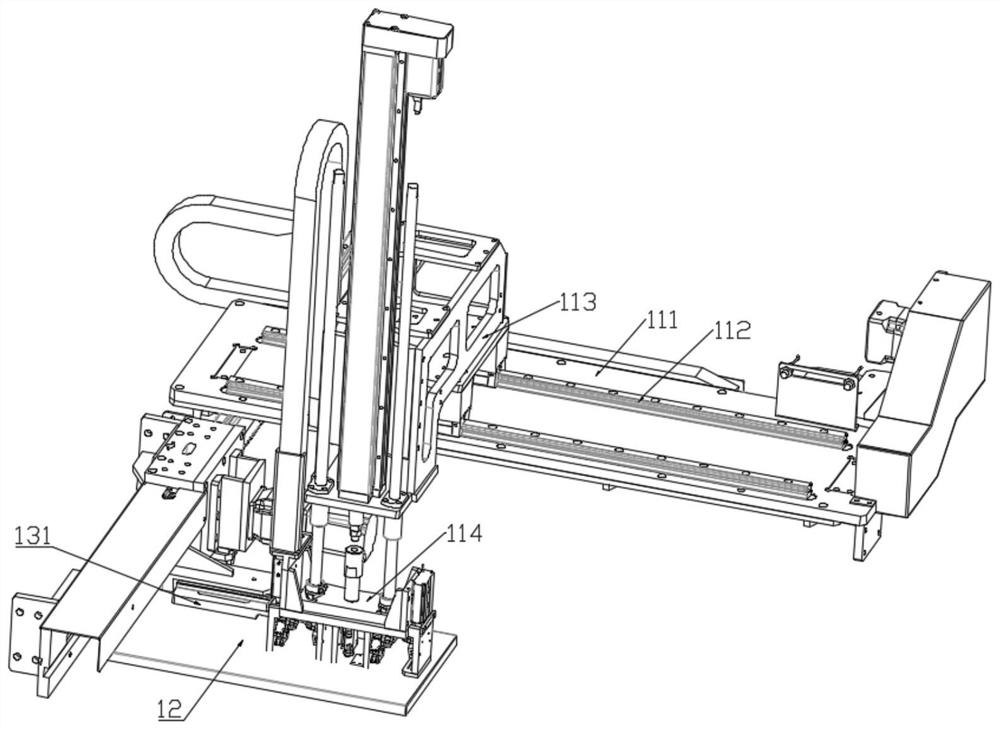

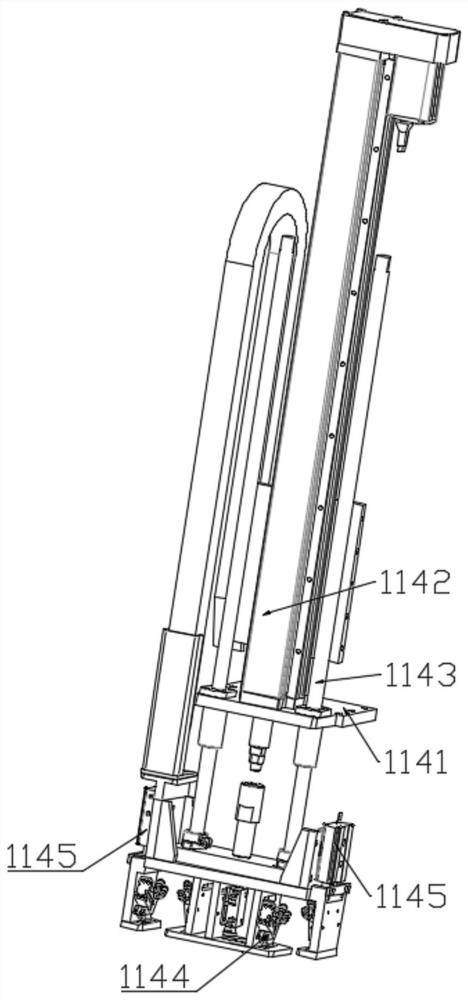

Three-way catalytic converter packaging system

ActiveCN112975376AAutomate the packaging processAccurate packagingAssembly machinesVehicle componentsStructural engineeringMechanical engineering

The invention provides a three-way catalytic converter packaging system. The system comprises a machine table and a liner moving and taking mechanism, a carrier moving and taking mechanism, a wrapping mechanism and a barrel mounting mechanism which are mounted on the machine table, the liner moving and taking mechanism drives a liner to move to the wrapping mechanism, the carrier moving and taking mechanism drives a carrier to move to the liner which firstly reaches the wrapping mechanism, the wrapping mechanism is folded to wrap the liner outside the carrier, and the barrel mounting mechanism pushes the liner and the carrier in the wrapping mechanism into a barrel. According to the system, packaging of the carrier, the liner and the barrel is completed, the carrier is wrapped with the liner, and then the liner and the carrier are pushed into the barrel; and according to the system, automatic packaging can be achieved, packaging is accurate, packaging steps are simplified, packaging efficiency is high, and packaging quality is high.

Owner:江苏首华智能装备有限公司

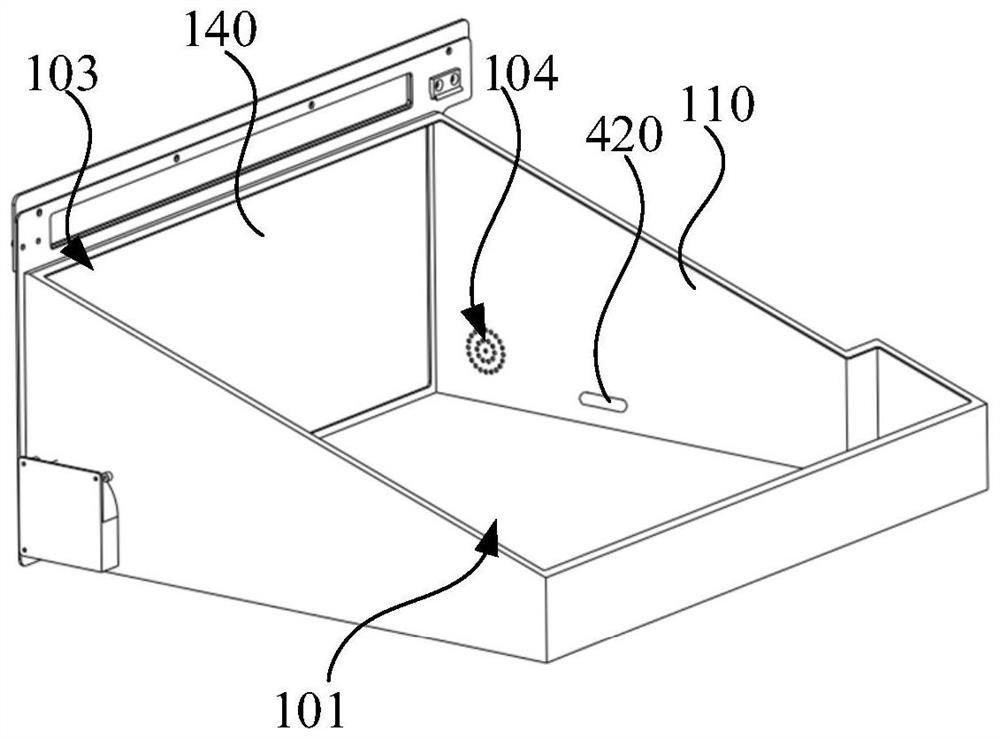

New energy automobile battery installation clamp

InactiveCN114094160ASmooth packingImprove installation efficiencyFinal product manufactureSecondary cells manufactureAutomotive engineeringElectrical battery

The invention discloses a new energy automobile battery installation clamp, and belongs to the technical field of new energy automobiles. The new energy automobile battery installation clamp comprises a shell and an inner loading box arranged in the shell, wherein the inner loading box can vertically slide relative to the shell, bearing plates are arranged on the two sides of the bottom part of the inner loading box, the edge of one side of each bearing plate is pivoted with the inner loading box, and an elastic supporting device is arranged between each bearing plate and the inner loading box, so that the bearing plates are always in a horizontal supporting state when being used for bearing a battery; and the back sides of the bearing plates are connected to the outer shell through linkage devices, when the inner loading box overcomes the acting forces of the elastic supporting devices to continuously move downwards relative to the outer shell, the linkage devices drive the bearing plates to rotate, the bearing plates relieve supporting of the battery, and therefore the battery is released from the inner loading box. According to the new energy automobile battery installation clamp, the batteries can be separately arranged in the battery grooves, so that the installation efficiency of the batteries is improved.

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

Preparation technology of mandarin-orange Pu'er tea

The invention discloses a preparation technology of mandarin-orange Pu'er tea. A mandarin-orange Pu'er tea container is included. The container includes a first cylindrical strip and a second cylindrical strip which are perpendicular, the left side of the first cylindrical strip is provided with a fixed opening, the bottom of the second cylindrical strip is provided with a fixed opening, the topsof the first cylindrical strip and the second cylindrical strip are provided with fixed convex strips respectively, the size of the fixed convex strips is slightly larger than the size of the fixed openings, the first cylindrical strip and the second cylindrical strip are folded 90 degrees, the fixed convex strips are bent and inserted into the fixed openings to achieve occlusion, and the square mandarin-orange Pu'er tea container is formed. According to the method, the mandarin-orange Pu'er tea does not require an outer package, is environmentally friendly, has good taste and aroma, and has the significant effects of invigorating the spleen, nourishing the stomach, clearing heat, removing toxins, reducing phlegm, relieving a cough, reducing lipid and weight, nourishing the skin, resistingatherosclerosis, resisting aging, dispelling the effects of alcohol, regulating qi, nourishing the stomach and resisting haze, the overall package is uniform, and the tea is easily broken for use.

Owner:广东八方茶园茶业有限公司

Garbage device

The invention relates to a garbage device for containing and packaging garbage. The garbage device comprises a garbage ring and a sealing mechanism, wherein the garbage ring comprises a barrel-shapedfilm which is arranged on one side of the sealing mechanism; the sealing mechanism comprises a heating assembly, a baffle and a manual pushing assembly; the manual pushing assembly can drive the baffle to move relative to the heating assembly under the action of external force; when the baffle does not move towards the heating assembly, a hollow part is formed between the baffle and the heating assembly, and the part, penetrating through the hollow part, of a free end of the barrel-shaped film is used for forming a garbage bag for containing the garbage; and when the manual pushing assembly drives the baffle to make the barrel-shaped film in contact with the heating assembly, the barrel-shaped film is thermally cut and sealed. According to the garbage device, through arranging the manual pushing assembly in the garbage device with the garbage bag exposed to the external space, the interaction between people and the device is enhanced, the instability of the intelligent device is avoided, and the consumption of resources and cost is reduced.

Owner:深圳市袋鼠易收科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com