Full-automatic non-woven fabric packaging machine

A fully automatic, cloth-wrapped technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of affecting product packaging, poor product effect, and non-combustibility, so as to improve folding effect, good cutting effect, and improve The effect of packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A fully automatic non-woven packaging machine, such as figure 1As shown, it includes a working box 1, the middle part of the right end of the working box 1 is movably connected with a box door 2 through a hinge, the upper end of the working box 1 is fixedly connected with a blanking device 3 at the rear, and the upper end of the working box 1 is fixedly connected with a conveying mechanism 4 at the front. The left part of the upper end of the working box 1 and the right part of the upper end are jointly fixedly connected with a traction device 5, the upper part of the front end of the working box 1 is fixedly connected with a folding device 6, the middle part of the front end of the working box 1 is fixedly connected with a longitudinal heat sealing mechanism 7, and the left part of the front end of the working box 1 The base 8 is fixedly connected with the right part of the front end, the bearing in the middle part of the front end of the base 8 is connected with the tr...

Embodiment 2

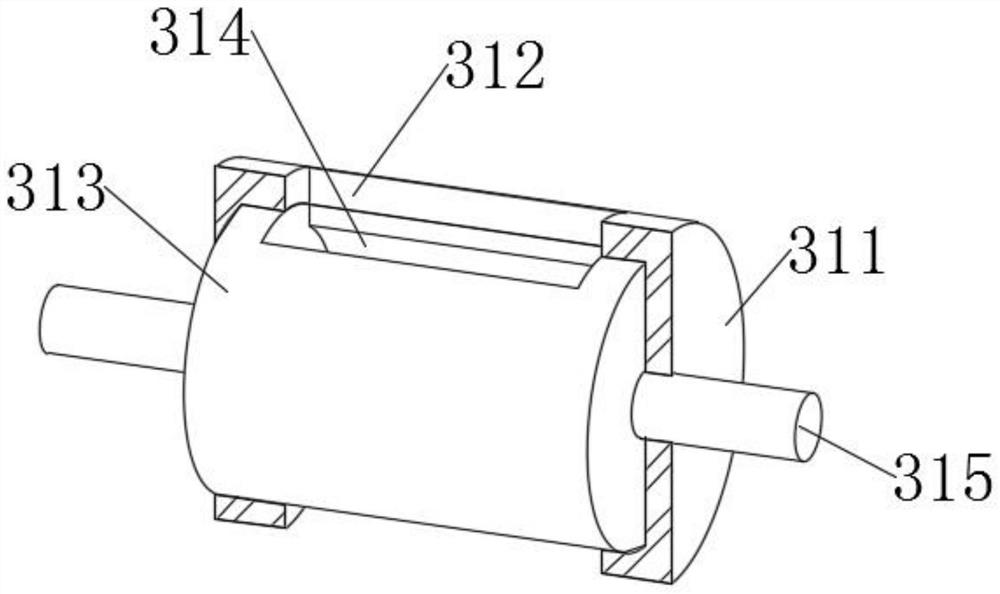

[0037] On the basis of Example 1, as Figure 2-4 As shown, a fully automatic non-woven packaging machine includes a working box 1, the middle part of the right end of the working box 1 is movably connected with a box door 2 through a hinge, the upper end of the working box 1 is fixedly connected with a feeding device 3 at the rear, and the working box 1 The front part of the upper end is fixedly connected with a conveying mechanism 4, the left part of the upper end of the working box 1 and the right part of the upper end are jointly fixedly connected with a traction device 5, the upper part of the front end of the working box 1 is fixedly connected with a folding device 6, and the middle part of the front end of the working box 1 is fixedly connected with a longitudinal heat sink. Sealing mechanism 7, the left part of the front end of the working box 1 and the right part of the front end are all fixedly connected with the base 8, the bearing in the middle part of the front end ...

Embodiment 3

[0040] On the basis of Example 1, as Figure 5-8 As shown, a fully automatic non-woven packaging machine includes a working box 1, the middle part of the right end of the working box 1 is movably connected with a box door 2 through a hinge, the upper end of the working box 1 is fixedly connected with a feeding device 3 at the rear, and the working box 1 The front part of the upper end is fixedly connected with a conveying mechanism 4, the left part of the upper end of the working box 1 and the right part of the upper end are jointly fixedly connected with a traction device 5, the upper part of the front end of the working box 1 is fixedly connected with a folding device 6, and the middle part of the front end of the working box 1 is fixedly connected with a longitudinal heat sink. Sealing mechanism 7, the left part of the front end of the working box 1 and the right part of the front end are all fixedly connected with the base 8, the bearing in the middle part of the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com