Beneficiation method of vanadium-titanium magnetite concentrate

A technology of vanadium-titanium magnetite concentrate and beneficiation method, which is applied in chemical instruments and methods, wet separation, solid separation and other directions, can solve the problems of high cost, difficult to effectively remove titanium in the crystal lattice, complicated process, etc. The effect of improving flotation performance, maintaining activity stability, and improving cleavage activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

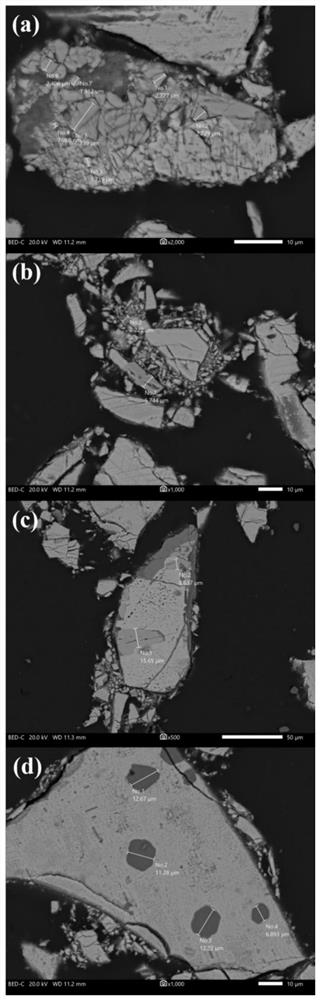

[0049] Fe grade 54.61%, TiO 2 The vanadium-titanium magnetite concentrate I with a grade of 14.42% was tested.

[0050] Mix the vanadium-titanium magnetite I with 0.1M sodium hexametaphosphate aqueous solution to make a slurry with a concentration of 40%, and then spray it into the grinding equipment under 20MPa high pressure for grinding, and the grinding particle size is below 5 microns. The proportion accounts for more than 95%. The fine ore after grinding enters the magnetic separation process for magnetic separation, and the magnetic field strength is 0.8T. Obtain vanadium-titanium magnetite concentrate II and titanium-rich titanium rough ore; the Fe grade of vanadium-titanium magnetite concentrate II is 63.25%, and the recovery rate is 86.34%;

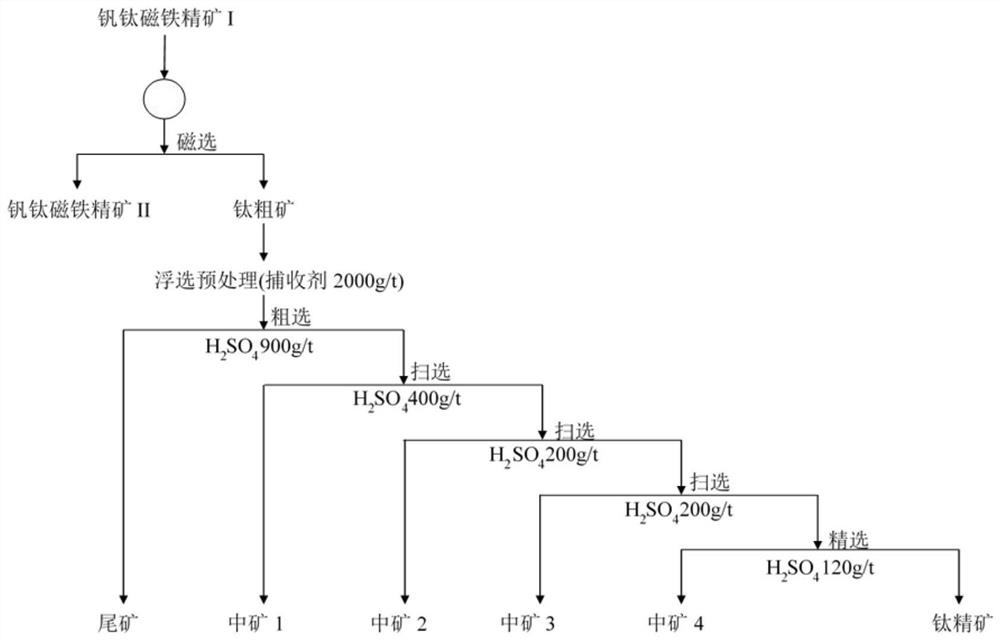

[0051] Pretreatment and flotation of titanium-rich titanium ore:

[0052] Disperse titanium-rich coarse titanium ore in a solution containing collector (styrene phosphoric acid; 2000g / t) to obtain pulp 2; spray pulp 2, and flo...

Embodiment 2

[0054] In order to explore the effect of ultra-fine grinding particle size on the separation efficiency of iron and titanium, we take the grade of Fe obtained after process separation as 54.53% and TiO 2 The grade of 15.34% iron concentrate I is mixed with 0.1M sodium hexametaphosphate aqueous solution to make a slurry with a concentration of 40%, and then sprayed into the grinding equipment under 20MPa high pressure for grinding, and the grinding particle size is variable. The products after grinding are screened into five different particle size groups (see Table 1), and then enter the magnetic separation process for magnetic separation with a magnetic field strength of 0.8T. Obtain vanadium-titanium magnetite concentrate II and titanium-rich titanium rough ore; the titanium-rich titanium rough ore is pretreated and flotation (same as embodiment 1):

[0055] The magnetic separation results are shown in Table 1.

[0056] Table 1 embodiment 2 selection results

[0057]

...

Embodiment 3

[0062] In order to explore the effect of magnetic field strength on the separation efficiency of iron and titanium, we take the grade of Fe obtained after process selection as 53.99% and TiO 2 The vanadium-titanium magnetite concentrate I with a grade of 14.86% is mixed with 0.1M sodium hexametaphosphate aqueous solution to make a slurry with a concentration of 40%, and then it is sprayed into the grinding equipment under 20MPa high pressure for grinding, and the grinding particle size is -5 micron, enter into magnetic separation process then and carry out magnetic separation, and magnetic field intensity is variable (seeing table 2).

[0063] Obtain the vanadium-titanium magnetite concentrate II and the titanium-rich titanium rough ore; the titanium-rich titanium rough ore is subjected to pretreatment and flotation (same as Example 1). The selection process is as follows figure 2 shown.

[0064] Table 2 embodiment 3 selection results

[0065]

[0066]

[0067] As ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com