Plasma-assisted method for catalyzing nitrogen activation dissociation by metal cluster

A technology of metal plasma and nitrogen, which is applied in the field of cluster science, can solve the problems of difficult activation and dissociation of nitrogen, unfavorable environmental protection, harsh reaction conditions, etc., and achieve the effect of optional metal targets, easy operation, and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) At room temperature, use a mechanical pump and a molecular pump to pump the air pressure of the cluster beam source cavity and the mass spectrometry detection vacuum chamber to 10 -5 below pa;

[0035] (2) Turn on the laser and preheat it, put the prepared 10.0atm N 2 / He gas mixture (N 2 The volume percent concentration is 5%) into the pipeline connected with the intake valve;

[0036] (3) Add voltage to the accelerating electric field in the mass spectrometer, reflected electric field and microchannel plate detector, microchannel plate voltage 2050V, accelerating electric field electrode voltage 2685V, 1500V, reflected electric field electrode voltage 2805V, 1575V;

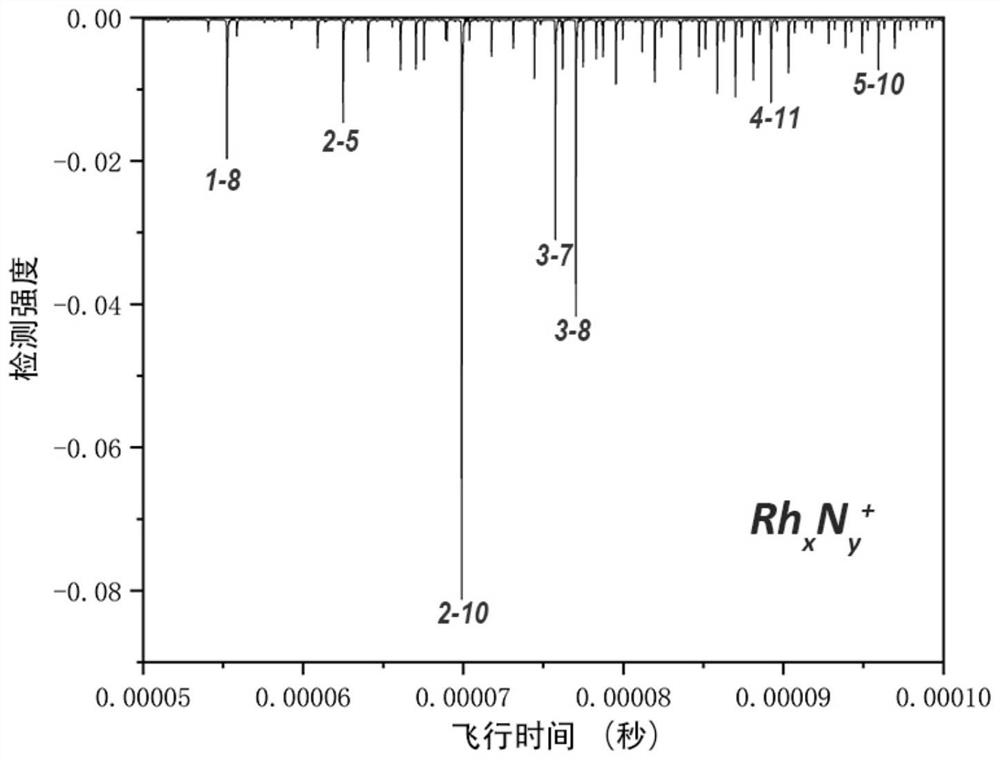

[0037] (4) Set the pulse width of the carrier gas pulse valve to 235 μs and open it. At this time, the pressure of the cluster beam source cavity is 3.9×10 -3 Pa, the pressure of the mass spectrometry vacuum chamber is 1.1×10 -5 Pa; turn on the motor to make the rhodium target rotate at a constant...

Embodiment 2

[0043] (1) At room temperature, use a mechanical pump and a molecular pump to pump the air pressure of the cluster beam source cavity and the mass spectrometry detection vacuum chamber to 10 -5 below pa.

[0044] (2) Turn on the laser and preheat it, put the prepared 10.0atm N 2 / He gas mixture (N 2 The volume percent concentration is 5%) into the pipeline connected with the intake valve;

[0045] (3) Add voltage to the accelerating electric field in the mass spectrometer, reflected electric field and microchannel plate detector, microchannel plate voltage 1950V, accelerating electric field electrode voltage 2685V, 1500V, reflected electric field electrode voltage 2805V, 1575V;

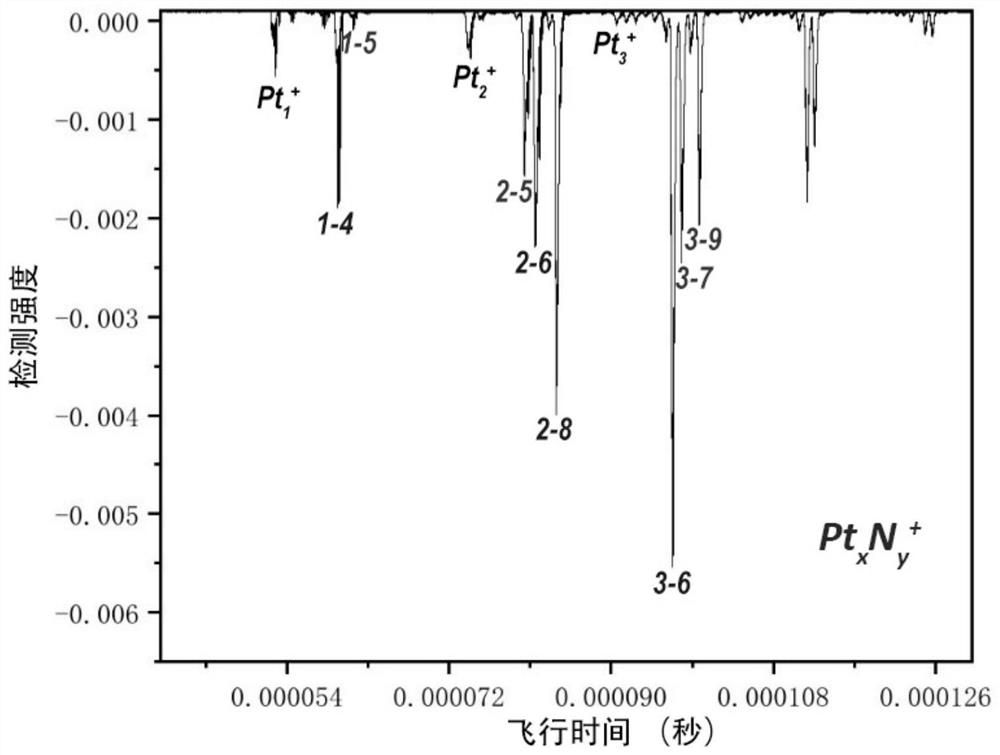

[0046] (4) Set the pulse width of the carrier gas pulse valve to 230 μs and open it. At this time, the pressure of the cluster beam source cavity is 3.0×10 -3 Pa, the pressure of the mass spectrometry vacuum chamber is 1.1×10 -5 Pa, turn on the motor to make the platinum target rotate at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com