Washing machine control method and washing machine

A control method and washing machine technology, applied in the field of washing machines, can solve the problems of large error, inability to judge the dirtyness of washing water, inaccurate turbidity of clean water, etc., and achieve the effects of accurate detection and judgment and expansion of detection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

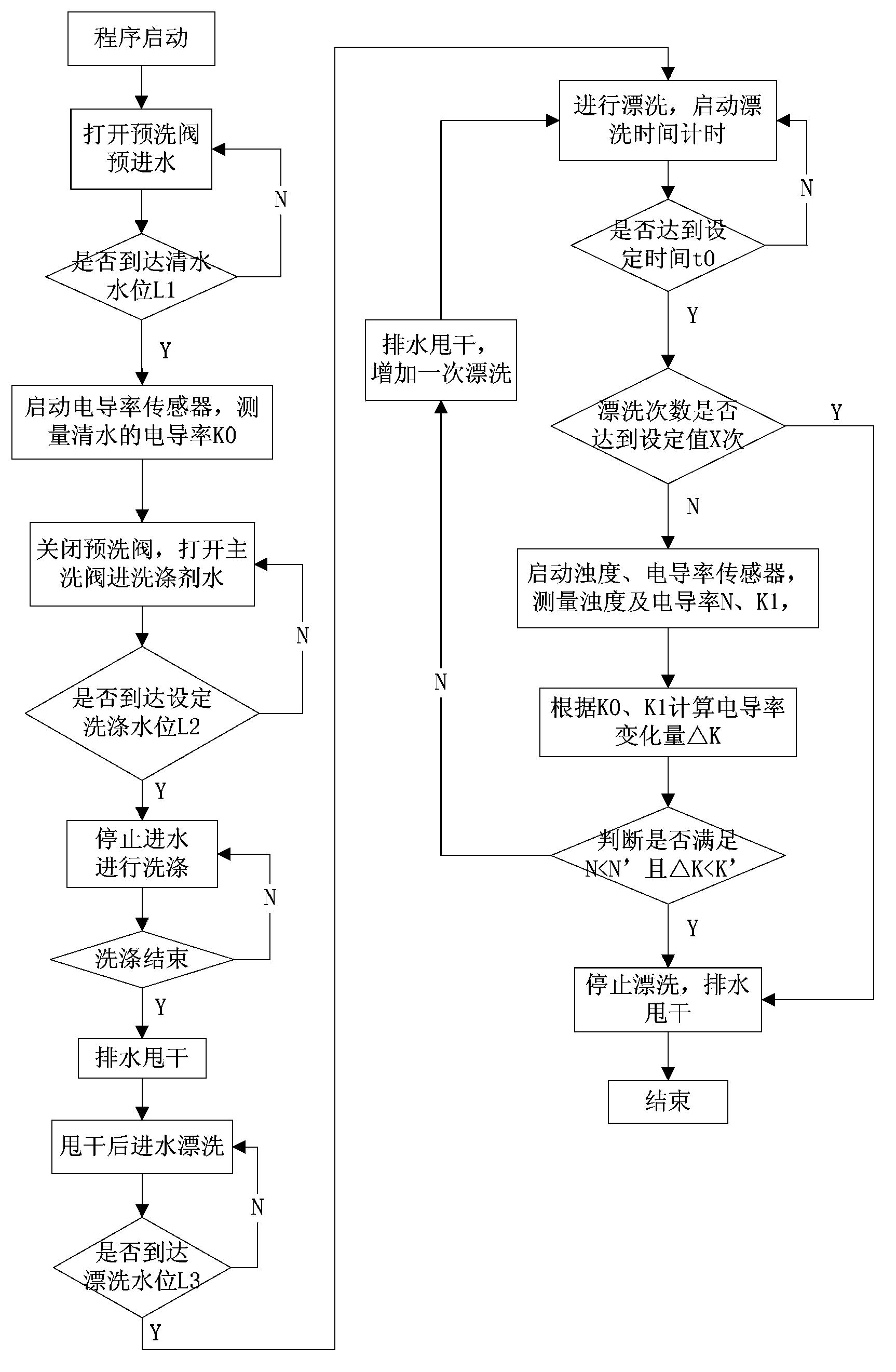

[0038] The washing machine of the present invention can detect whether the rinsing is clean, whether stains, detergents, washing powder, and softener remain. By detecting the conductivity and turbidity value of the water, it can be judged whether the laundry additives have residuals.

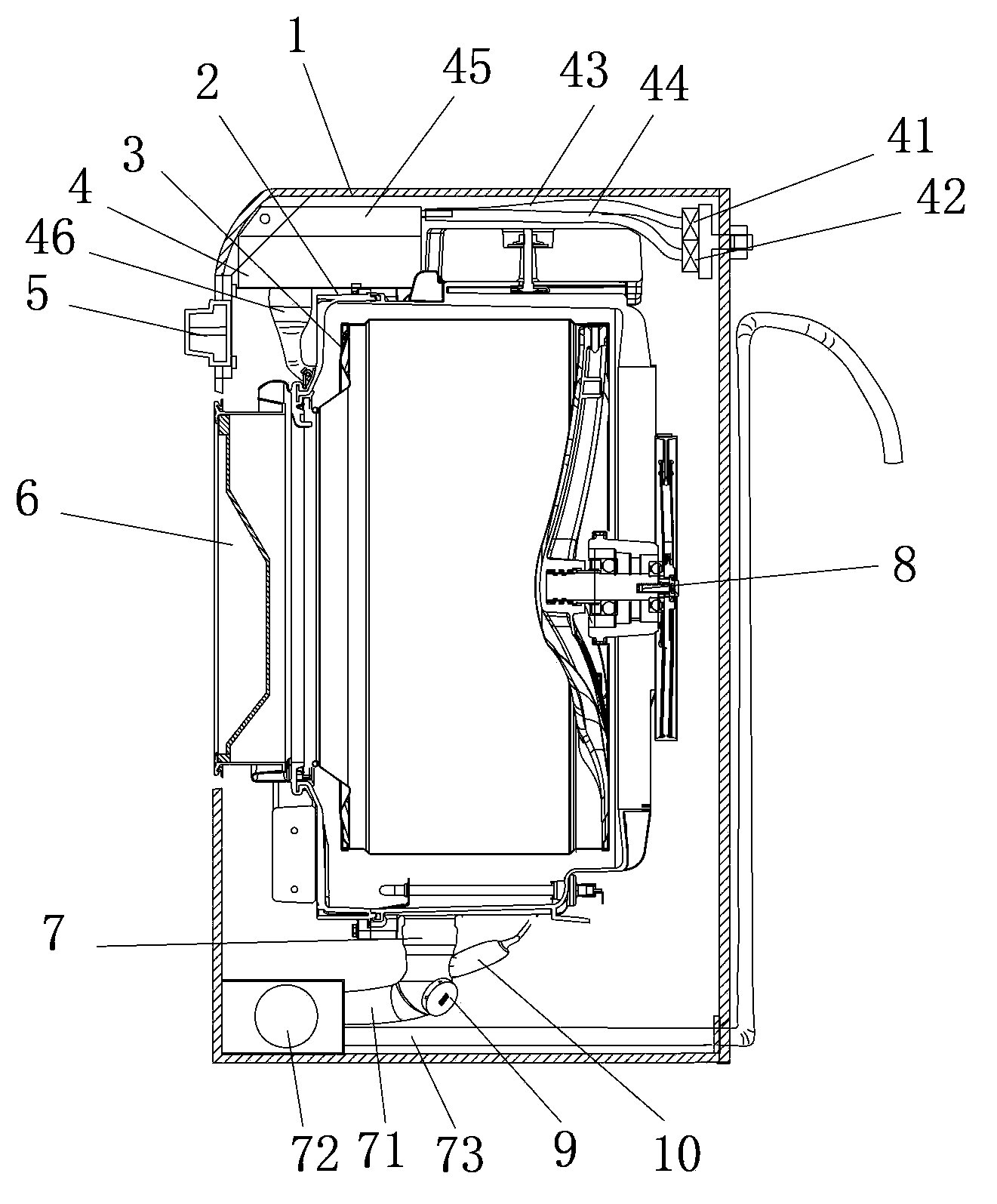

[0039] Such as figure 1 As shown, the washing machine of the present invention includes: a box body 1, an outer tube 2, an inner tube 3, a water inlet system 4, a computer board controller 5, a door cover 6, a drainage system 7, a motor drive device 8, and other components. The water inlet system 4 includes a prewash valve 41, a main wash valve 42, a prewash water inlet pipe 43, a main wash water inlet pipe 44, a detergent box 45, and a water inlet hose 46. The pre-wash valve 41 communicates with the cavity of the detergent box 45 through the pre-wash water inlet pipe 43, and no laundry additives can be placed in the cavity of the detergent box 45, and communicates with the outer cylinder 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com