High-performance polyester composite elastic fiber and manufacturing method thereof

A composite elastic fiber and composite fiber technology, applied in cationic dyeable elastic composite fiber and its manufacturing field, can solve the problems of non-coloring of PET components, PET does not have cationic dyeability, performance impact, etc., and achieve cationic dyeability Excellent, excellent wrinkle resistance and shape retention, the effect of overcoming insufficient coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

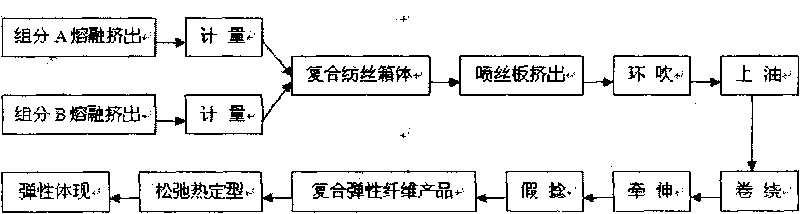

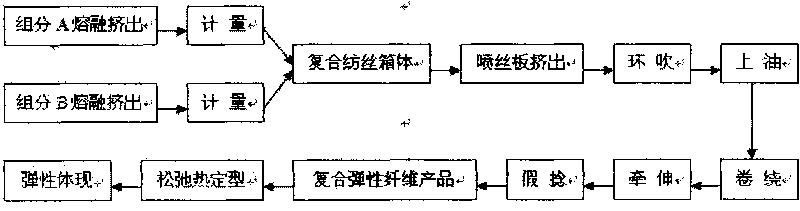

Method used

Image

Examples

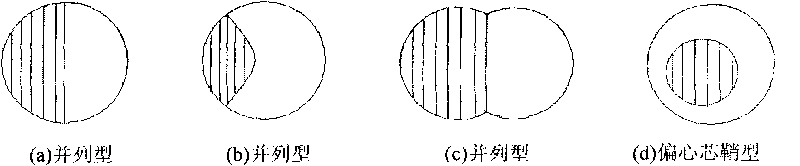

Embodiment 1

[0019] The CDP component A with an intrinsic viscosity of 0.58dL / g and the CDP component B that has been viscosified to 0.80dL / g in the solid phase, the weight ratio of the two is 30:70, and the composite spinning is carried out in a parallel structure, and the spinning The temperature is 280°C, and the fiber is dry-heated at 150°C to obtain a cationic dyeable composite elastic fiber with excellent properties. The crimp stretch rate is 35%, the crimp elastic recovery rate is 80%, and the dyeable temperature is 130°C. The results are shown in Table 1.

Embodiment 2

[0021] The CDP component A with an intrinsic viscosity of 0.70dL / g and the CDP component B with a solid phase viscosity increased to 1.05dL / g, the weight ratio of the two is 70:30, and composite spinning is carried out according to the eccentric core-sheath structure, The spinning temperature was 288°C, and the fiber was treated with heat and humidity at 90°C to obtain a cationic dyeable composite elastic fiber with excellent performance. The crimp stretch rate was 42%, the crimp elastic recovery rate was 71%, and the dyeable temperature was 130°C. The results are shown in Table 1 .

Embodiment 3

[0023] The CDP component A with an intrinsic viscosity of 0.60dL / g and the CDP component B with a solid phase viscosity increased to 1.10dL / g, the weight ratio of the two is 40:60, and the composite spinning is carried out in a parallel structure, and the spinning The temperature is 290°C, and the fiber is dry-heated at 150°C to obtain a cationic dyeable composite elastic fiber with excellent properties. The crimp stretch rate is 53%, the crimp elastic recovery rate is 79%, and the dyeable temperature is 130°C. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com