Method for multifunctional sorting of textile by using graphene oxide derivative

A derivative, graphene technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve problems such as affecting the wearability of fabrics, and achieve the effects of easy operation, broad application prospects, and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

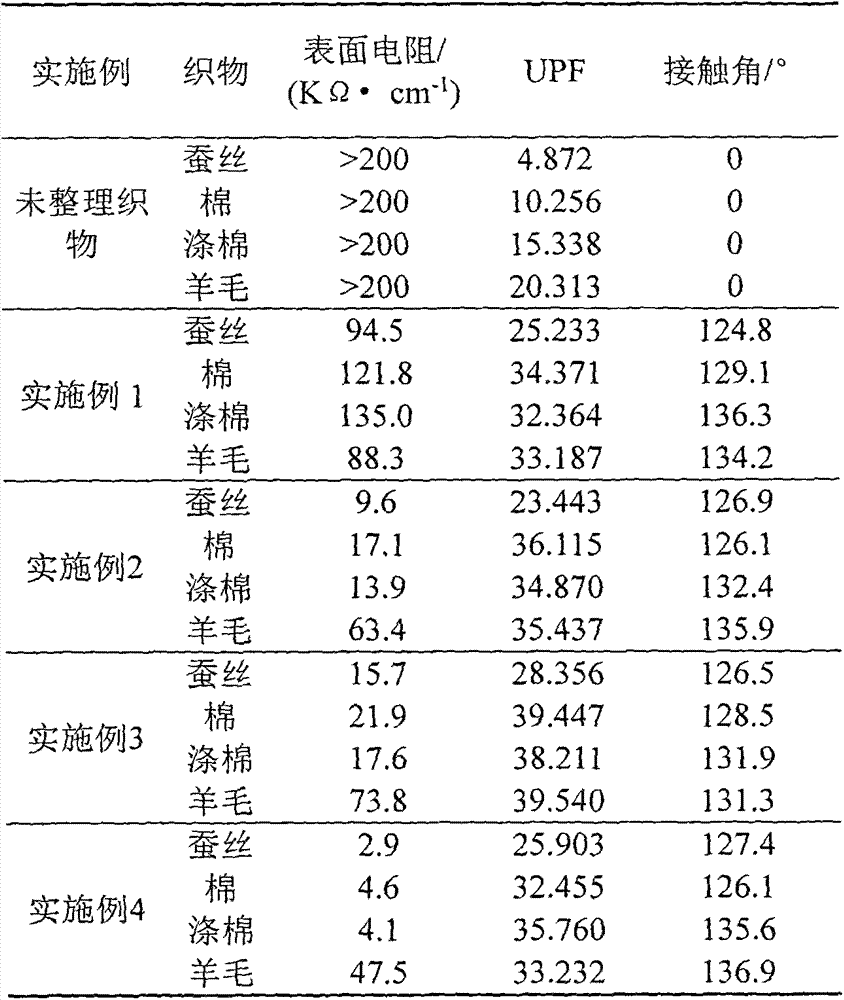

Embodiment 1

[0022] A kind of graphene oxide derivative is used for the method of multifunctional finishing of textiles, and its process is as follows:

[0023] Add 0.5 parts by mass of graphene oxide or its derivatives, 0.2 parts by mass of sodium dodecylbenzenesulfonate, and 10 parts by mass of urea into the aqueous solution, and ultrasonically react for 1 hour at 20°C and 600W power, and dissolve the above solution Place it under ultraviolet light with a light intensity of 100W / cm and a wavelength of 365nm for 10 minutes, soak the fabric in the above pH 4 solution for 1 hour, then dry the fabric at 80°C for 1 hour, and soak the dried fabric in Reduction was carried out in 0.5% hydrosulfite solution, the reduction temperature was 90°C, the reduction time was 1 h, and finally washed and dried to obtain a graphene self-assembled flexible conductive fabric, which has good conductivity, UV resistance and water repellency.

Embodiment 2

[0025] A kind of preparation method of graphene conduction, anti-ultraviolet, water-repellent multifunctional fabric, its process is as follows:

[0026] Add 0.8 parts by mass of graphene oxide or its derivatives, 0.4 parts by mass of sodium dodecylsulfonate, and 20 parts by mass of ammonia water to the aqueous solution, and ultrasonically react for 0.6h at 30°C and 800W power, and the above solution Place it under ultraviolet light with a light intensity of 80W / cm and a wavelength of 365nm for 20min, soak the fabric in the above pH 6 solution for 2h, then dry the fabric at 60°C for 2h, and dip the dried fabric into 0.4% sodium hydrosulfite solution for reduction, reduction temperature 95 ° C, reduction time 0.5h, finally washed, dried, repeat the above steps 5 times, to obtain graphene self-assembled flexible conductive fabric, and has good conductivity, anti-ultraviolet and Water repellent function.

Embodiment 3

[0028] A kind of preparation method of graphene conduction, anti-ultraviolet, water-repellent multifunctional fabric, its process is as follows:

[0029] Add 0.9 parts by mass of graphene oxide or its derivatives, 0.1 parts by mass of sodium dodecylbenzenesulfonate, and 15 parts by mass of ammonia water to the aqueous solution, and ultrasonically react for 2 hours at 40°C and 600W power, and the above solution Place it under ultraviolet light with a light intensity of 90W / cm and a wavelength of 365nm for 15 minutes, soak the fabric in the above pH 5 solution for 0.6 hours, then dry the fabric at 70°C for 1 hour, and soak the dried fabric Reduction in 0.4% hydrazine hydrate solution, the reduction temperature is 85°C, the reduction time is 2h, and finally washed and dried, and the above steps are repeated 3 times to obtain a graphene self-assembled flexible conductive fabric, which has good conductivity, UV resistance and Water repellent function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com