Method for producing stretch knit warm fabric with high shape preservation property

A production method and fabric technology, applied in the direction of knitting, weft knitting, fabric surface trimming, etc., can solve the problems of reducing the elasticity and service life of spandex, breaking and falling off of spandex, and reducing the size of clothes, so as to achieve high-quality color fastness, Effect of reducing coil transfer and reducing elastic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A production method of high shape retention elastic knitted warm fabric, comprising the steps of:

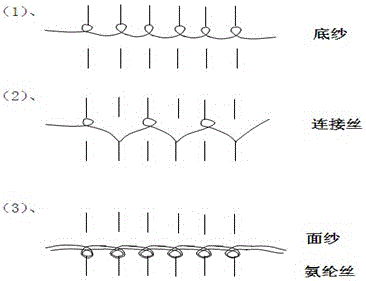

[0028] Woven fabric gray cloth→gray cloth opening→pre-setting→dyeing→pressing water drying cloth→grabbing→setting→scalding→shearing; the weaving method of the fabric gray cloth is as follows: the veil, the bottom yarn, the intermediate connecting yarn and the spandex yarn are passed through the weft Knitted gray fabric is produced by weaving, in which the face yarn is a blended yarn of cotton fiber and viscose fiber, the bottom yarn is DTY fine-denier polyester network low-elastic filament that has been steamed and shaped at a vacuum temperature of 130°C, and the intermediate connecting yarn is DTY polyester Network low elastic yarn, spandex yarn is 20D spandex yarn with 2.5 times of draft; the weaving diagram is as follows figure 1 As shown: the bottom yarn is the reverse side of the gray cloth weaving process, which is a loop structure, and the stitches are full of need...

Embodiment 2

[0044] The difference from Example 1 is that the veil is modal fiber.

[0045] The performance test results of the high shape retention elastic knitted thermal fabric are as follows:

[0046] 1. Elasticity: The elastic elongation in the warp direction is 52%, and the recovery rate is 93%; the elastic elongation in the weft direction is 145%, and the recovery rate is 92%.

[0047] 2. Shrinkage: After washing 10 times, the horizontal shrinkage is -2.8%, and the vertical shrinkage is -4.2%.

[0048] 3. Shape retention: After 12 washes, no spandex and other fibers were found to have damage such as melting and cracking, the size change was small, and the cloth surface hairiness was very little, achieving the purpose of high shape retention.

Embodiment 3

[0050] The difference from Example 1 is that the face yarn is a blended yarn of viscose fiber, wool fiber and long-staple cotton fiber.

[0051] The performance test results of the high shape retention elastic knitted thermal fabric are as follows:

[0052] 1. Elasticity: Warp elastic elongation is 55%, recovery rate is 95%; weft elastic elongation is 148%, recovery rate is 95%.

[0053] 2. Shrinkage: After washing 10 times, the horizontal shrinkage is -3.2%, and the vertical shrinkage is -3.8%.

[0054] 3. Shape retention: After washing for 15 times, no spandex and other fibers are found to have damage such as melting and cracking, the size changes are small, and the cloth surface hairiness is very small, achieving the purpose of high shape retention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com