Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169 results about "Low molecular weight chitosan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Molecular Weight Chitosan. Low molecular weight chitosan is on the confines of chitosan and chitosan oligosaccharide. Compared with normal chitosan, its absorptivity and bioactivity is obviously higher. Molecular weight could range from 20000-8000000 to meet customers' different requirements.

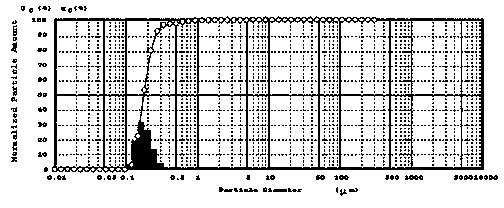

Chitosan/sheet silicate nano compound stephanoporate crosslinked microsphere sorbent and preparation method thereof

InactiveCN101347719AImprove adsorption capacityLow priceOther chemical processesSilicon compoundsSorbentLow molecular weight chitosan

The invention discloses a chitosan / layered silicate nano composite porous crosslinked microsphere adsorbent and a preparation method thereof; in the adsorbent, the layered silicate which is in nano-state is dispersed in the chitosan microsphere which is treated with chemical crosslinking. The preparation method is as follows: the chitosan with low molecular weight / layered silicate intercalation solution is prepared, the intercalation solution is blended with the chitosan with high molecular weight and is contacted with alkaline coagulant to prepare the microsphere, the microsphere is treated with pre-crosslinking and crosslinking, acid solution is used for removing pre-crosslinking agent to obtain the chitosan / layered silicate nano composite porous crosslinked microsphere adsorbent. By comprehensively utilizing the characters of chitosan and layered silicate in terms of adsorption property and jointly applying intercalation composition, solidification and granulation by alkali solution, and pre-crosslinking and crosslinking techniques, a porous microsphere adsorbent which has low price and excellent adsorption performance for heavy metal ions and organic pollutants can be prepared.

Owner:SOUTH CHINA NORMAL UNIVERSITY

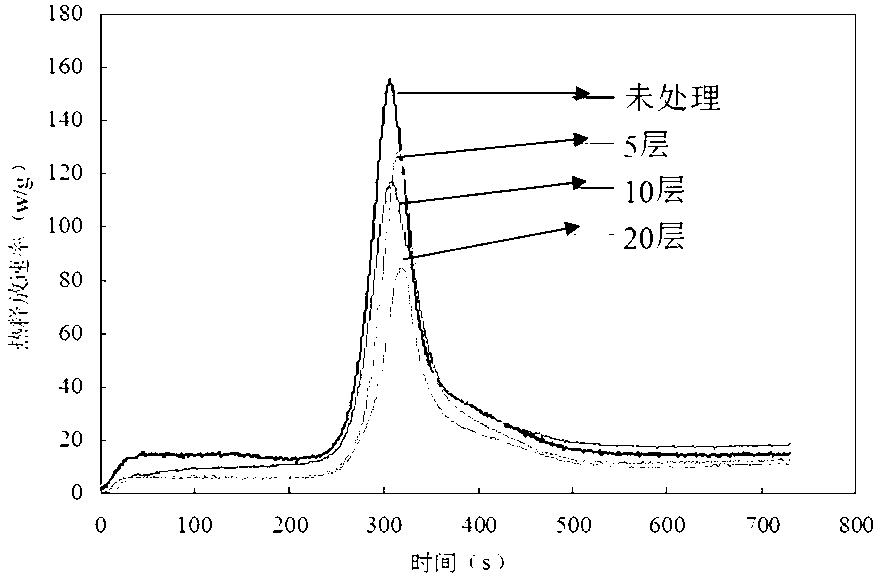

Flame-retardant pure silk and preparation method thereof

ActiveCN103321044AEasy to operateMeet environmental protection requirementsAnimal fibresEnvironmental resistanceRoom temperature

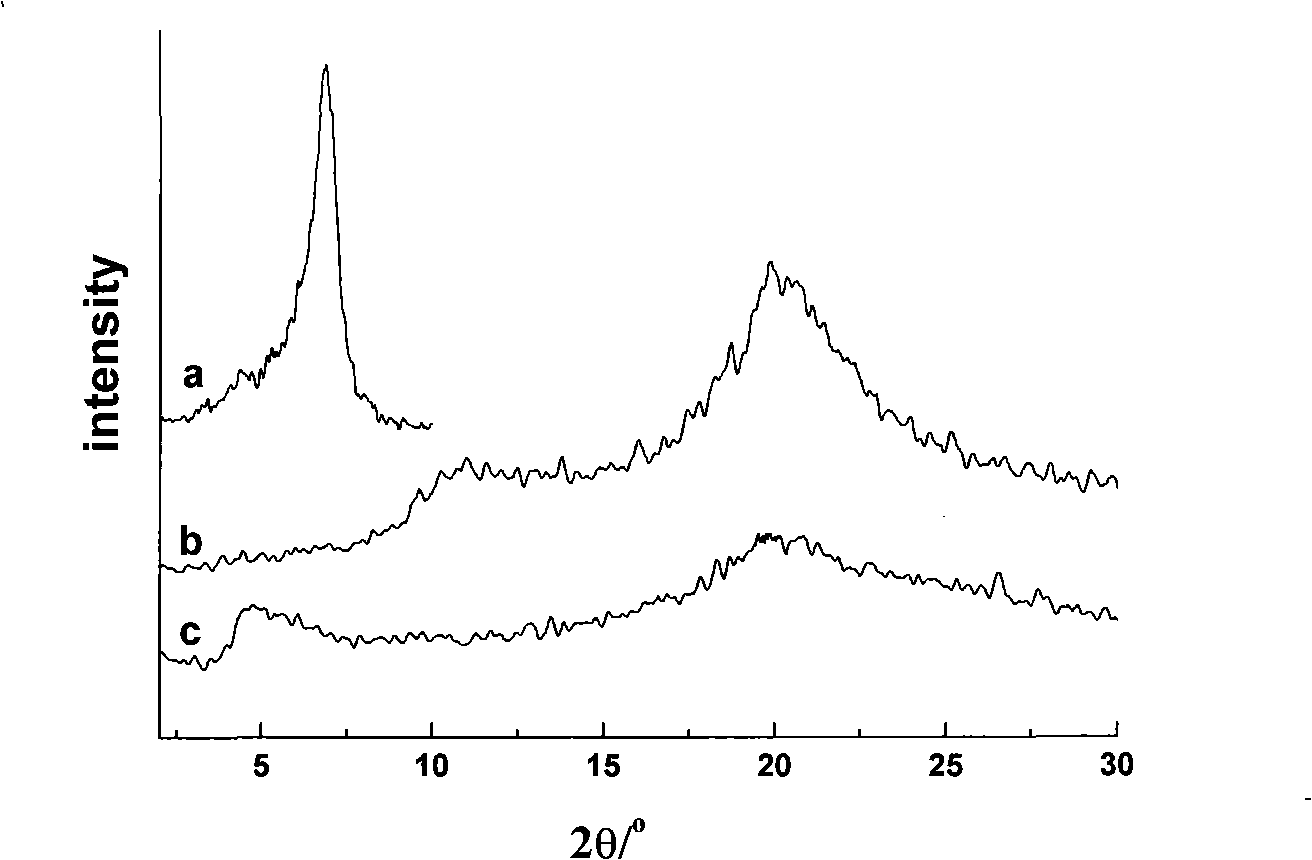

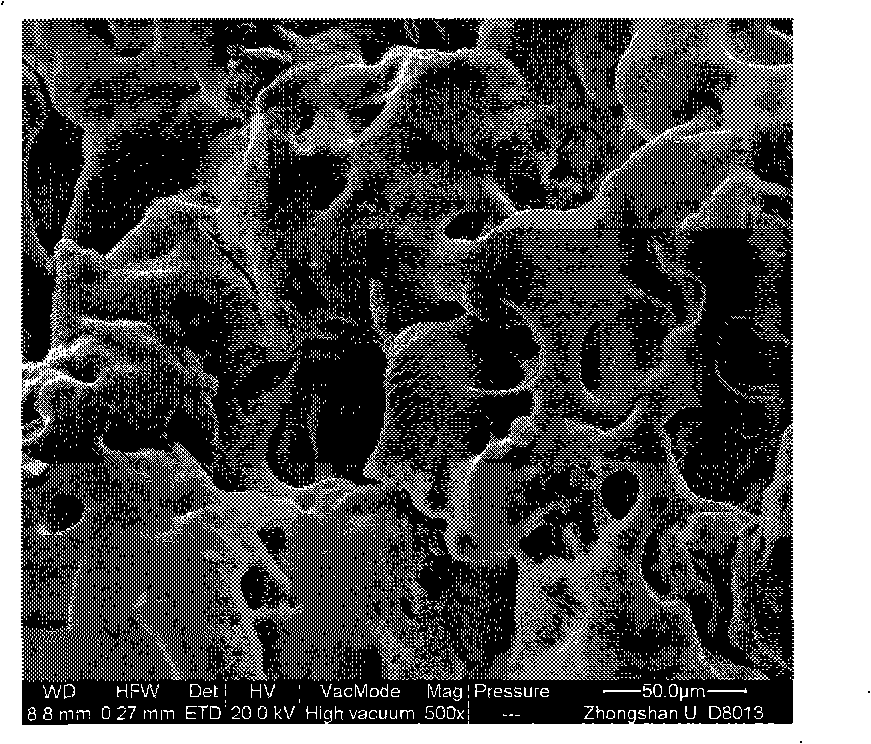

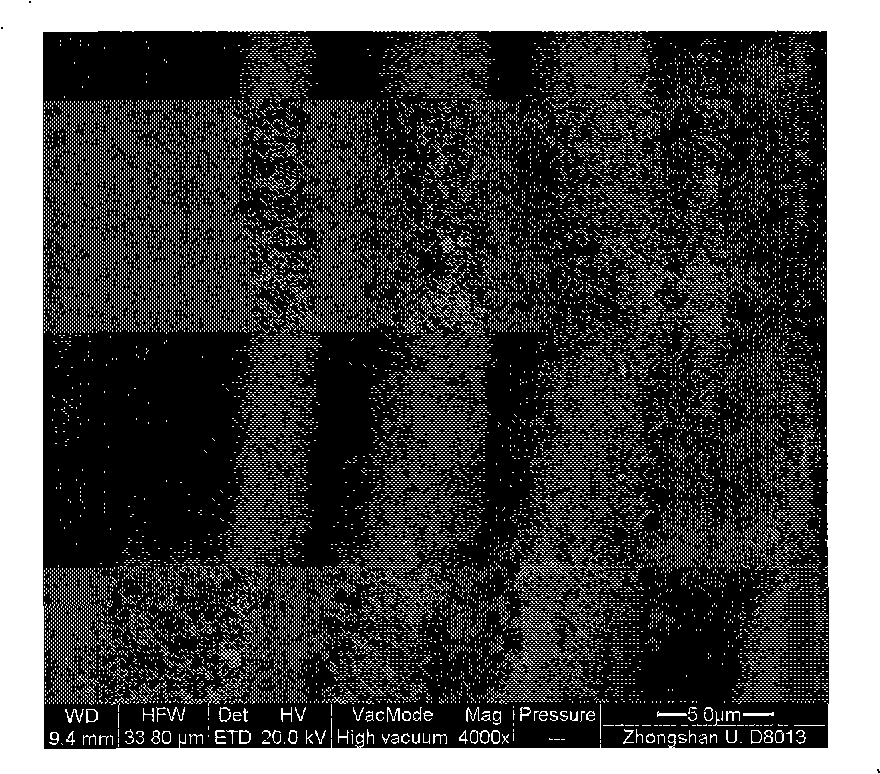

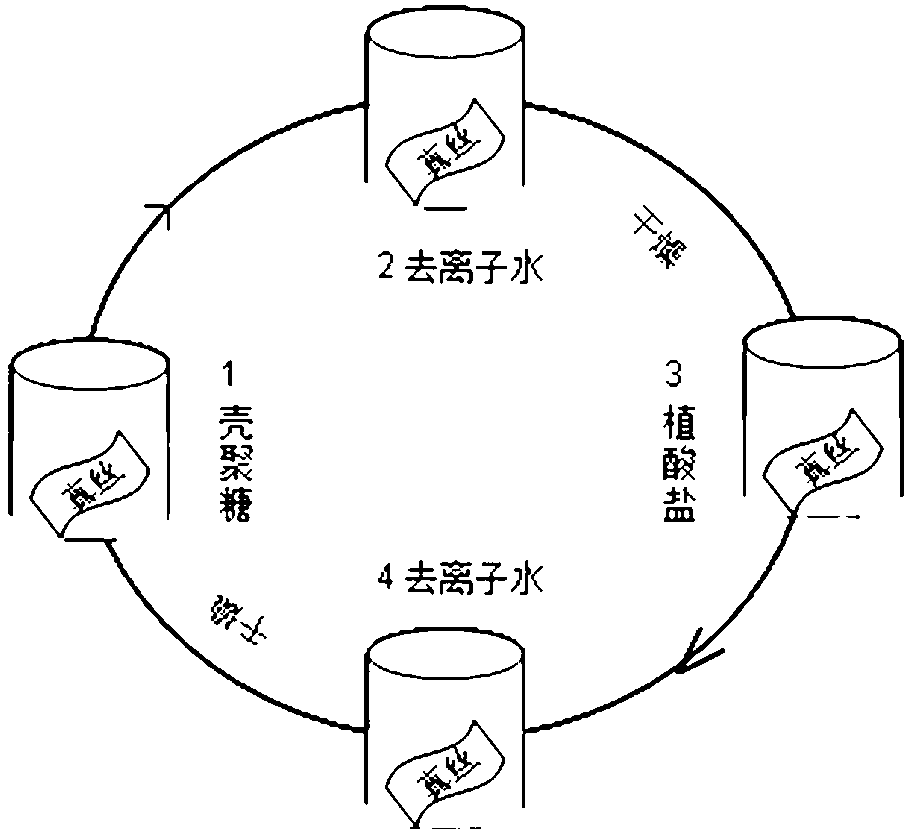

The invention discloses a flame-retardant pure silk and a preparation method of the flame-retardant pure silk. The preparation method comprises the following steps of: firstly, soaking the pure silk into a low molecular weight chitosan solution, washing by using deionized water, drying the washed pure silk, then soaking the dried pure silk into a sodium phytate solution, then taking the pure silk out, washing the pure silk with deionized water and then drying; and repeating the steps till the flame-retardant pure silk is obtained. A flame retardant comes from natural animals and plants, is nontoxic and belongs to an ecological type flame-retardant finishing agent; the flame-retardant pure silk is prepared by adopting an electrostatic self-assembling technology at room temperature, the preparation method is simple to operate and accords with an environment-friendly requirement, energy is saved and emission is reduced; and the prepared flame-retardant pure silk has a favorable flame-retardant effect.

Owner:苏州盛泽科技创业园发展有限公司

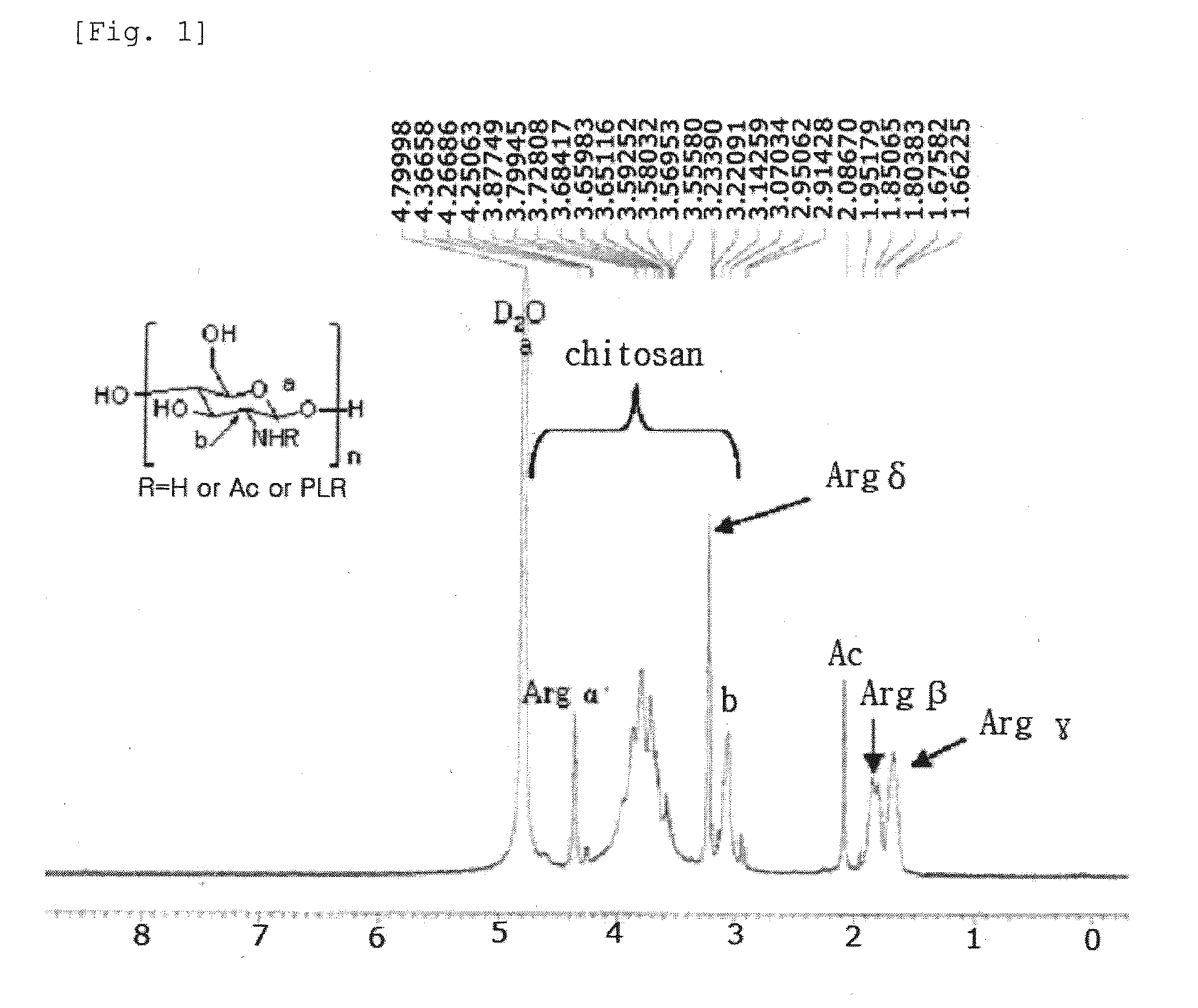

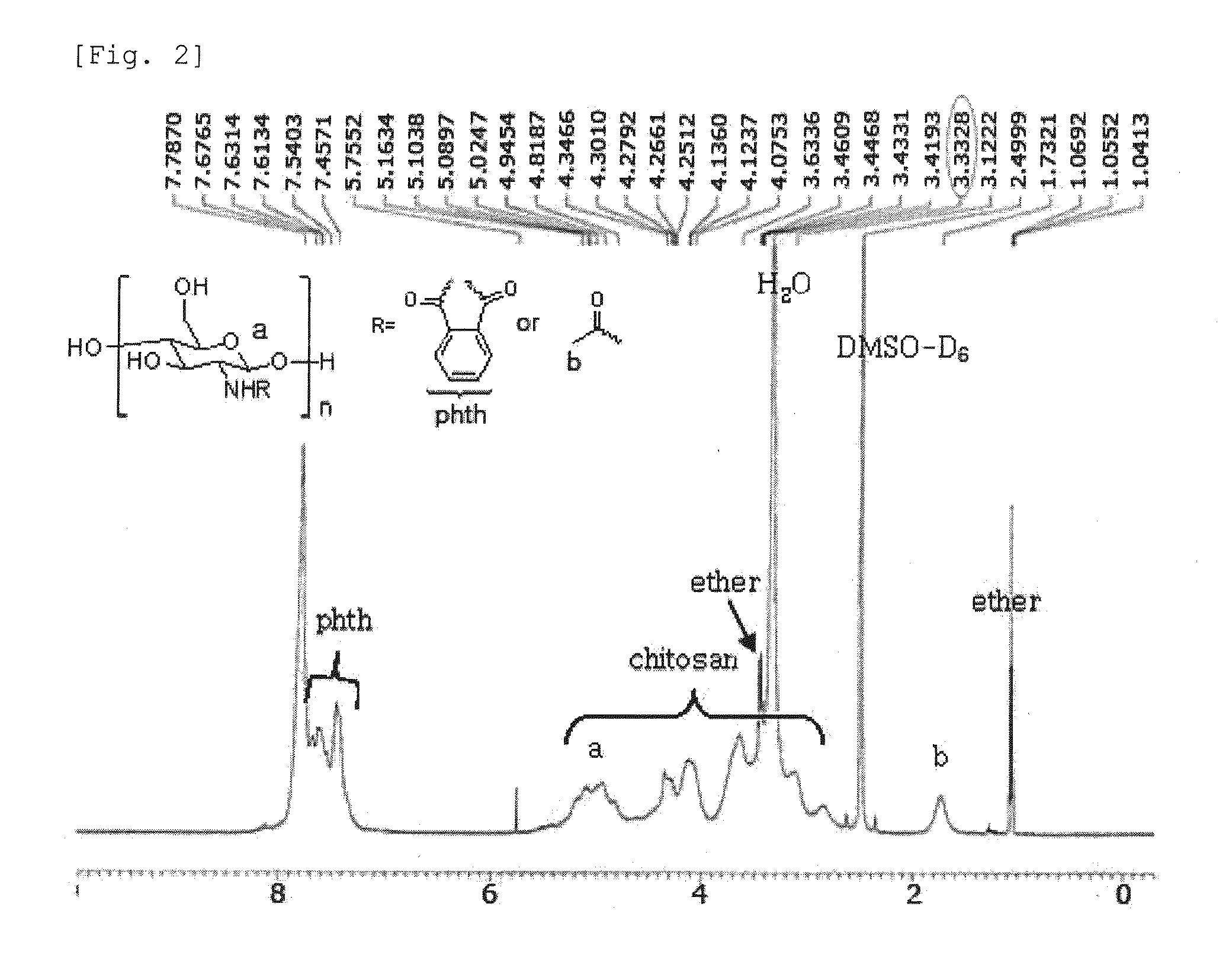

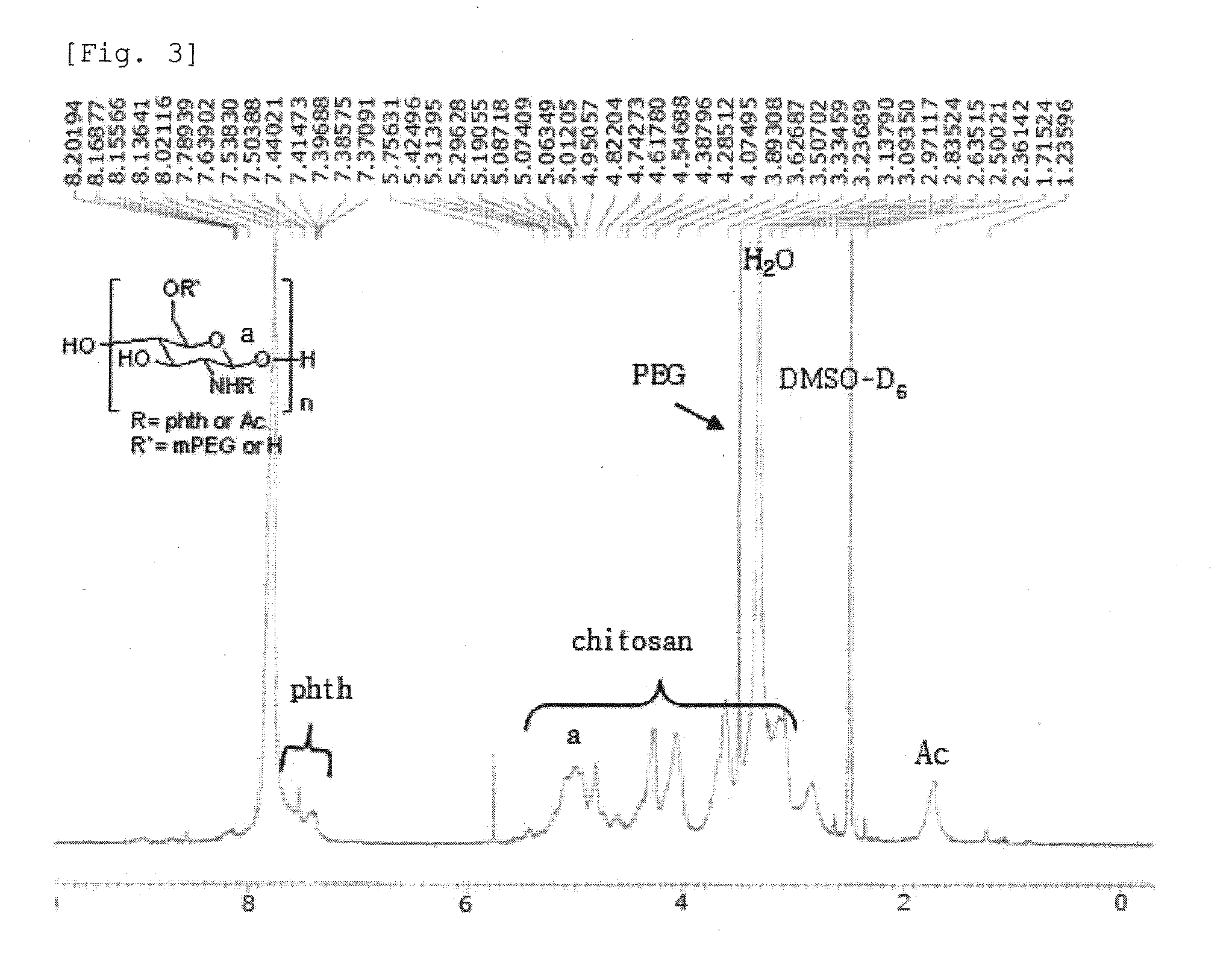

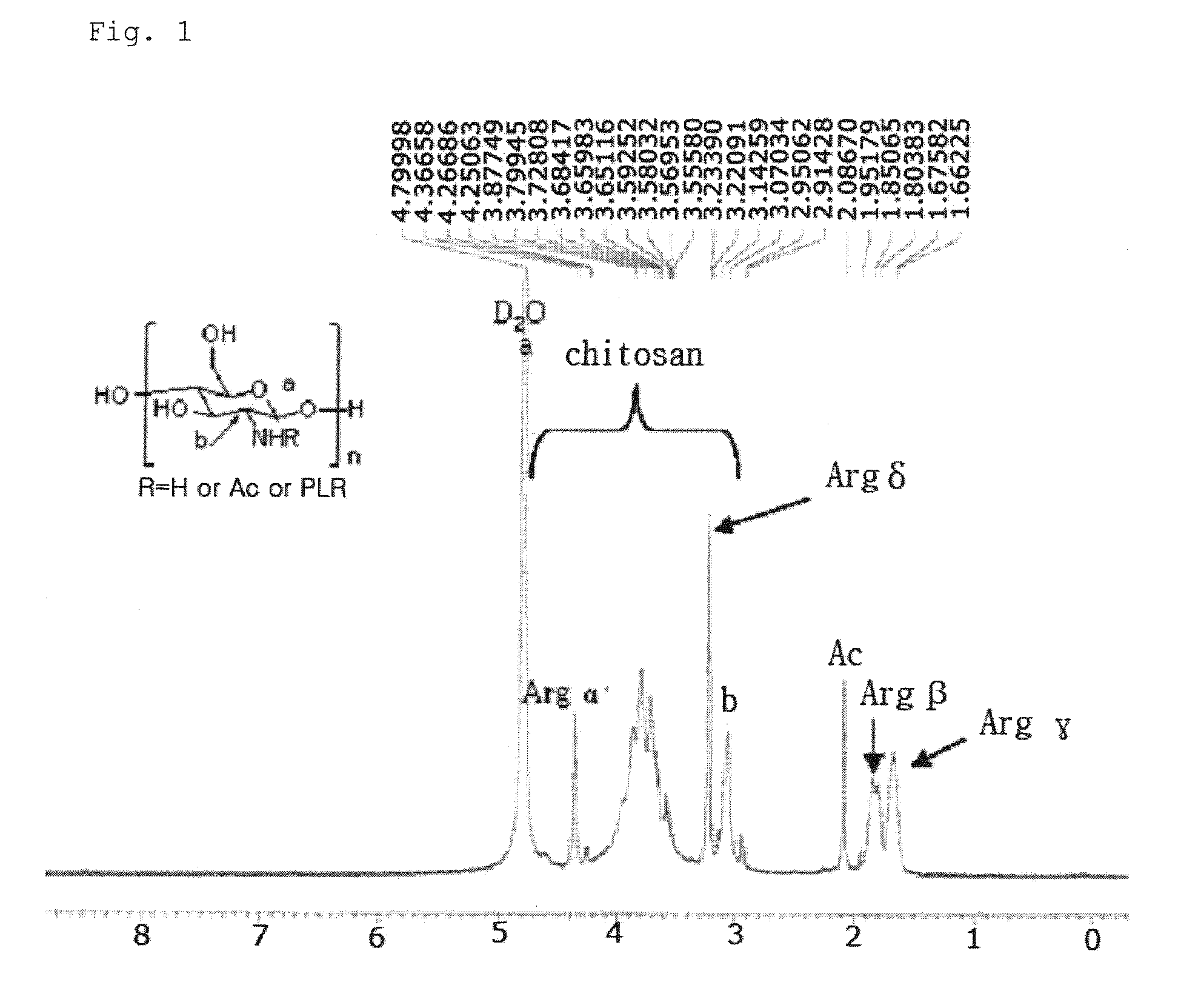

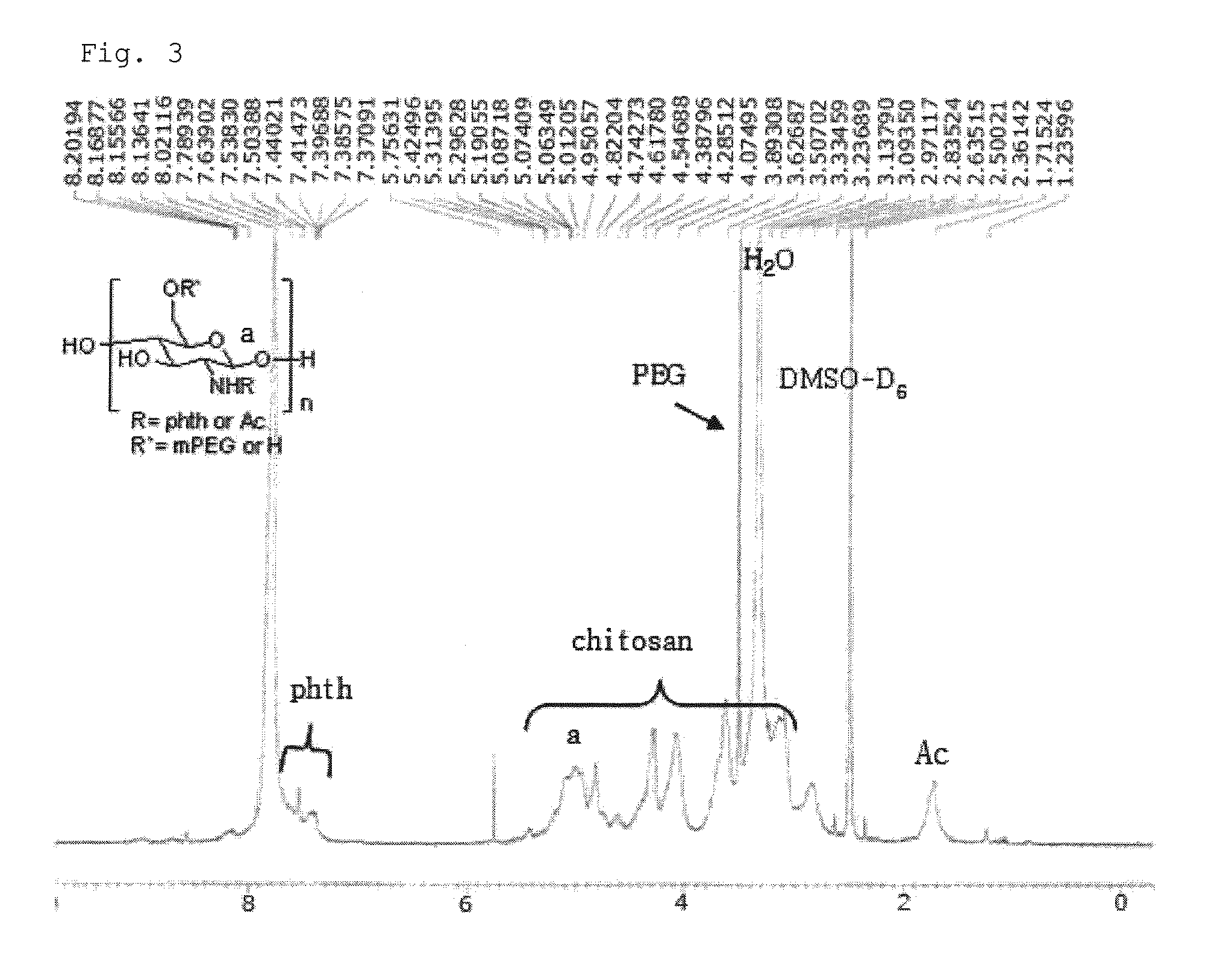

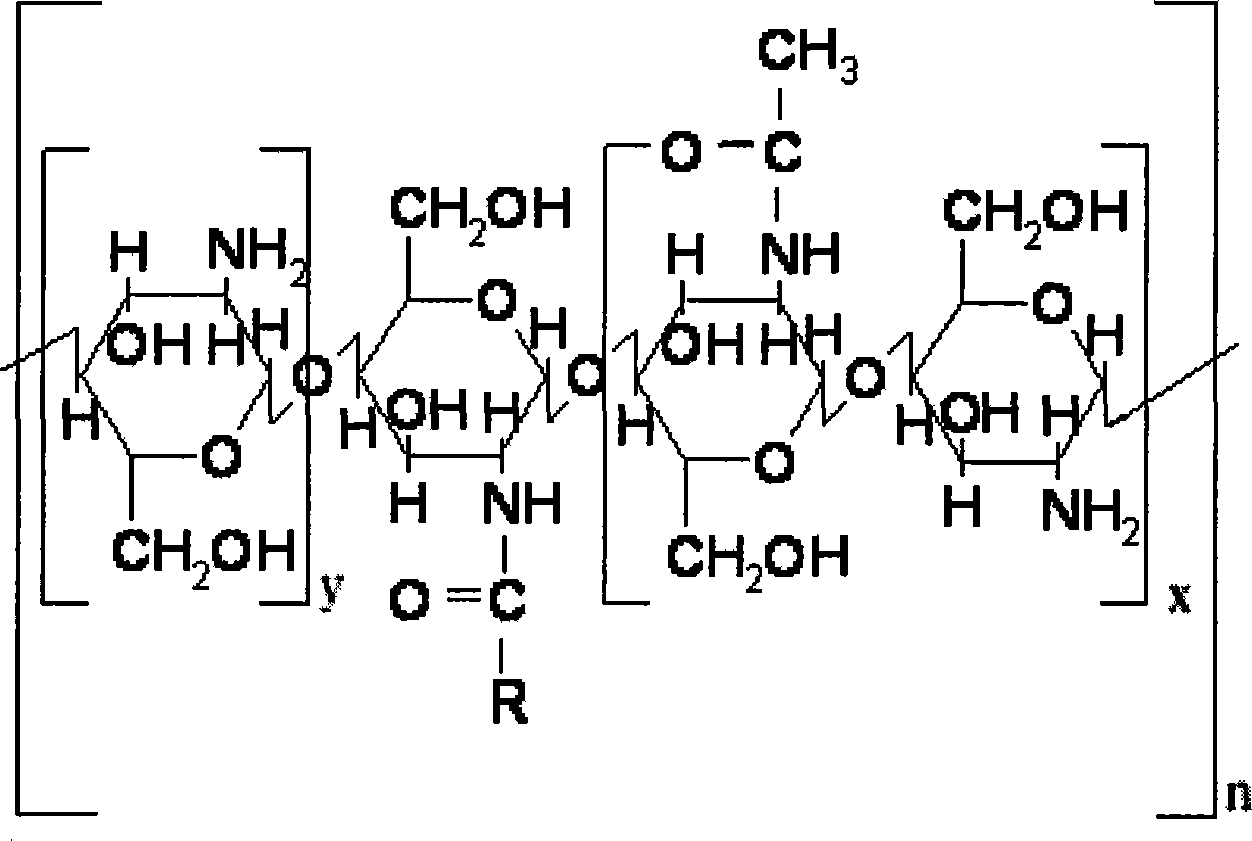

Chitosan Based Polymer Conjugate and a Method for Producing the Same

InactiveUS20100113559A1Improve in vivo transfer efficiencyLow cytotoxicityPeptide/protein ingredientsGenetic material ingredientsPolyethylene glycolCytotoxicity

The present invention relates to a conjugate of chitosan and polyamine polymer that is useful for transferring a desired gene medicine into cells, and a method for preparing the same. In particular, the present invention relates to a double conjugate that is prepared by 1 in king poly-L-arginine to low molecular weight chitosan or triple conjugate that is prepared by additionally linking polyethylene glycol (PEG) to the double conjugate, and a method for preparing the same. The chitosan based cationic polymer conjugate of the present invention forms a complex with negatively charged gene medicine such as plasmid DNA and small interfering RNA to efficiently transfer the desired gene medicine into cells with low cytotoxicity. Accordingly, the conjugate can be used as an effective delivery system for in vivo administration of gene medicine.

Owner:ENGENE INC

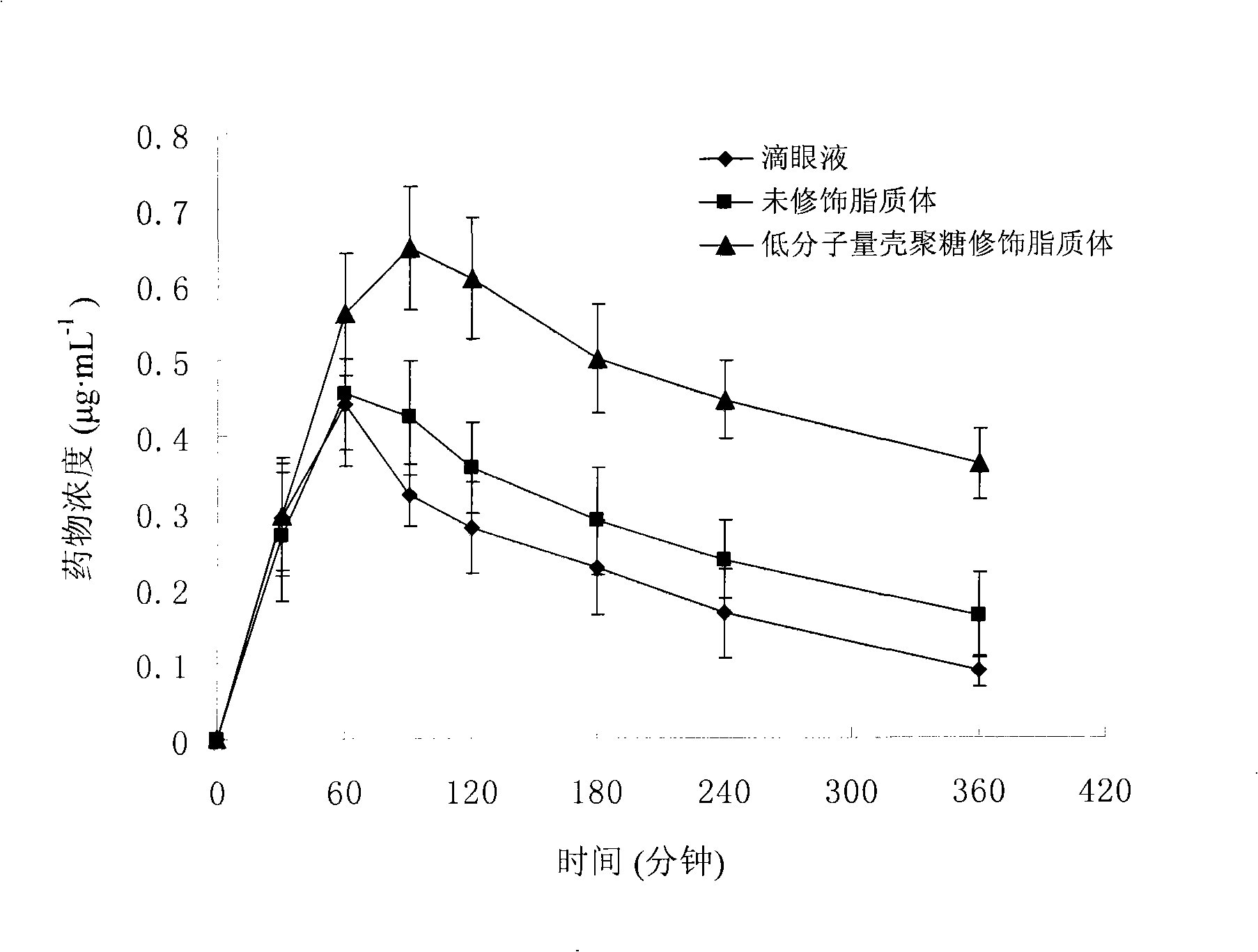

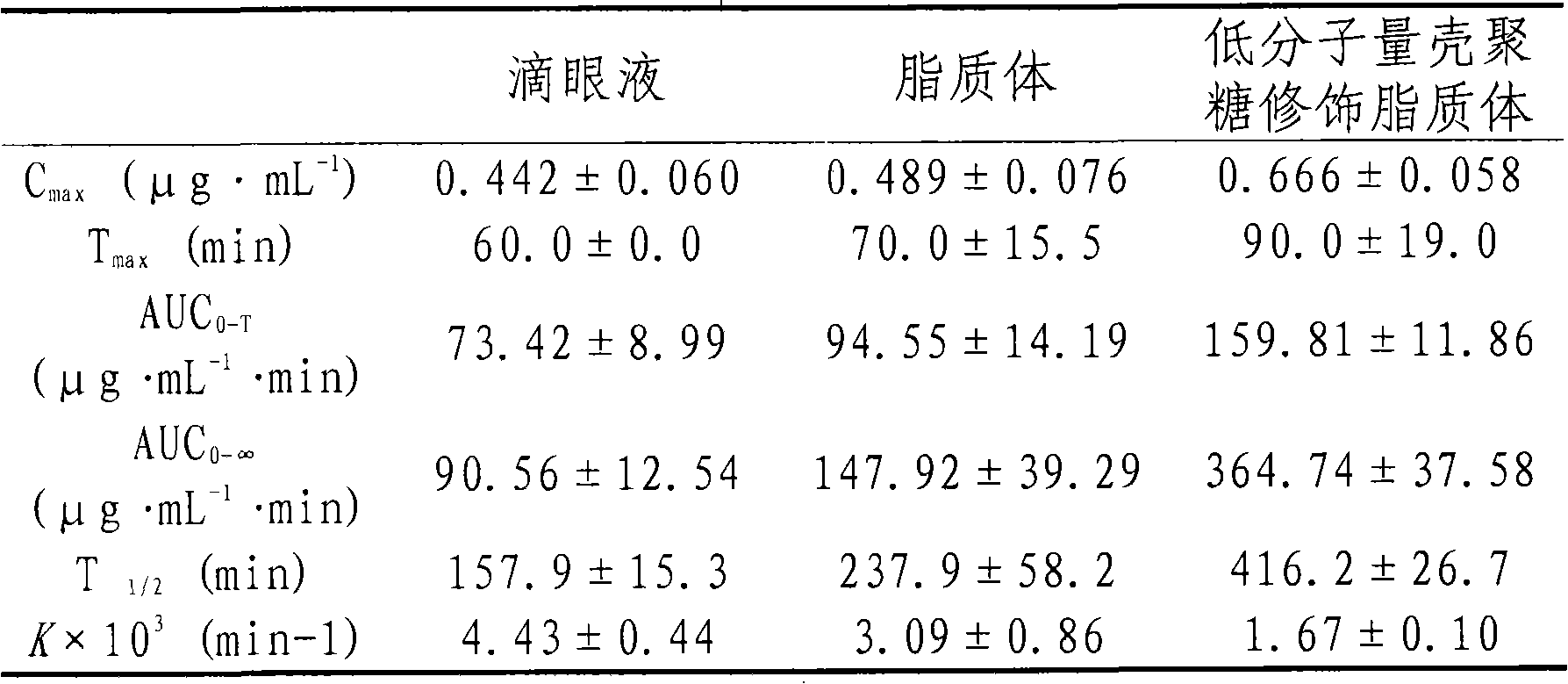

Low molecular weight chitosan modified liposomes and preparation method thereof

InactiveCN101406454AProlong the action timePromote absorptionPharmaceutical non-active ingredientsLiposomal deliverySide effectCholesterol

The invention relates to the field of pharmaceutical preparation, and particularly discloses a novel medicinal carrier, namely a low molecular weight chitosan modified liposome and a preparation method thereof. The low molecular weight chitosan modified liposome consists of phospholipid, cholesterol, low molecular weight chitosan, a medicine and other additives. The carrier can be combined with the medicine so as to form pharmaceutical preparations for clinic application. Compared with the prior liposome, the low molecular weight chitosan modified liposome has the advantages that the low molecular weight chitosan modified liposome has unique characteristics, can improve the absorption and transportation of the medicine, the bioavailability, the slow-releasing and long-acting action, can realize the targeted administration action, reduce the toxic and side effects of the medicine, decrease the administration frequency, improve the compliance of a patient and facilitate the administration. In addition, the preparation method has the advantages that the preparation method is convenient and is suitable for industrialized production, and has extremely high application value in the field of pharmaceutical preparation.

Owner:SHENYANG PHARMA UNIVERSITY

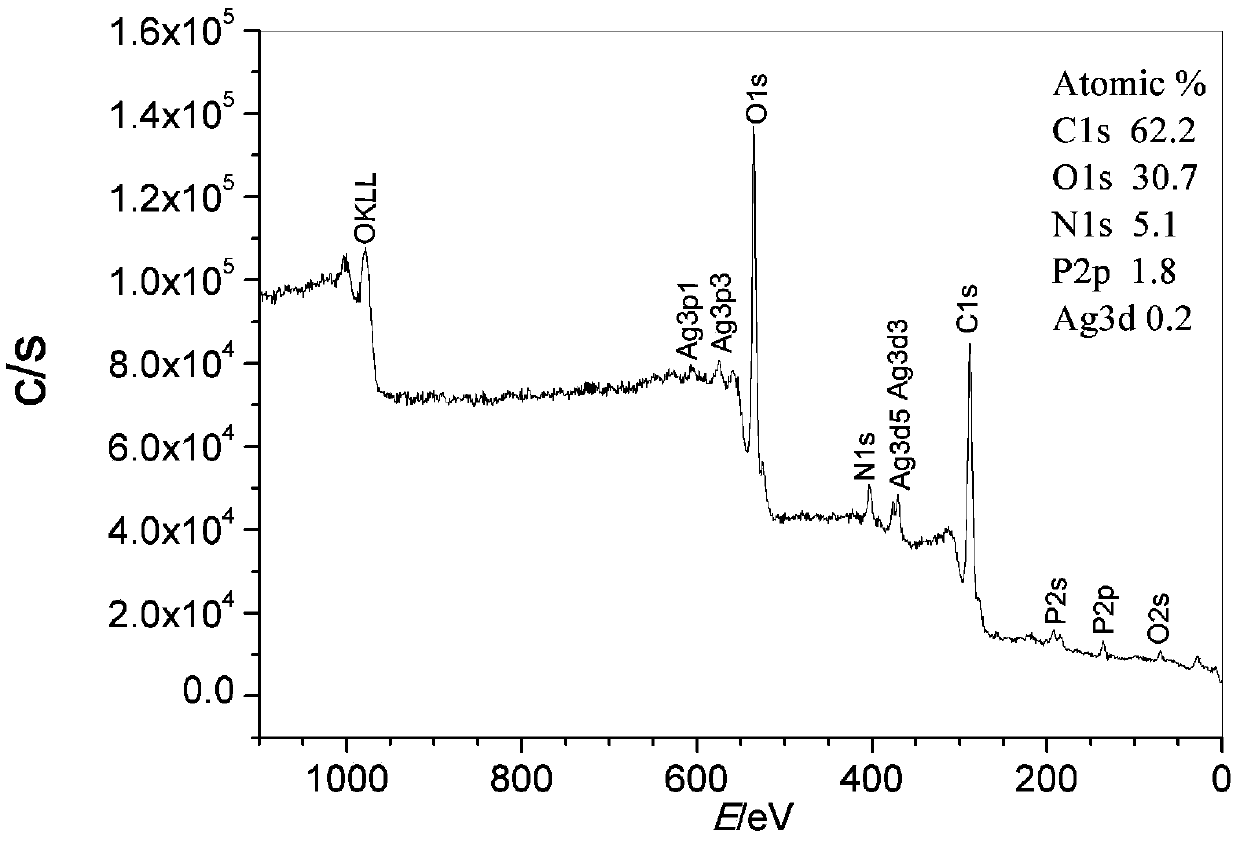

Silver-loaded low-molecular-weight chitosan composite microsphere antibacterial agent and preparation method thereof

ActiveCN105494430ABroad-spectrum bactericidalHigh antibacterial activityBiocideDead animal preservationEscherichia coliCross-link

The invention provides a silver-loaded low-molecular-weight chitosan composite microsphere antibacterial agent and a preparation method thereof. Low-molecular-weight chitosan is used as a raw material, and a low-molecular-weight chitosan acetic acid solution, a silver nitrate solution and a vanillic aldehyde ethanol solution are mixed to form composite sol; then paraffin is used as a continuous phase, sorbitan monooleate and alkylphenol ethoxylates are used as a compound emulsifier, a silver / low-molecular-weight chitosan sol is used as a monomer, and sodium tripolyphosphate is used as a cross-linking agent for preparing an emulsion system for emulsification crosslinking, and finally washing and drying are performed, so that the silver-loaded low-molecular-weight chitosan composite microsphere antibacterial agent is obtained. Due to the fact that the low-molecular-weight chitosan is used as the raw material, nanometer silver particles can enter microspheres, and the antibacterial activity of the composite antibacterial agent is obviously improved. The obtained antibacterial agent has the broad-spectrum bactericidal activity, and has the efficient fatality rate for both escherichia coli and staphylococcus aureus.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Packaging material with antistatic and antibacterial properties and preparation method of packaging material

The invention discloses a packaging material with antistatic and antibacterial properties. The packaging material is prepared from the following raw materials in parts by weight: 50-70 parts of low-density polyethylene resin, 10-30 parts of linear polyethylene resin, 6-8 parts of stearate, 5-10 parts of glass fiber, 1-3 parts of thermoplastic plastic, 3-5 parts of 20% calcium carbonate masterbatch, 2-5 parts of an antistatic agent, 1-3 parts of a lubricant, 3-6 parts of zinc oxide whisker, 4-8 parts of graphene and 1-5 parts of two kinds of low molecular weight chitosan. According to the packaging material disclosed by the invention, chitosan instead of nano silver is adopted as an antibacterial raw material, and the cost can be remarkably reduced; by adding graphene which is a special-structure conductive material, a better effect of promoting the antistatic property is realized; the zinc oxide whisker with a four-leg three-dimensional structure is added; when zinc oxide is dispersed in a matrix, adjacent needle-shaped parts are in mutual lap joint to form a conductive path which cooperates with the permanent antistatic agent to efficiently give antistatic property to the material; and meanwhile, since calcium carbonate masterbatch is added as a degrading component, the degradation property of the packaging material is good.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

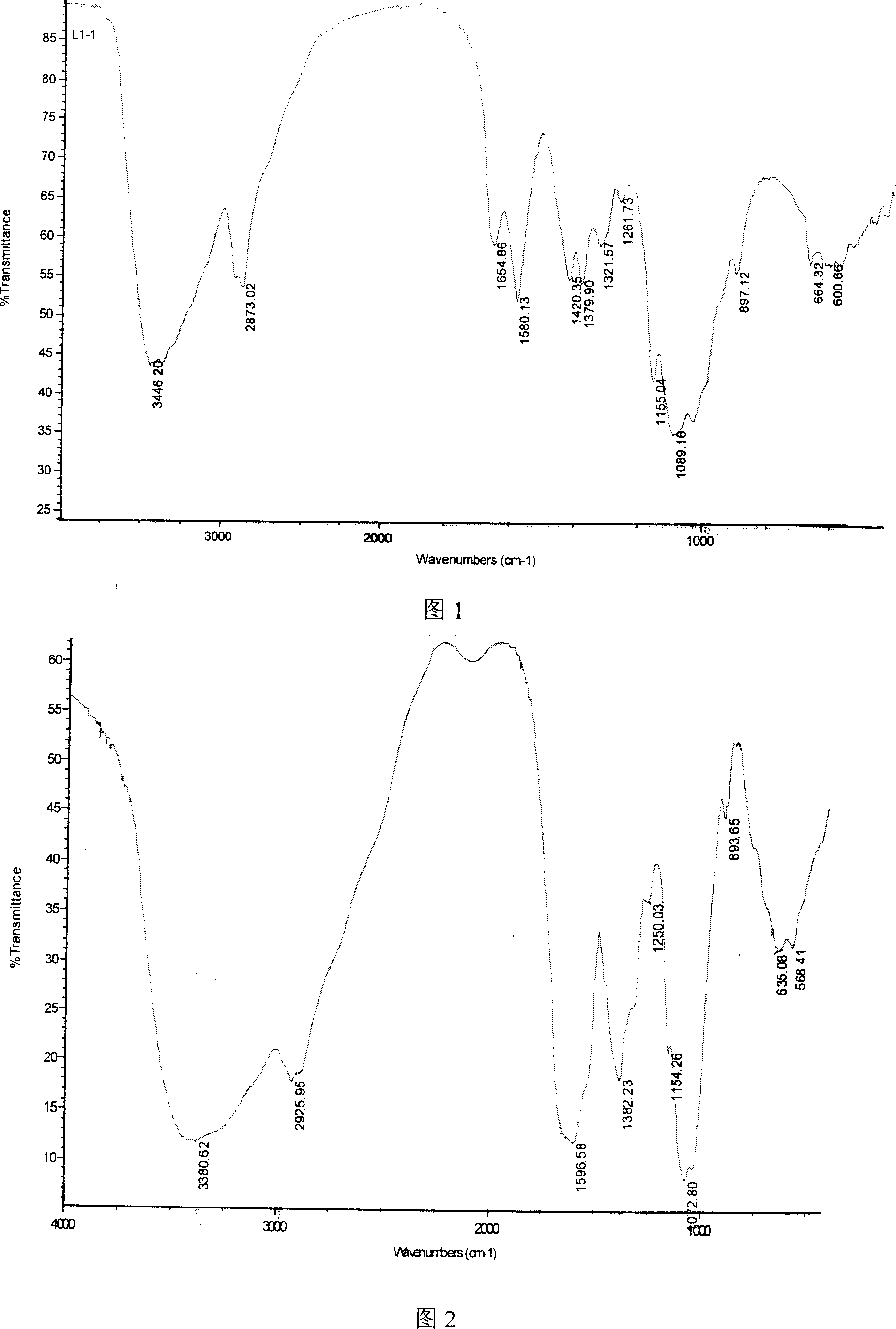

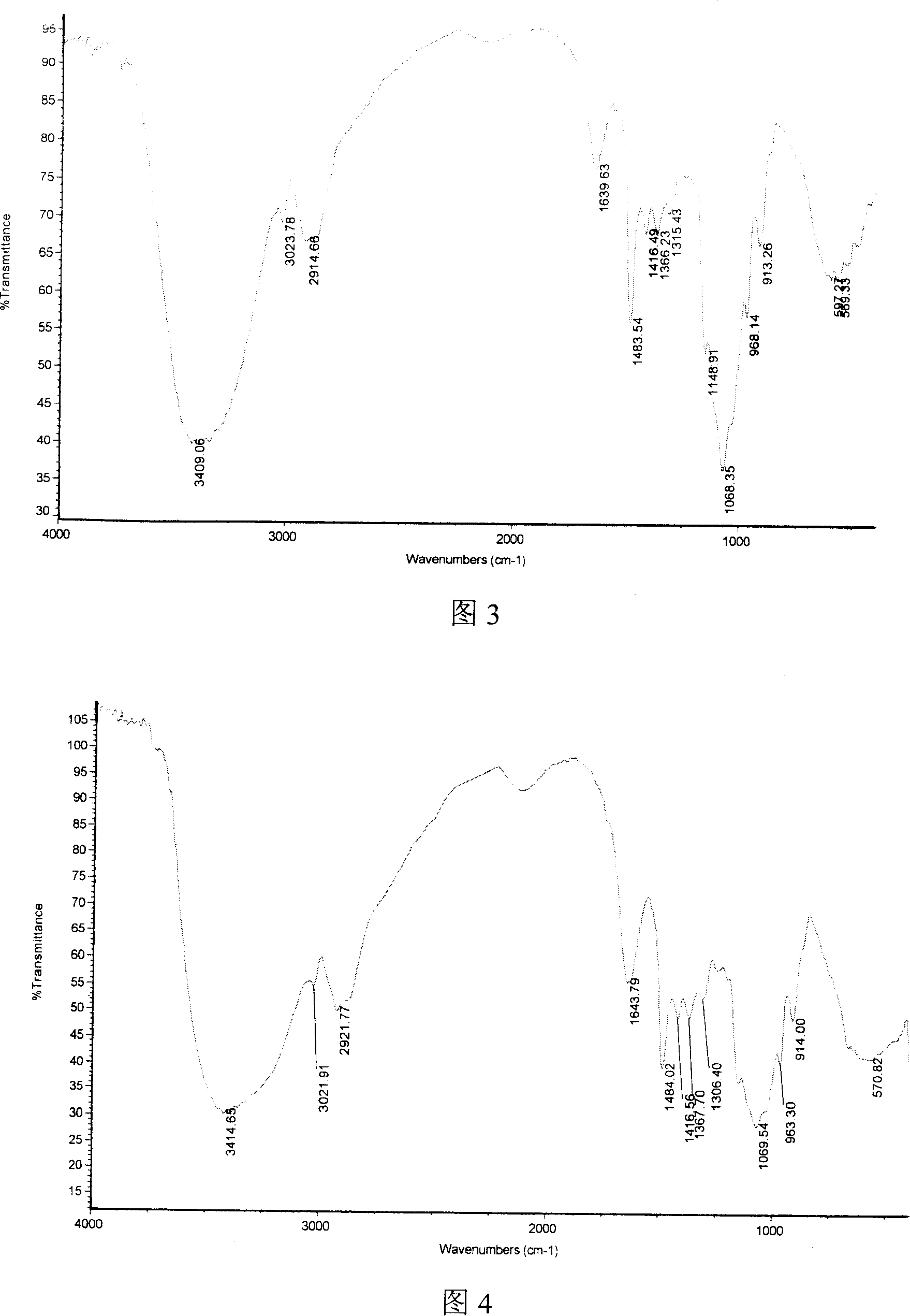

Chitosan quaternary ammonium salt, preparing method and application of the same

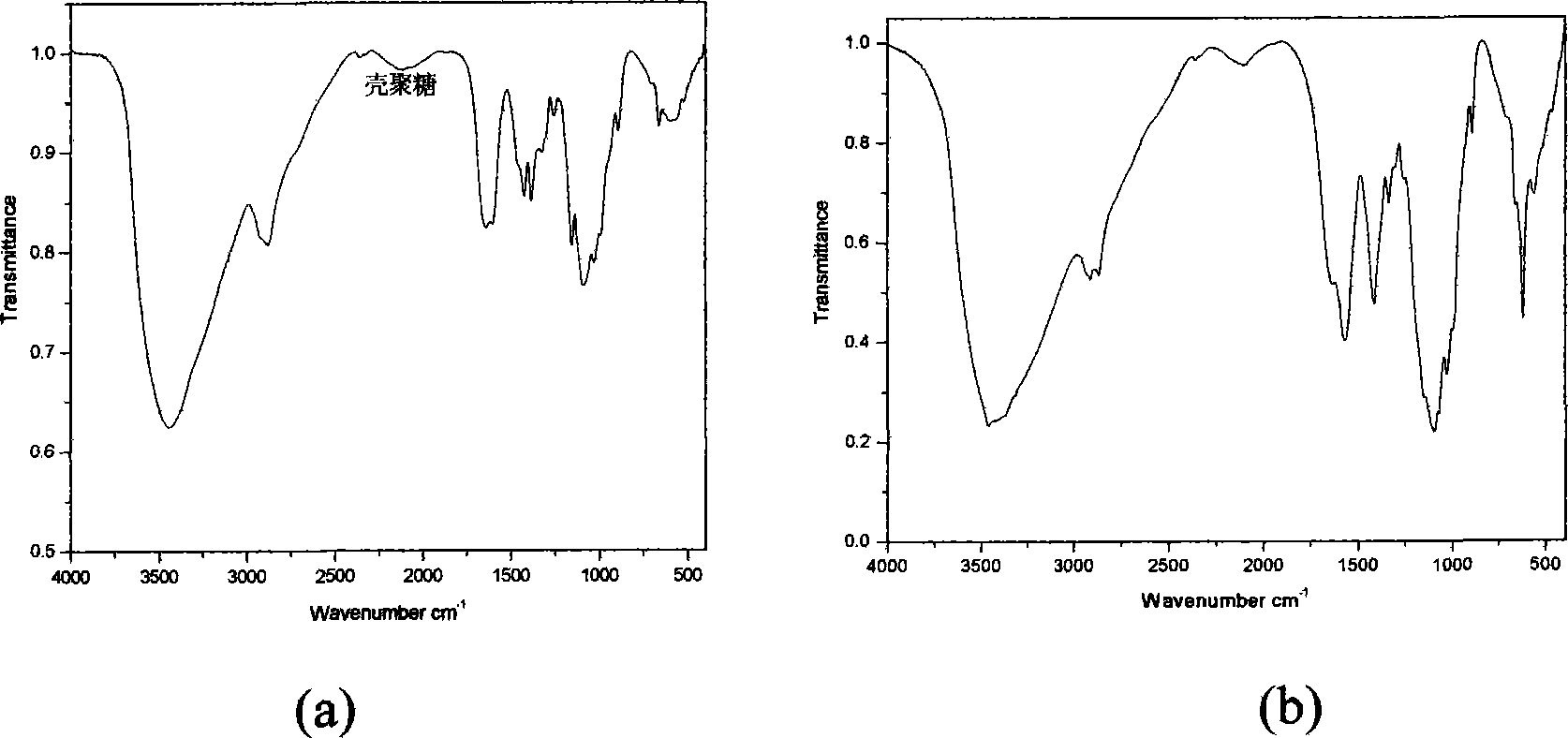

InactiveCN101130574ASimple preparation processLow costCosmetic preparationsMake-upAntioxidantOxidation resistant

The invention discloses a preparing method and application of polyose quaternary ammonium salt in oceanography engineering technique domain, which comprises the following steps: modify for high and low molecular weight chitose with glycidyl trimethyl ammonium chloride; adopting different condition; preparing hydroxypropyl trimethyl amchlor chitose; proceeding simulation for the structure with infrared spectrum; analyzing for IR spectrogram; replacing with N upper; possessing oxidation resistance desiccating moisture keeping active; setting the active stronger than chitose quaternary ammonium salt. This invention can increase oxidation resistance and desiccating moisture keeping property of the chitose, which can be used as antioxidant and humectant for food and cosmetic product.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Chitosan durable antibiotic tidying method for Cashmere (wool) fabric

A chitosan anti-bacterium finishing method of cashmere and wool fabric is a finishing method that uses the chitosan with low molecular weight as a finishing agent, epoxy chloropropane as a cross linker, lye as a curing agent, acetic liquor as a neutralizing agent, and goes through washing wool fabric, finishing (chitosan degradation liquor: MW 2000 to 10000 g / mol, 3 to 30cps, dosage: 5 to 20 percent of the weight of fabric; the cross linker is made from epoxy chloropropane, of which the dosage: is 0.05 to 0.50 percent of the chitosan finishing agent), through steps of washing of lye (0.1 to 1 percent of NaOH liquor), neutralization (0.5 to 2 percent of acetum) and drying (10 to 20 min under 70 to 90 DEG C). The fabric has good antibacterium property and after 50 times of washing, the bacteriostasis ratios are that: golden brown staphylococcus is 93.2 to 99.9 percent; colon bacillus is 72.4 to 92.4 percent; Candida albicans is 86.3 to 99.8 percent, moreover, the fabric is washable and has good fastness which can reach Grade four after 5o times of washing.

Owner:DALIAN POLYTECHNIC UNIVERSITY

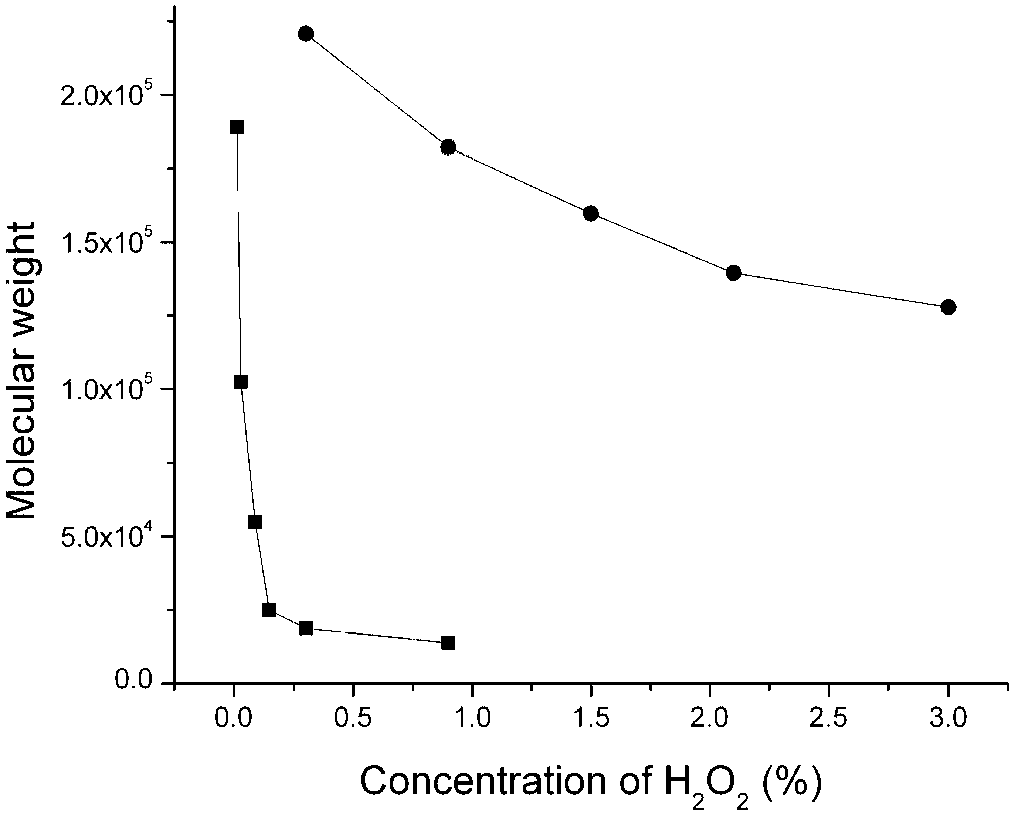

Method for degrading chitosan

InactiveCN102702386AIncrease reaction rateRapid responseSugar derivativesSugar derivatives preparationChemical structureTemperature control

The invention belongs to the marine chemistry engineering technology, and in particular relates to a method for degrading chitosan by hydrogen peroxide with the help of microwave temperature control, comprising the following steps: dissolving high molecular weight chitosan with dilute acid to obtain a chitosan solution; adding hydrogen peroxide in the chitosan solution for reaction under microwave; and heating the obtained solution and controlling the reaction temperature under microwave to obtain chitosan of different molecular weights at different degradation time. Compared with the conventional way of degrading chitosan by heating the hydrogen peroxide, hydrogen peroxide of a lower concentration is required at the same temperature, a low molecular weight chitosan can be obtained in less time, and the basic chemical structure of the obtained low molecular weight chitosan is basically the same as that of the initial chitosan raw material.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Preparing low molecular weight chitosan by sensitizing radiation degradation method

The sensitizing and readiation degrading process of preparing low molecular weight chitosan includes the following steps: mixing refined solid chitosan with water solution of sensitizer to form semi-solid sample, regulating pH to 4 with inorganic acid or organic acid and reaching chitosan concentration of 16-25 wt% and sensitizer concentration of 15-30 wt%, gamma ray irradiation in the dosage of 1-10 kGy to degrade at room temperature, and spray drying or vacuum drying to obtain low molecular weight chitosan. Adding the sensitizer can lower the irradiation dosage greatly, and obtain chitosan product with narrow molecular weight distribution and small molecular weight. The present invention can obtain chitosan with molecular weight as low as 3000, and the process is convenient, safe, economic, practical, high in yield and environment friendly.

Owner:PEKING UNIV

Preparation of low-molecular weight chitoglycan or chitooligose

Production of low-molecular weight chitoglycan or chitooligose is carried out by fixing dispase on N-succinchitoglycan aquogel ball from cross-linking method, degrading chitoglycan from fixed enzyme, controlling enzymolysis time, regulating degraded product pH to 8-9 from sodium hydroxide, depositing by alcohol, washing and vacuum drying to obtain low-molecular weight chitoglycan or chitooligose with free amidogen. It achieves much yield, less molecular weight distribution and continuous industrial production. It can be used for medicine and food.

Owner:WUHAN UNIV

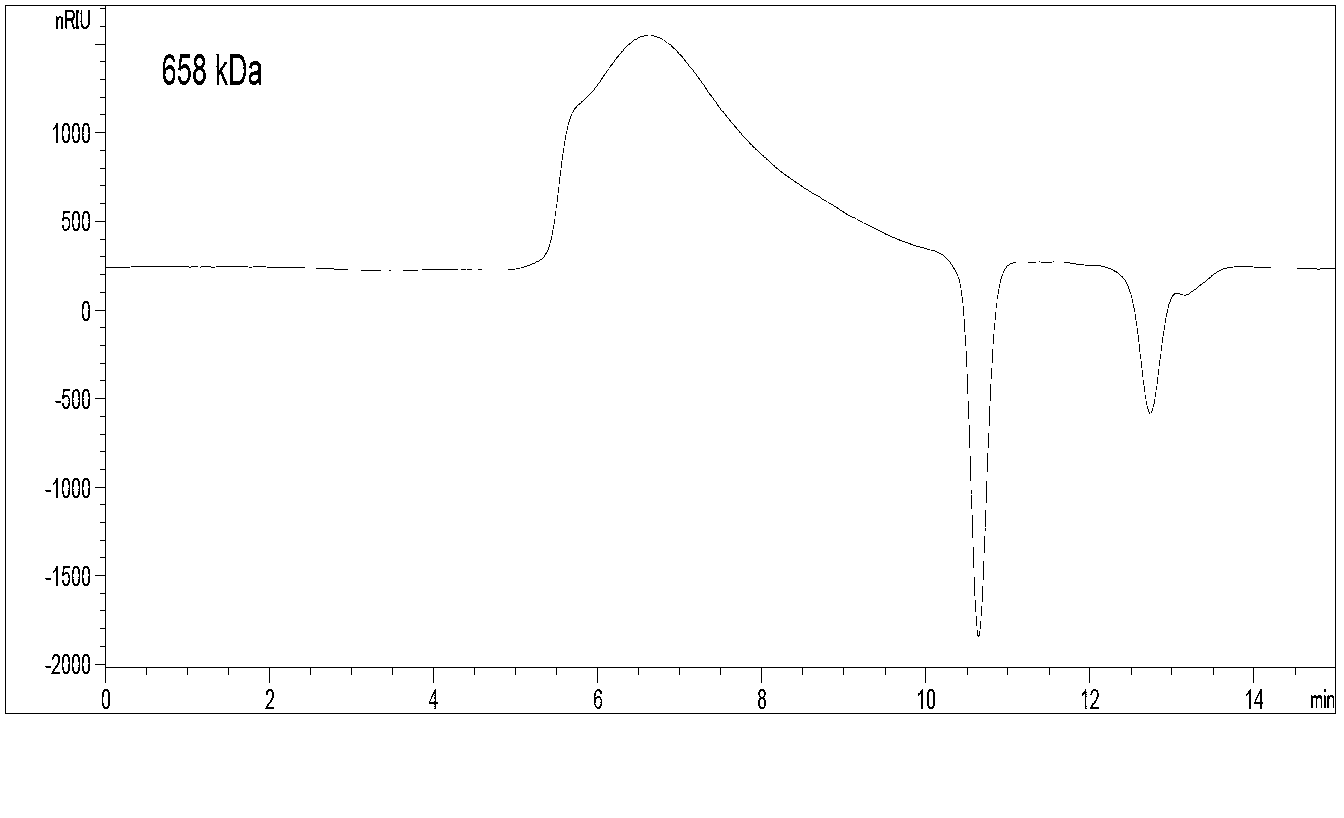

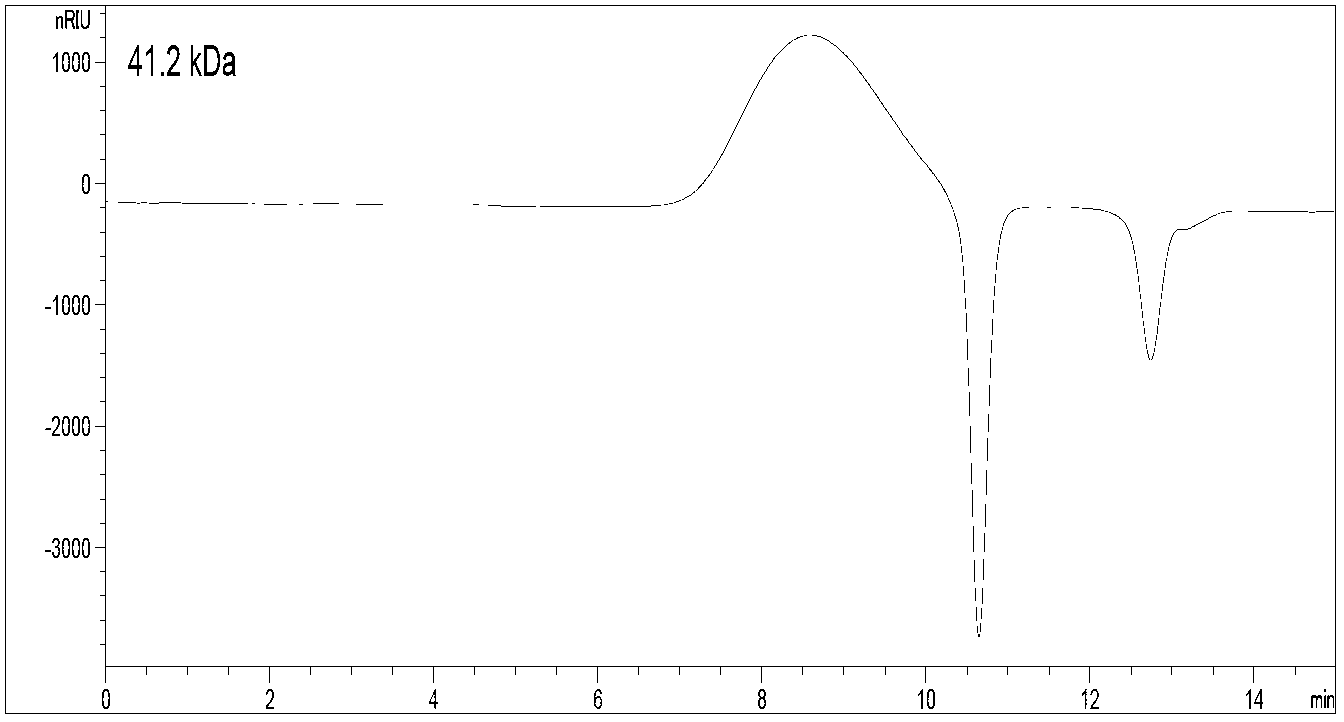

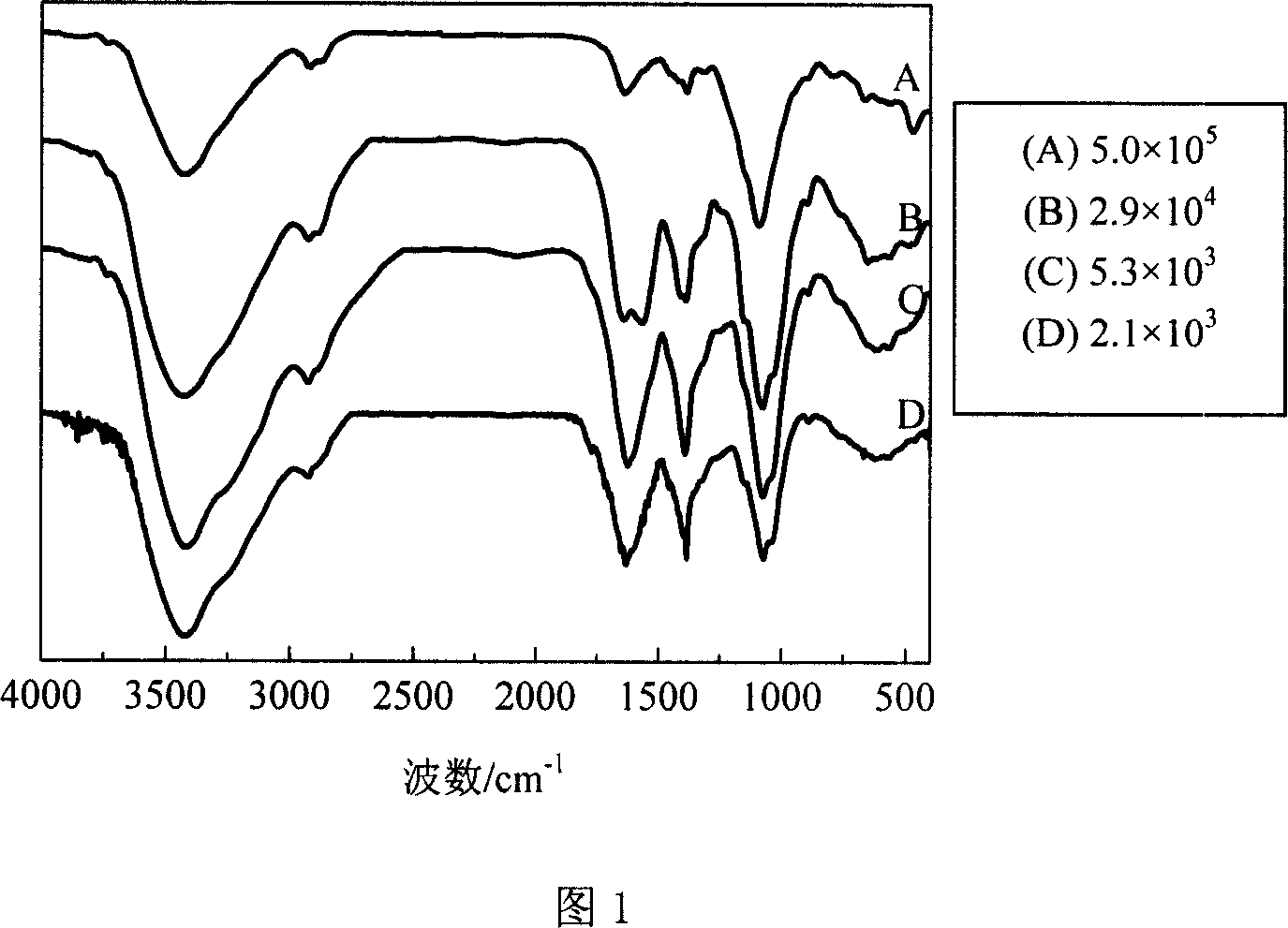

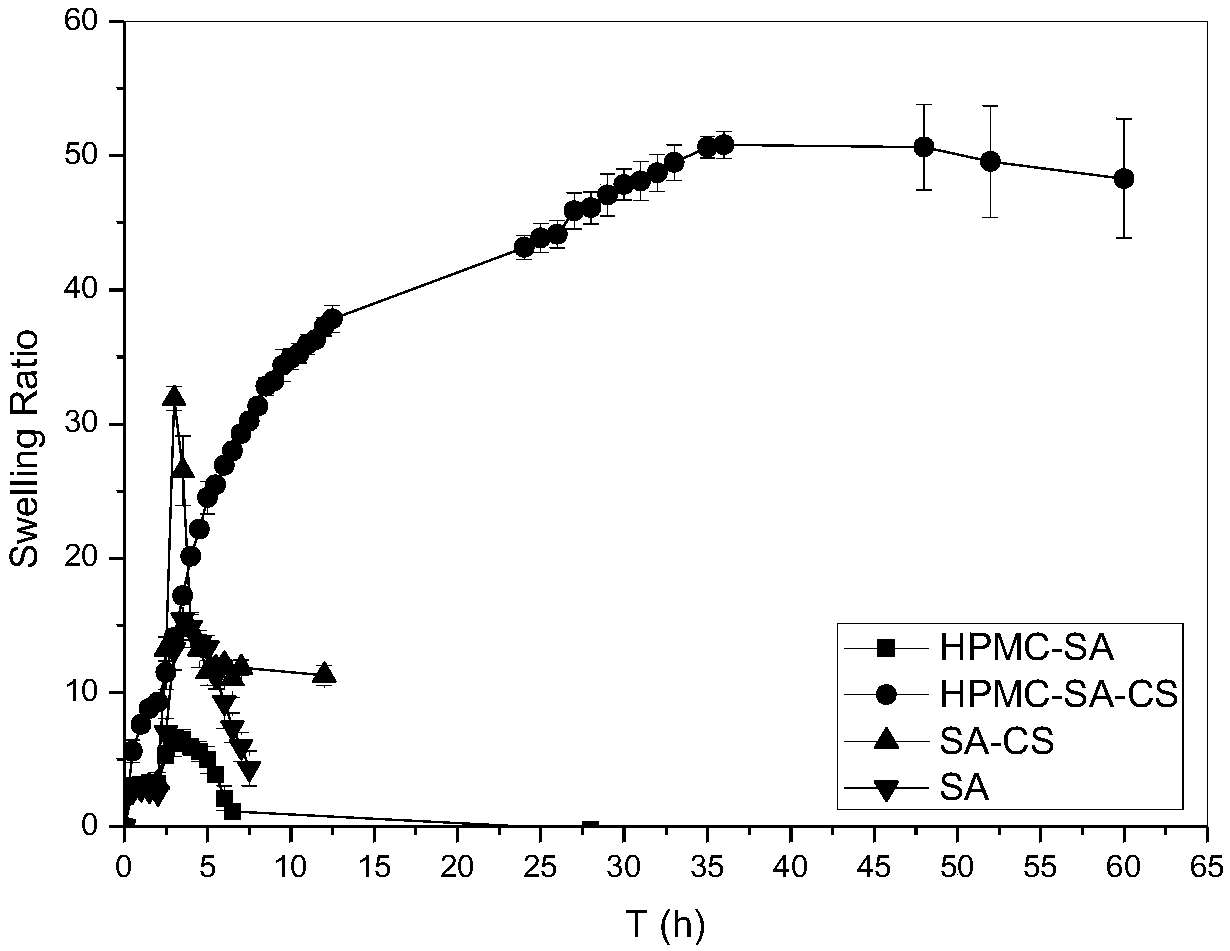

A preparing method for slow release hydrogel carrier material and an application thereof

ActiveCN108384031AStable structureGood slow releaseOrganic active ingredientsPeptide/protein ingredientsPolyelectrolyteMacromolecular drug

The invention belongs to the field of a medicine slow release carrier material and specifically discloses a preparing method for slow release hydrogel carrier material with a semi-interpenetrating structure modified by a polyelectrolyte membrane and an application thereof. The slow release hydrogel material is comprised of HPMC and SA as raw materials, firstly an HPMC-SA semi-interpenetrating composite gel is prepared by a Ca2+ physical crosslinking method and polyelectrolyte membrane modification is performed on the HPMC-SA hydrogel with low molecular weight CS so as to increase the stabilityof the HPMA-SA hydrogel, so that the HPMA-SA-CS hydrogel is obtained. The hydrogel has advantages of mild preparing condition, simple method, less reagent and no violent reactions. BSA and micromolecule indissolvable IDM are regarded as model medicine and the slow release effect of the HMPC-SA-CS composite hydrogel material on macro-molecule medicine and micromolecule medicine is investigated. The result shows that the gel system continuously swell for 50 hours, the swellability reaches above 52 times and the slow release effect of the protein medicine and IDM is increased.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

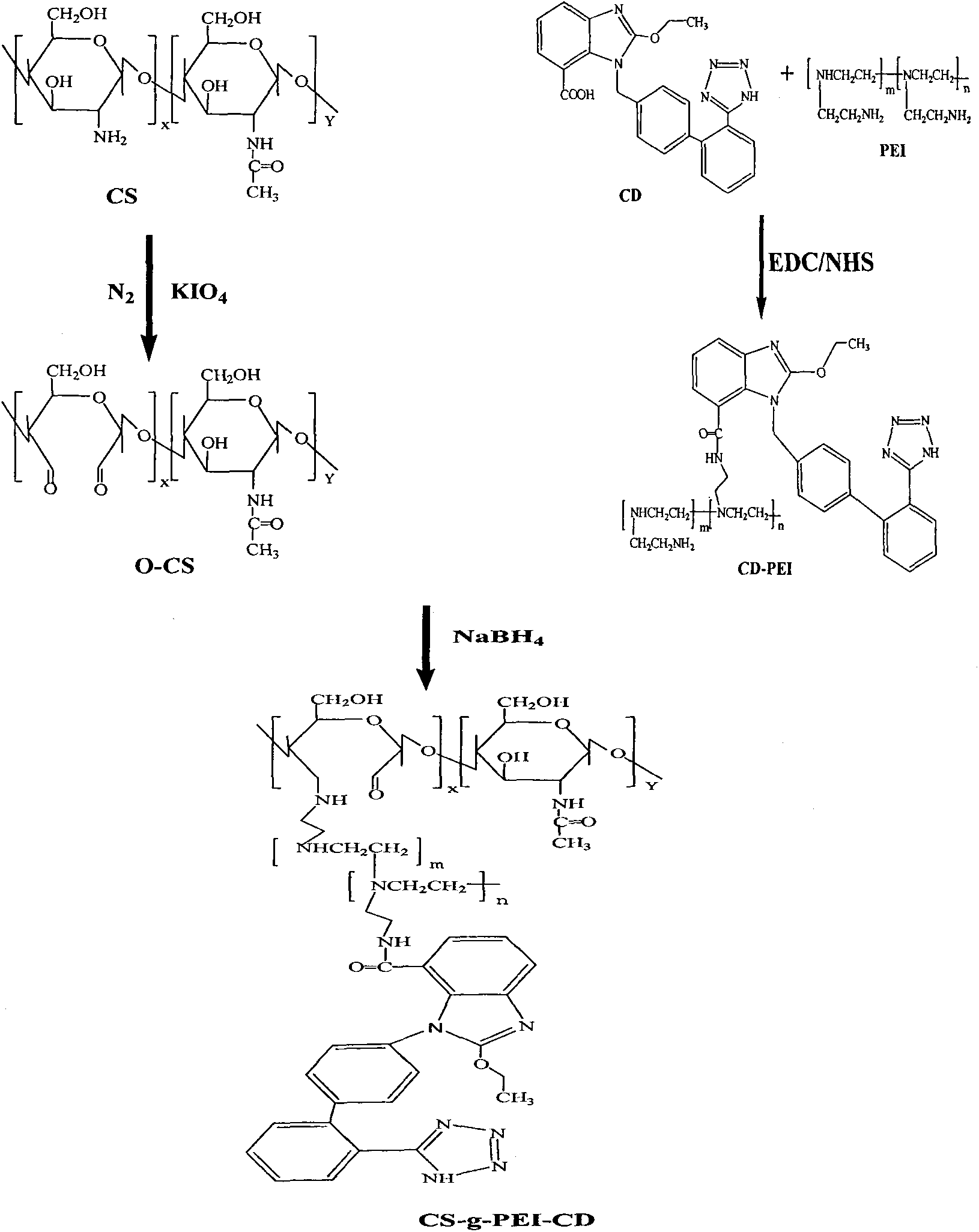

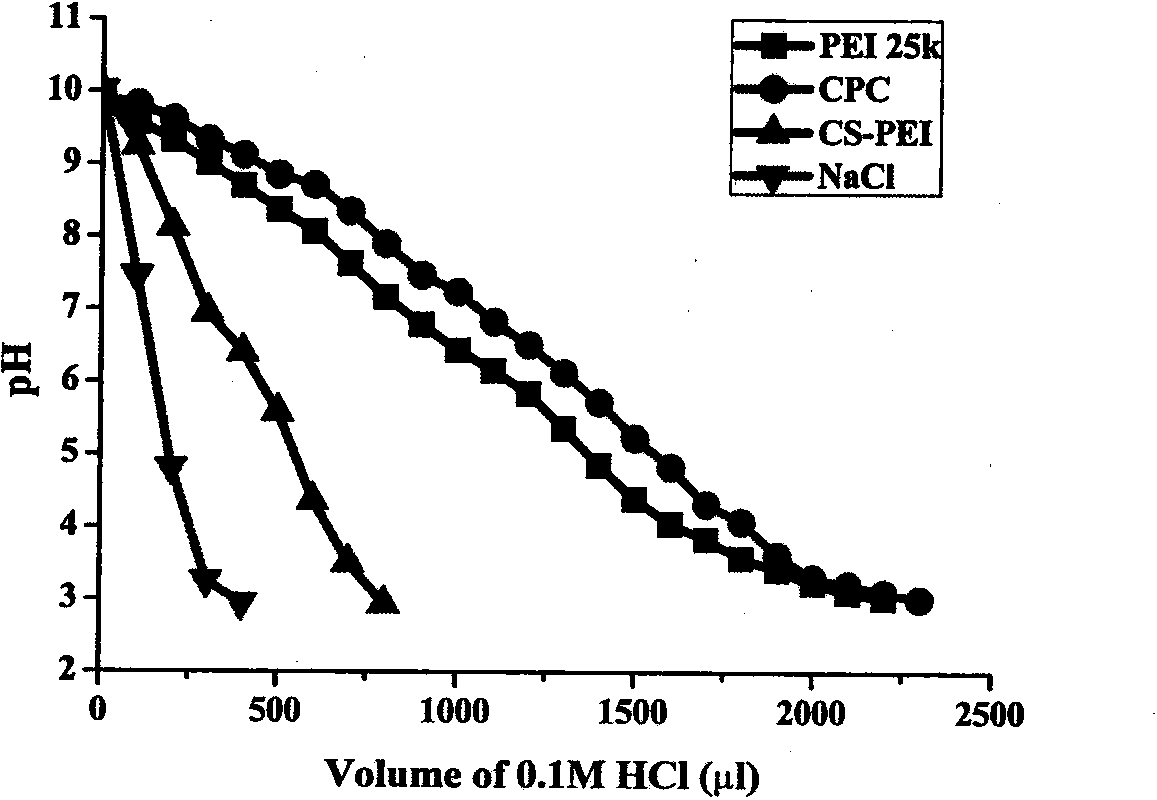

Multifunctional cationic polymer gene vector, and preparation method and application thereof

InactiveCN103396557AHas a targeted effectEnhanced proton buffering capacityGenetic material ingredientsPharmaceutical non-active ingredientsCytotoxicityPlasmid dna

The invention relates to a multifunctional cationic polymer gene vector and a preparation method and application thereof. A multifunctional cationic polymer is synthesized by oxidizing low molecular weight chitosan used as a framework material with potassium periodate and subjecting the oxidized low molecular weight chitosan and polyethyleneimine coupled with a sartan-class drug to reduction and ammonification. To overcome technical problems, the invention provides the novel cationic polymer with targeting performance of the acceptor of the tumor cell AT1, multiple proton buffering capability and adjuvant therapy effects on tumors and provides a preparation method with the advantages of mild conditions, low cost, applicability and reliability for the cationic polymer. A compound formed by the cationic polymer provided by the invention and plasmid DNA has the advantages of low cytotoxicity, good targeting performance, high transfection efficiency, substantial in-vitro antineoplastic effects, etc.; the polymer can be used for preparation of a non-virus gene transfer system capable of simultaneously transferring a gene drug and a chemical drug for cooperated treatment of a tumor.

Owner:CHINA PHARM UNIV

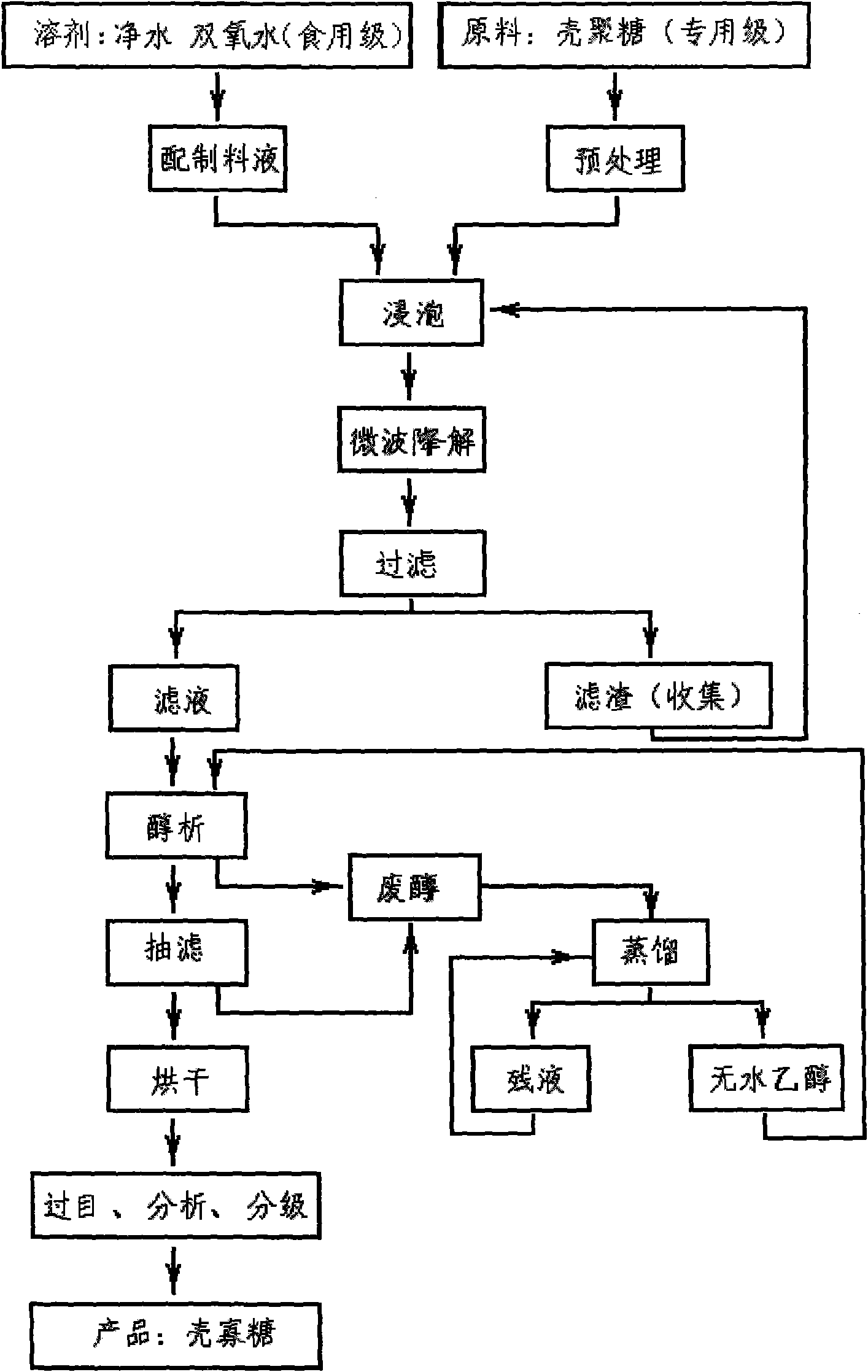

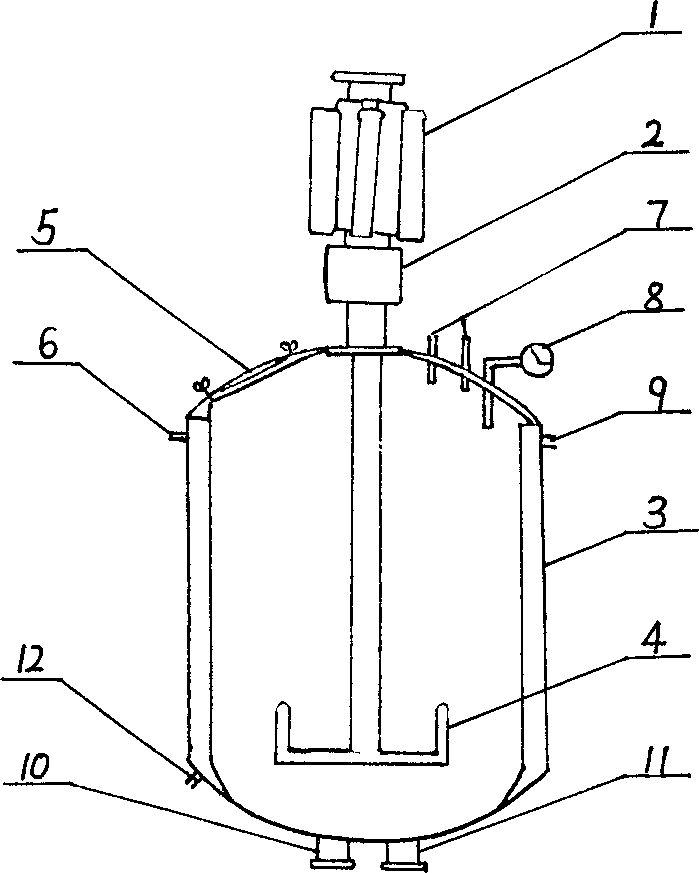

Method for preparing chitosan into water-soluble chitosan oligosaccharide

The invention relates to a method for preparing chitosan into water-soluble chitosan oligosaccharide, which takes the chitosan as raw material and comprises the following steps of: treating the chitosan by rinsing and drying technique, and then soaking in material liquid prepared by purified water and food grade hydrogen peroxide; carrying out microwave radiation degradation treatment, and formingthe mixed liquid of low molecular weight chitosan oligosaccharide which can be dissolved in the material liquid and chitosan part of which is not dissolved; after that, filtering and obtaining the residue of the chitosan and the chitosan oligosaccharide solution; and finally, adding the chitosan oligosaccharide solution into absolute alcohol for alcohol precipitation, and then carrying out suction filtration and drying, thus obtaining the finished product of the water-soluble chitosan oligosaccharide. By adopting the microwave radiation degradation treatment technology and exciting energy bya physical method, the higher molecular weight chitosan is degraded into the low molecular weight water-soluble chitosan oligosaccharide with stable structure, no reaction by-product is generated in the degradation process, and no contaminant is produced; furthermore, compared with the preparation method in the prior art, the method has the advantages of advanced technique, simple working procedures, little production facility investment, high purity of the product, stable quality and the like, thus opening up wide market application prospect for preparing the chitosan oligosaccharide by taking the chitosan as raw material.

Owner:SHANGHAI 007 MOTIVE TECH DEV

Technology for producing high chitosan, microcrystall chitosan and water-soluble low molecular chitosan

The production process of chitosans includes the following steps: placing the cleaned shrimp peel and crab shell as raw material into a reactor still, making deproteinization, decalcification, decolouration and deactylation to obtain flake chitosan with high deacetylation degree; then making the flake chitosan produce polymerization reaction respectively with glacial acetic acid and NaOH solutionto separate out crystal type chitosan; centrifugal-drying and pulverizing to obtain microcrystal chitosan; utilizing oxidant to cut the flake chitosan with macromolecular weight to reduce its molecular weight, then using ethyl alcohol to make precipitation, washing, vacuum-drying and pulverizing so as to obtain the water-soluble low-molecular weight chitosan product.

Owner:周家武

Antibacterial chitosan gel and preparation method thereof

ActiveCN104027300ALower resistanceHigh biosecurityOrganic active ingredientsPeptide/protein ingredientsCarrageenanIrritation

The invention relates to antibacterial chitosan gel and a preparation method of the antibacterial chitosan gel. The preparation method includes the steps of preparing complex liquid containing chitosan, preparing a fibroin ethanol solution, preparing a carrageenan solution, preparing a quaternary phosphonium compound solution, preparing gel and other steps. According to the antibacterial chitosan gel, high-molecular-weight chitosan and low-molecular-weight chitosan compounds are used as main base materials in cooperation with antibiotic synergist, gelatinizing agents, histocyte repairing auxiliary materials and the like for being compounded, and use of other chemicals, biological drugs and other ingredients is avoided; as a result, the safety of the gel is improved, cost is reduced, irritation to patients is reduced, and health restoration of the patients is facilitated. The ability of the prepared antibacterial chitosan gel to resist bacteria such as staphylococcus aureus, coliform bacteria, streptococcus and pseudomonas aeruginosa reaches more than 99 percent, so the antibacterial chitosan gel shows good bacteriostatic ability.

Owner:JIANGSU RUIJING TECH DEV

Agaricus bisporus film-free preservative and use thereof

InactiveCN102177960ANo pollution in the processChange colorFruit and vegetables preservationVitamin CAdditive ingredient

The invention discloses an agaricus bisporus film-free preservative and use thereof. The agaricus bisporus film-free preservative is an aqueous solution of the following components in percentage by mass: 1.2 to 2.5 percent of low-molecular-weight(1,000 to 3,000) chitosan oligosaccharide, 0.4 to 0.6 percent of citric acid, 0.4 to 0.6 percent of sodium chloride, 0.2 to 0.3 percent of vitamin C, 0.0001 to 0.0003 percent of cysteine. Compared with the agaricus bisporus preservative in the prior art, the agaricus bisporus film-free preservative disclosed by the invention has the prominent advantages that: the edible low-molecular-weight chitosan oligosaccharide is used as a main ingredient; film is not formed; color is not changed; the operation is convenient; the shelf period can be prolonged by 3 to 5 days at normal temperature (25 DEG C) and by 15 to 20 days at a low temperature (5 DEG C); and the preservative is edible, pollution-free, environment-friendly and low in cost.

Owner:LIANYUNGANG ACAD OF AGRI SCI

Method for preparing low molecular weight chitosan under steady magnetic field condition

InactiveCN101397580AEasy to recycleImprove degradation rateOn/in organic carrierFermentationCelluloseAcetic acid solution

The invention discloses a method for preparing low-molecular chitosan under a static magnetic field, which comprises the steps of: the preparation of chitosan acetic acid solution, the preparation of magnetic chitosan microspheres, the preparation of magnetic immobilized cellulose and the preparation of the low-molecular chitosan. The method not only can improve the degradation rate of macromolecular substances, but also can provide theoretical base for realizing continuous production; simultaneously, the method is convenient for recycling the enzyme, improving the utility ratio of immobilized enzyme and reducing the cost.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of low molecular weight chitosan

ActiveCN107652373AGood anti-fatigue effectAdvantages of preparation methodRadiation DosagesFiltration

The invention belongs to the technical field of chitosan degradation, and concretely relates to a preparation method of low molecular weight chitosan. The preparation method of the low molecular weight chitosan comprises the following steps: immersing chitosan in a solution containing hydrogen peroxide and water-soluble humic acid for a period of time, performing filtration to obtain filter residues, freezing the filter residues three times, unfreezing the frozen filter residues, drying the unfrozen chitosan in a shady place, grinding the dried chitosan to form fine powder, and irradiating thefine powder at normal temperature under normal pressure. The preparation method of the low molecular weight chitosan can effectively reduce the radiation dosage, and the obtained product has a narrowmolecular weight distribution and a low molecular weight.

Owner:广州华大生物科技有限公司

Chitosan based polymer conjugate and a method for producing the same

InactiveUS8431543B2Improve in vivo transfer efficiencyLow cytotoxicityPeptide/protein ingredientsGenetic material ingredientsPolyethylene glycolCytotoxicity

The present invention relates to a conjugate of chitosan and polyamine polymer that is useful for transferring a desired gene medicine into cells, and a method for preparing the same. In particular, the present invention relates to a double conjugate that is prepared by 1 in king poly-L-arginine to low molecular weight chitosan or triple conjugate that is prepared by additionally linking polyethylene glycol (PEG) to the double conjugate, and a method for preparing the same. The chitosan based cationic polymer conjugate of the present invention forms a complex with negatively charged gene medicine such as plasmid DNA and small interfering RNA to efficiently transfer the desired gene medicine into cells with low cytotoxicity. Accordingly, the conjugate can be used as an effective delivery system for in vivo administration of gene medicine.

Owner:ENGENE INC

Subcellular organelle target directional Chitosan oligosaccharide-aliphatic acid grafting matter and preparation and application thereof

InactiveCN101081876AReflect the function of transportFast intakePharmaceutical non-active ingredientsFermentationSubcellular organelleFatty acid

The present invention provides chitosan-fatty acid grafting in the structure as shown, and the chitosan has molecular weight of 1-100 kDa, deacetylating degree of 70-100 % and partial free amino radicals substituted by alkyl radical in the substitution degree of 1-90 %. Through one improved alkylating modification process, degraded chitosan or low molecular weight chitosan is alkylation modified to form the chitosan-fatty acid grafting in special structure. The chitosan-fatty acid grafting may form micelle capable of being used as particle carrier for subcellular organelle in relevant research and preparing target medicine.

Owner:ZHEJIANG UNIV

Method for preparing chitosan-silver ion anti-bacterial viscose fiber from corps straw

InactiveCN101440535ASoft touchGood moisture absorptionMonocomponent cellulose artificial filamentWet spinning methodsCelluloseBiocompatibility Testing

The invention relates to method for preparing a chitosan-silver ion antibacterial viscose fiber from crop straws, which belongs to the technical field of viscose fiber. The method adopts rich-resource crop straws as raw materials, removes impurities by a chemical degumming method to obtain cellulose crude slurry, and prepares a viscose spinning stock solution thereof. A chitosan acetum is prepared from low molecular weight chitosan and acetic acid, and is then mixed with a silver nitrate solution and ammonia in proportion to obtain an antimicrobial agent; and the antimicrobial agent is added to the viscose spinning stock solution to prepare the antibacterial viscose fiber through spinning. The antibacterial viscose fiber prepared by the method belongs to a natural antibacterial product, is soft in handfeel, nontoxic and nonirritating to human body, and a textile made from the antibacterial viscose fiber has the characteristics of good moisture absorption and retention, biocompatibility and low cost, and is most applicable to antibacterial core material and sanitary towel fabric in food film package.

Owner:JIANGNAN UNIV

Method for preparing chitosan oligosaccharide with trichoderma reesei cellulase

InactiveCN101280330ALow costAvoid destructionMicroorganism based processesFermentationSodium acetateStrong acids

The invention relates to a method for preparing chitosan oligosaccharide by using trichoderma reesei cellulose. After purified chitosan oligosaccharide powder is swelled by using water, acetic acid solution is added to completely dissolve the chitosan oligosaccharide powder, aspergillus niger cellulose is dissolved by using ammonium acetate or sodium acetate aqueous solution, to prepare enzyme solution with a concentration of 0.5 to 2mg / ml; when the temperature is lower than 40 to 55DEG C, the enzyme solution is added to perform enzymolysis reaction, to obtain low molecular weight chitosan oligosaccharide, after performing acetone-water fractional precipitation, low molecular weight products with different distribution scopes can be obtained through concentration drying. The advantages of the invention is that the reaction conditions are mild, strong acids and strong alkalis are not adopted, the damage to the oligomer is avoided, the invention is free from environmental contamination, and is an ideal method for degrading the chitosan oligosaccharide.

Owner:NANCHANG HANGKONG UNIVERSITY

Low molecular weight chitosan oligosaccharides and its preparation method

ActiveUS20070089978A1Increase the frequency of collisionsIncrease ratingsBiocideAnimal repellantsSolventWater soluble chitosan

The present invention relates to low molecular weight chitosan oligosaccharides and its preparation method. Chitosan oligosaccharides were obtained under microwave irradiation assisted the electrolyte. The method of preparing chitosan oligosaccharides was described as follows: acid solvent containing electrolyte was added to chitosan. The reaction was performed at 480˜800 W for 3˜12 min. After irradiation ceased, the reaction liquid was cooled to room temperature. Then the solution was adjusted to neutrality with 1˜10 M NaOH or KOH and obtained the pale yellow floc. The processes of precipitation, filtering, desiccation and crushing are settled sequentially. Finally, chitosan oligosaccharides were obtained. Method of the present invention makes chitosan degrade to water-soluble chitosan oligosaccharides and it makes some inert substance become active. The method of the present invention can cut down energy consumption, decrease pollution and save time and raw materials. It has applying perspective of industry and potentiality of extensive market.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

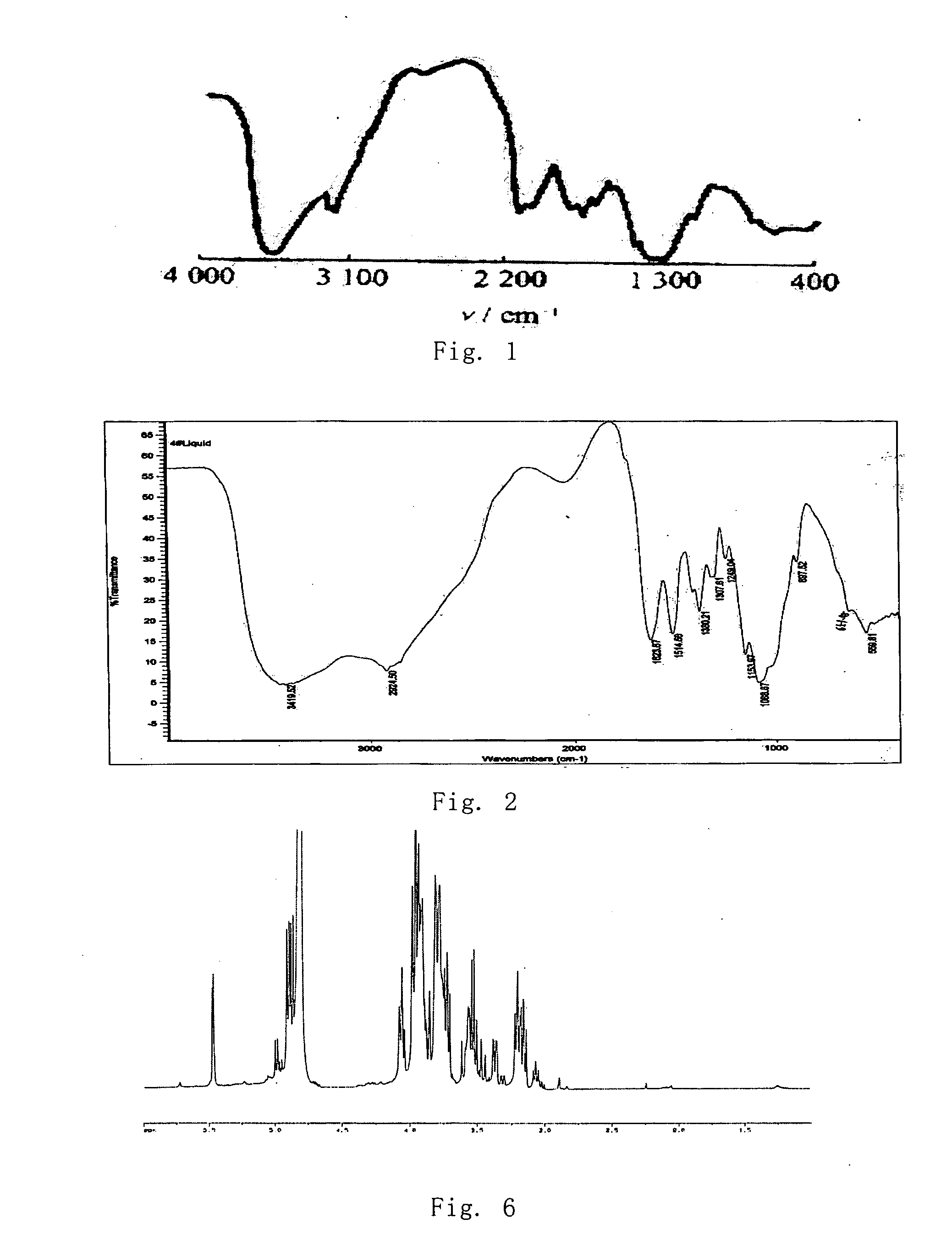

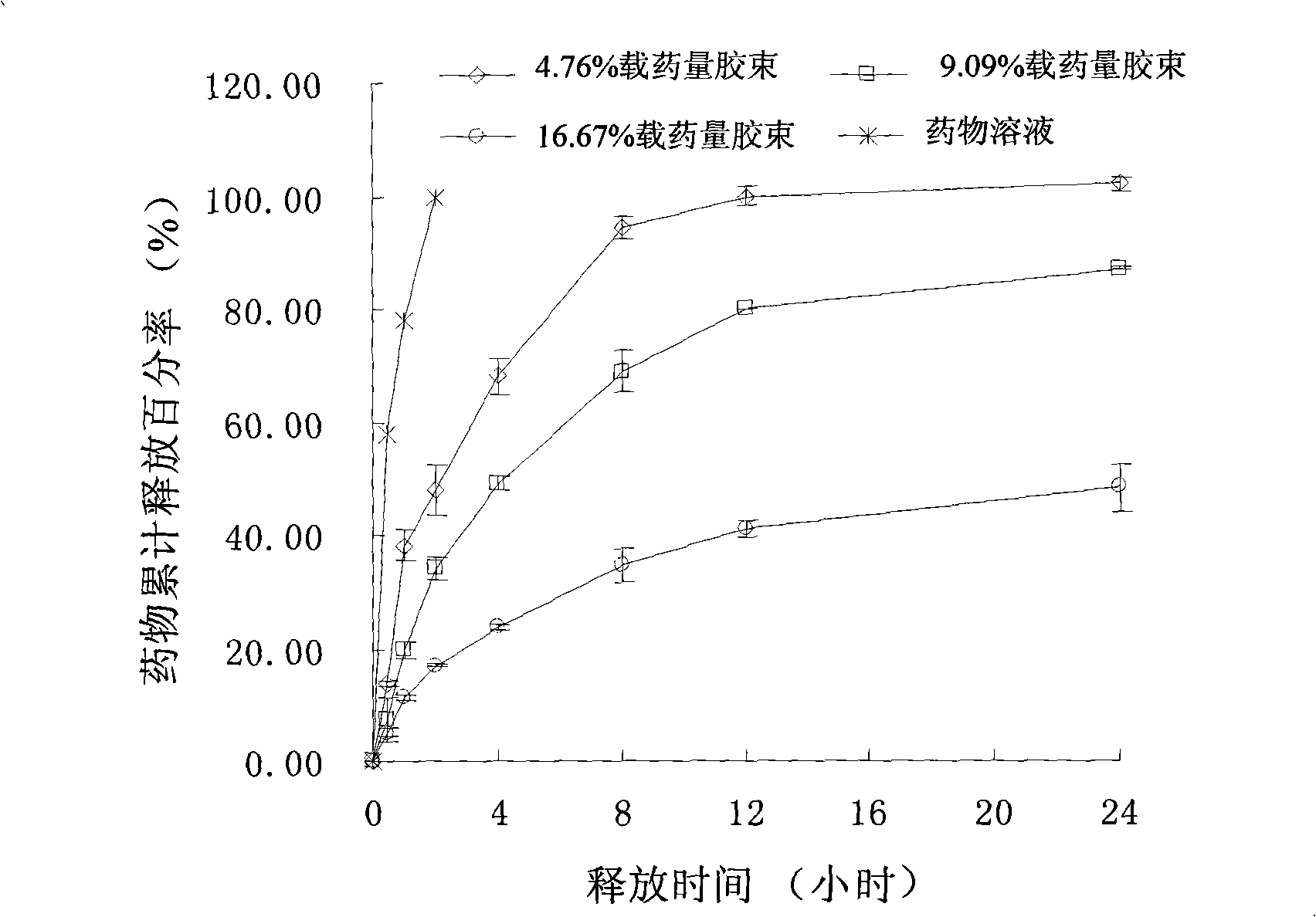

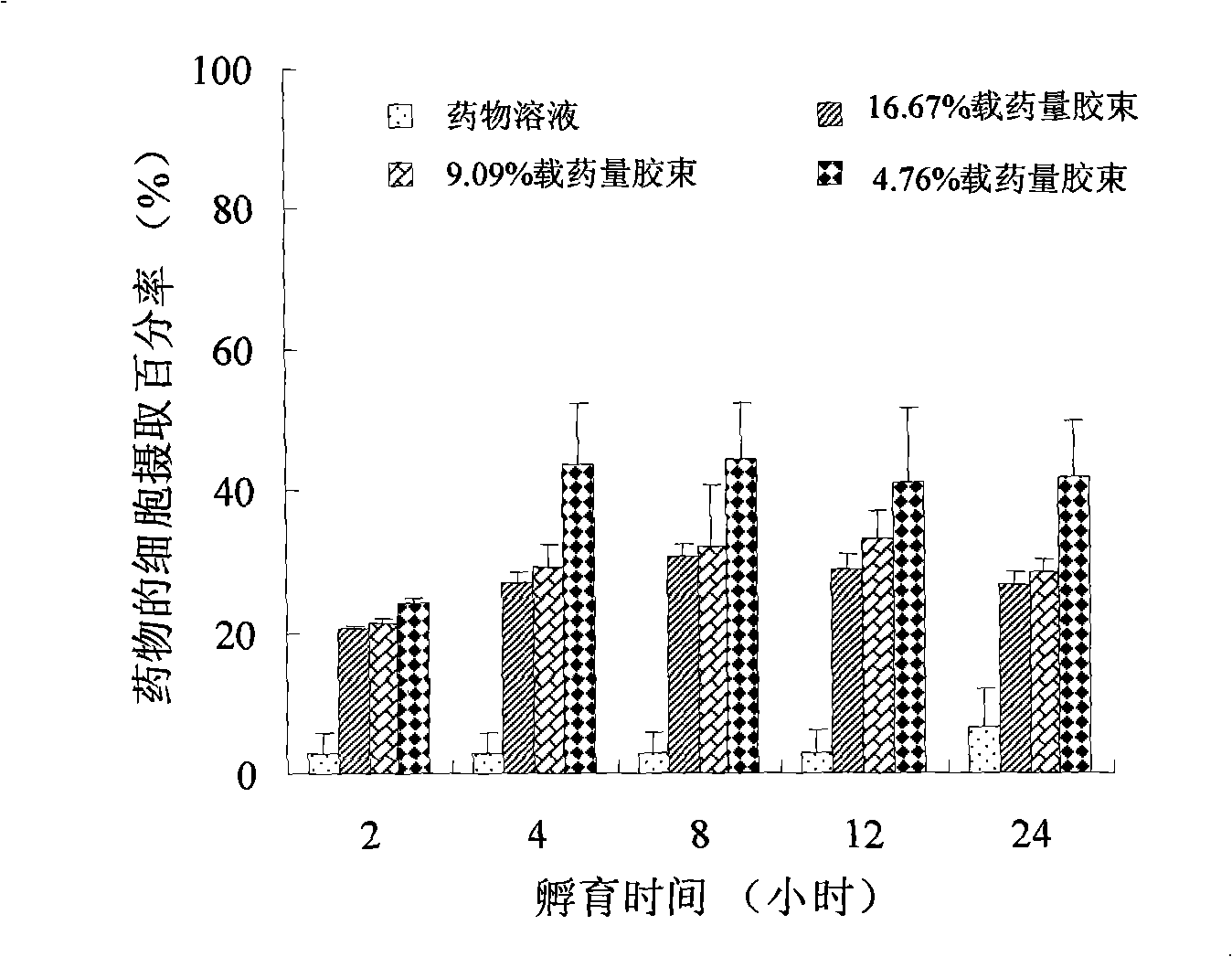

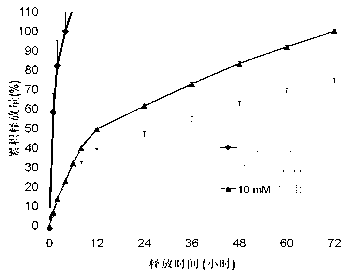

Chlorin e6 chitosan-stearic acid graft micelle

InactiveCN101524326AReduced phototoxic side effectsSmall toxicityOrganic active ingredientsEnergy modified materialsStearic acidLow molecular weight chitosan

The invention provides a preparation of chlorin e6 chitosan-stearic acid graft micelle. The preparation comprises a chitosan-stearic acid graft and chlorin e6, wherein, the chlorin e6 accounts for 4.76-16.76% of the total weight; the chitosan-stearic acid graft is formed by chemically grafting low molecular weight chitosan with average molecular weight being 18.0 KDa and stearic acid; and the amino substituted ration of the chitosan-stearic acid graft accounts for 4.96%. The invention utilizes the chitosan-stearic acid graft micelle to effectively pack the photosencitizer of chlorin e6, so as to prepare the intracellular administration preparation of chlorin e6 chitosan-stearic acid graft micelle. Compared with the chlorin e6 solution, the preparation of the invention can significantly improve the drug concentration of chlorin e6 in tumour cells and provide probability for the follow-up realization of efficient and harmless photodynamic therapy of tumors.

Owner:ZHEJIANG UNIV

Method for preparnig functional protein powder by usnig waste water produced by processing fish powder

InactiveCN1502624AReduced settling timeGood effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFlocculationMicrowave

The present invention relates to a method for preparing functional protein powder by utilizing waste water produced by processing fish powder, said method includes the following steps: neutralizing said waste water, making flocculation, diluting obtained flocculate, microwave degrading and using magnetic membrane to make filtration so as to obtain the invented protein powder. The weight percentage concentration of the acid for making neutralization is 1-10 % , and pH value after neutralization is 6-7. The described flocculation adopts chitosan colloid solution, and its use level is that the volume ratio of it and fish power waste water protein is 1:30-1:50, and the flocculation time is 6-12 hr, and the described microwave degrading time is 2-5hr.

Owner:OCEAN UNIV OF CHINA

Glutathione sensitive alkylated chitosan and preparation and application thereof

InactiveCN102875695APayload resistanceAchieve controlled releasePharmaceutical non-active ingredientsHigh concentrationDisulfide bond

The invention provides a disulfide-bond bonded alkylated chitosan. The alkylated chitosan is prepared by performing alkylated modification on low-molecule chitosan by bonding of a disulfide bond. The alkylated chitosan can form a polymer micelle by self-aggregating in an aqueous medium, can be efficiently absorbed by cells and can serve as a nano carrier with high performance, and by utilizing high-concentration glutathione in the cells, the controlled release of a medicine is realized; by the carrier, the medicine can be safely transported in a body; controlled release of a macromolecule in target cells is explored; and theoretical and technological basis is supplied for target controlled release treatment of the medicine.

Owner:ZHEJIANG UNIV

Marine culture biological cleanser and preparation method thereof

ActiveCN101891307AConserve fresh water resourcesLow costBiological water/sewage treatmentEnzyme digestionSucrose

The invention discloses a marine culture biological cleanser and a preparation method thereof. The marine culture biological cleanser comprises the following components in percentage by mass: 5-18 ppm of chitosan oligosaccharide, 50-70% of sea water, 6-12% of biological bacterium solution, 6-12% of sucrose and 15-26% kelp dreg. The biological bacterium solution is a microbial preparation which is compounded and cultured from photosynthetic bacteria, bacillus and lactic acid bacteria. The chitosan oligosaccharide is prepared by the following steps: extracting chitin from Alaska queen crab, deacetylating the chitin to prepare chitosan, and carrying out enzyme digestion on the chitosan to obtain low-molecular weight chitosan. The invention saves the fresh water resources, lowers the cost and enhances the purifying effect for marine culture.

Owner:山东巴斯德生物科技有限公司

Proanthocyanidin sustained release nano-micro spheres, as well as preparation method and application thereof

ActiveCN103536583AOvercome environmental problemsOvercome the conditionsPowder deliveryOrganic active ingredientsPulmonary inhalationPhospholipid

The invention relates to proanthocyanidin sustained release nano-micro spheres. The proanthocyanidin sustained release nano-micro spheres comprise 1-5 parts of proanthocyanidin, 1-12 parts of chitosan or derivatives thereof, 1-12 parts of phospholipid or derivatives thereof and 1-10 parts of excipients, wherein the chitosan and the derivatives thereof are one or more of high, medium and low-molecular weight chitosan, chitosan oligosaccharide, chitosan quaternary ammonium salt and carboxymethyl chitosan. The particle size of the proanthocyanidin sustained release nano-micro spheres is 10nm-0.3 mu m; the proanthocyanidin is prepared into the powder sustained release nano-micro spheres, and the proanthocyanidin sustained release nano-micro spheres can directly play a role in the lung as a pulmonary inhalation medicine-carrying formulation, improve the bioavailability of the proanthocyanidin and reduce the dosage by sustained release; the proanthocyanidin nano-micro spheres can also be applied as an oral sustained release formulation; the proanthocyanidin nano-micro spheres have appropriate particle size and morphology and other powder properties, as well as sustained release; furthermore, the preparation method has the advantages of simplicity and convenience in operation, stable process and easiness in industrial production.

Owner:WEIFANG MEDICAL UNIV

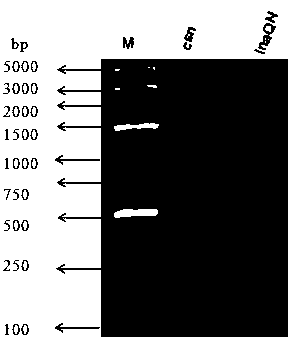

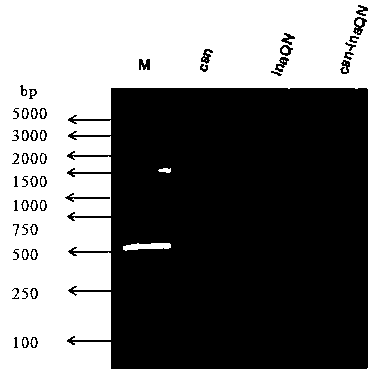

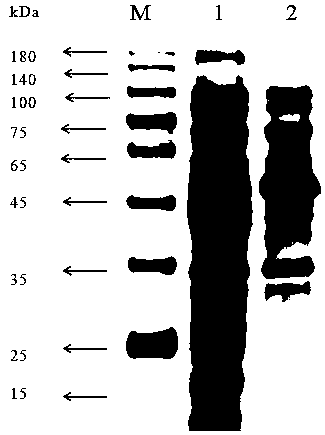

Display system of chitosanase cell surface and preparation and application thereof

InactiveCN108642027AReduce cumbersome stepsLow costBacteriaMicroorganism based processesNucleotideIce nucleus

The invention provides a display system of a chitosanase cell surface. A fused gene segment is obtained by fusing a gene csn and a gene inaQN, wherein the gene csn is coded with chitosanase and the gene inaQN of an N-terminal structural domain of an ice nucleating protein is responsible for transmembrane transport and has an anchoring function. The fused gene segment is expressed on the surface ofa host cell, and the display system of the chitosanase cell surface is obtained. The nucleotide sequence of the gene csn is showed as SEQID NO.1. The nucleotide sequence of the gene inaQN is showed as SEQIDNO. 2. The invention further provides a preparation method of the display system of the chitosanase cell surface. The display system of the chitosanase cell surface can directly react with thechitosan in a solution, tedious steps of protein purification are saved, and cost of producing low-molecular-weight chitosan and oligomeric chitosan is reduced greatly. The display system of the chitosanase cell surface has great application prospects in the field of low molecular weight chitosan and oligomeric chitosan preparation.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com