Preparing low molecular weight chitosan by sensitizing radiation degradation method

A low-molecular-weight chitosan technology, which is applied in the field of low-molecular-weight chitosan preparation by radiation method, can solve the problems of difficult control of acid hydrolysis conditions, difficult product separation and purification, long production cycle, etc., and is conducive to large-scale industrial production , high yield of low molecular weight products, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

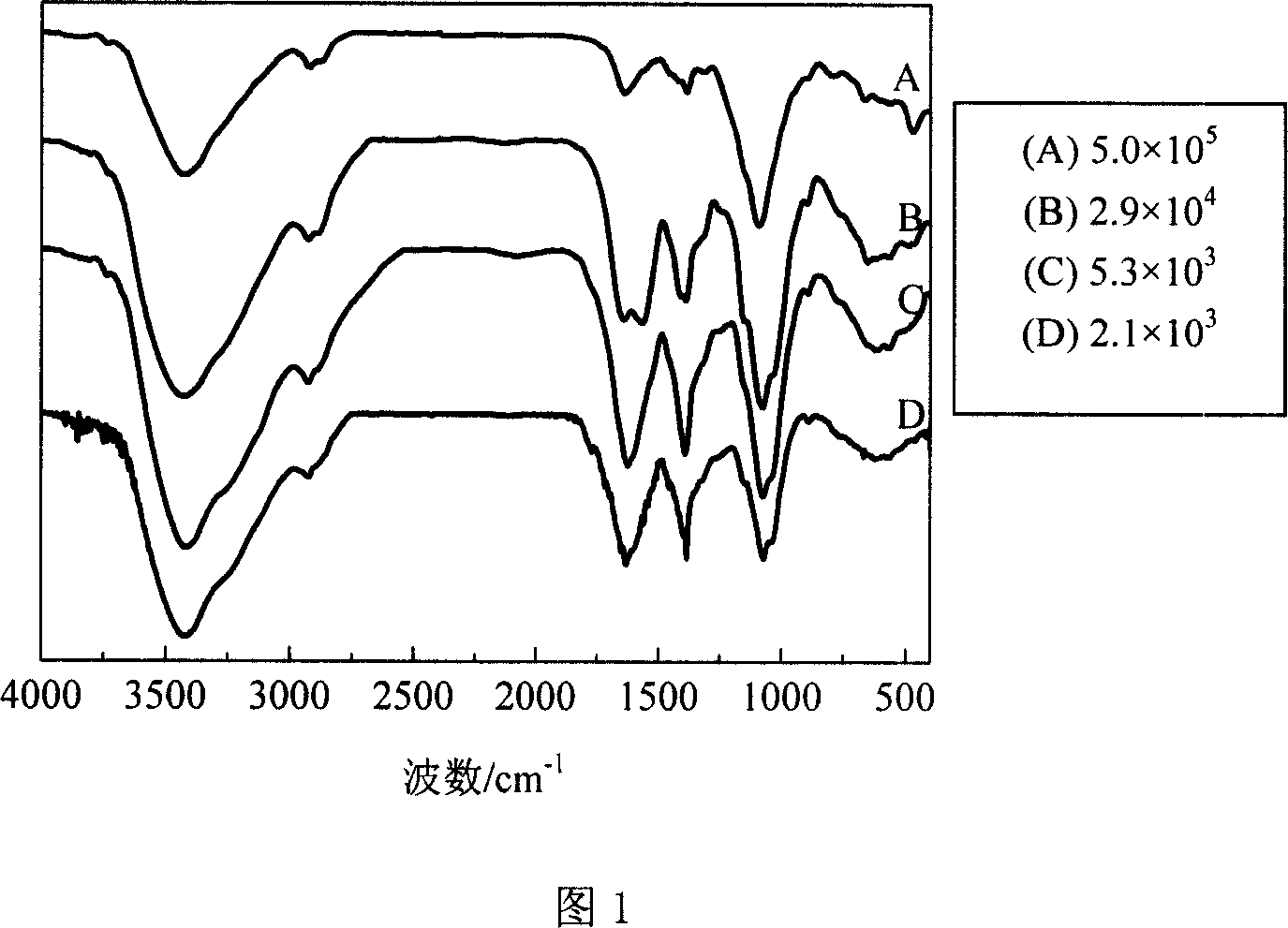

[0020] Commercialized high molecular weight chitosan (molecular weight is about 500,000) is mixed with the aqueous solution containing hydrogen peroxide, wherein the mass concentration of chitosan is 20%, the mass concentration of hydrogen peroxide is 25%, and the pH is adjusted with hydrochloric acid to around 4. then use 60 Coγ-rays are irradiated at room temperature, and the absorbed dose is 1-8 kGy. The low molecular weight chitosan prepared under the above-mentioned different dosages is shown in the table below:

[0021] project

Dose (kGy)

Average relative molecular weight (Dalton)

Radiolysis sample one

1

29196.4

Radiolysis Sample II

2

10755.8

Radiolysis Sample Three

3

5394.8

Radiolysis Sample Four

4

2140.5

Radiolysis Sample Seven

6

1468.0

Radiolysis Sample Eight

8

1124.3

[0022] * The data was tested and provided by the Chitin Research ...

Embodiment 2

[0027] Because the source of chitosan is different, the producer of production is different, and its property such as the molecular weight of chitosan, deacetylation degree has bigger difference, when adopting the method described in embodiment 1 to degrade chitosan like this, can change according to different situations The mass concentration of chitosan, and the amount of hydrogen peroxide added. If the molecular weight of the original chitosan is on the low side, such as 150,000, the concentration of the chitosan can be increased to 25%, and the concentration of the sensitizer added is also increased to 30% accordingly; if the molecular weight of the original chitosan is too large , such as 800,000, the concentration of chitosan can be reduced to 16%, and the concentration of the added sensitizer is correspondingly reduced to 16%. Then adjust the pH to 4 with hydrochloric acid, 60 Co gamma-rays were irradiated at room temperature, and the molecular weight of chitosan obtai...

Embodiment 3

[0029] The hydrochloric acid in above-mentioned embodiment 1 is changed into acetic acid, then adopts same step, can obtain the low molecular weight chitosan product of acetic acid type, after adding acetic acid, the molecular weight ratio of gained chitosan under the same absorbed dose is in adding hydrochloric acid condition The molecular weight of chitosan obtained is slightly higher, and other properties are basically the same.

[0030] Note: Low molecular weight chitosan products of hydrochloric acid type or acetic acid type can be directly used as medicines and food additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com