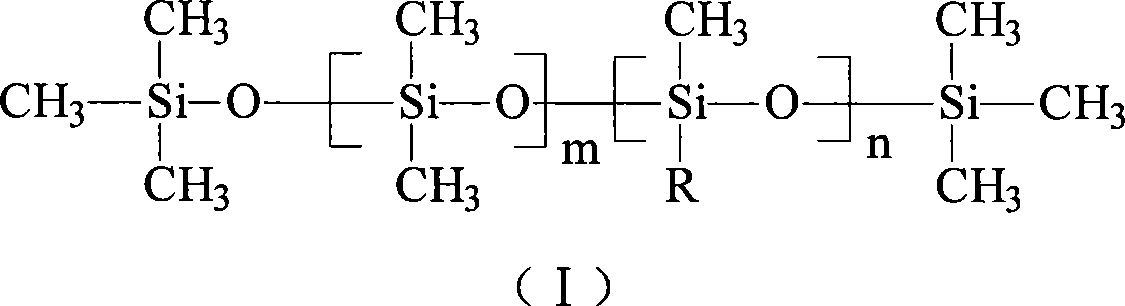

Masked non-ionic surfactant, preparation method and application thereof

A non-ionic surface and active agent technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of surfactant surface activity, emulsification performance and comprehensive balance performance to be improved, and achieve broad processing The effect of latitude, excellent performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

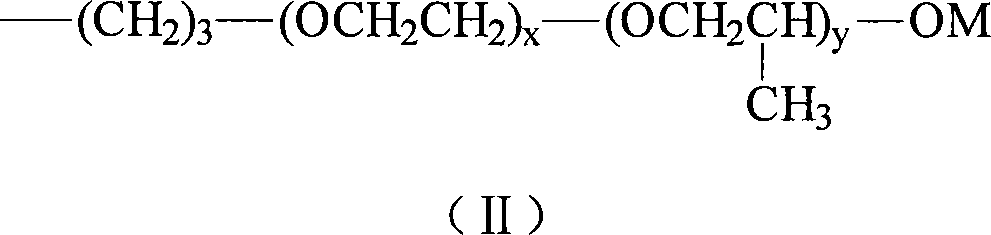

[0036] A) Add 5.8g of allyl alcohol, 150g of ethylene oxide and 100g of propylene oxide into the reactor, in the presence of 0.0025g of bimetallic catalyst hexacyanocobaltate zinc compounds, the pressure is ≤0.2Mpa, and the reaction temperature is 115°C React for 5 hours under the same conditions to obtain acryl-terminated polyether; then add 2.0g of sodium hydroxide, raise the temperature to 120°C under normal pressure and keep it warm for 3 hours, then carry out vacuum distillation, then cool the material to 75°C, and add excess chlorine methane and control the pressure to ≤0.4Mpa, adjust the pH to 5.2, and filter the material to obtain the modified polyether R1. Adjust the ratio of materials to prepare modified polyether R2;

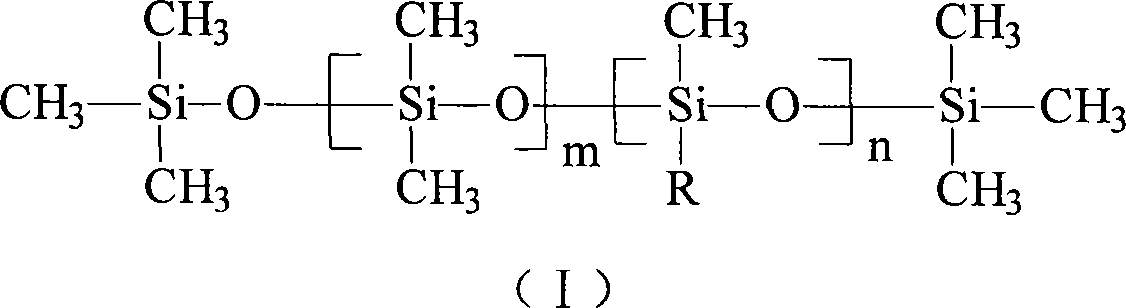

[0037] B) react octamethylcyclotetrasiloxane, hydrogen-containing silicone oil, and hexamethyldisiloxane under the action of sulfuric acid at a reaction temperature of 70°C for 5 hours to obtain polysiloxane (II), wherein The molar ratio between octa...

Embodiment 2

[0047]A) Add 5.8g of allyl alcohol, 200g of ethylene oxide and 100g of propylene oxide into the reactor, in the presence of 0.003g of bimetallic catalyst hexacyanocobaltate zinc compounds, the pressure is ≤0.2Mpa, and the reaction temperature is 100°C React under the conditions for 6 hours to obtain acryl-terminated polyether; then add 3.5g of sodium hydroxide, raise the temperature to 125°C under normal pressure and keep it warm for 3 hours, then carry out vacuum distillation, then cool the material to 70°C, and add methyl chloride And control the pressure ≤ 0.4Mpa and keep it warm for 1 hour, then adjust the pH to 5-6, and filter the material to obtain the modified polyether R1. Adjust the ratio of materials to prepare modified polyether R2;

[0048] B) react octamethylcyclotetrasiloxane, hydrogen-containing silicone oil, and hexamethyldisiloxane under the action of sulfuric acid at a reaction temperature of 75°C for 4 hours to obtain polysiloxane (II), wherein The molar ra...

Embodiment 3

[0058] A) Add 5.8g of allyl alcohol, 200g of ethylene oxide and 100g of propylene oxide into the reactor, in the presence of 0.003g of bimetallic catalyst hexacyanocobaltate zinc compounds, the pressure is ≤0.2Mpa, and the reaction temperature is 130°C Under the conditions of reaction for 4 hours, acryl-terminated polyether was obtained; then 3.5g of sodium hydroxide was added, the temperature was raised to 125°C under normal pressure and kept for 3 hours, and then vacuum distillation was carried out, and then the material was cooled to 70°C, and excess chlorine was added Butane and control the pressure ≤ 0.4Mpa and keep it warm for 1 hour, adjust the pH to 5-6, and filter the material to obtain the modified polyether R1. Adjust the ratio of materials to prepare modified polyether R2;

[0059] B) react octamethylcyclotetrasiloxane, hydrogen-containing silicone oil, and hexamethyldisiloxane under the action of sulfuric acid at a reaction temperature of 75°C for 4 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com