Micro emulsion type water-based metal anti-rusting liquid

A technology of base metal and anti-rust liquid, applied in the field of micro-emulsion type water-based metal anti-rust liquid, can solve the problems of harm to the operator's health, loss of anti-rust effect, and failure of anti-rust performance to reach anti-rust oil, etc. Solve the effect of difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 12g of silicone oil into a four-neck flask, then add 3g of Tween 20 and 2g of Span 80 in sequence, heat and stir, the speed is controlled at 900r / min, and the temperature is controlled at 70°C.

[0034] (2) Dissolve 5g of sodium carbonate, 15g of monoethanolamine borate, 10g of triethanolamine, and 2g of polyethylene glycol in an appropriate amount of deionized water in sequence, and slowly add them dropwise into (1) after completely dissolving.

[0035] (3) Continue stirring the mixture in (2) at constant temperature for 1 h.

[0036] (4) After stirring, add 2g sodium hydroxymethylcellulose and 2g n-butanol to the above solution, make up the remaining amount of deionized water to 250g, slow down the speed to 200r / min, and continue stirring at room temperature for 30min. That's it.

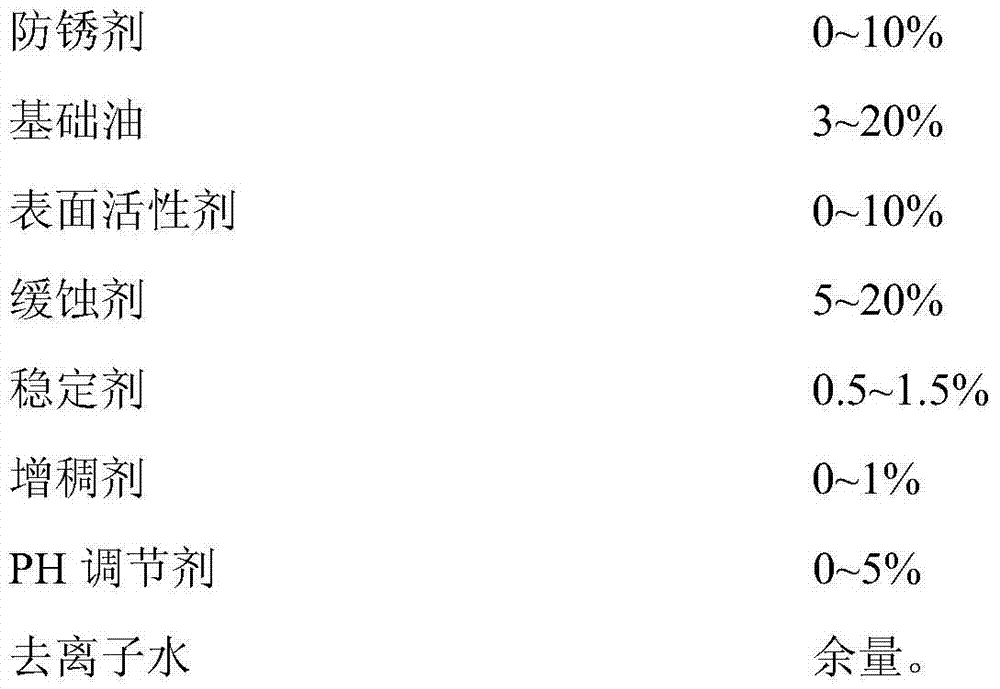

[0037] The formula composition of table one embodiment 1

[0038] component name

Embodiment 2

[0040] (1) Add 12g of kerosene to a four-neck flask, then add 4.5g of Tween 80 and 0.5g of Span 80 in turn, heat and stir, the speed is controlled at 900r / min, and the temperature is controlled at 50°C.

[0041] (2) Dissolve 15g of monoethanolamine borate, 15g of triethanolamine, and 2g of polyethylene glycol in an appropriate amount of deionized water in sequence, and slowly add it dropwise into (1) after completely dissolving.

[0042] (3) Continue stirring the mixture in (2) at constant temperature for 1 h.

[0043] (4) After stirring, add 2g sodium hydroxymethylcellulose, 2g n-butanol, and 10g ammonia water to the above solution, make up the remaining amount of deionized water to 250g, slow down the speed to 200r / min, and continue stirring at room temperature for 30min. That's it.

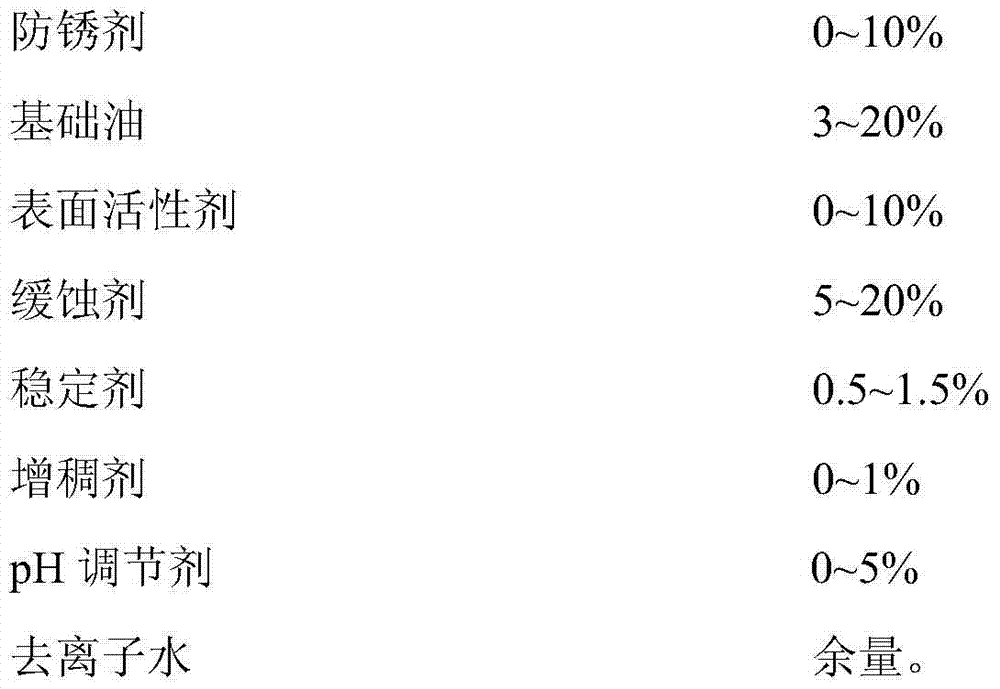

[0044] The formula composition of table two embodiment 2

[0045] component name

[0046] polyethylene glycol

Embodiment 3

[0048] (1) Add 10g of mechanical oil to a four-neck flask, then add 0.75g of AEO-3, 0.5g of AEO-7, and 1.25g of AEO-9 in turn, heat and stir, with the speed controlled at 500r / min and the temperature controlled at 50°C.

[0049] (2) Dissolve 5g of sodium carbonate, 20g of monoethanolamine borate, 20g of triethanolamine, and 2g of polyethylene glycol in an appropriate amount of deionized water in sequence, and slowly add them dropwise into (1) after completely dissolving.

[0050] (3) Continue stirring the mixture in (2) at constant temperature for 1 h.

[0051] (4) After stirring, add 2g sodium hydroxymethylcellulose and 5g n-butanol to the above solution, make up the remaining amount of deionized water to 250g, slow down the speed to 200r / min, and continue stirring at room temperature for 30min. That's it.

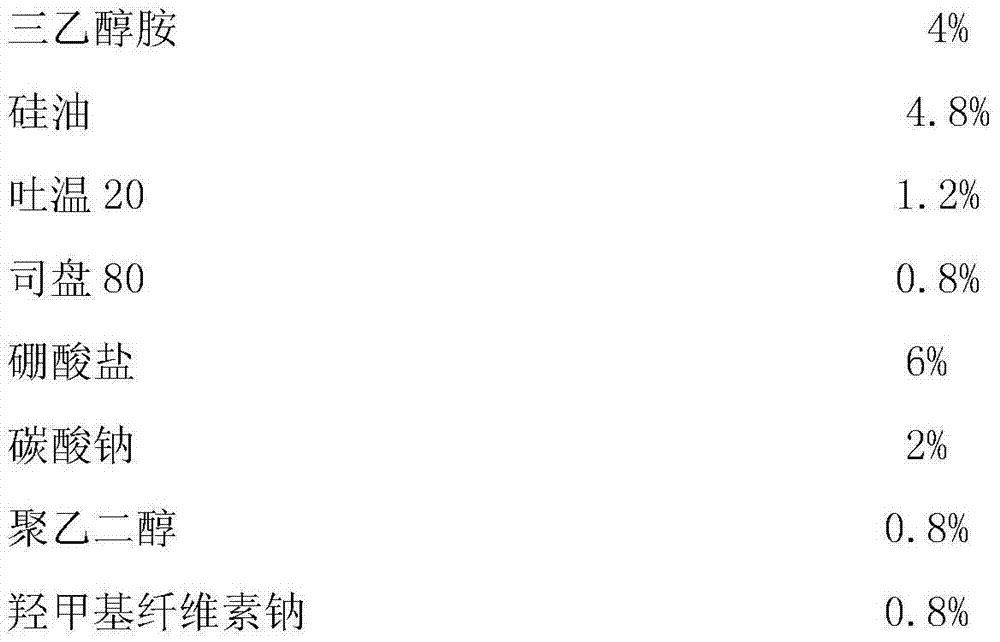

[0052] The formula composition of table three embodiment 3

[0053] component name

[0054] Deionized water

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com