Method for preparing rosin-based surfactant

A technology based on surfactants and surfactants is applied in the field of preparation of rosin-based surfactants, which can solve problems such as insufficient application fields, incomplete varieties, and no literature reports, and achieve outstanding green effect, low surface tension, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of rosin-based surfactant, comprising the steps of:

[0016] The first step, add its quality 0.1~1.0% catalyzer, 0~18% polyalcohol and 2~3000% polyethylene glycol or alkylene oxide in molten rosin or derivative thereof, and it is heated at a temperature of Reaction at 230-290°C for 2-5 hours; Among them, the catalysts are MgO, ZnO, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester, bis(3,5- One or more of di-tert-butyl-4-hydroxybenzylphosphonic acid monoethyl ester) calcium, 2,6-di-tert-butyl p-cresol, the proportion of the mixture is any proportion; the catalyst accounts for rosin or The percentage of its derivative mass can be 0.1%, 0.2%, 0.3%, 0.5%, 0.7%, 0.9%, and the percentage of polyethylene glycol accounting for rosin or its derivative mass can be 10%, 100%, 500%, 800%, 1500%, 1800%, 2000%, 2500%, the molecular weight of polyethylene glycol can be 200, 600, 1000, 4000, 6000, 8000, 10000, 20000, rosin deriv...

Embodiment 2

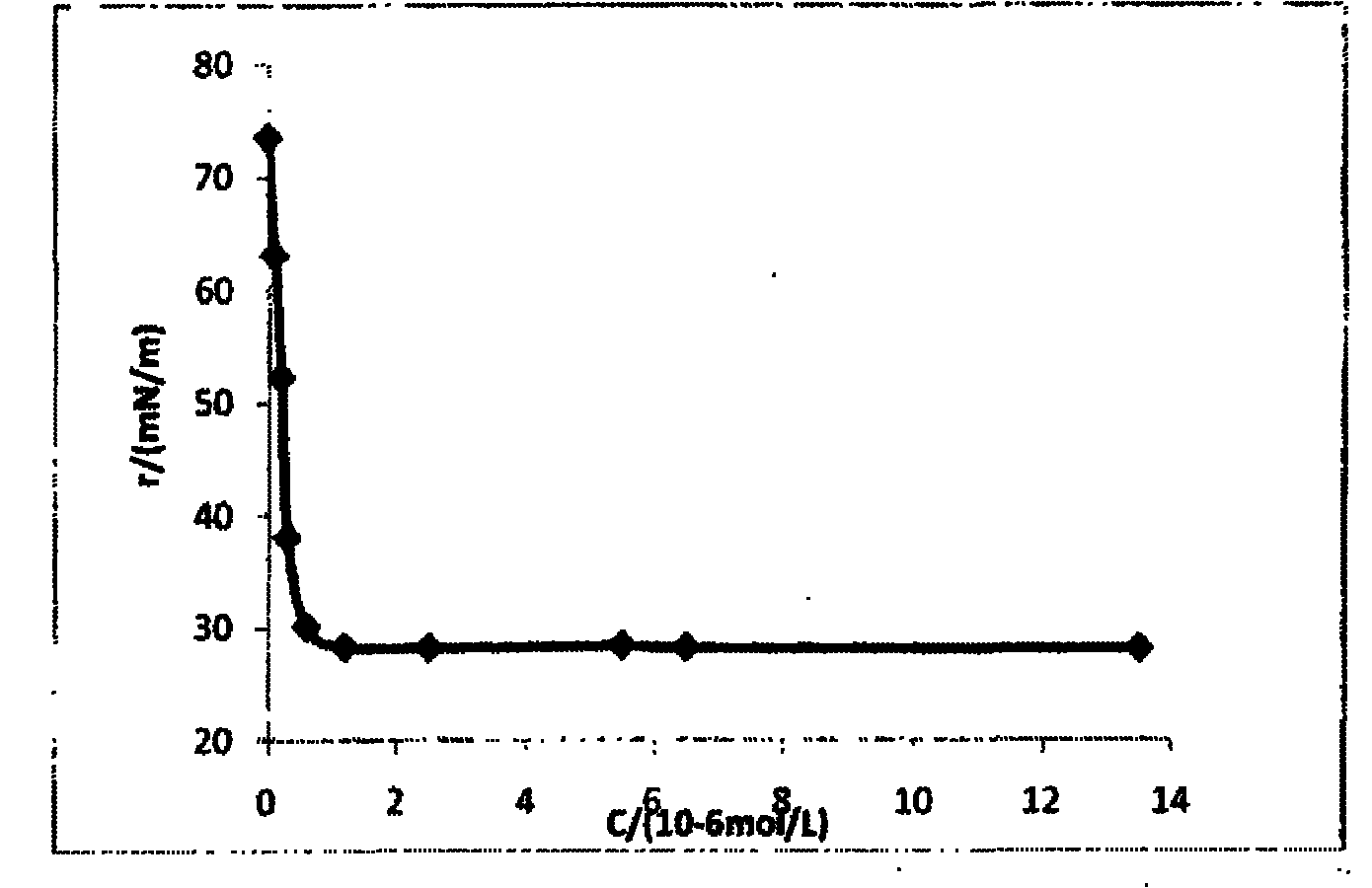

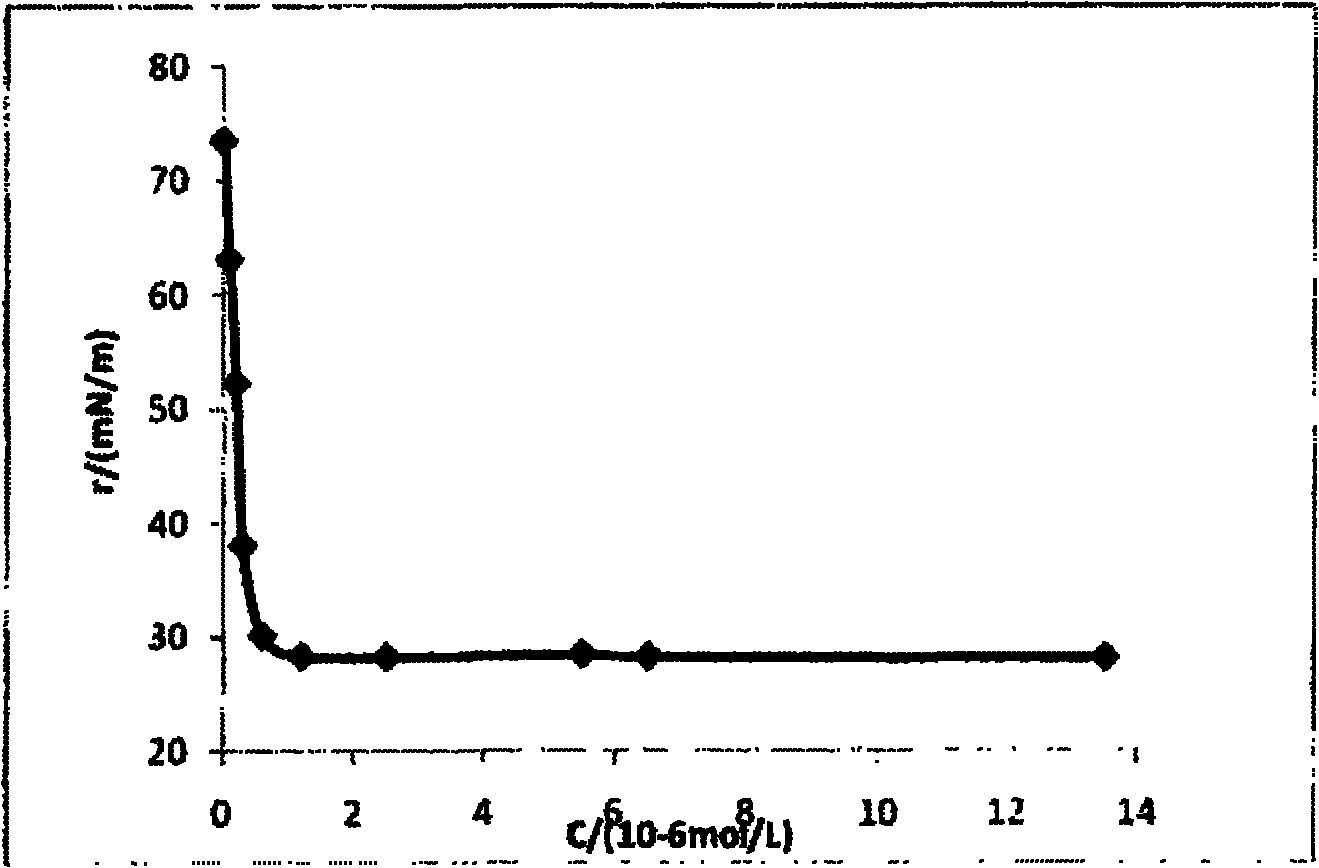

[0021] Heat and melt 87g of rosin, when the temperature rises to 230°C, add 0.3g of ZnO, and add 230g of polyethylene glycol 4000 several times in batches, raise the temperature to 265°C, keep it for 4h, depressurize and evacuate, when the temperature drops to 85 At ℃, add 0.6g tert-butylhydroquinone and 6g phosphorus pentoxide in batches, and discharge after 3 hours of heat preservation to obtain a rosin-based surfactant; its critical micelle concentration is 1.2×10 -6 mol / L, the surface tension is 28.4mN / m, the calcium soap dispersibility is 4.8%, and the Krafft point is less than 0°C.

Embodiment 3

[0023] Heat and melt 50g of maleic rosin, when the temperature rises to 230°C, add 0.2g of MgO, and add 413g of polyethylene glycol 10000 in batches, raise the temperature to 270°C, keep it for 4h, depressurize and evacuate, when the temperature drops When the temperature reaches 85°C, add 0.2g p-, p-dicumyl diphenylamine and 4g phosphorus oxychloride in batches, keep warm for 3 hours, and discharge to obtain a rosin-based surfactant; its critical micelle concentration is 1.8× 10 -5mol / L, the surface tension is 26.3mN / m, the calcium soap dispersibility is 3.6%, and the Krafft point is less than 0°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com