High-toughness welding electrode matched with 14Cr1MoR for hydrogen steel

A 14cr1mor, hydrogen-in-steel technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of temper embrittlement, decreased toughness, etc., and achieve improved mechanical properties, arc stability, and reasonable control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Second, the present invention provides a preparation method for the supporting high-toughness welding rod of heat-strength steel 14Cr1MoR for hydrogen-facing steel, comprising the following steps,

[0055] S1 Mix the skin powder evenly;

[0056] S2 Add water glass accounting for 21-23wt.% of the powder component mass content, and carry out wet mixing, wherein the potassium-sodium ratio of water glass is 1:1, and the Baume concentration is 41-43Be;

[0057] In S3, the mixture obtained in S2 is loaded on the welding core on a hydraulic welding rod machine to produce a welding rod.

[0058] The 3rd, the present invention provides the welding method of the supporting high-toughness electric welding rod of heat-strength steel 14Cr1MoR that faces hydrogen steel, comprises the following steps:

[0059] Preheat the test plate to 200~250°C before welding, dry the electrode at 380°C for no less than 1 hour before welding, keep warm at 150°C, and use it at any time. During the we...

Embodiment 1-6

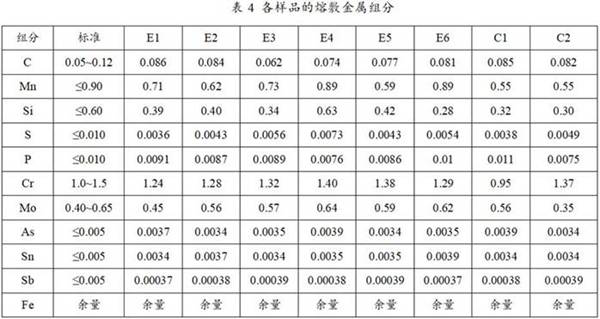

[0062] The heat-strength steel 14Cr1MoR for hydrogen steel is matched with high-toughness welding electrodes, including the welding core and the coating covering the surface of the welding core. The components of the coating are shown in Table 1.

[0063] The chemical composition of the solder core is shown in Table 2.

[0064] The preparation method is as follows: After mixing the ingredients of the drug skin evenly, adding water glass with a potassium-sodium ratio of 1:1 at 20°C (Baume density is 41-43Be) accounting for 21-23 wt.% of the drug skin weight. Stir evenly, send it into a hydraulic machine to wrap it on the surface of the welding core, and form the welding rod of the present invention after baking at a low temperature of 80°C and at a high temperature of 380°C.

[0065] In Examples 1-6, the mass ratio of coating and welding core is 3:7.

[0066] The welding method is as follows: preheat the test plate to 200~250°C before welding, dry the electrode at 380°C for no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com