Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce airspeed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

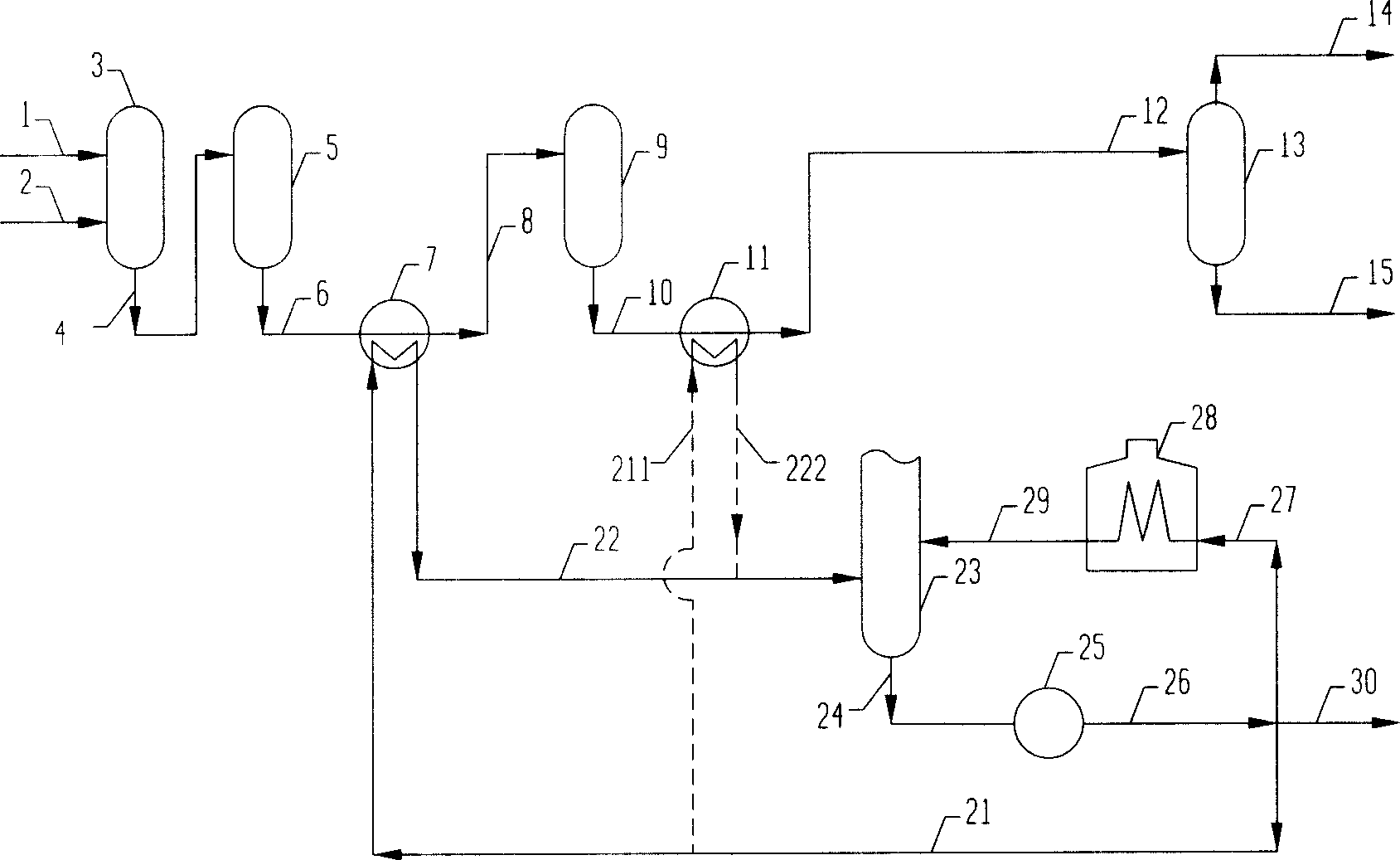

Method of recovering heat in hydrocarbon hydrogenating conversion process

InactiveCN101067095AReduce consumptionSmall scaleExothermal chemical reaction heat productionExothermal chemical reactions for heatingThermal energyHydrogen

The present invention relates to method of recovering heat in hydrocarbon hydrogenating conversion process. The low temperature heat absorbing oil and the reaction resultant are heat exchanged to form high temperature heat absorbing oil, which enters to the bottom of the fractionating tower so as to mix with the liquid phase material flow inside the fractionating tower before being shunt into low temperature heat absorbing oil for reuse. The process is especially suitable for hydrogenating conversion of coal tar, and has the advantages of high heat utilizing rate, reduced hydrogen circulating system scale and reduced the scale of reboiling furnace in the fractionating tower. In addition, the heat absorbing oil heat exchanger may be used as the heater for starting the reactor or sulfurizing to reduce heat load of the heating furnace.

Owner:何巨堂 +1

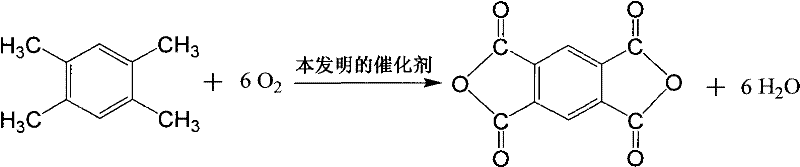

Catalyst for preparing pyromellitic dianhydride from durene through gaseous catalytic oxidation and preparation method thereof

ActiveCN102000596AReduce airspeedReduce energy consumptionPhysical/chemical process catalystsOrganic chemistryChemistryHigh weight

The invention relates to a catalyst for preparing pyromellitic dianhydride from durene through gaseous catalytic oxidation and a preparation method thereof, belonging to the technical field of catalytic oxidation. The catalyst is characterized by comprising V2O5, TiO2 and P2O5, wherein the molar ratio of V2O5 to TiO2 to P2O5 is 1:3.750-15.000:0.125-0.313. The catalyst provided by the invention has the advantages of low airspeed, low energy consumption, high selectivity and high weight gain percentage during application, is helpful to energy saving and resource consumption reduction and is beneficial to increasing the yield and the purity of pyromellitic dianhydride and reducing the production cost for preparing pyromellitic dianhydride through gaseous catalytic oxidation. The provided preparation method of the catalyst has simple and succinct technological steps and can ensure the overall embodiment of the effect of the catalyst.

Owner:常熟市知识产权运营中心有限公司

Load typed varadium catalyst and its preparing method and application

InactiveCN1431045AReduce vanadium contentReduce airspeedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen atmosphere

A carried vanadium catalyst is prepared from activated carbon or gamma-Al2O3, vanadium and assistant through pulverizing activated carbon or gamma Al2O3 by 20-80 meshes, preparing the solutions of V precursor and assistant precursor, immersing for 18-36 hr, drying at 110-120 deg.c for 4-6 hrs, calcining at 450-650 deg.c for 4-5 hrs in nitrogen atmosphere and putting in drier. Its advantages are high transform rate of ethylbenzene (more than 60%) and high selectivity to styrene (more than 96%).

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

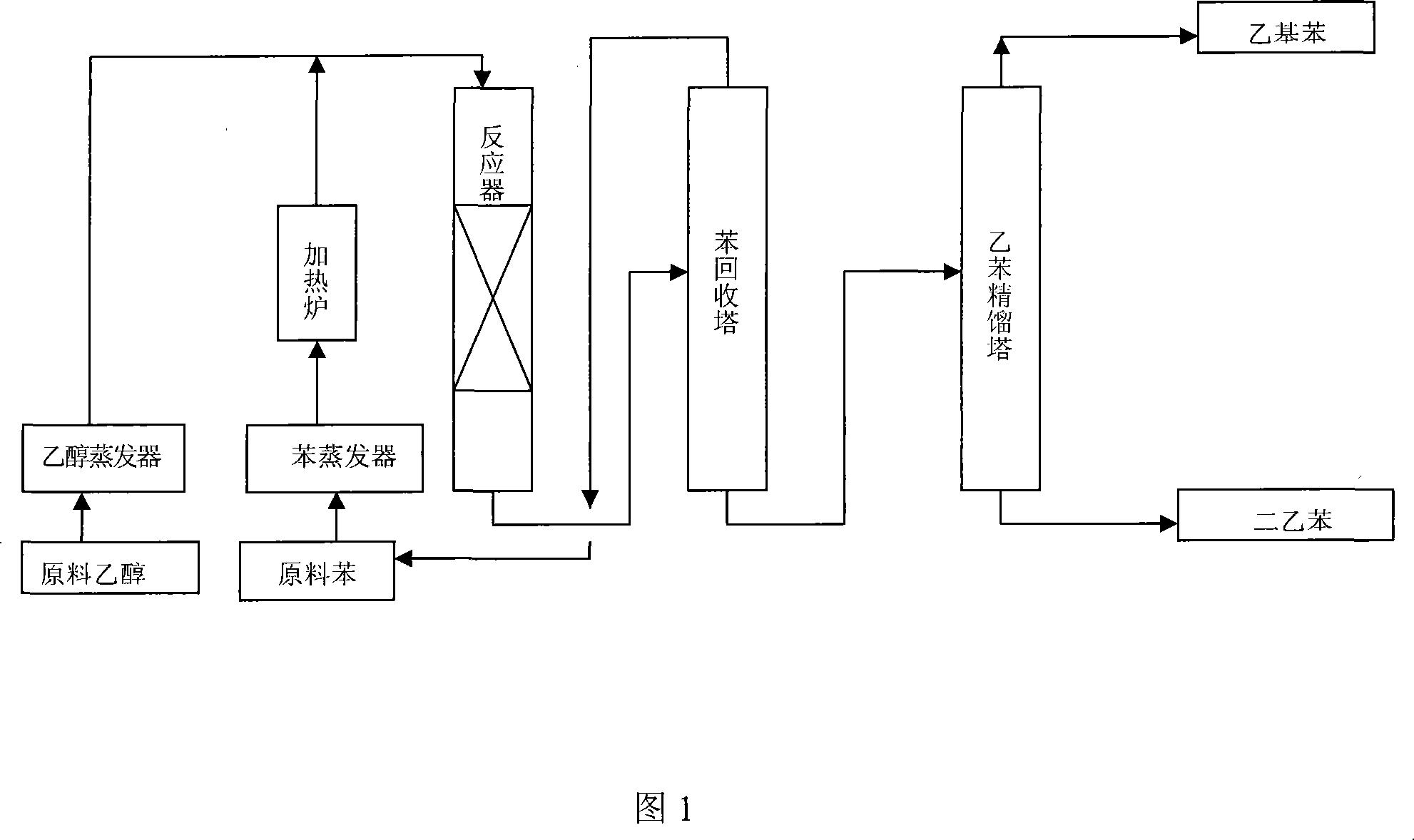

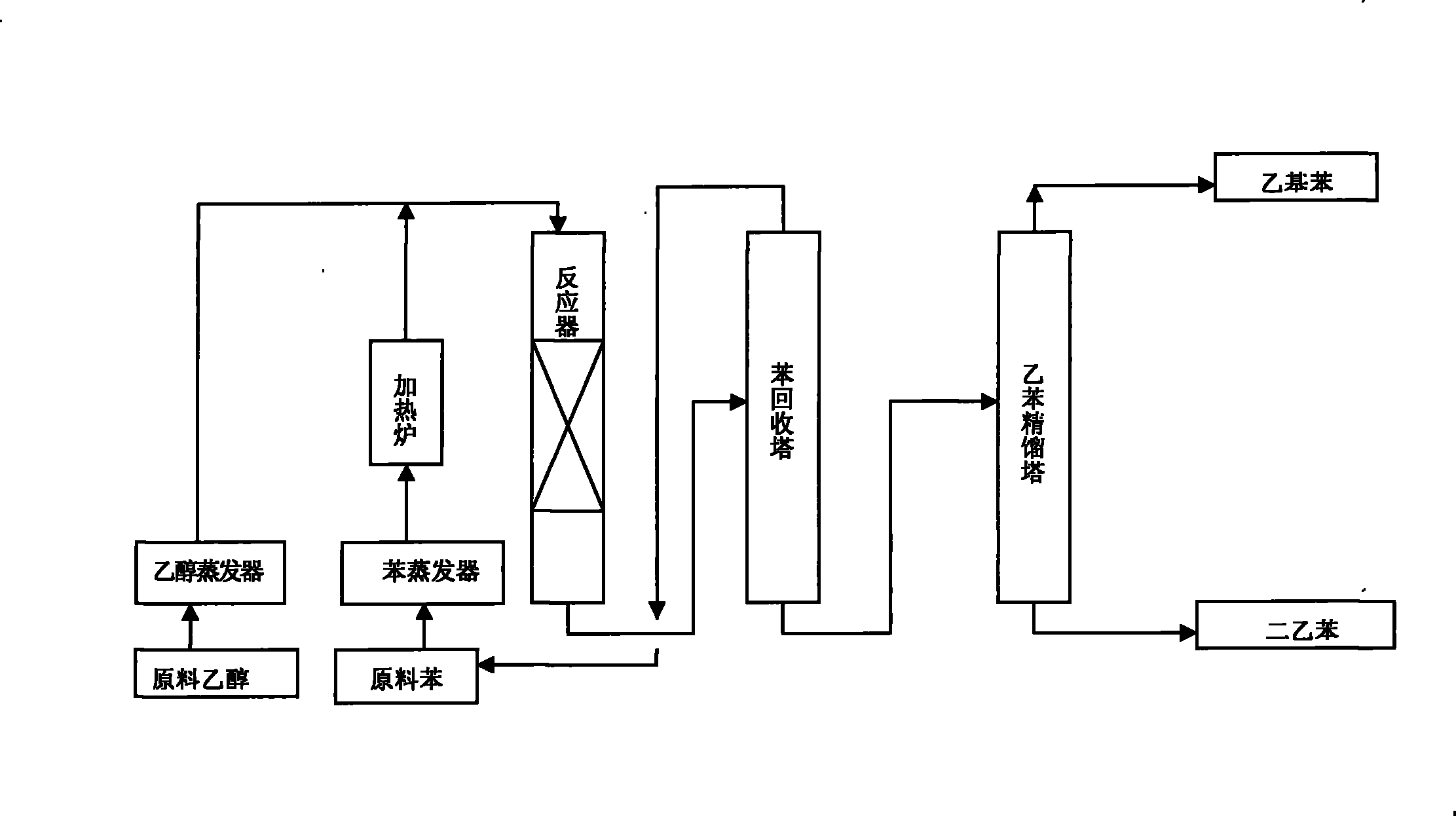

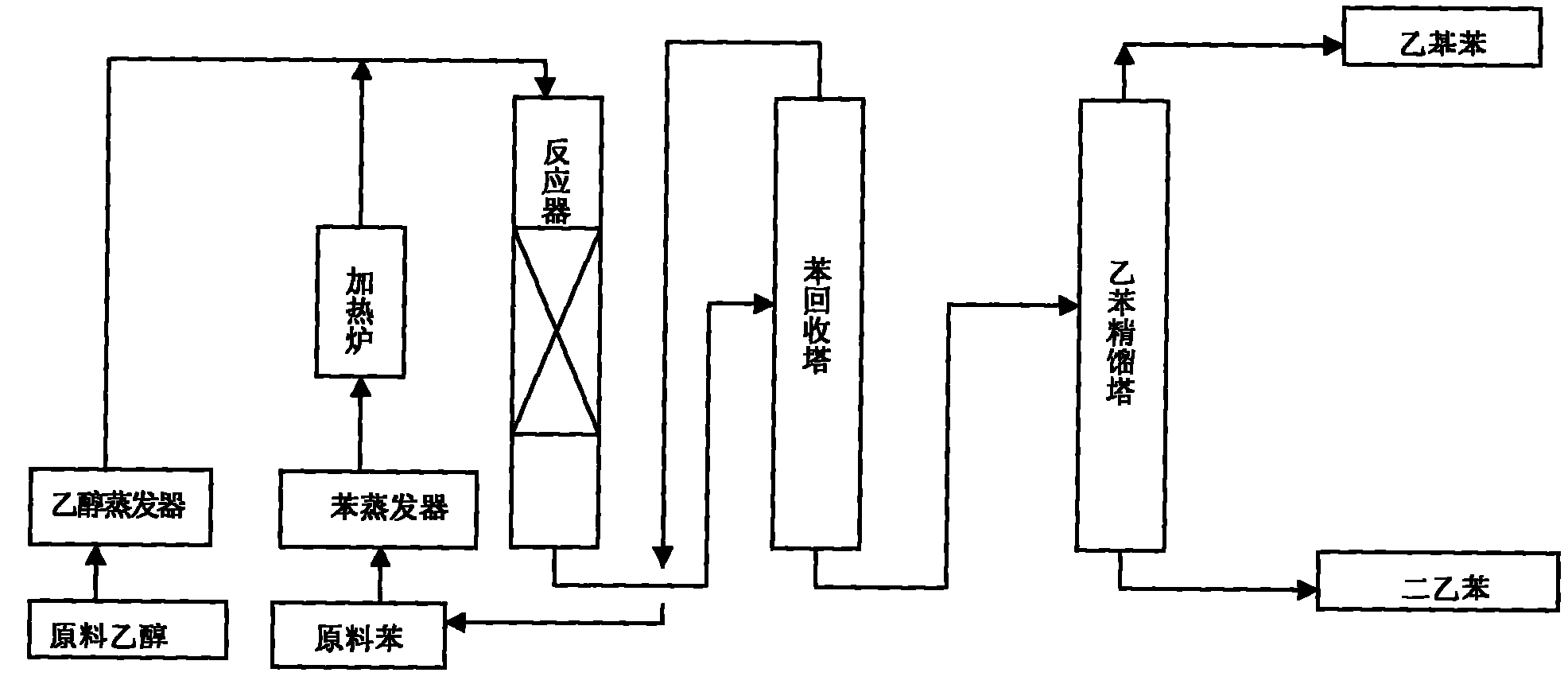

Method for synthesizing ethyl benzene and diethyl benzene

InactiveCN101085711AEliminate the dehydration stepIncrease profitDistillation purification/separationHydrocarbon by hydrocarbon and non-hydrocarbon condensationOperational costsDiethyl benzene

The invention discloses a method for synthesizing ethyl benzene and diethyl. It takes benzene and ethanol as raw material and comprises following steps: (A) benzene ethylization: heating benzene and ethanol for gasification, feeding them into reactor filled with molecular screen catalyst, the molar ratio between benzene and ethanol is 4- 8: 1, and the condition is at 350- 420 Deg. C and 0.7- 2 MPa; (B) recovering benzene: distilling reactant of ethylization, separating and getting mixture of benzene and ethyl benzene and diethyl; dewatering recovered benzene and using it as material for ethylization in step (A); (C) separating and refining: distilling said mixture, separating and getting ethyl benzene and diethyl. The invention replaces ethane with ethanol and finishes ethylization with one step. It is characterized by simnple process, high utilization rate of ethanol and saved investment and operational cost.

Owner:常州世鑫化工有限公司

Alkylbenzene detergents with high 2-isomer content

InactiveUS7008914B2High olefin conversionLong life-timeSurface-active detergent compositionsHydrocarbonsHydrogen fluorideAlkyl transfer

This invention is directed to a fluorine-containing mordenite catalyst and use thereof in the manufacture of alkylbenzene (LAB) by alkylation of benzene with an olefin. The olefin may have from about 10 to 14 carbons. The fluorine-containing mordenite is prepared typically by treatment with an aqueous hydrogen fluoride solution. The benzene alkylation may be conducted using reactive distillation. This invention is also directed to a process for production of LAB having a high 2-phenyl isomer content by use of the fluorine-containing mordenite in conjunction with a conventional solid LAB alkylation catalyst. The two catalysts may be used in a mixed catalyst bed or may be packed in series, with the relative proportions being adjusted to provide a desired 2-phenyl isomer content of in the final product.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

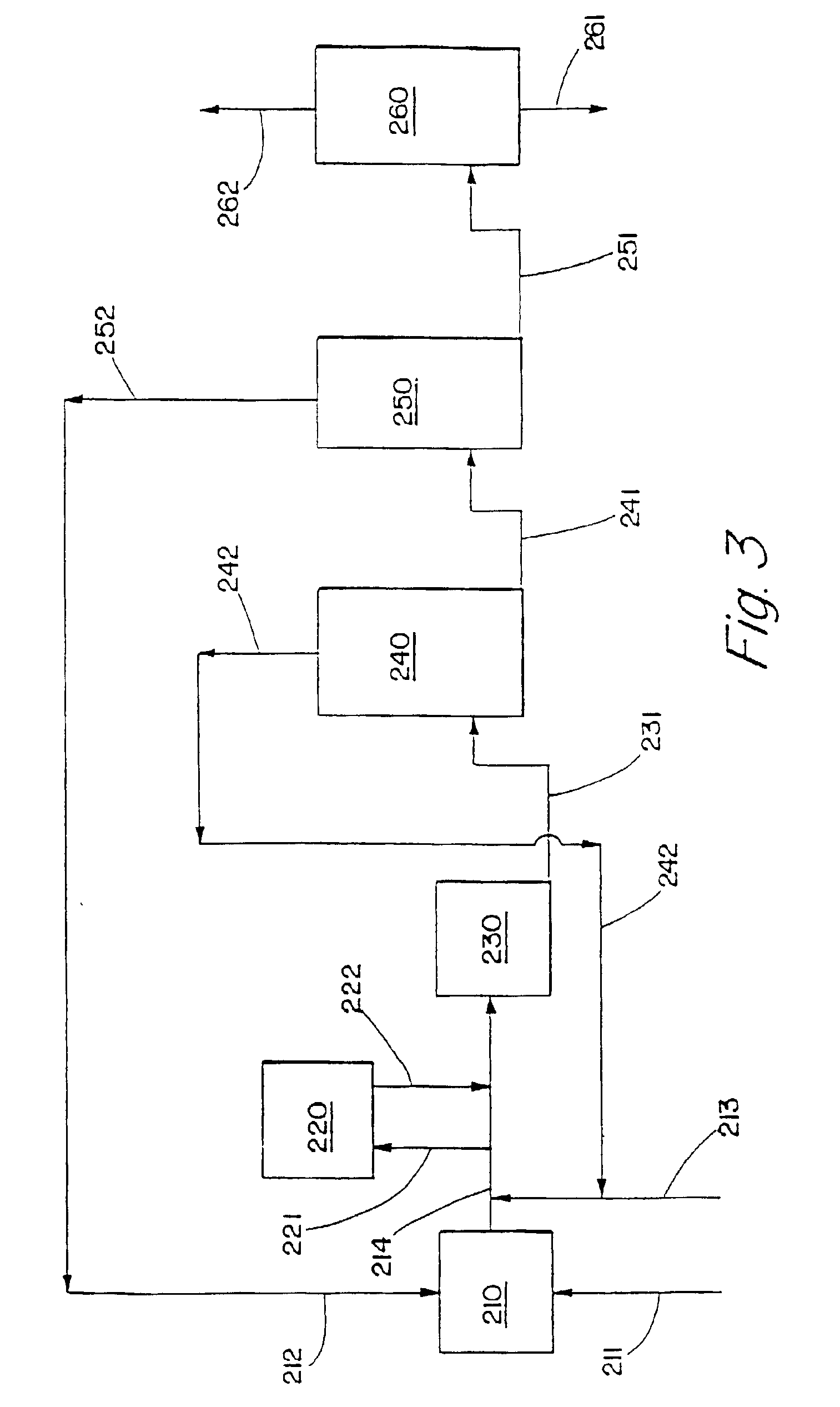

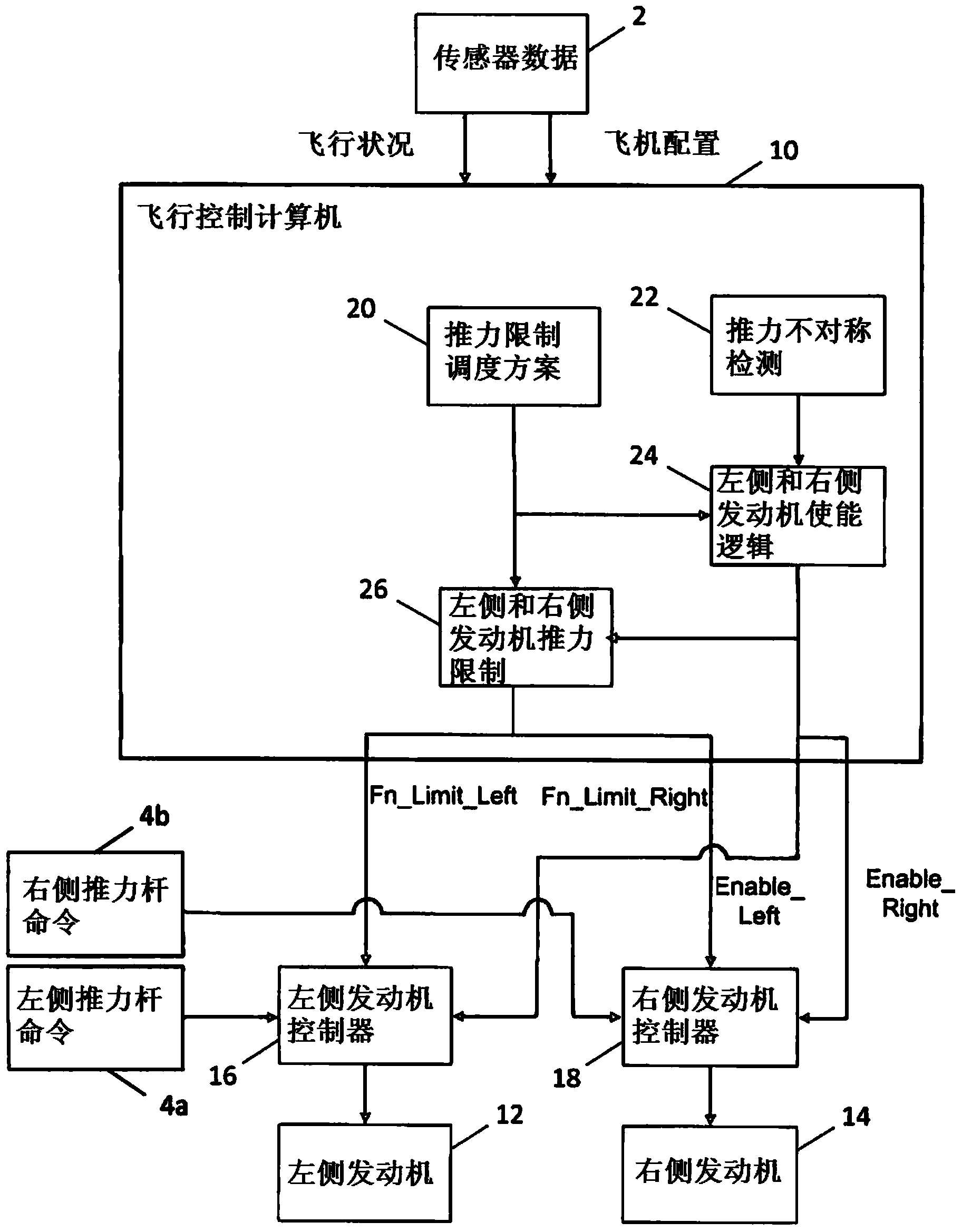

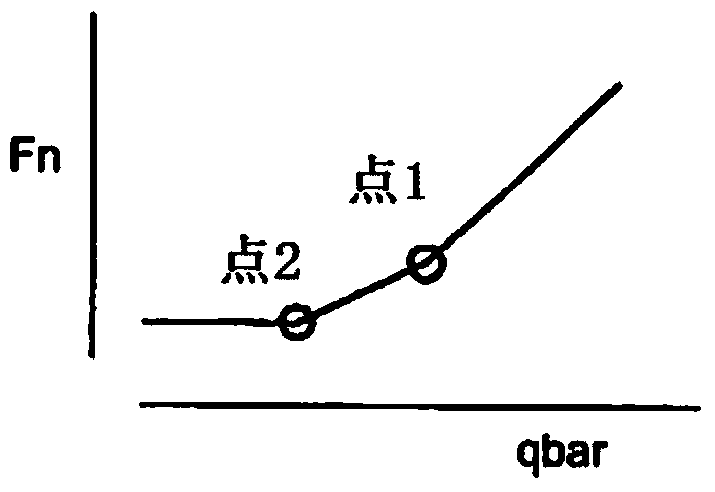

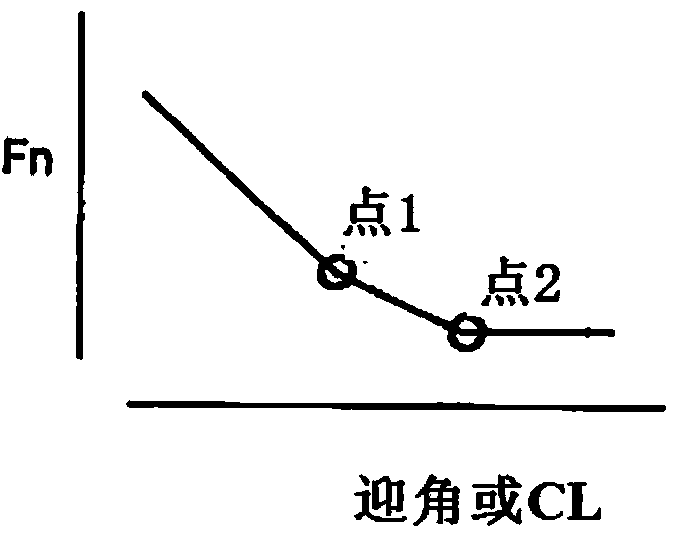

Modified thrust limit schedule for control of thrust asymmetry

ActiveCN103502096ALow approach speedSufficient output control capabilityAircraft power plantsVehicle position/course/altitude controlComputer moduleAirspeed

A flight control and engine control function for a multi-engine aircraft which automatically controls maximum thrust on the operating engine to a value lower than the nominal thrust limit schedule in the event of loss of thrust on another engine. The maximum engine thrust of the operating engine is controlled (limited) such that the resulting thrust asymmetry can be controlled at airspeeds lower than would otherwise be the case. The decrease in engine-out minimum control speed can reduce the limitation on landing speeds that would otherwise be caused by engine-out minimum control speed.

Owner:THE BOEING CO

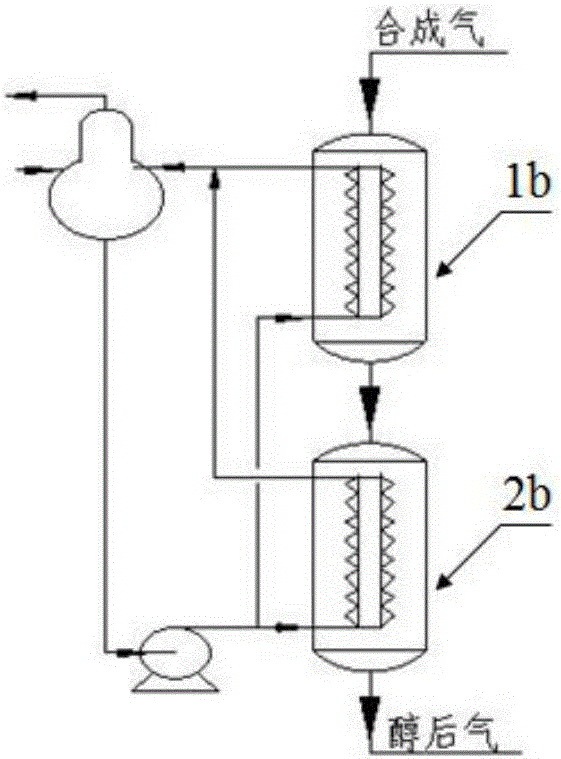

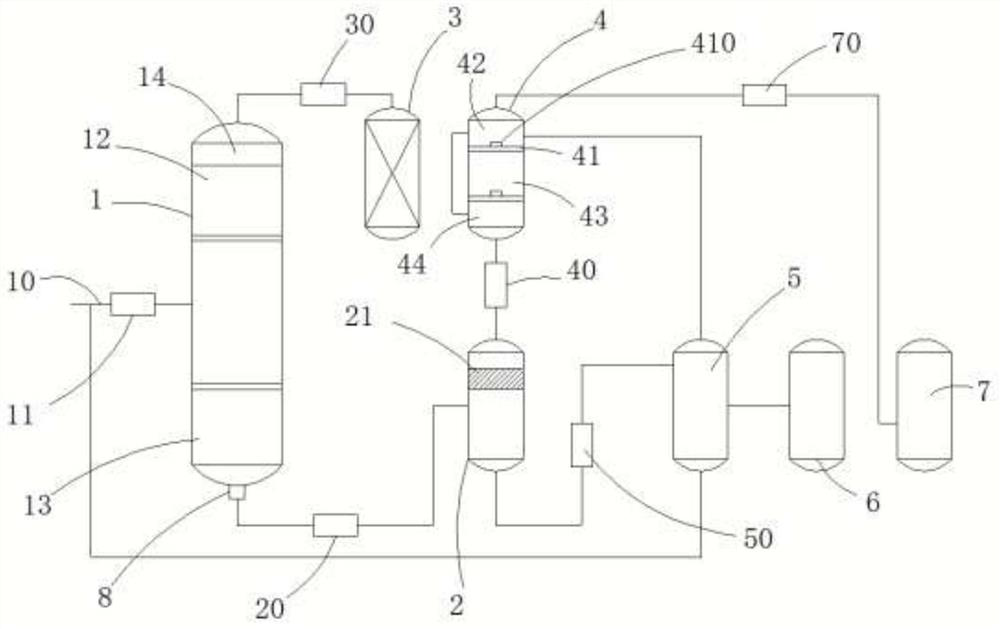

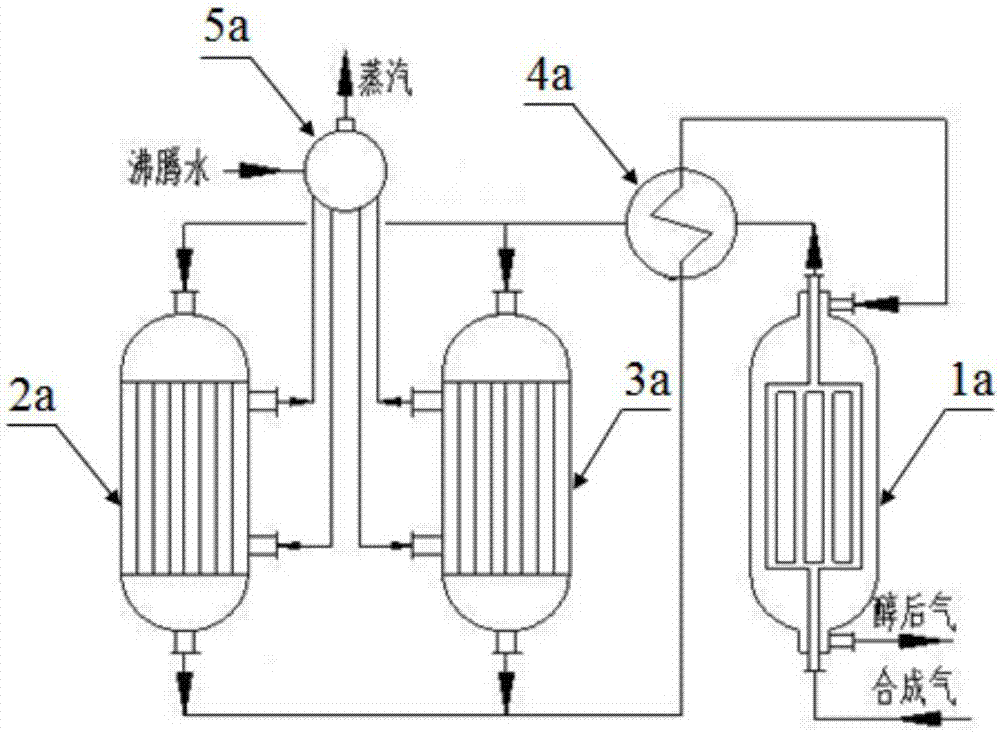

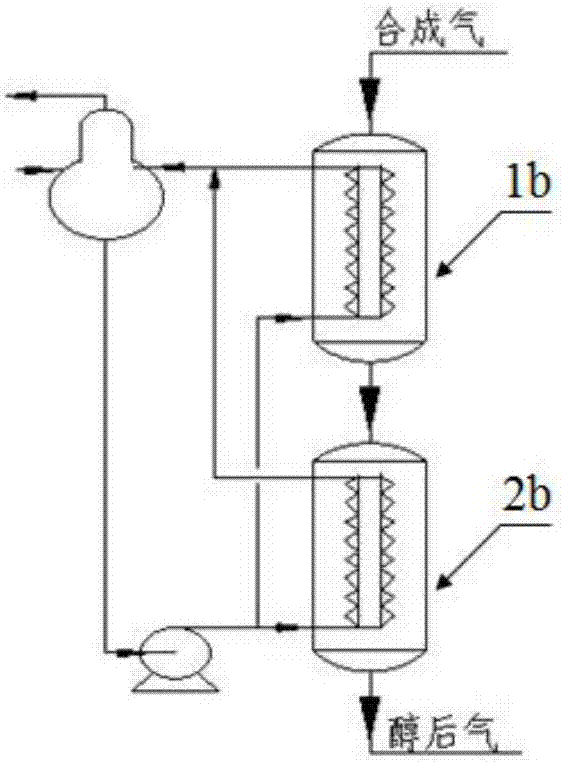

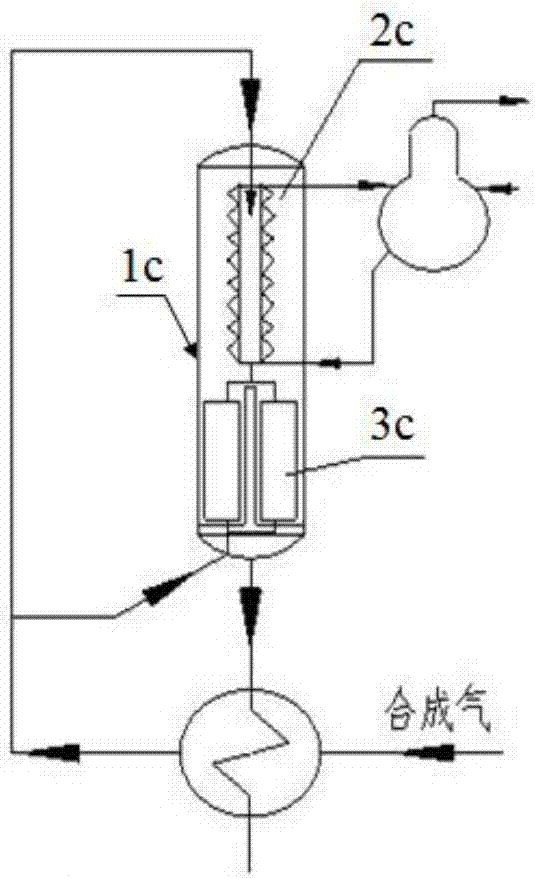

Energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation method and energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation device

ActiveCN105753646AReduce CO concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation method which comprises the following steps: respectively reheating fresh synthesis gas and recycle gas, mixing the fresh synthesis gas with the recycle gas, introducing the mixed gas into a first reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the first reactor, guiding the mixture to flow to a first methyl alcohol separator, separating out methyl alcohol, pressurizing the separated gas, preheating, then introducing into a second reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the second reactor, guiding the mixture to flow to a second methyl alcohol separator, separating out methyl alcohol, preheating the separated gas which separately serves as the recycle gas and fresh synthesis gas, mixing the recycle gas and the fresh synthesis gas, and feeding the mixture into the first reactor so as to perform next round of circulating preparation of methyl alcohol. The invention further discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation device. The method is relatively high in single-pass alcohol net value and relatively small in circulation ratio, achieves a ton-alcohol steam yield as high as 1.2-1.3 ton, and is high in energy heat recovery amount.

Owner:NANJING GOODCHINA CHEM TECH

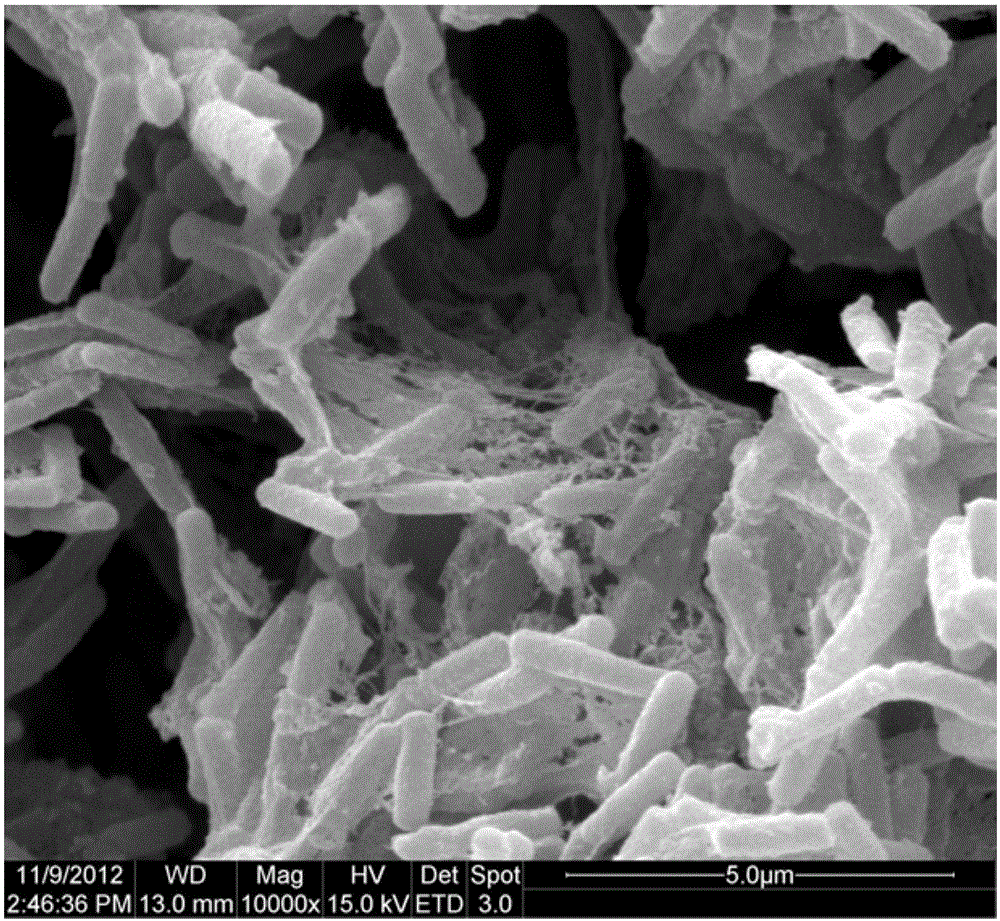

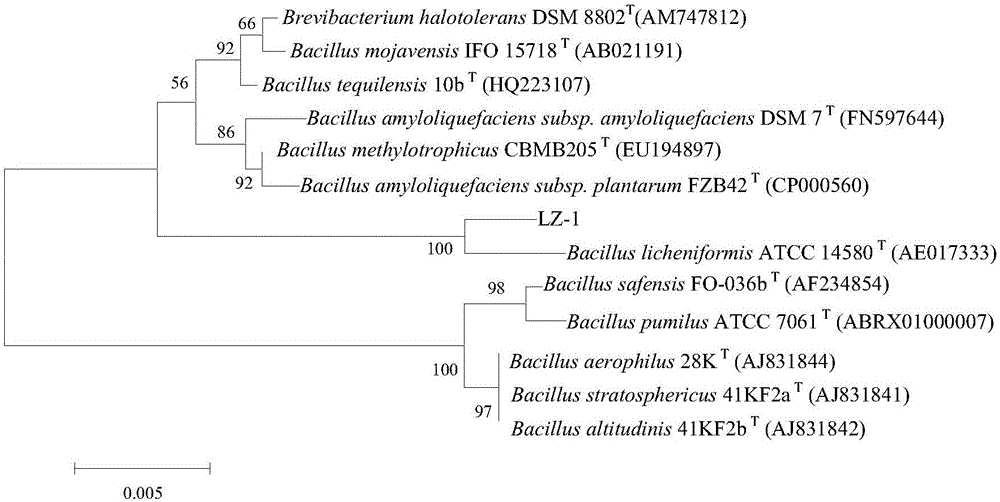

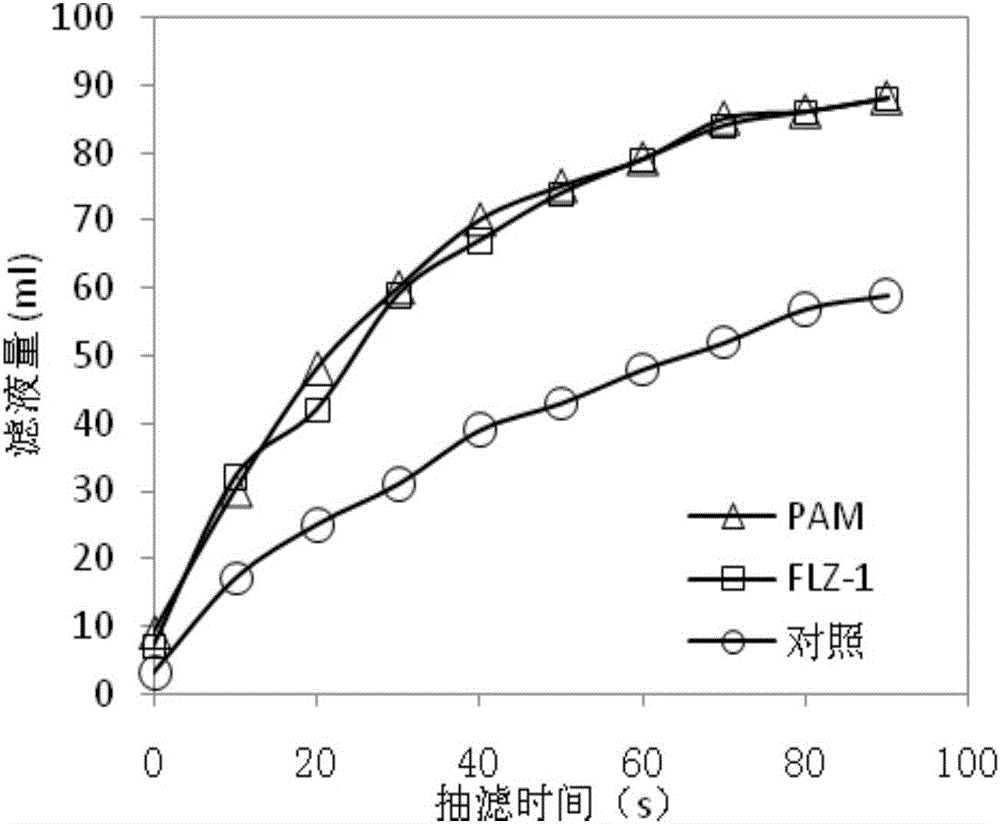

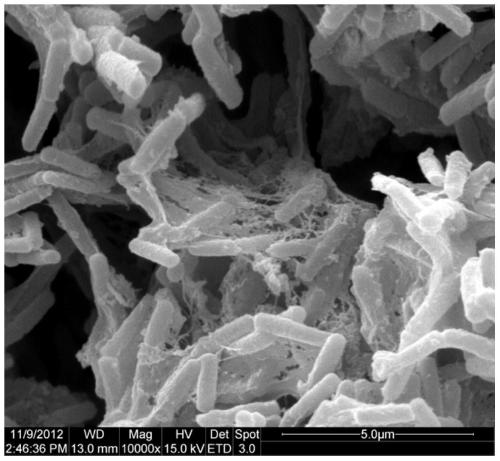

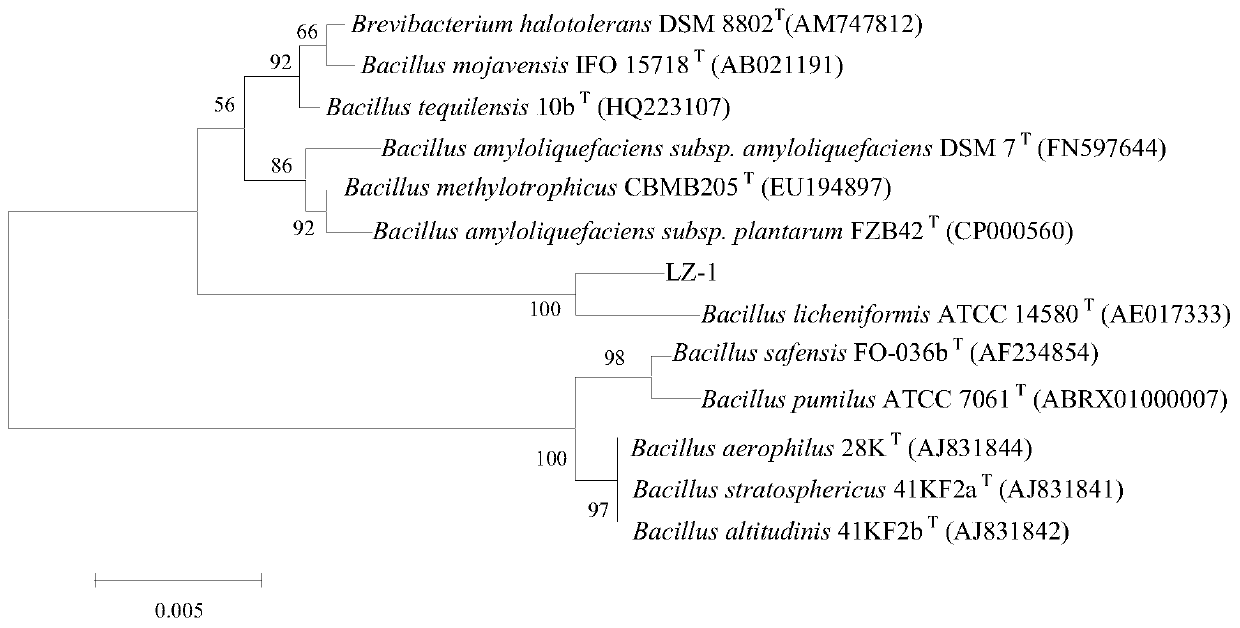

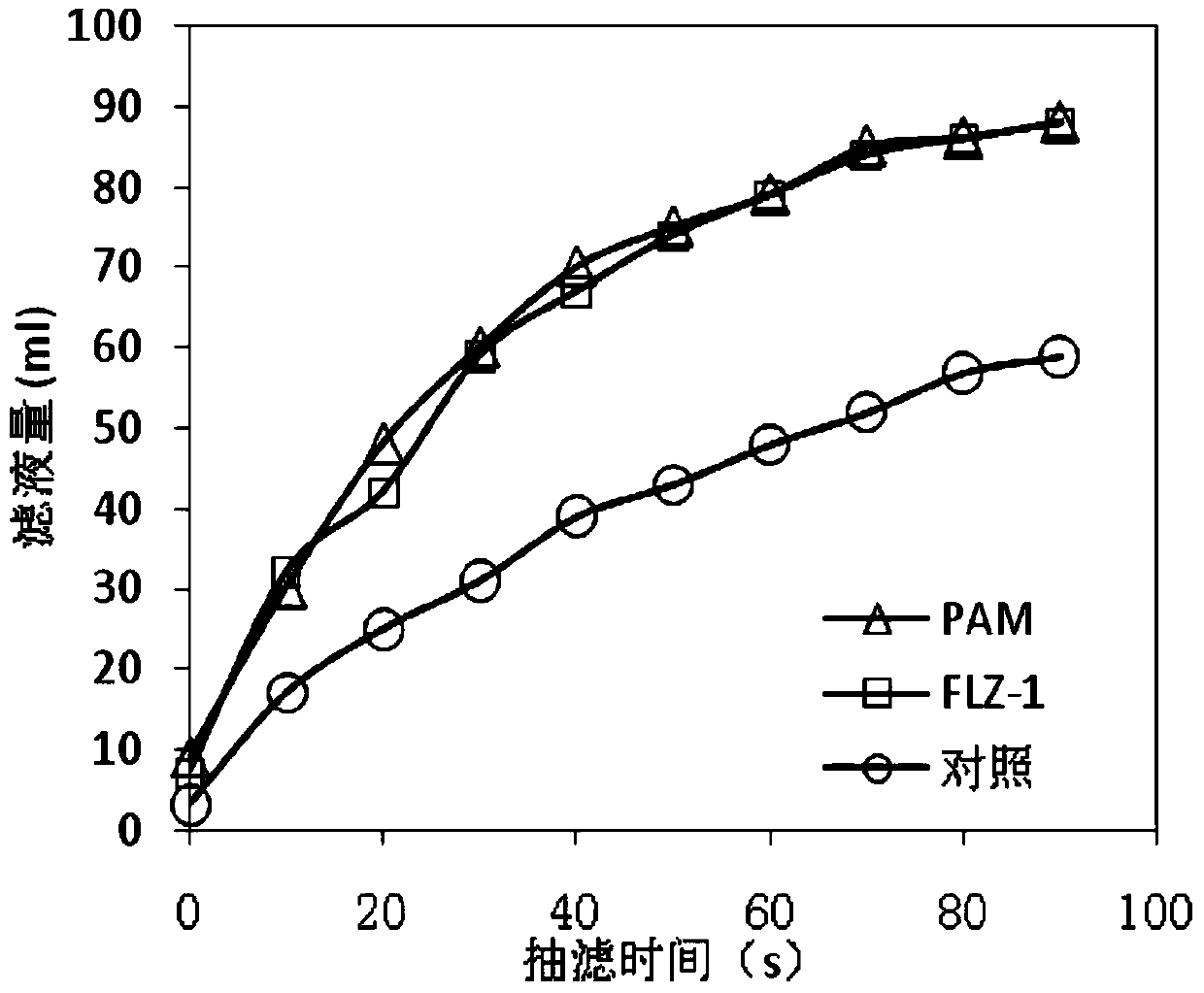

Bacillus licheniformis, method for preparing flocculating agent from bacillus licheniformis and application of flocculating agent

ActiveCN106244478AWide growth temperature rangeHas alkali resistanceSludge treatment by de-watering/drying/thickeningBacteriaBacillus licheniformisSludge cake

The invention relates to bacillus licheniformis, a method for preparing a flocculating agent from the bacillus licheniformis and an application of the flocculating agent. The strain is bacillus licheniformis LZ-1 which is preserved in China General Microbiological Culture Collection Center on November 06, 2012 with preservation number of CGMCC No.6782. With the application of the bacillus licheniformis LZ-1 as well as a production method provided by the invention, a fermentation broth, which is high in flocculating activity, is obtained under the condition that an initial pH value is alkaline, and high-molecular-weight polysaccharide, which is 0.8-3.2*10<7>Da, serves as a major flocculating active ingredient. The polysaccharide flocculating agent provided by the invention has the advantages of being high in flocculating activity, low in dosage, low in production cost and the like, and the flocculating agent has a flocculating conditioning effect on sludge. The bacillus licheniformis LZ-1 fermentation broth or a product, which is extracted from the fermentation broth and contains the polysaccharide flocculating agent, can be applied to deep dewatering by sludge plate-frame pressure filtration in a mode of replacing a polyacrylamide flocculating agent, so that sewage treatment plant concentrated sludge, which is 96-98% in moisture content, is further dewatered into a sludge cake which is lower than 60% in moisture content and the size of the sludge is diminished to be 1 / 20-1 / 10 of an original size.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI +2

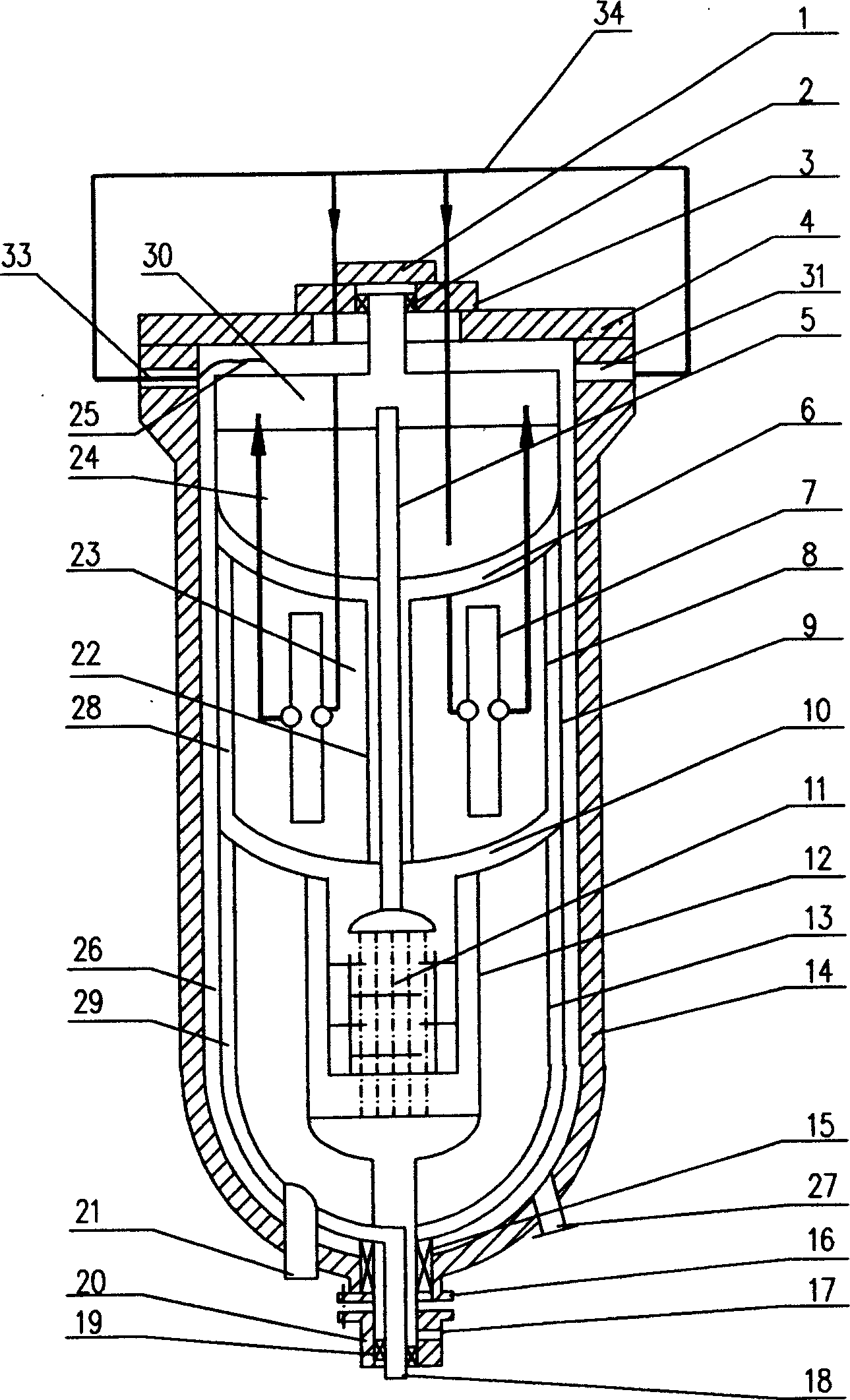

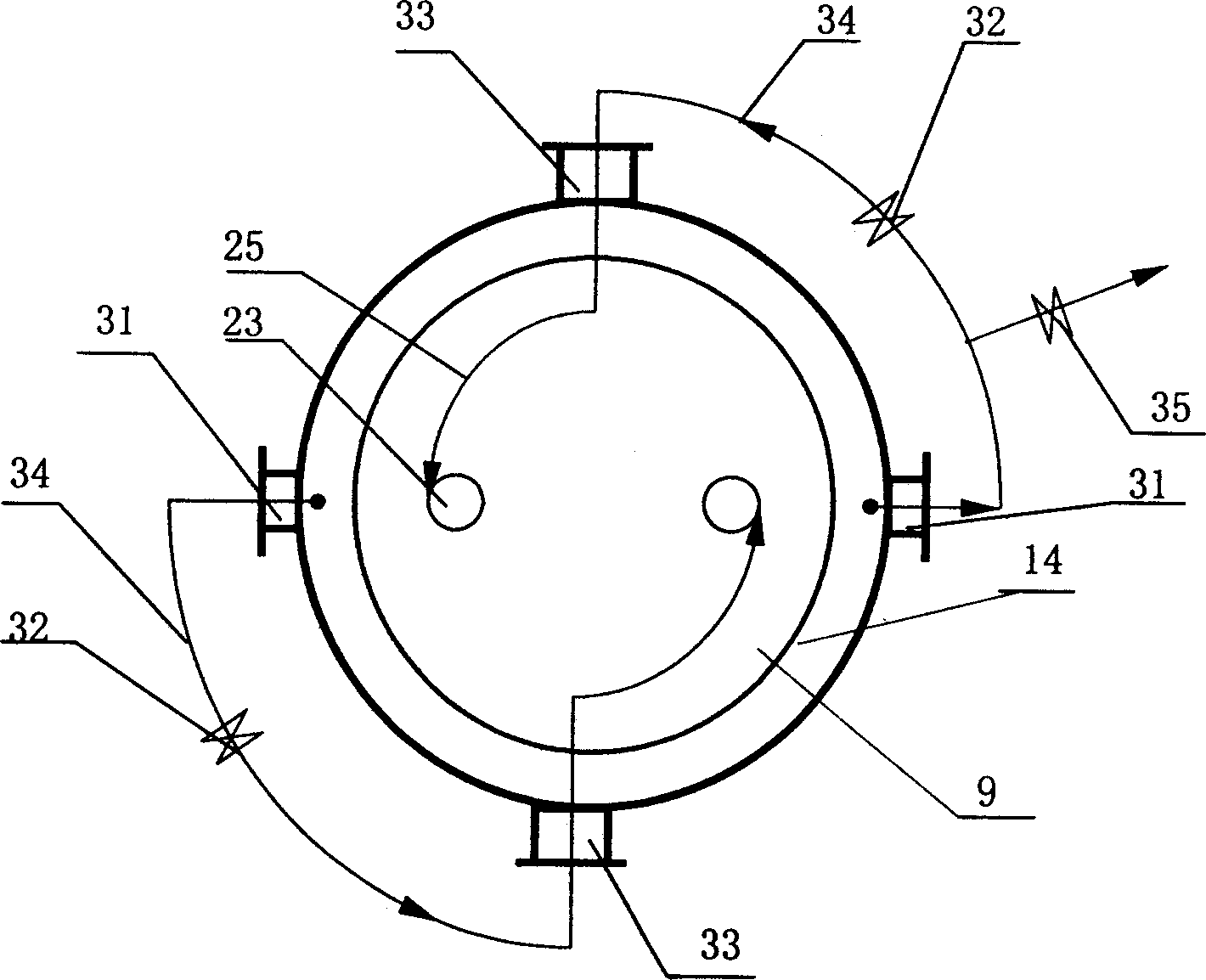

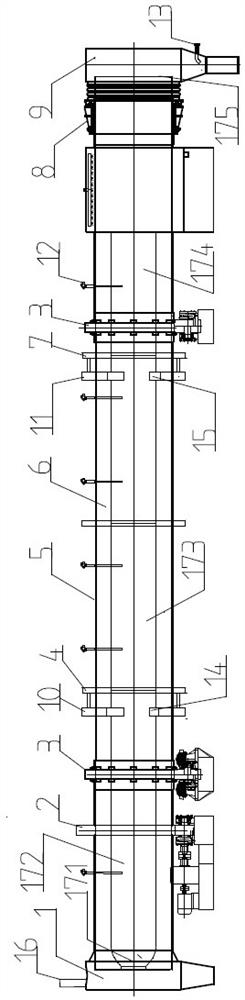

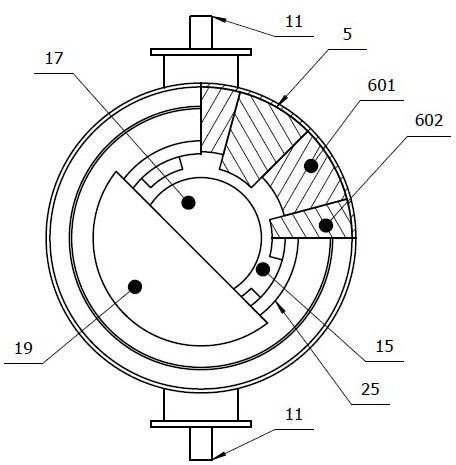

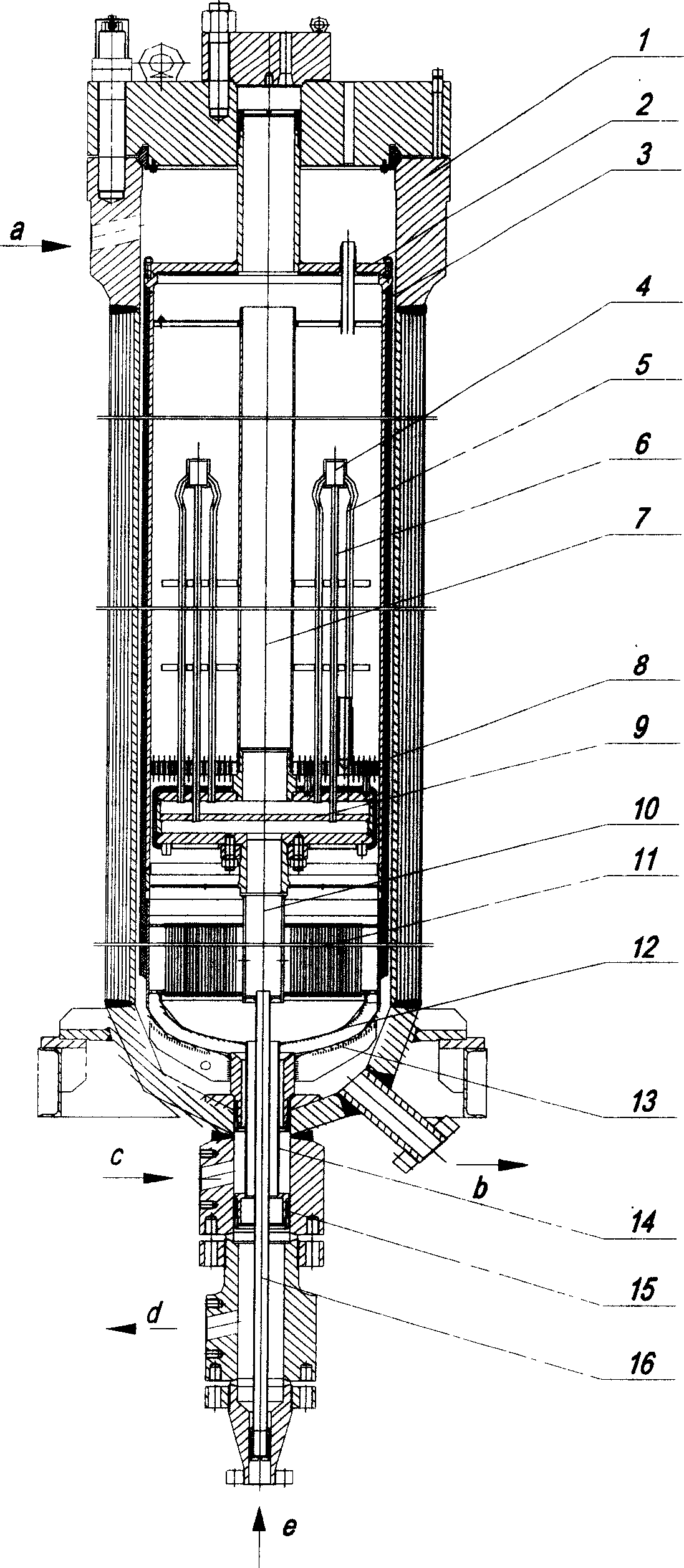

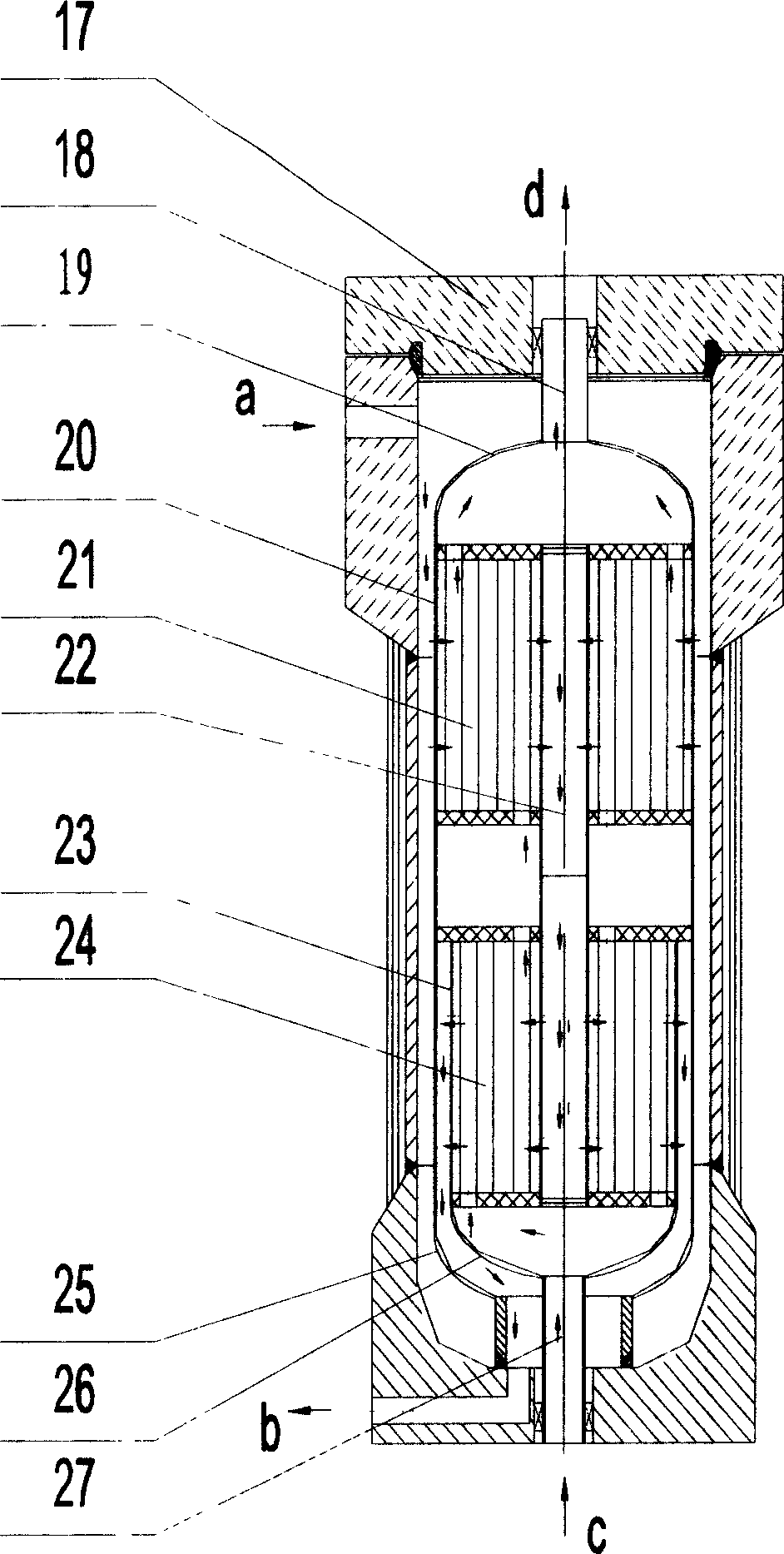

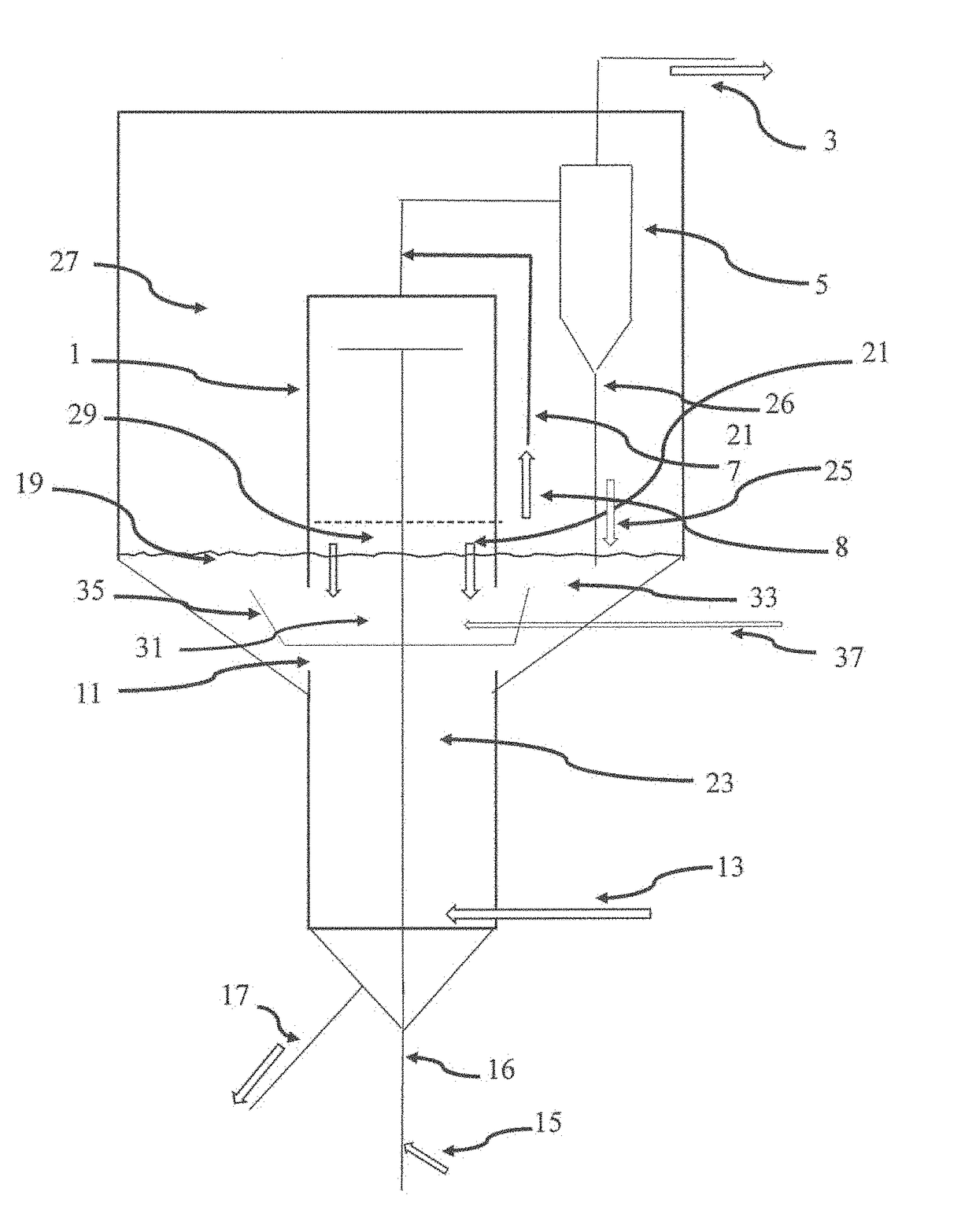

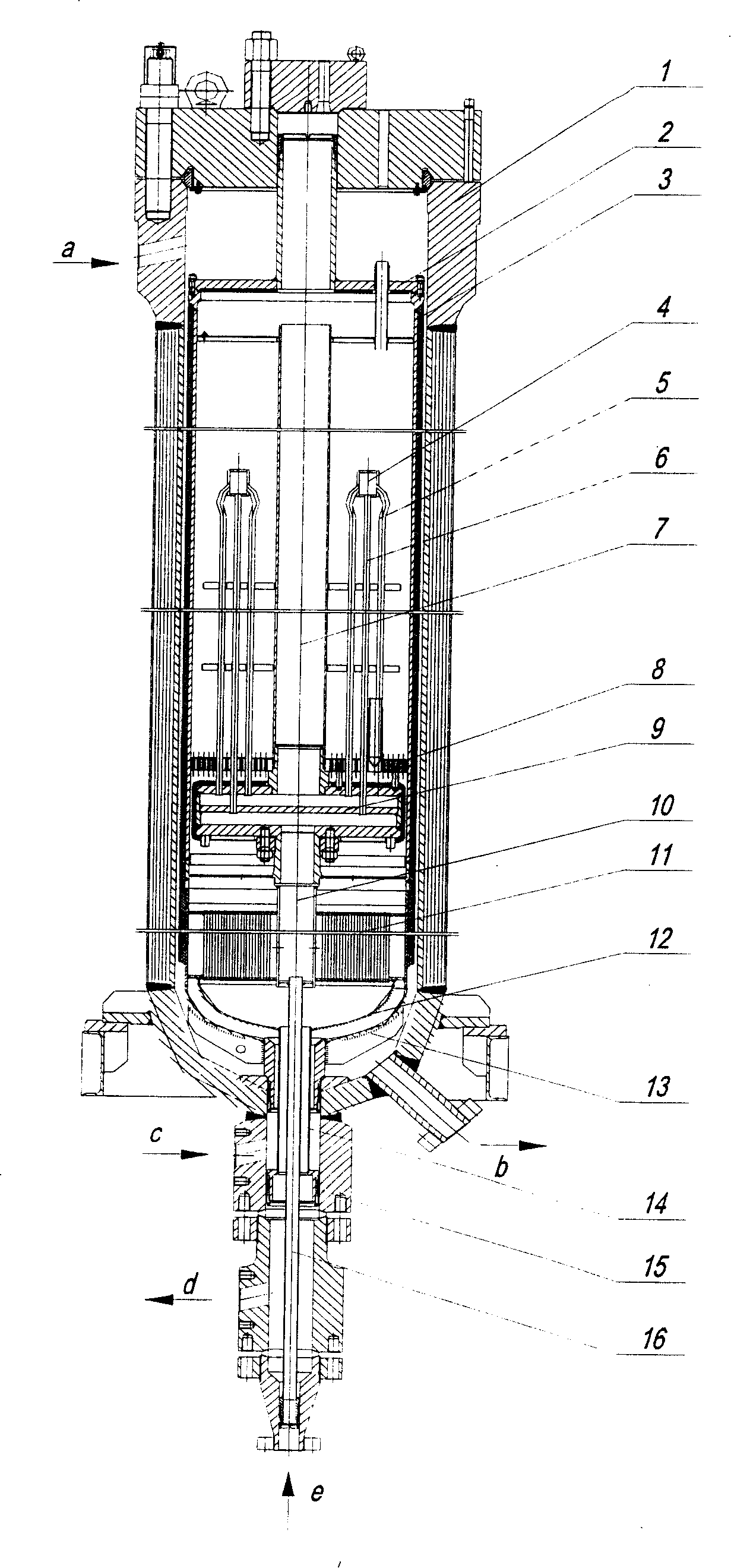

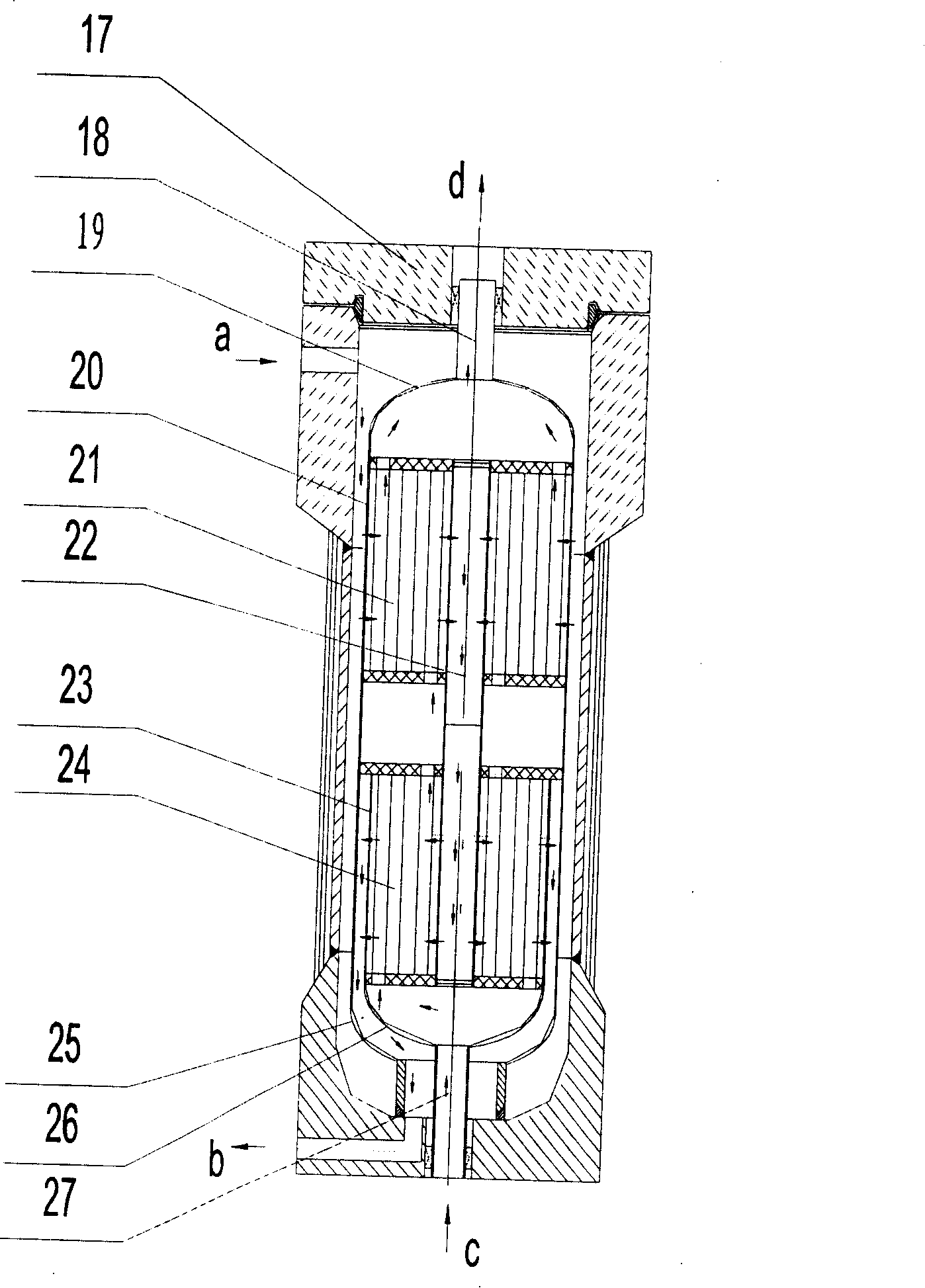

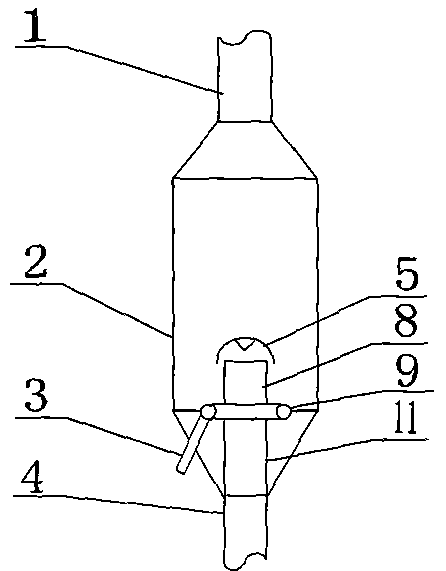

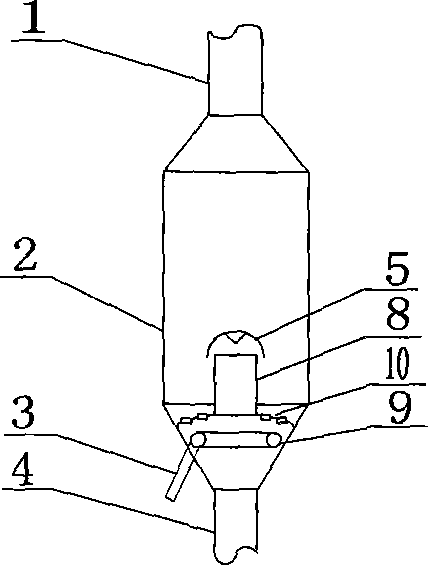

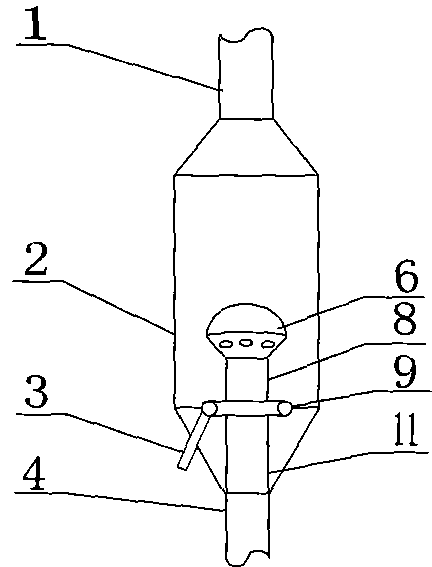

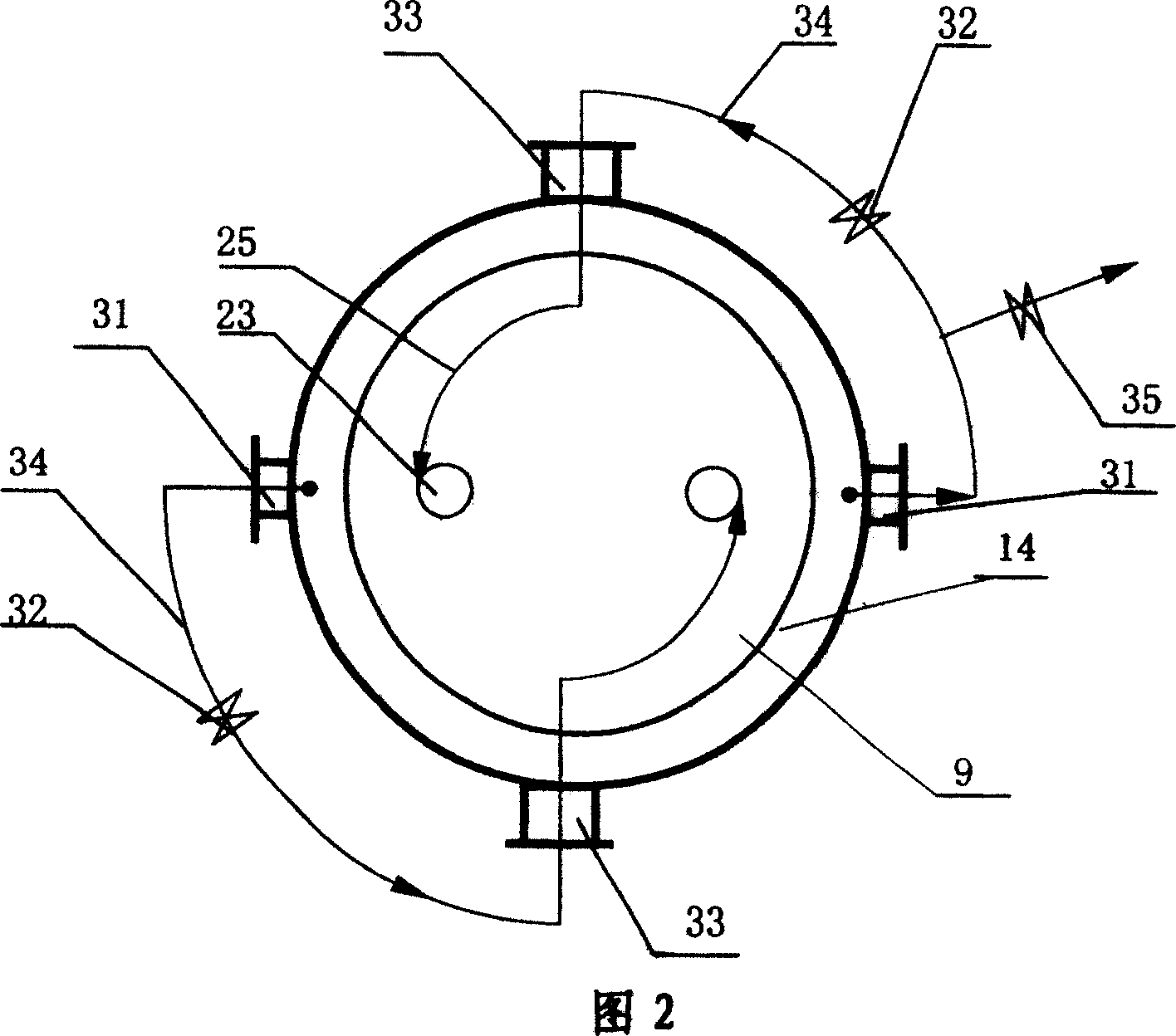

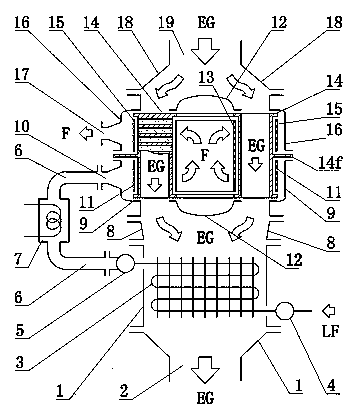

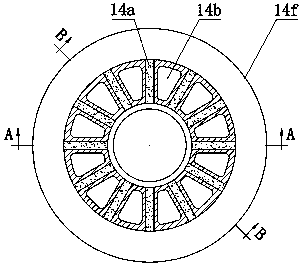

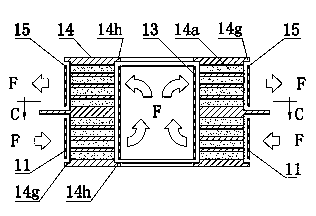

Multistage gas solie chemical reactor

ActiveCN1785494ASimple structureAmmonia concentration did not decreaseChemical/physical processesGas solidNuclear engineering

A multi-segment chemical gas-solid reactor is composed of a pressurized external cylinder and a heated internal cylinder, which has three layers, two pot-shaped gas collectors between adjacent two layers, and two heat exchangers installed respectively in the centers of the second and the third layers. Its advantages are high purity of product, high grade of vapor and low airflow resistance.

Owner:HUNAN ANCHUN ADVANCED TECH

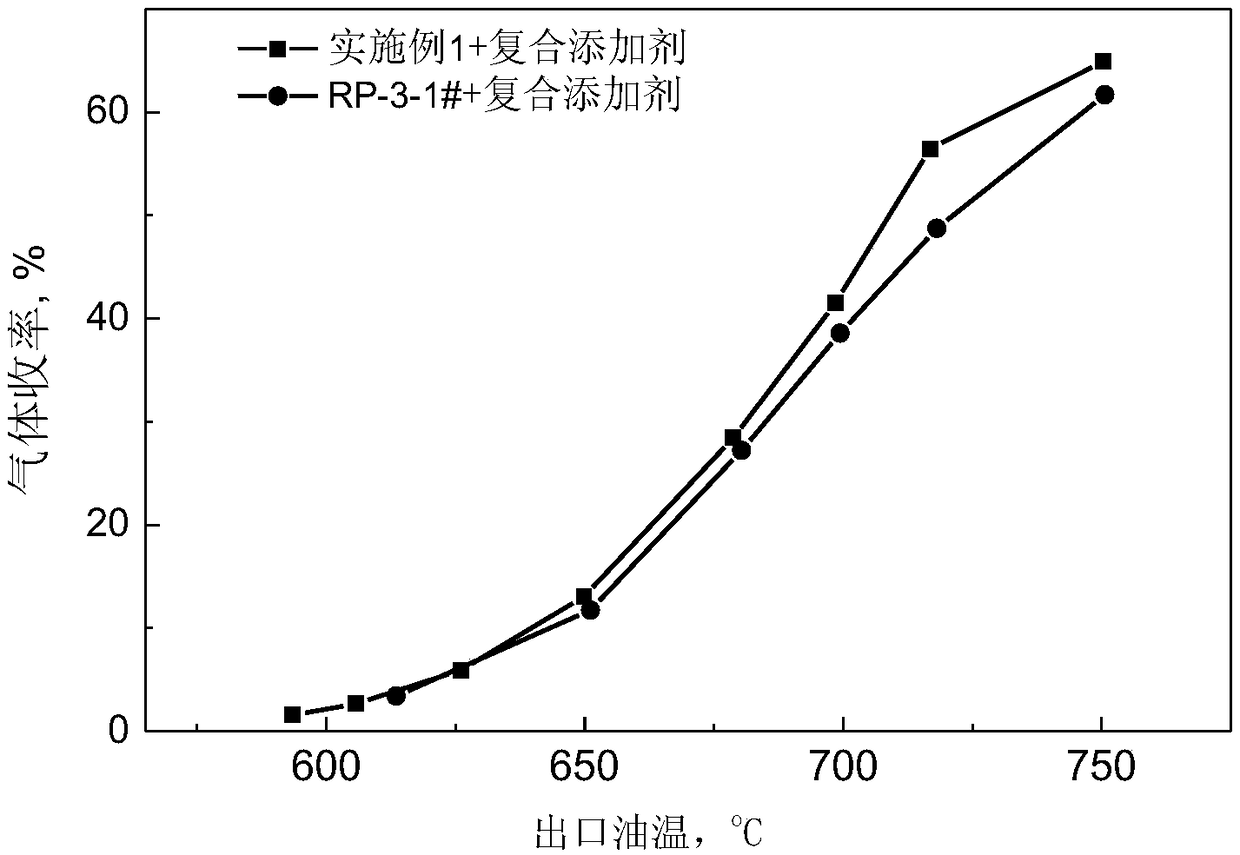

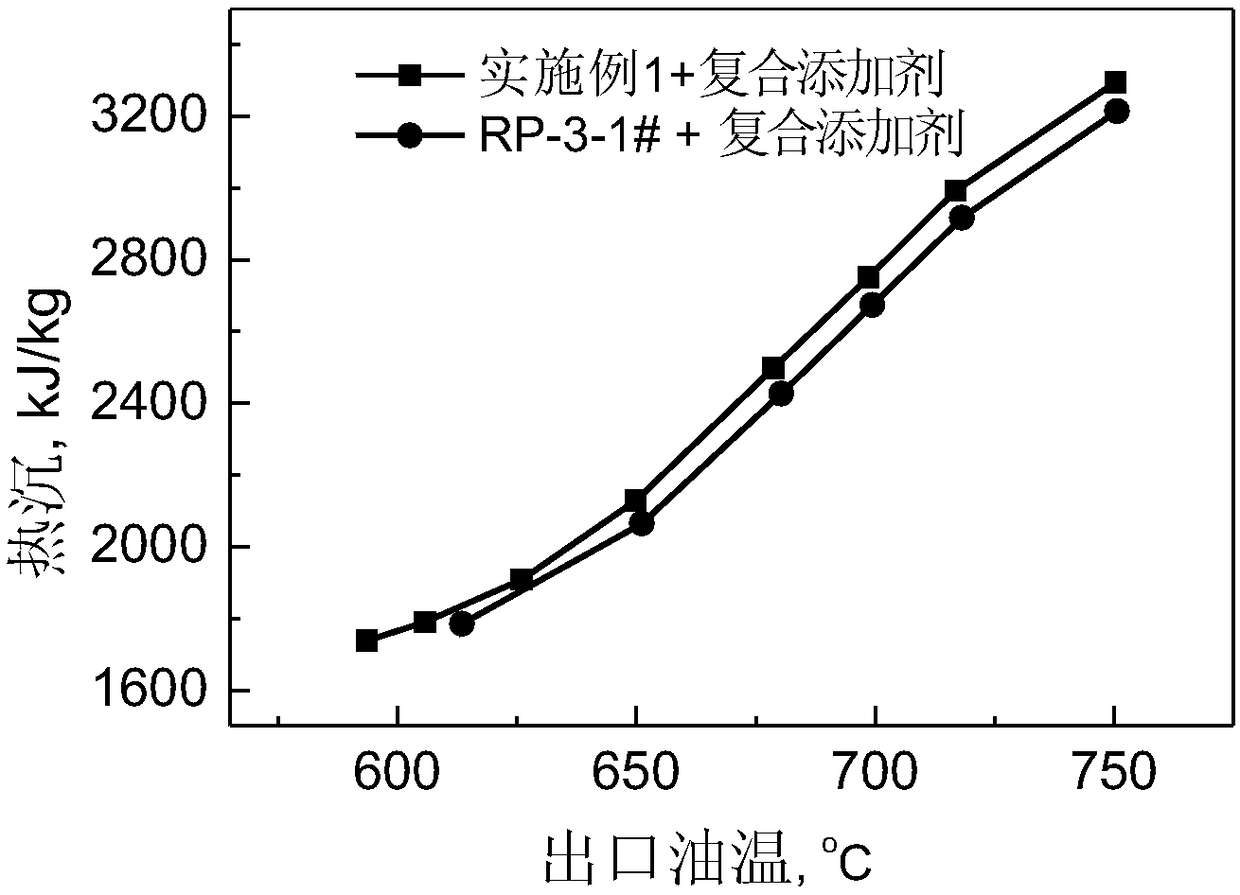

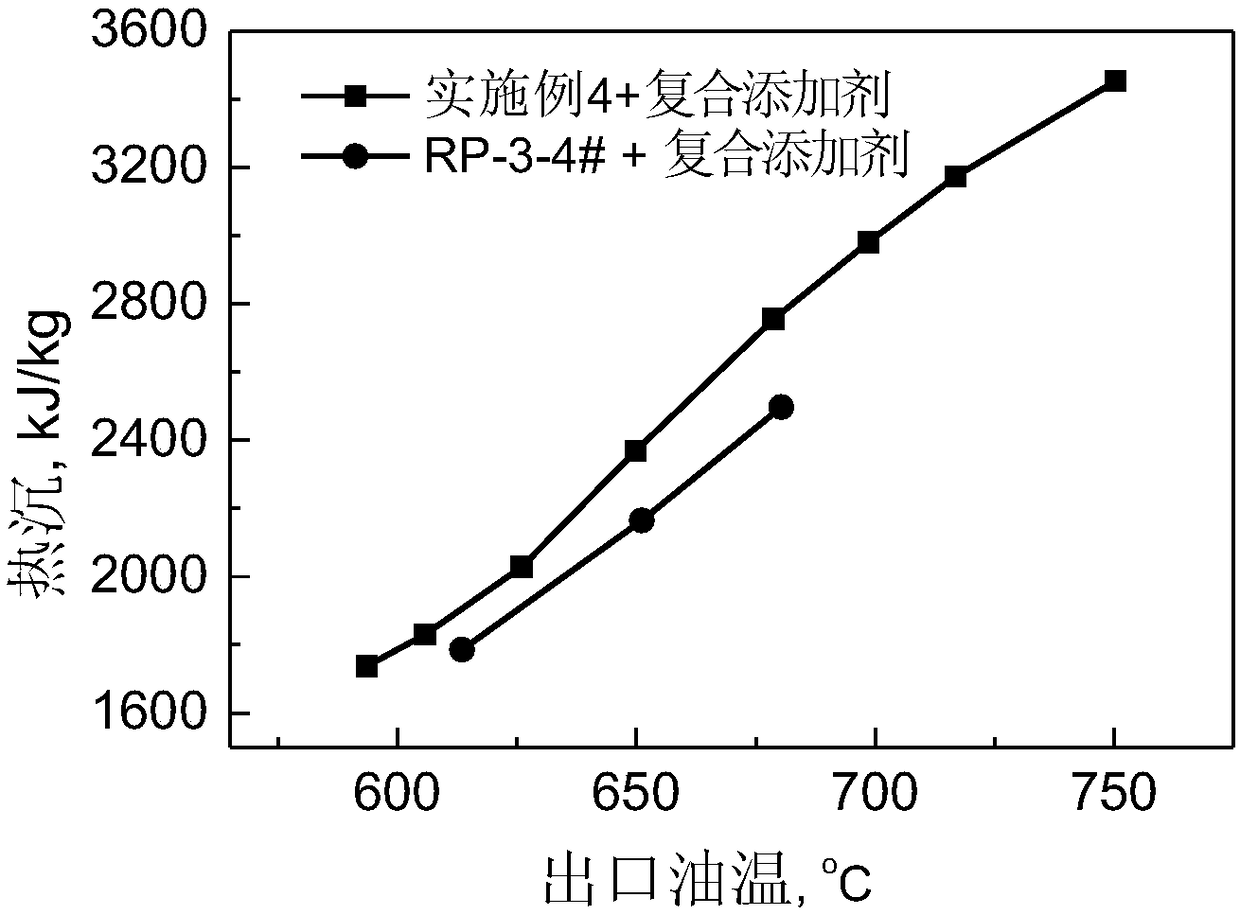

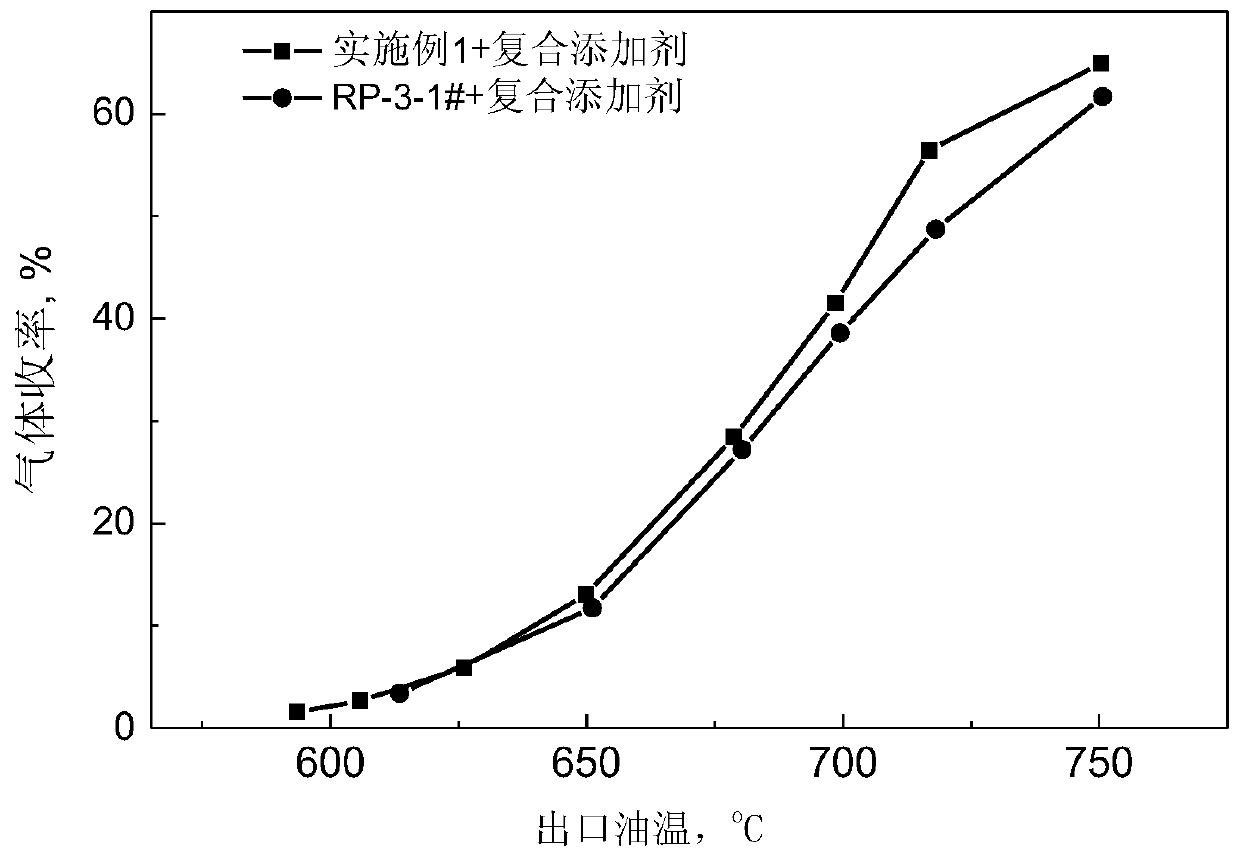

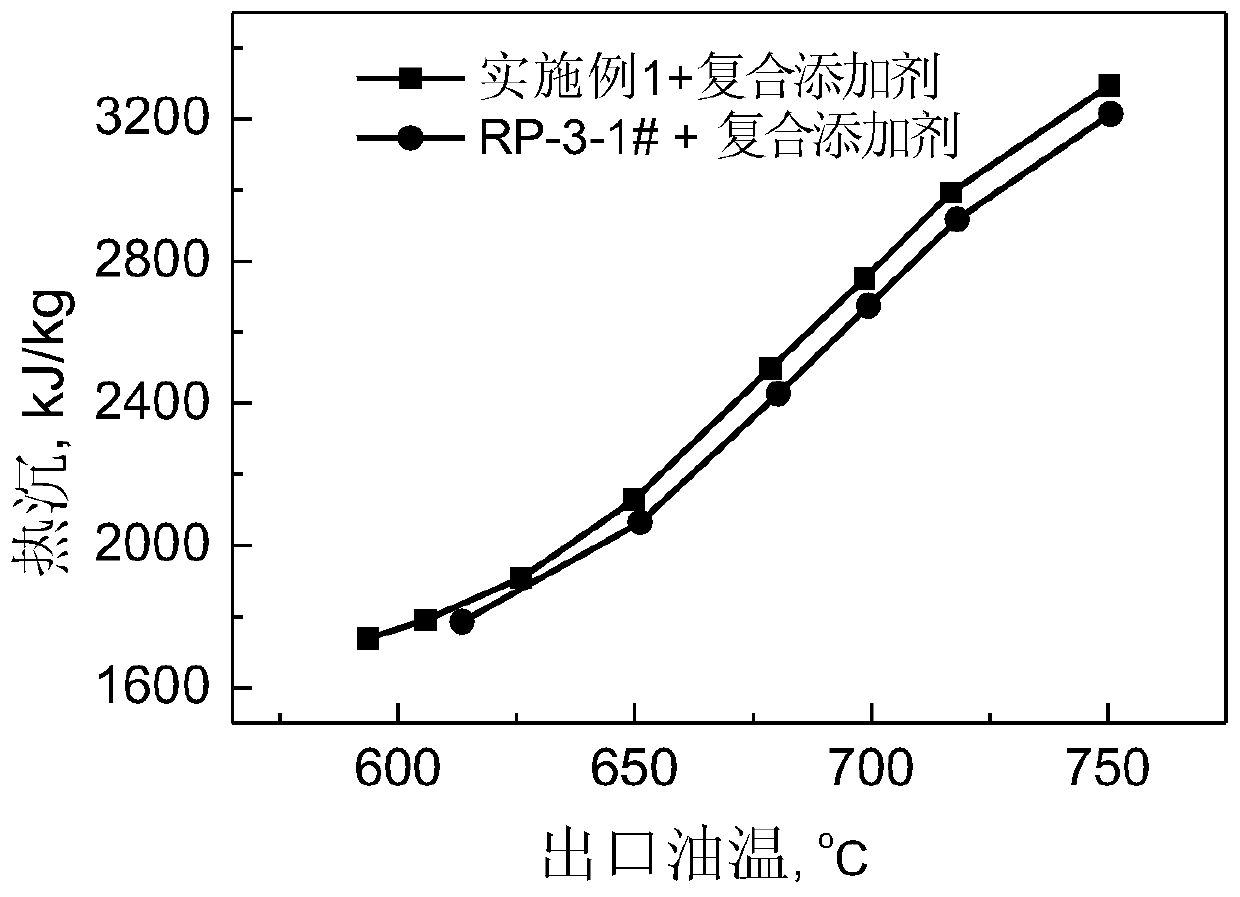

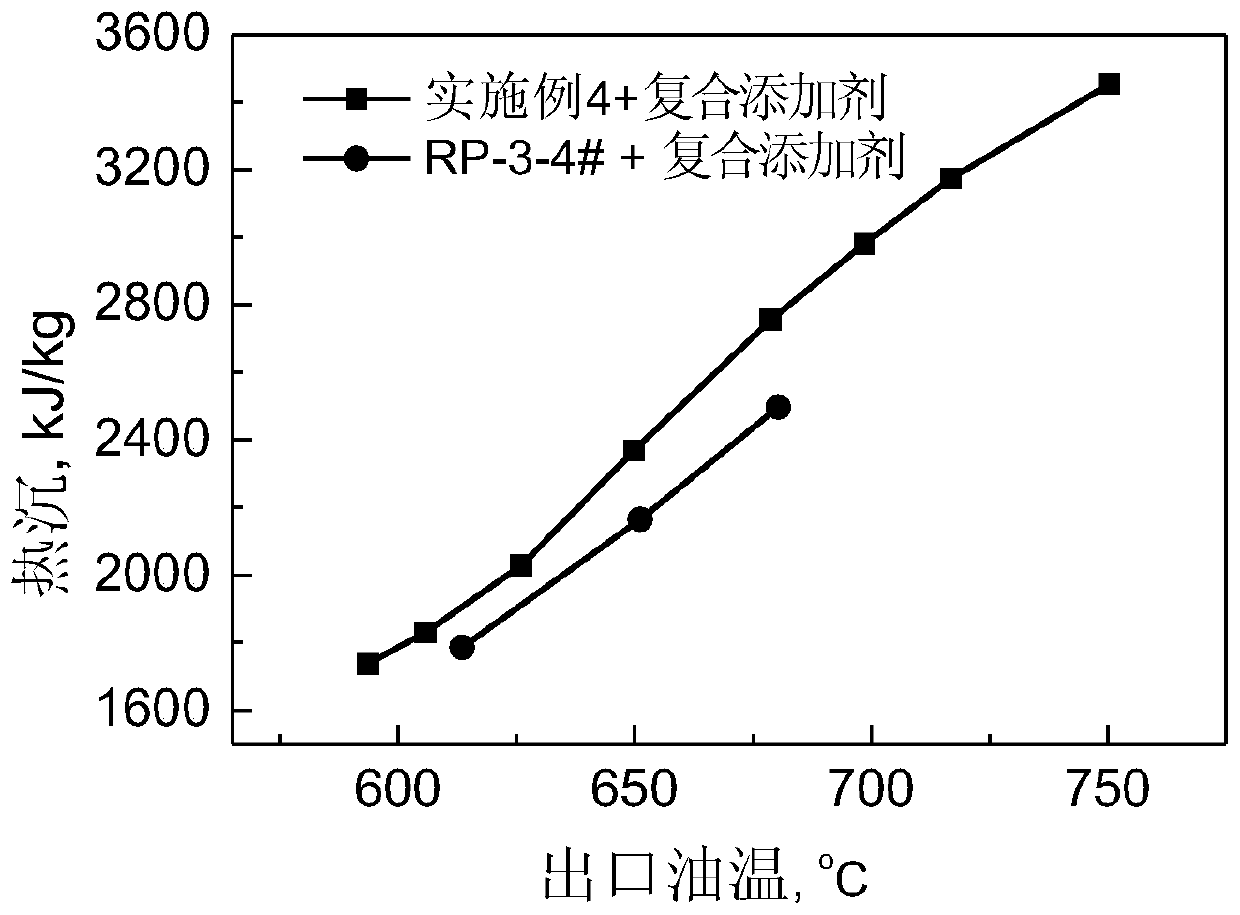

Endothermic aviation fuel and preparation method thereof

ActiveCN108795514AImprove thermal stabilityHigh calorific valueLiquid carbonaceous fuelsTreatment with hydrotreatment processesHeat sinkChemistry

The invention discloses an endothermic aviation fuel. According to the endothermic aviation fuel, a flashing point is higher than 60 DEG C, a fuel net heating value is larger than 43.0 MJ / kg, a heat sink at 750 DEG C is larger than or equal to 3.4 MJ / kg, and the thermal stability passes a JFTOT test at 355 DEG C in 300 minutes; the aviation fuel is prepared from larger than or equal to 30wt% of alkane and larger than or equal to 50wt% of cyclane, the aromatic hydrocarbon content is less than 5wt%, a bromine number is 0, and the sulphur content is less than 1 ppm. The endothermic aviation fuelhas the characters of high thermal stability, high heat value, low volatility, high heat sink and better anti-coking performance; after a compound additive is added, the performance of the aviation fuel can be further improved, especially, the anti-coking performance of the fuel at high temperatures is obviously improved.

Owner:TIANJIN UNIV

Double-layer catalyst and preparation thereof, and application of catalyst in preparation of pyromellitic dianhydride

ActiveCN102658188BProduction of homoanhydrideLess impuritiesOrganic chemistryPhysical/chemical process catalystsPtru catalystPyromellitic dianhydride

The invention belongs to preparation and application of a catalyst, and particularly relates to a double-layer catalyst and preparation thereof, and application of the catalyst in preparation of pyromellitic dianhydride. The preparation method comprises the following steps: respectively weighing effective quantities of active components (V2O5, TiO2, P2O5, Na2O, MoO3 and Sb2O3), compounds of other metals and whiskers, preparing solutions, preparing spraying slurry, spraying the slurry on a support, roasting, cooling and carrying out other technical steps to obtain catalysts E and G; respectively putting the catalysts G and E at a raw material gas mixture inlet end and a reaction gas outlet end; and preparing the pyromellitic dianhydride under the conditions of low air speed, low temperature and the like. The invention solves the problems of high operating condition requirements, massive product impurities, heavy color, low purity and the like, and has the advantages of low operating condition requirements, high product purity, fewer impurities and the like.

Owner:SHIJIAZHUANG HAOPU CHEM

Directly-heated rotary kiln for reduction nitridation reaction

PendingCN112880389AIncrease material levelImprove fill rateRotary drum furnacesEngineeringFerrochrome

The invention provides a directly-heated rotary kiln for reduction nitridation reaction. The directly-heated rotary kiln is used for producing vanadium-nitrogen alloy, nitrided ferrovanadium, reduced iron, nitrided ferrochromium and other products and comprises a rotary pipe, refractory materials, a driving wheel, a bearing wheel, an electric heating system, a kiln head box, a kiln tail box and other parts. A cylindrical or prismatic inner cavity enclosed by the refractory materials is a kiln chamber. The electric heating system comprises a positive electrode and a negative electrode, a heating power source applies direct-current voltage to the positive electrode and the negative electrode, the electrodes make contact with a heated material in the rotary kiln, current flows through the material through the positive electrode and then flows to the negative electrode, the materials serve as a resistor for heating, and heating of the materials is completed. Protrusions with the height of 1cm are arranged on the inner wall of the kiln chamber, the length-diameter ratio of the heating section is optimized, a material level maintaining device and the like are additionally arranged on a feeding channel or a discharging port of the kiln chamber, the filling rate of materials in the kiln chamber is increased, the requirement for the voltage level of a heating power source is lowered, the productivity of the directly-heated rotary kiln is increased, and energy consumption is reduced.

Owner:冯良荣

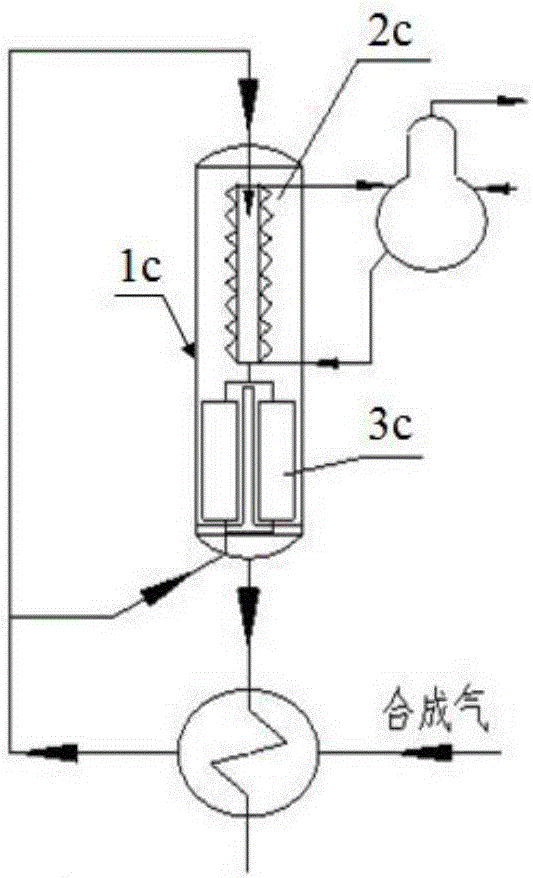

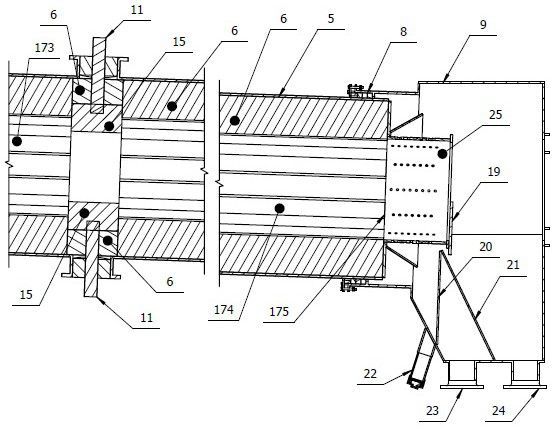

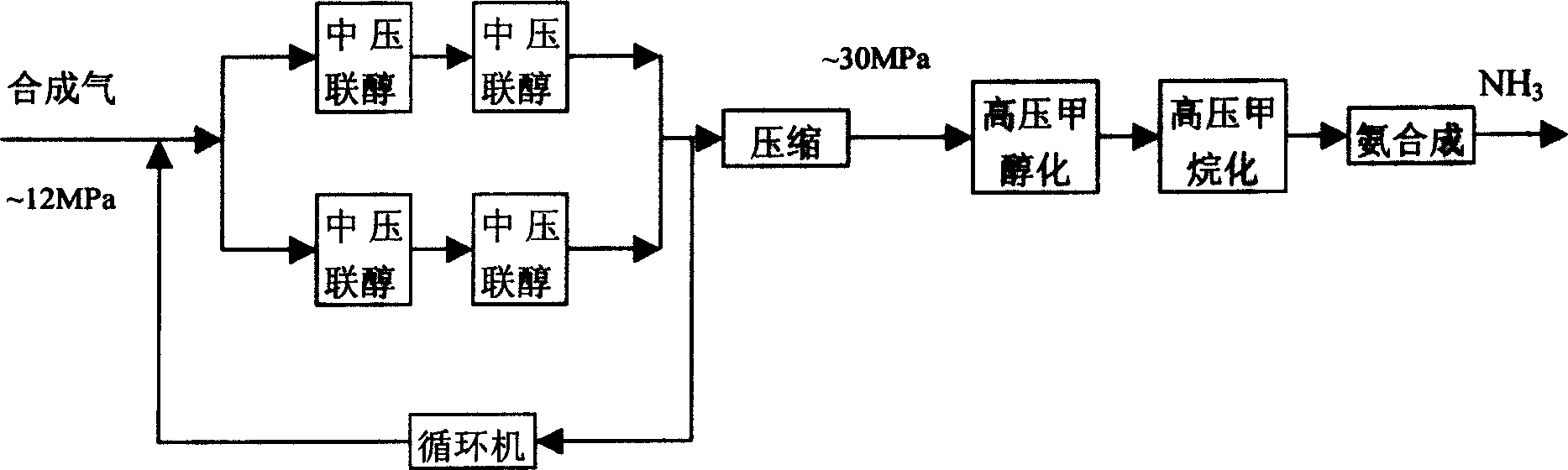

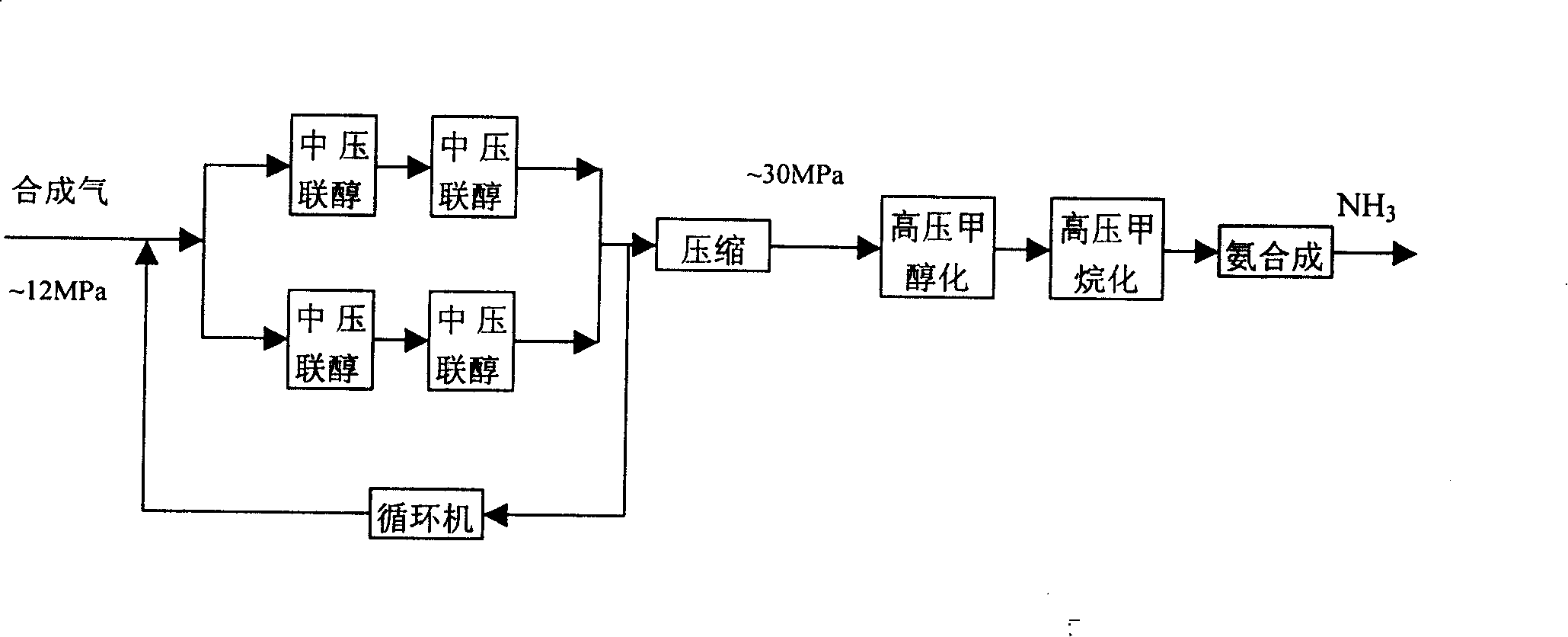

Externally heated medium and high pressure process and apparatus for synthesizing material ammonia with methanol and methane

InactiveCN1887689AIncrease production capacityHigh alcohol to ammonia ratioHydrogen productionHigh pressureTower

The present invention is externally heated medium and high pressure process and apparatus for synthesizing material ammonia gas with methanol and methane. The apparatus includes medium pressure combined methanol synthesizing apparatus with serially and parallelly connected towers; high pressure methanolizing apparatus comprising oil separator, water cooler and high efficiency methanol separator; and externally heated high pressure methanating apparatus comprising methanating tower, heat exchanger outside the tower, steam heater, water cooler, ammonia cooler and gas-water separator. The apparatus has the advantages of high alcohol / ammonia ratio, complete refining of synthesized material ammonia gas, low CH4 in produced inert gas, low heat consumption, etc.

Owner:ZHEJIANG UNIV OF TECH

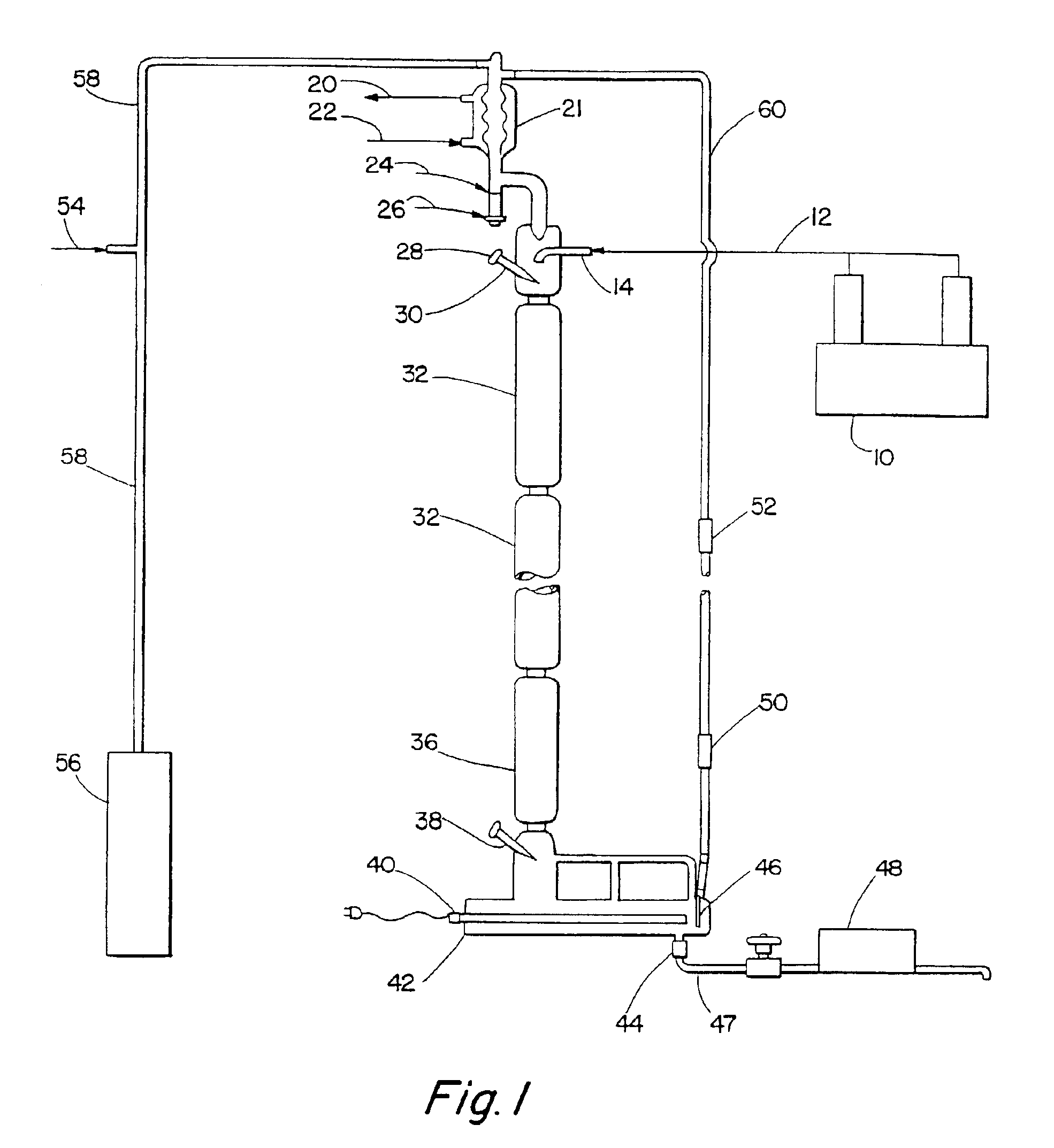

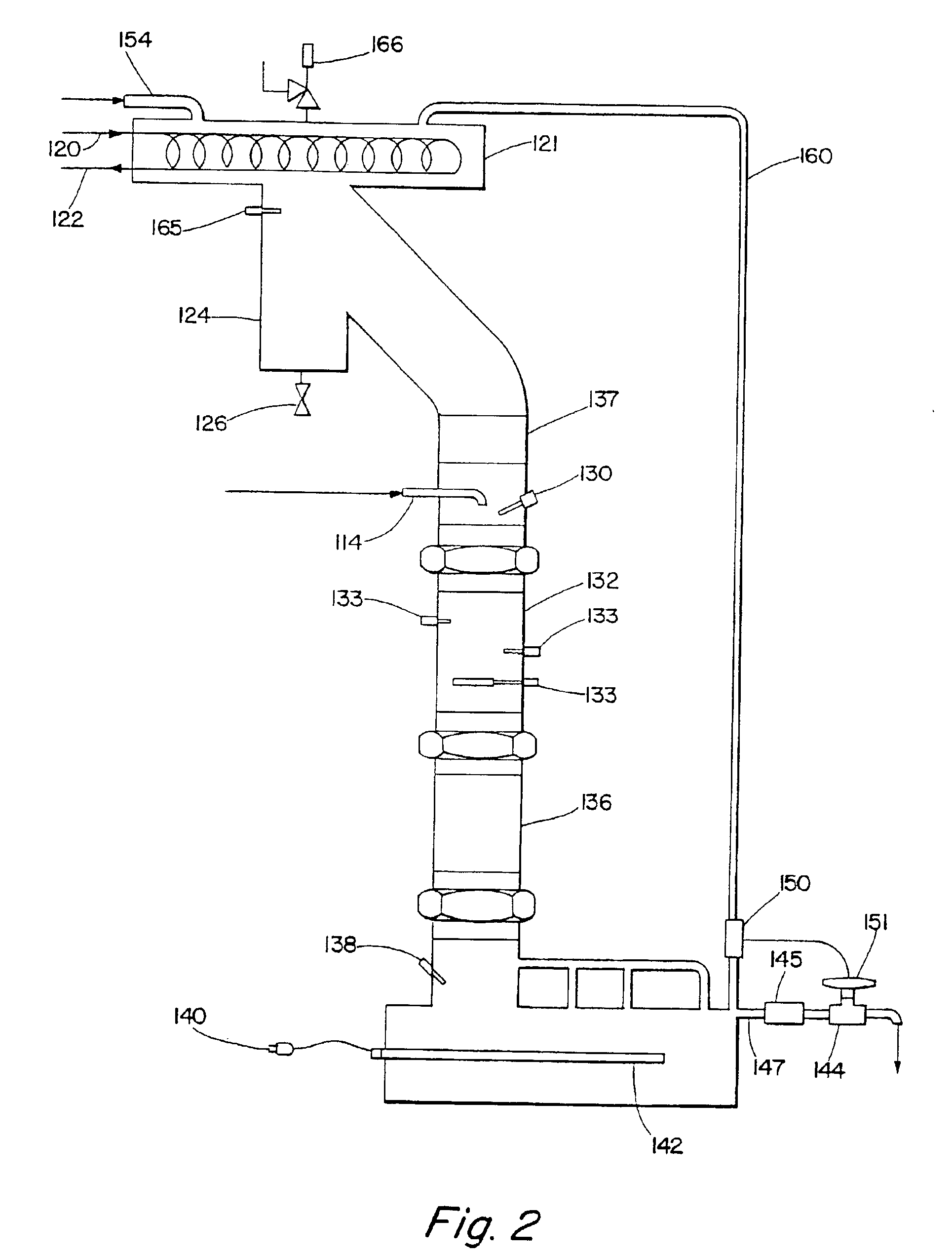

Higher containment vss with multi zone stripping

ActiveUS20180208857A1High degreeReduce airspeedCatalytic crackingVertical chamber coke ovensCycloneProcess engineering

This patent application discloses engineering design modifications to the VSS exit, stripper entrance and the primary cyclone diplegs that can significantly reduce the underflow of reactor riser products into the stripper and reactor vessel and thereby produce higher desired product selectivities, improved stripping efficiency and a stripper vent gas, that continuously flows through the reactor vessel, with a low coke forming potential due to its low concentration of ethylene and higher molecular weight material, that could, if desired, be recovered separately from the primary riser products.

Owner:MARATHON PETROLEUM

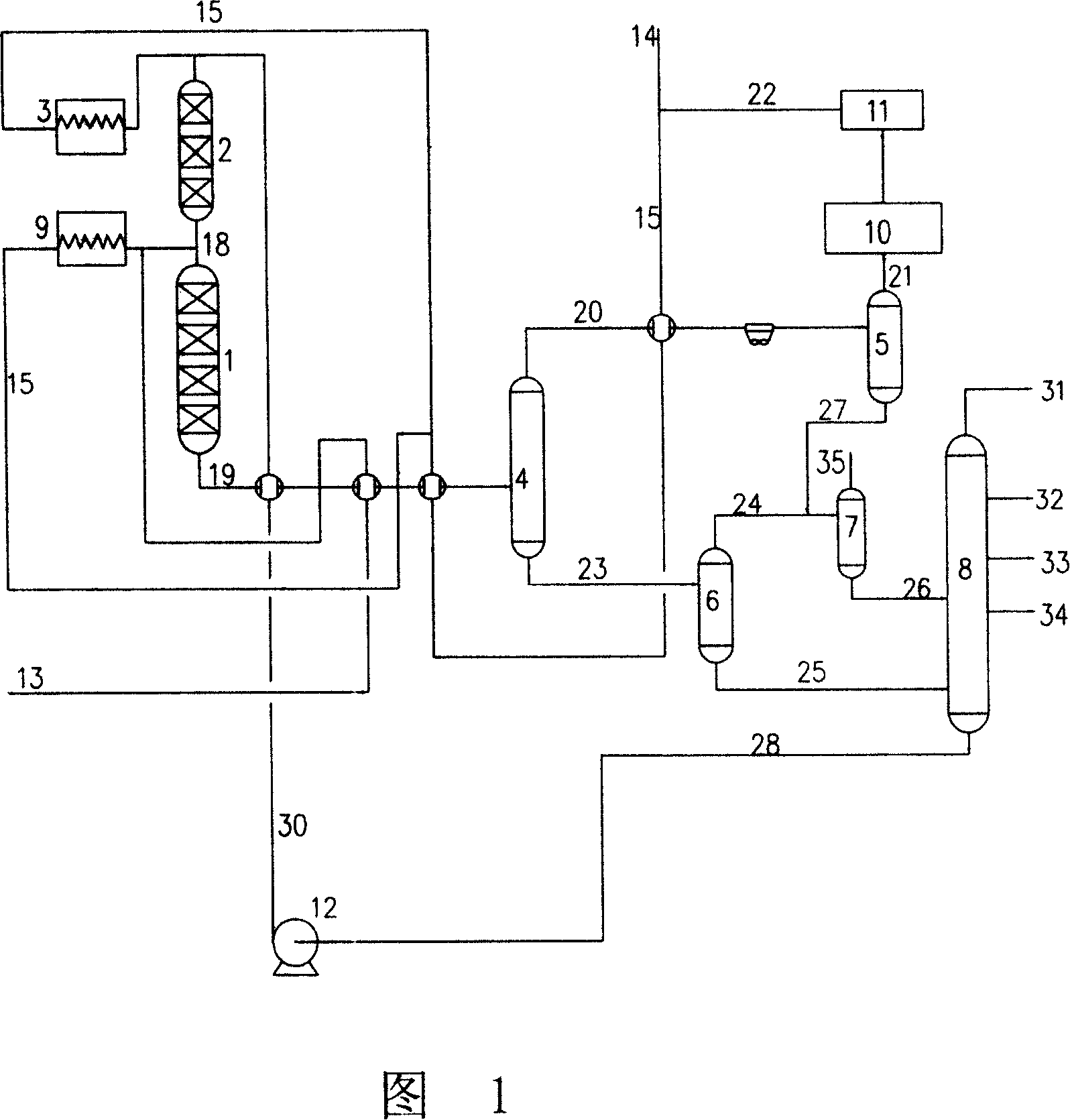

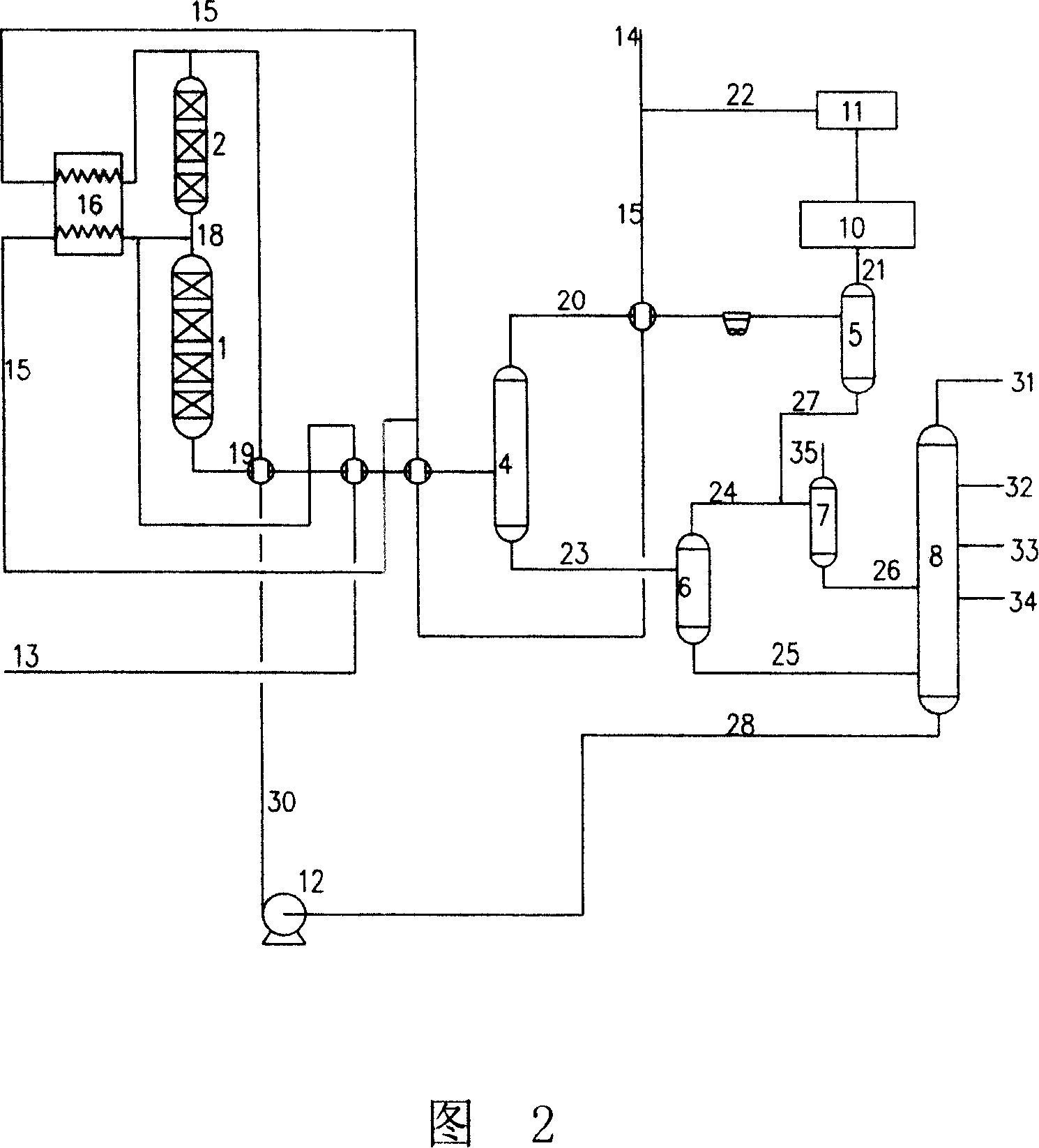

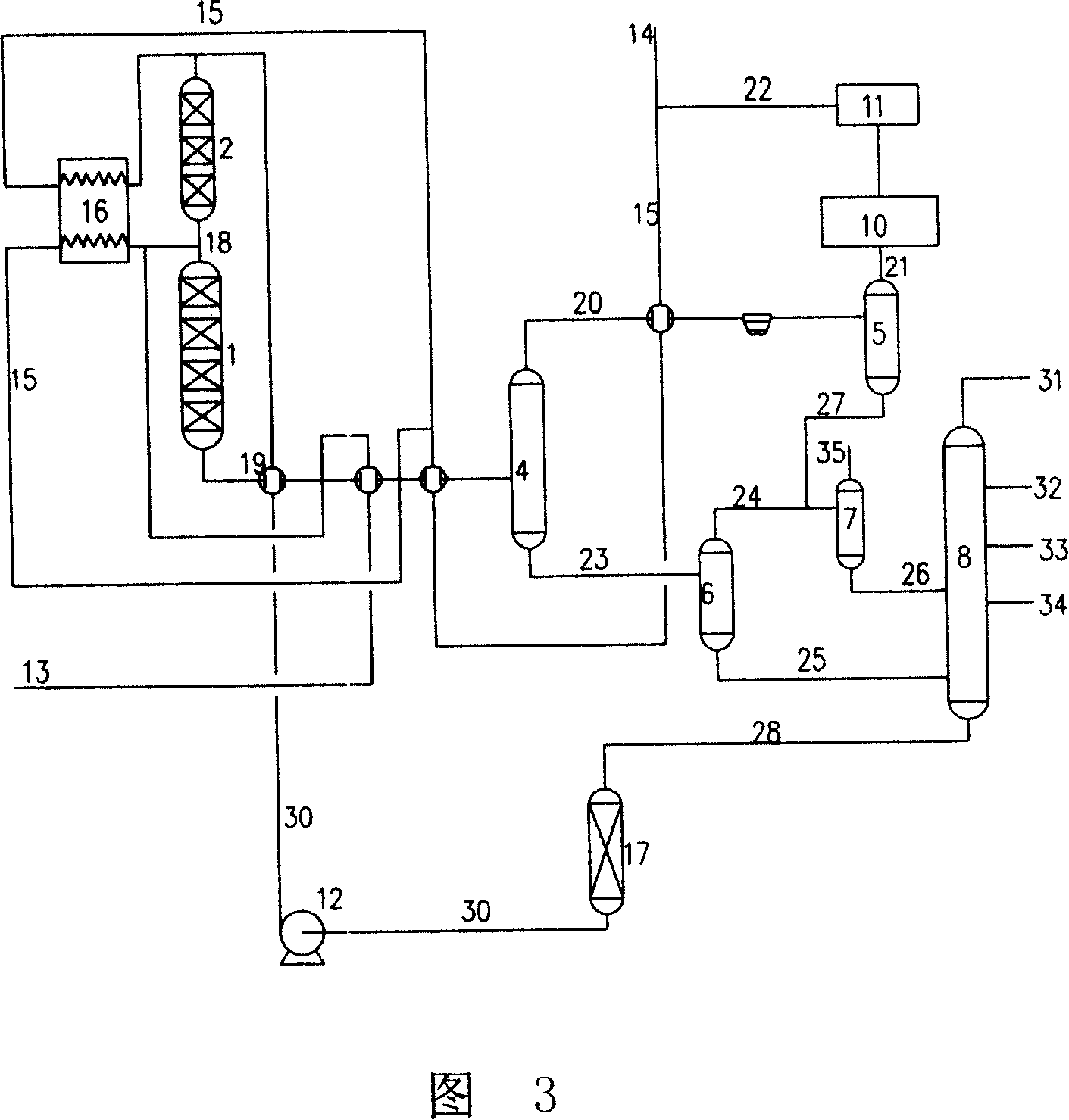

Hydrocarbons hydrocracking method

ActiveCN100371423CReduce the amount of cold hydrogenControl the amount of cold hydrogenTreatment with hydrotreatment processesHydrogenCracking reaction

The invention discloses a hydrogenation cracking method of hydrocarbon, which consists of first reactor and second reactor, wherein the first reactor is refined hydrogen reactor or hydrogenation refining and hydrogenation cracking reactor; the second reactor is hydrogenation cracking reactor; the crude oil and flow material from second reactor enters in the first reactor with hydrogen to do hydrogenation refining reaction or hydrogenation refining and hydrogenation cracking reaction; the effluent from the first reactor is separated to obtain circulated hydrogen, object product and non-conversing oil; all or partial non-conversing oil can be circulating oil in the second reactor with hydrogen, which proceeds hydrogenation cracking reaction; the effluent from the second reactor enters in the first reactor; the composite hydrogen can be new hydrogen to supplement, which mixes gas with circulating hydrogen.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

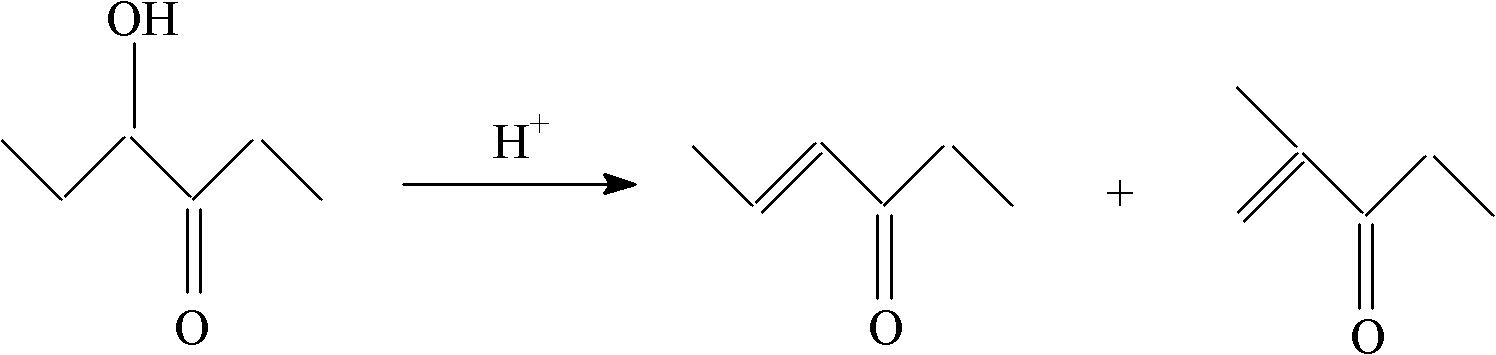

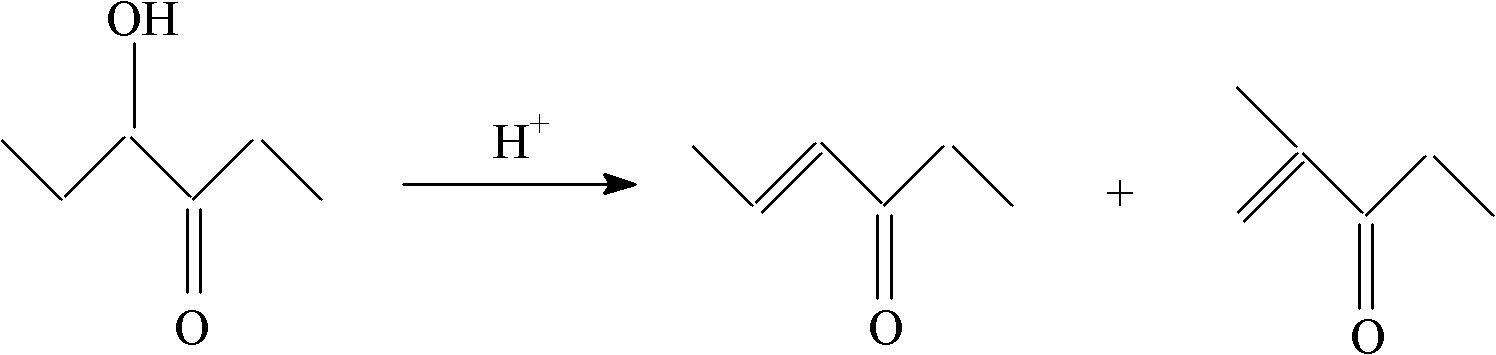

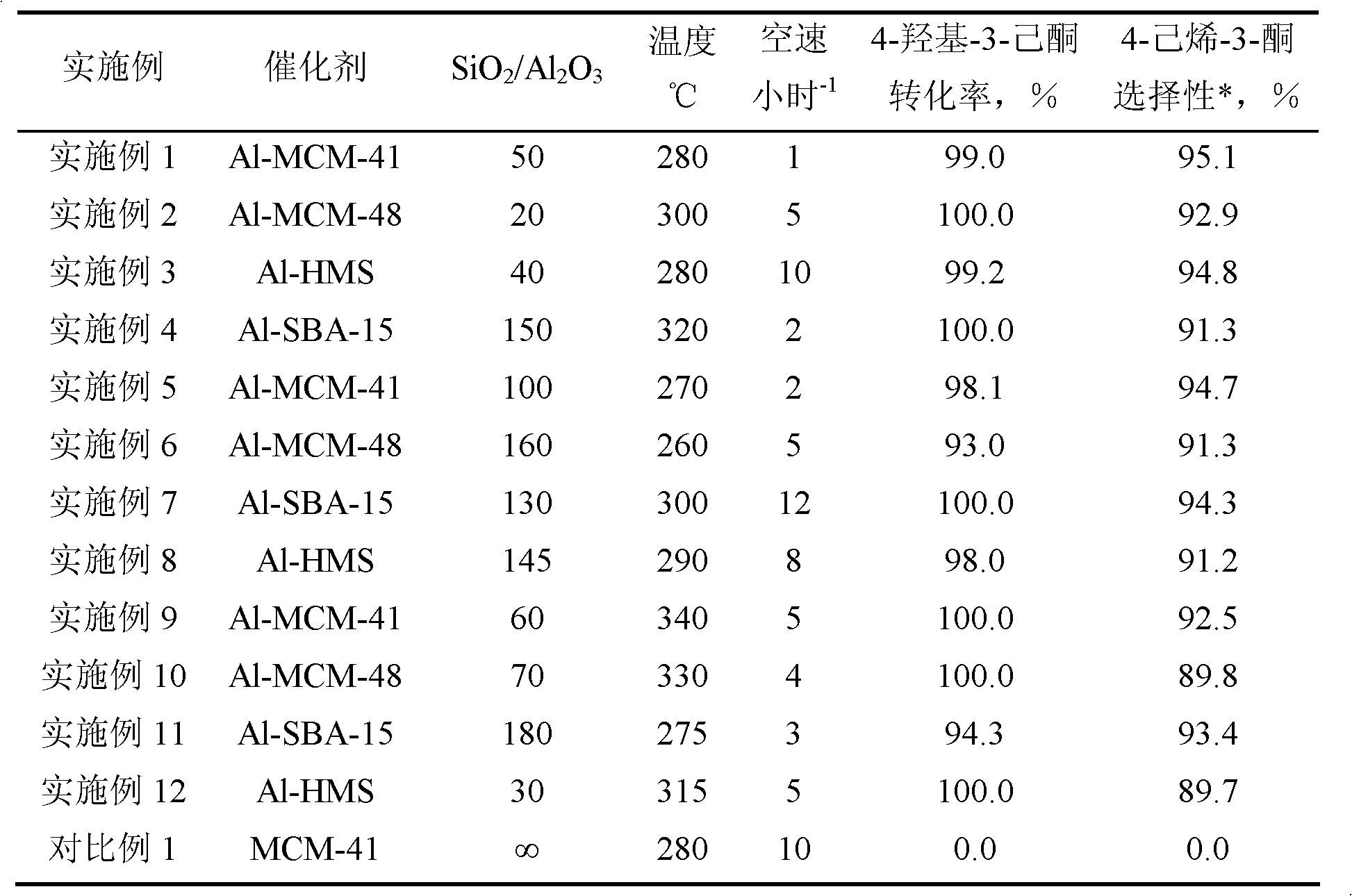

Method for preparing 4-hexene-3-ketone by 4-hydroxy-3-hexanone dehydration

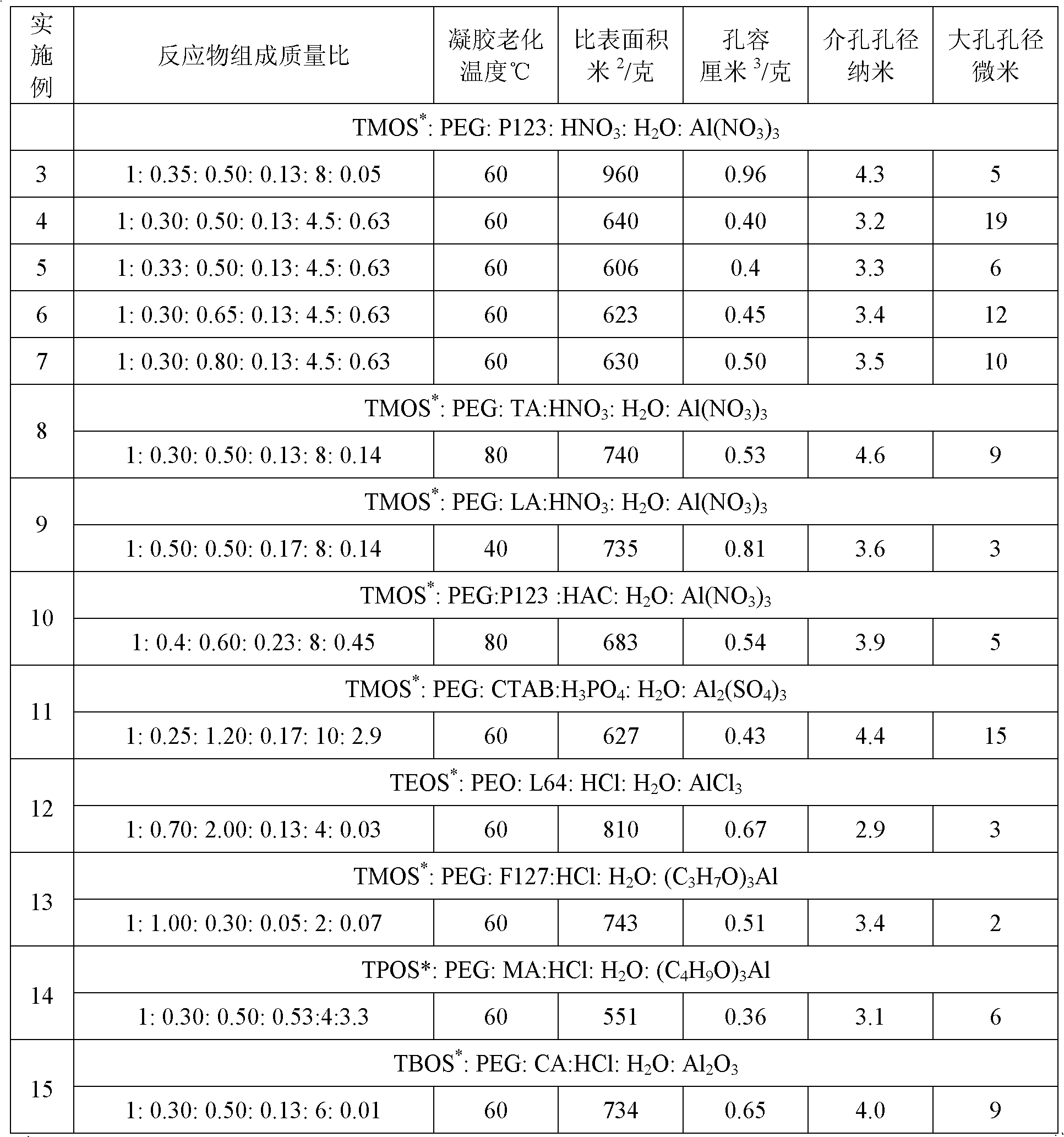

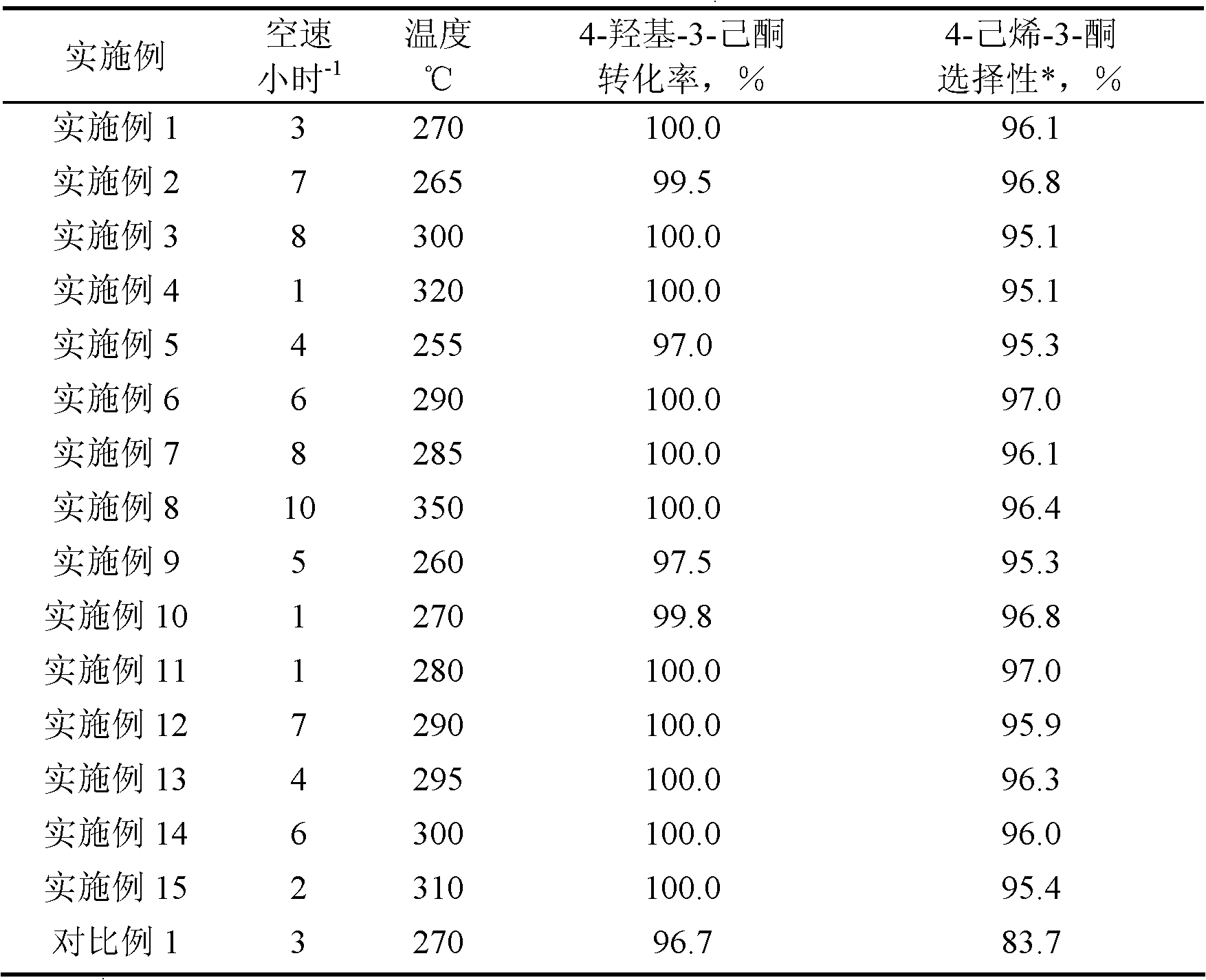

InactiveCN103030545ALarge specific surface areaWell-developed pore structurePhysical/chemical process catalystsOrganic compound preparationLow activityReaction temperature

The invention relates to a method for preparing 4-hexene-3-ketone by 4-hydroxy-3-hexanone dehydration, which mainly solves the problems of low activity of a catalyst, high reaction temperature, and low space velocity in the prior art. Aiming at well solving the problems, the method adopts the technical scheme that the 4-hydroxy-3-hexanone is used as a raw material, and the reaction raw material comes into contact with the catalyst to generate the 4-hexene-3-ketone when the reaction temperature is 200 to 400 DEG C and the liquid weight hourly space velocity is 0.5 to 15 h<-1> relative to the 4-hydroxy-3-hexanone; and the catalyst is a mesoporous / macroporous silica and alumina oxide material with a composite pore structure The method can be used for the industrial production of the 4-hexene-3-ketone prepared by the 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing pyromellitic dianhydride from durene through gaseous catalytic oxidation and preparation method thereof

ActiveCN102000596BReduce airspeedReduce energy consumptionPhysical/chemical process catalystsOrganic chemistryResource consumptionCatalytic oxidation

The invention relates to a catalyst for preparing pyromellitic dianhydride from durene through gaseous catalytic oxidation and a preparation method thereof, belonging to the technical field of catalytic oxidation. The catalyst is characterized by comprising V2O5, TiO2 and P2O5, wherein the molar ratio of V2O5 to TiO2 to P2O5 is 1:3.750-15.000:0.125-0.313. The catalyst provided by the invention has the advantages of low airspeed, low energy consumption, high selectivity and high weight gain percentage during application, is helpful to energy saving and resource consumption reduction and is beneficial to increasing the yield and the purity of pyromellitic dianhydride and reducing the production cost for preparing pyromellitic dianhydride through gaseous catalytic oxidation. The provided preparation method of the catalyst has simple and succinct technological steps and can ensure the overall embodiment of the effect of the catalyst.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Externally heated medium and high pressure process and apparatus for synthesizing material ammonia with methanol and methane

InactiveCN100402415CIncrease production capacityHigh alcohol to ammonia ratioHydrogen productionMethanationPhysical chemistry

The present invention is externally heated medium and high pressure process and apparatus for synthesizing material ammonia gas with methanol and methane. The apparatus includes medium pressure combined methanol synthesizing apparatus with serially and parallelly connected towers; high pressure methanolizing apparatus comprising oil separator, water cooler and high efficiency methanol separator; and externally heated high pressure methanating apparatus comprising methanating tower, heat exchanger outside the tower, steam heater, water cooler, ammonia cooler and gas-water separator. The apparatus has the advantages of high alcohol / ammonia ratio, complete refining of synthesized material ammonia gas, low CH4 in produced inert gas, low heat consumption, etc.

Owner:ZHEJIANG UNIV OF TECH

Equipment and method for low-temperature methanol double washing based on heat exchange and modified methanol

PendingCN113144831AReasonable equipment structure designProcess OptimizationDispersed particle separationProcess engineeringMethanol water

Owner:灵谷化工集团有限公司

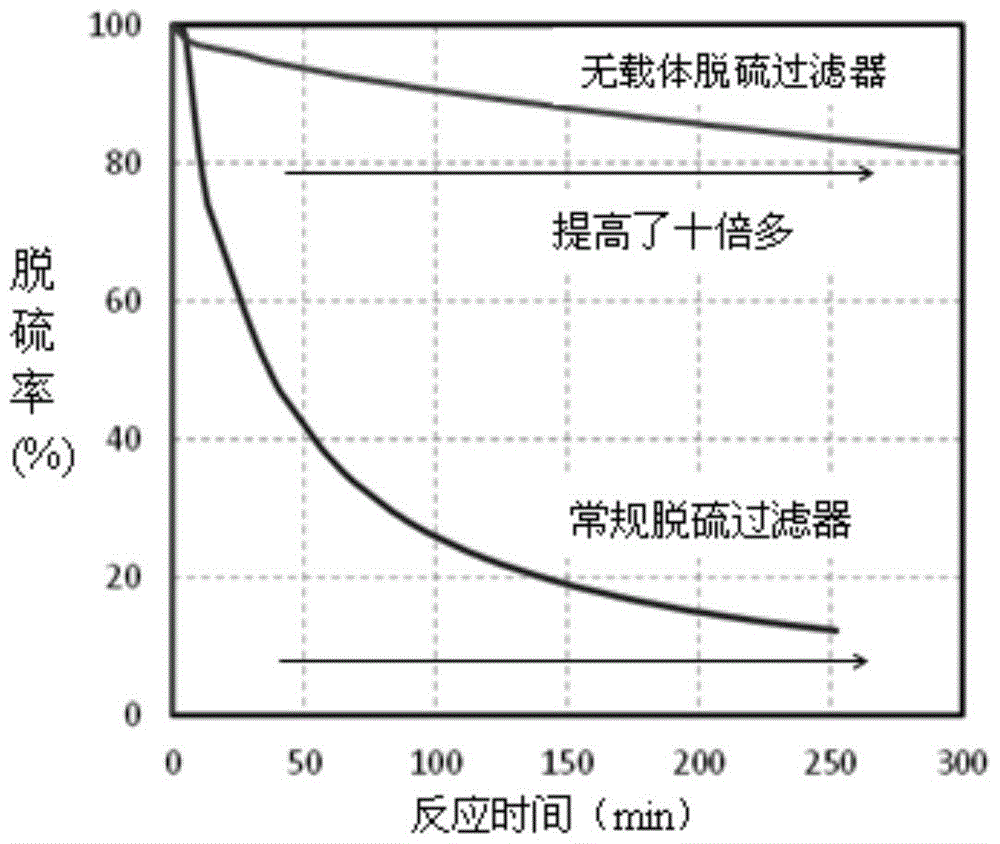

A kind of dry desulfurization filter for diesel engine exhaust and preparation method thereof

ActiveCN104607044BImprove desulfurization capacityImprove combustion efficiencyDispersed particle separationHoneycombEngineering

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

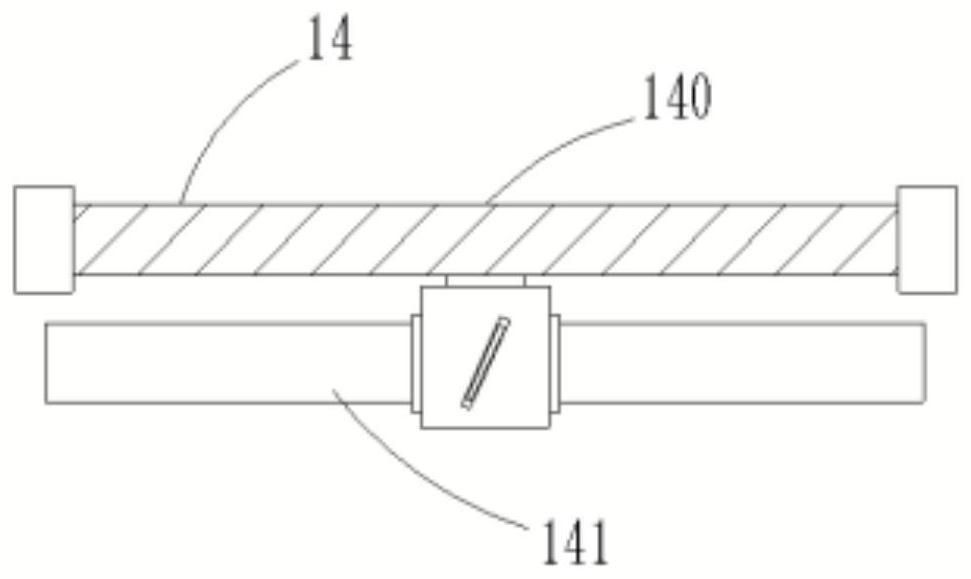

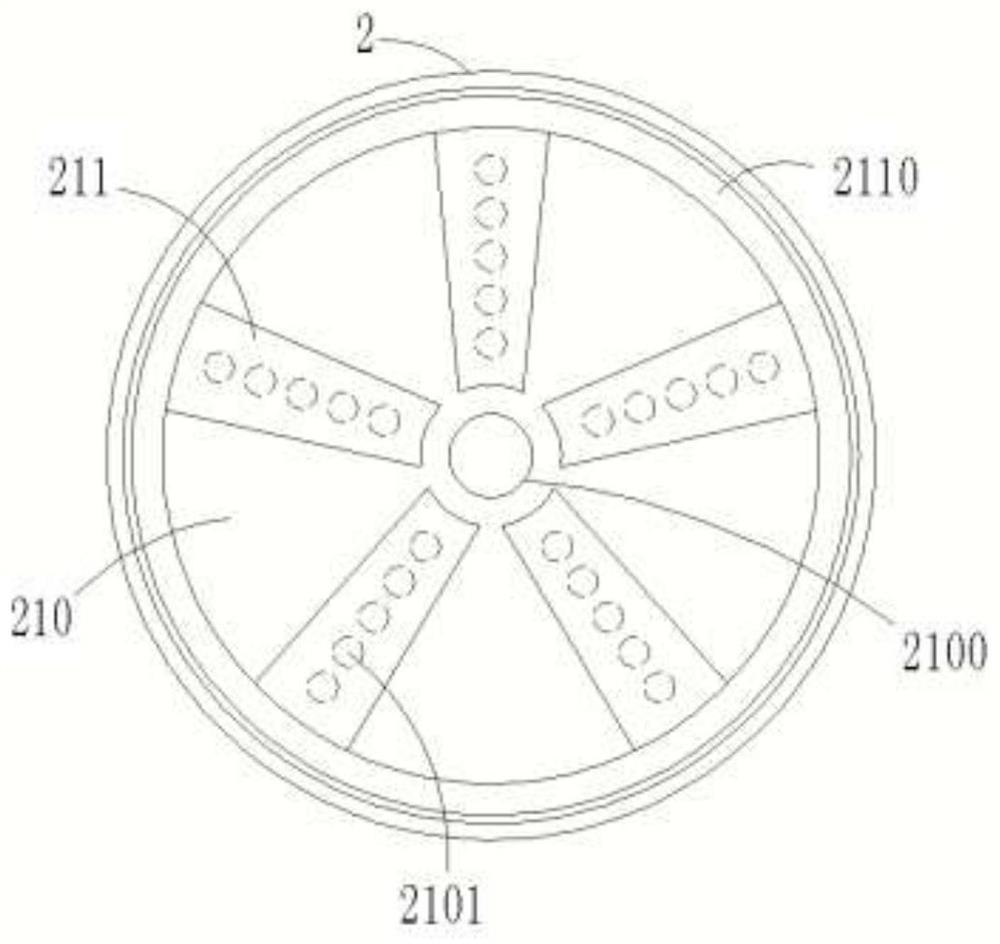

Method for improving density of fast bed and reactor

InactiveCN104941528AReduce uplink speedHigh densityChemical/physical processesProduct gasPetrochemical

The invention provides a method for improving the density of a fast bed and belongs to the technical field of fluidization, petrochemical industry, olefin production and aromatic hydrocarbon production equipment, aiming at solving the problems of an existing fast bed reactor that the catalyst density is low, the catalyst storage amount is low and the airspeed is high. The method comprises entering and exhausting of the fast bed, oil gas and catalysts, and is characterized in that a reverse distribution facility is designed at the lower part of the fast bed to reduce the upward movement speed of the catalysts, and the density of the catalysts of the fast bed is increased by enhancing the slipping of the catalysts. By virtue of the method, the density of the catalysts of the fast bed can be greatly improved, the storage amount of the catalysts is improved, the airspeed of the fast bed reactor is greatly reduced, and the conversion capability of the fast bed reactor is improved; and furthermore, the feeding requirements of a plurality of types of process gas can be met. The invention further provides a reverse distributor for realizing the method and gas feeding distributor equipment. The method is used for catalytic cracking, olefin production and aromatic hydrocarbon production devices and the like.

Owner:刘英聚

Load typed varadium catalyst and its preparing method and application

InactiveCN1275687CReduce vanadium contentReduce airspeedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

A carried vanadium catalyst is prepared from activated carbon or gamma-Al2O3, vanadium and assistant through pulverizing activated carbon or gamma Al2O3 by 20-80 meshes, preparing the solutions of V precursor and assistant precursor, immersing for 18-36 hr, drying at 110-120 deg.c for 4-6 hrs, calcining at 450-650 deg.c for 4-5 hrs in nitrogen atmosphere and putting in drier. Its advantages are high transform rate of ethylbenzene (more than 60%) and high selectivity to styrene (more than 96%).

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

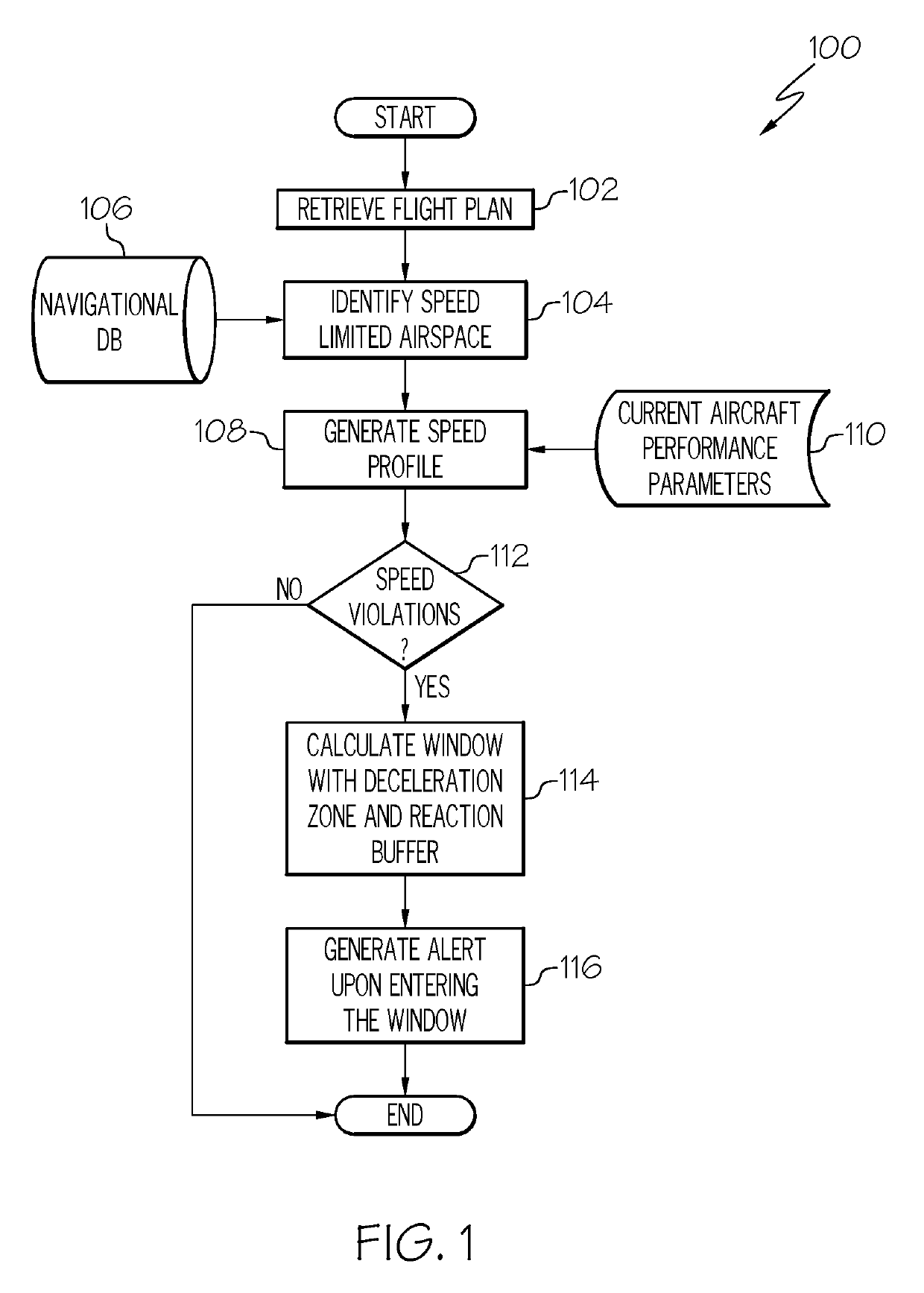

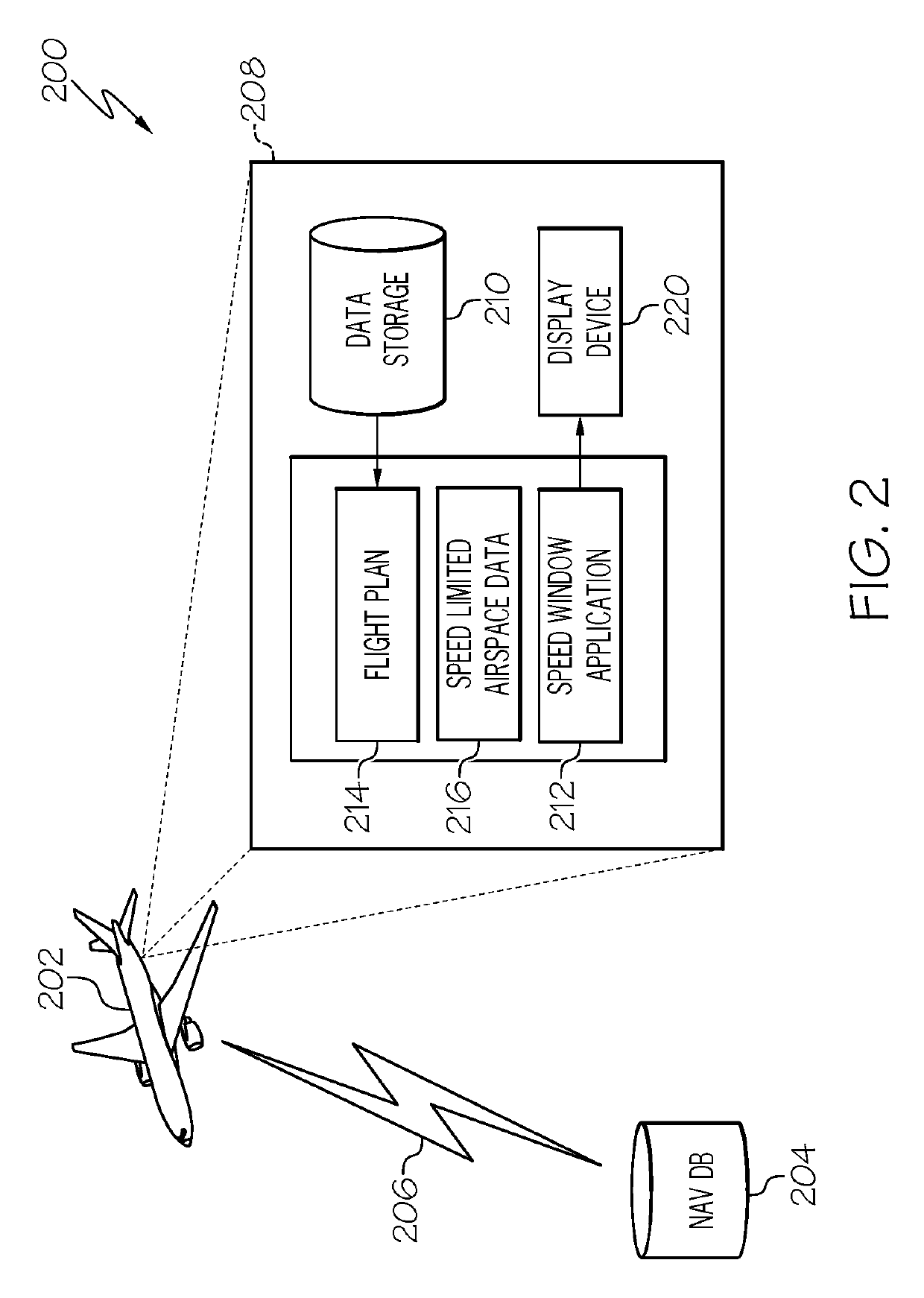

Method and system for generating an alert for an aircraft potentially exceeding speed limits in restricted airspace

ActiveUS20190291889A1Reduce airspeedInstruction delayNavigation instrumentsFlight plan managementSufficient timeAirspeed

Methods and systems are provided for generating an alert for an aircraft potentially exceeding speed limits in airspace with speed limitations. The method comprises retrieving a flight plan for the aircraft and identifying airspace with speed limitations along the flight plan. A speed profile is generated based on the in-flight aircraft's current position, speed and trajectory. Any predicted speed violations are identified by comparing the speed profile with the airspace with speed limitations along the flight plan. A predictive time window is calculated that allows for the in-flight aircraft to decelerate sufficiently to comply with the speed limits of the airspace with speed limitations. The predictive time window includes a zone for the aircraft to reduce its airspeed and a reaction buffer zone to allow the aircrew sufficient time to comply with instructions to decelerate the aircraft. Finally, an alert is generated for the crew of the in-flight aircraft upon entering the predictive time window.

Owner:HONEYWELL INT INC

An energy-saving two-stage alcohol production method and device with high and low temperature gradient alcohol separation between stages

ActiveCN105753646BReduce CO2 concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol production

Owner:NANJING GOODCHINA CHEM TECH

Method of 4-hydroxy-3-hexanone catalytic dehydration

InactiveCN103030540AHigh activityRaise the reaction temperatureMolecular sieve catalystsOrganic compound preparationReaction temperatureKetone

The present invention relates to a method of 4-hydroxy-3-hexanone catalytic dehydration, and mainly solves the problem of low catalyst activity, high reaction temperature and low space velocity in the prior art. According to the invention, 4-hydroxy-3-hexanone is used as a raw material, and the reaction raw material is in contact with a catalyst to produce 4-hexen-3-one at the conditions of a reaction temperature of 200-400 DEG C and the space velocity of 0.5-15 hr-1 with respect to the mass of 4-hydroxy-3-hexanone liquid, wherein the catalyst is at least one selected from the group consisting of Al-MCM-41, Al-MCM-48, Al-SBA-15, Al-HMS, Al-MSU-1 or Al-MSU-2. The technical solution solves the problem preferably. The method can be used in the industrial production of 4-hexen-3-one from 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of endothermic aviation fuel and preparation method thereof

ActiveCN108795514BNo emissionsIncrease relative volatilityLiquid carbonaceous fuelsTreatment with hydrotreatment processesBromine numberCyclic alkane

The invention discloses an endothermic aviation fuel. According to the endothermic aviation fuel, a flashing point is higher than 60 DEG C, a fuel net heating value is larger than 43.0 MJ / kg, a heat sink at 750 DEG C is larger than or equal to 3.4 MJ / kg, and the thermal stability passes a JFTOT test at 355 DEG C in 300 minutes; the aviation fuel is prepared from larger than or equal to 30wt% of alkane and larger than or equal to 50wt% of cyclane, the aromatic hydrocarbon content is less than 5wt%, a bromine number is 0, and the sulphur content is less than 1 ppm. The endothermic aviation fuelhas the characters of high thermal stability, high heat value, low volatility, high heat sink and better anti-coking performance; after a compound additive is added, the performance of the aviation fuel can be further improved, especially, the anti-coking performance of the fuel at high temperatures is obviously improved.

Owner:TIANJIN UNIV

Multistage gas solie chemical reactor

ActiveCN100376318CSimple structureAmmonia concentration did not decreaseChemical/physical processesGas solidNuclear engineering

A multi-segment chemical gas-solid reactor is composed of a pressurized external cylinder and a heated internal cylinder, which has three layers, two pot-shaped gas collectors between adjacent two layers, and two heat exchangers installed respectively in the centers of the second and the third layers. Its advantages are high purity of product, high grade of vapor and low airflow resistance.

Owner:HUNAN ANCHUN ADVANCED TECH

Bacillus licheniformis, method for preparing flocculant from it and application of flocculant

ActiveCN106244478BWide growth temperature rangeHas alkali resistanceSludge treatmentBacteriaSludge cakeBacillus licheniformis

The invention relates to bacillus licheniformis, a method for preparing a flocculating agent from the bacillus licheniformis and an application of the flocculating agent. The strain is bacillus licheniformis LZ-1 which is preserved in China General Microbiological Culture Collection Center on November 06, 2012 with preservation number of CGMCC No.6782. With the application of the bacillus licheniformis LZ-1 as well as a production method provided by the invention, a fermentation broth, which is high in flocculating activity, is obtained under the condition that an initial pH value is alkaline, and high-molecular-weight polysaccharide, which is 0.8-3.2*10<7>Da, serves as a major flocculating active ingredient. The polysaccharide flocculating agent provided by the invention has the advantages of being high in flocculating activity, low in dosage, low in production cost and the like, and the flocculating agent has a flocculating conditioning effect on sludge. The bacillus licheniformis LZ-1 fermentation broth or a product, which is extracted from the fermentation broth and contains the polysaccharide flocculating agent, can be applied to deep dewatering by sludge plate-frame pressure filtration in a mode of replacing a polyacrylamide flocculating agent, so that sewage treatment plant concentrated sludge, which is 96-98% in moisture content, is further dewatered into a sludge cake which is lower than 60% in moisture content and the size of the sludge is diminished to be 1 / 20-1 / 10 of an original size.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI +2

Method for synthesizing ethyl benzene and diethyl benzene

InactiveCN101085711BEliminate the dehydration stepIncrease profitDistillation purification/separationHydrocarbon by hydrocarbon and non-hydrocarbon condensationOperational costsDiethyl benzene

The invention discloses a method for synthesizing ethyl benzene and diethyl. It takes benzene and ethanol as raw material and comprises following steps: (A) benzene ethylization: heating benzene and ethanol for gasification, feeding them into reactor filled with molecular screen catalyst, the molar ratio between benzene and ethanol is 4- 8: 1, and the condition is at 350- 420 Deg. C and 0.7- 2 MPa; (B) recovering benzene: distilling reactant of ethylization, separating and getting mixture of benzene and ethyl benzene and diethyl; dewatering recovered benzene and using it as material for ethylization in step (A); (C) separating and refining: distilling said mixture, separating and getting ethyl benzene and diethyl. The invention replaces ethane with ethanol and finishes ethylization with one step. It is characterized by simnple process, high utilization rate of ethanol and saved investment and operational cost.

Owner:常州世鑫化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com