Directly-heated rotary kiln for reduction nitridation reaction

A nitriding reaction and direct heating technology, which is applied in the field of high-temperature kilns, can solve the problems of high manufacturing cost and unsafety of power supply, and achieve the effects of improving electricity safety, reducing power consumption, and increasing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

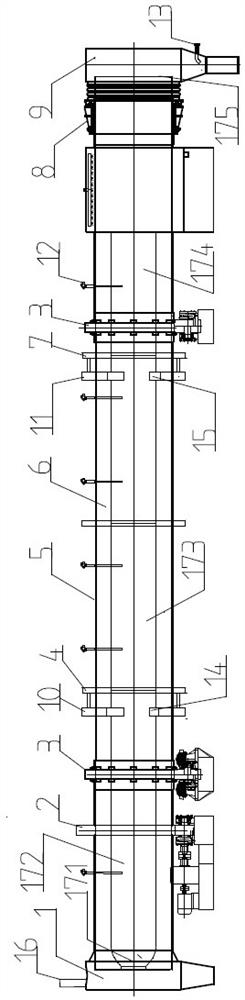

[0053] figure 1 with figure 2 It is the schematic diagram of embodiment 1. Such as figure 1 As shown, the direct-heating rotary kiln is used as a reactor for carbothermal reduction and / or nitriding reaction of raw materials such as metal oxides, and includes a kiln head box 1, a kiln head box tail gas outlet 16, a driving wheel 2, Bearing wheel 3, a group of two positive conductive materials 10, a group of two positive electrodes 14, a positive conductive slip ring 4, a rotary tube 5, a refractory material 6, a group of two negative conductive materials 11, a group of two negative electrodes 15, Negative conductive slip ring 7, 6 k-grading thermocouples 12, rotary sealing connection 8 between kiln tail box and rotary tube, kiln tail box 9 and air inlet 13 on kiln tail box. The refractory material 6 plays the role of fire resistance, heat preservation and insulation at the same time, and it is required that the resistance of the refractory material in contact with the mater...

Embodiment 2

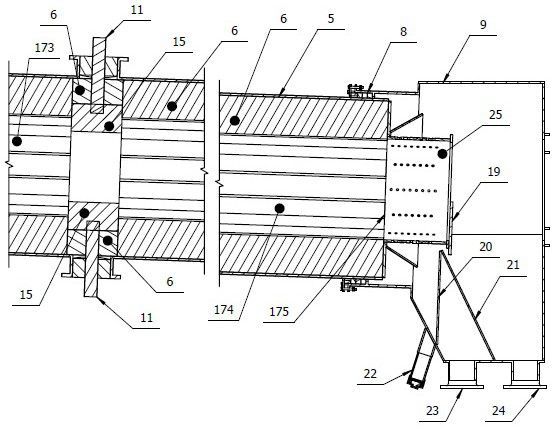

[0058] image 3 , Figure 4 with Figure 5It is the schematic diagram of embodiment 2. image 3 The figure shows the heating section 173 of the kiln chamber 17, the cooling section 174 and the kiln chamber discharge port 175, the negative electrode 15, the negative electrode conductive material 11 passing through the refractory material 6 and the rotary tube 5, the rotation between the kiln tail box and the rotary tube The sealing connection 8, the kiln tail box 9, the screen hole pipe 25 connected to the discharge port 175 of the kiln chamber, and the material retaining plate 19 covered on the screen hole pipe. The baffle plate 19 does not rotate with the rotary tube 5, but is in sliding frictional contact with the discharge port 175 of the kiln chamber in Embodiment 1 or the discharge port of the sieve tube in this embodiment. Partition plate 20 and sieve plate 21 are arranged in kiln tail box 9.

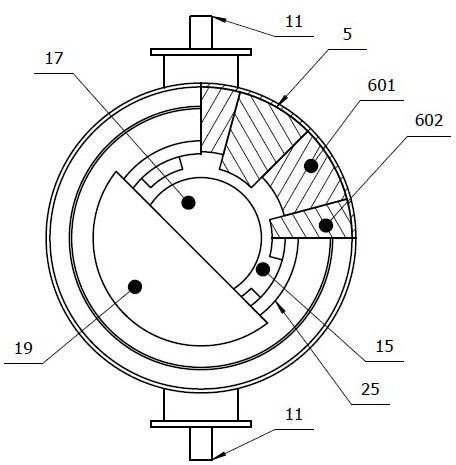

[0059] Figure 4 The conductive connection between the annular negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com