Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167results about How to "Increase daily output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

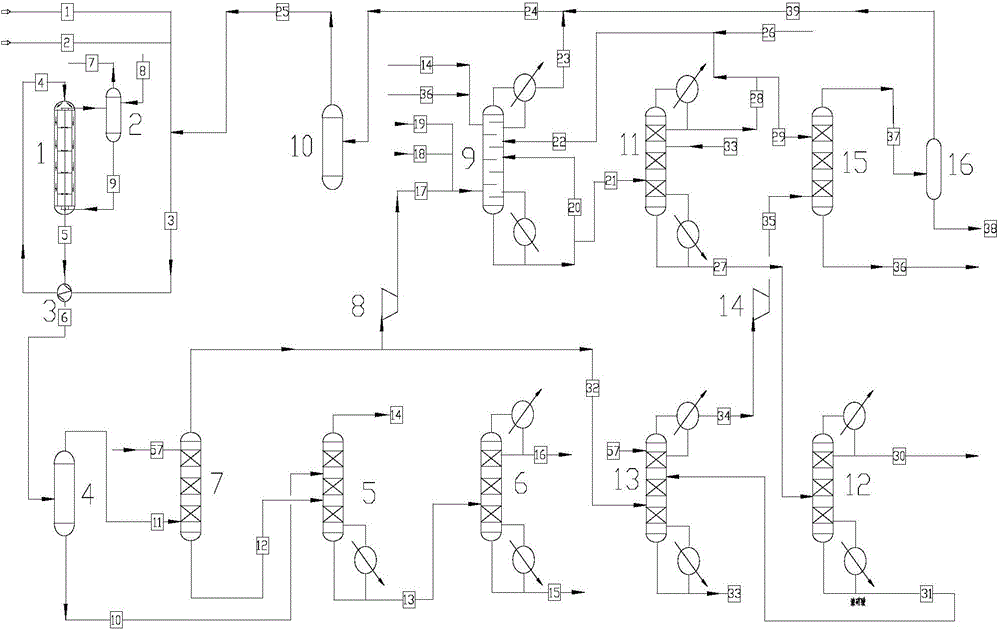

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

ActiveCN104098441AConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputSeparation technologyHigh pressure

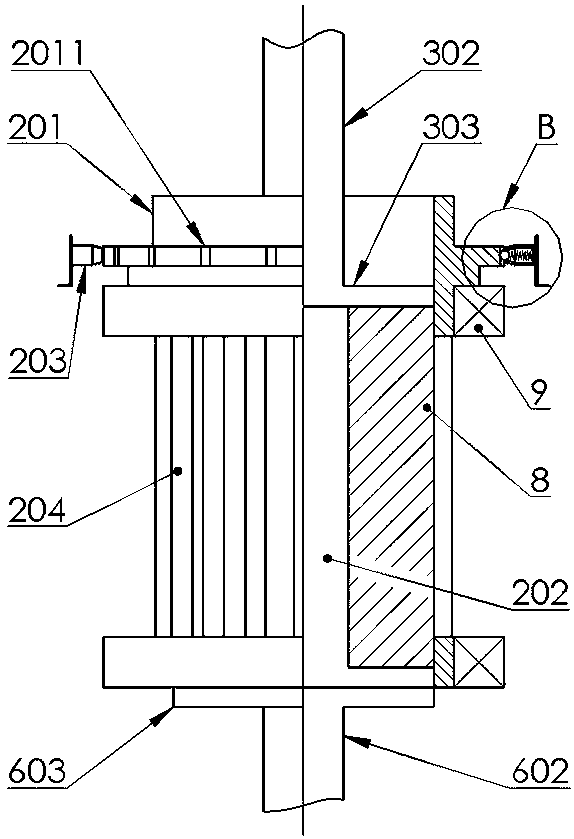

The invention relates to a technology and a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation. The technology comprises the following steps: adopting industrial NO, O2 and methanol as raw materials for an esterification reaction to produce methyl nitrite; adopting industrial CO and methyl nitrite for a carbonylation reaction in a plate reactor to produce carbonylation products, which mainly include dimethyl oxalate and dimethyl carbonate; separating the carbonylation products to obtain dimethyl carbonate products; subsequently adding hydrogen into dimethyl oxalate in the plate reactor to produce ethylene glycol products; conducting the coupling recovery treatment on waste acids in the esterification reaction and purge gases in the carbonylation reaction for recycling. The device system comprises an esterification reaction system, a carbonylation reaction system, a coupling recovery system for purge gases and waste acids and a hydrogenation reaction system. The technology has the characteristic that device consumption is remarkably reduced, and particularly the nitric acid waste liquid recycling and purge gas recycling technologies as well as the separation technologies thereof are highly coupled; recycling of the raw materials in reaction waste gases is realized, and the effect is remarkable.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

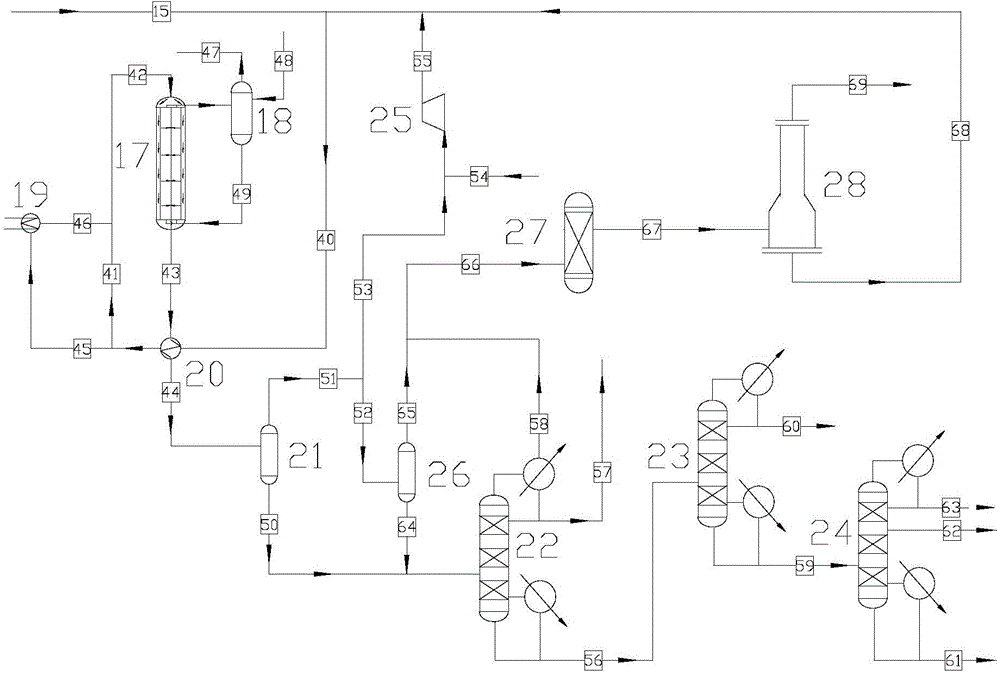

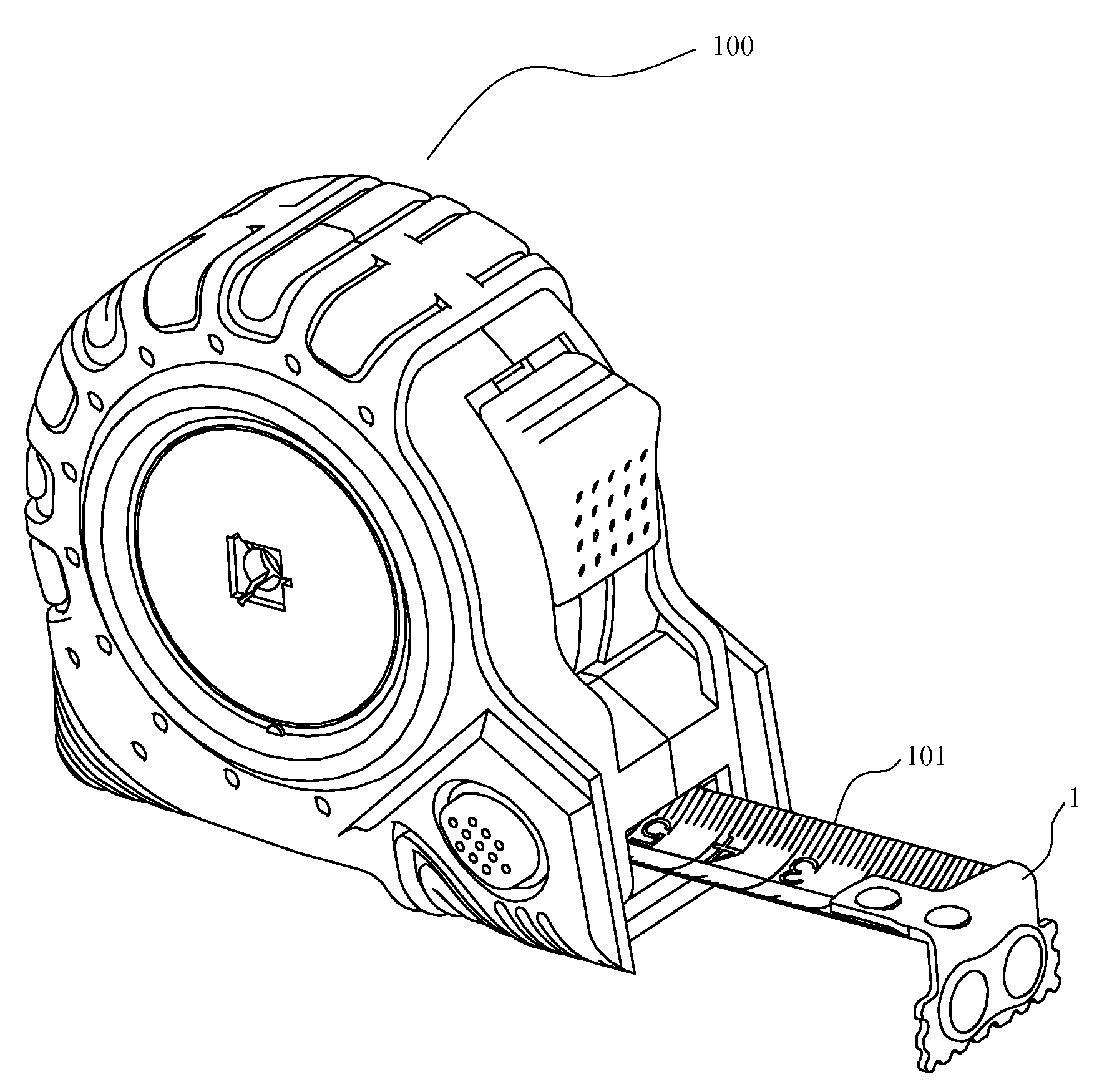

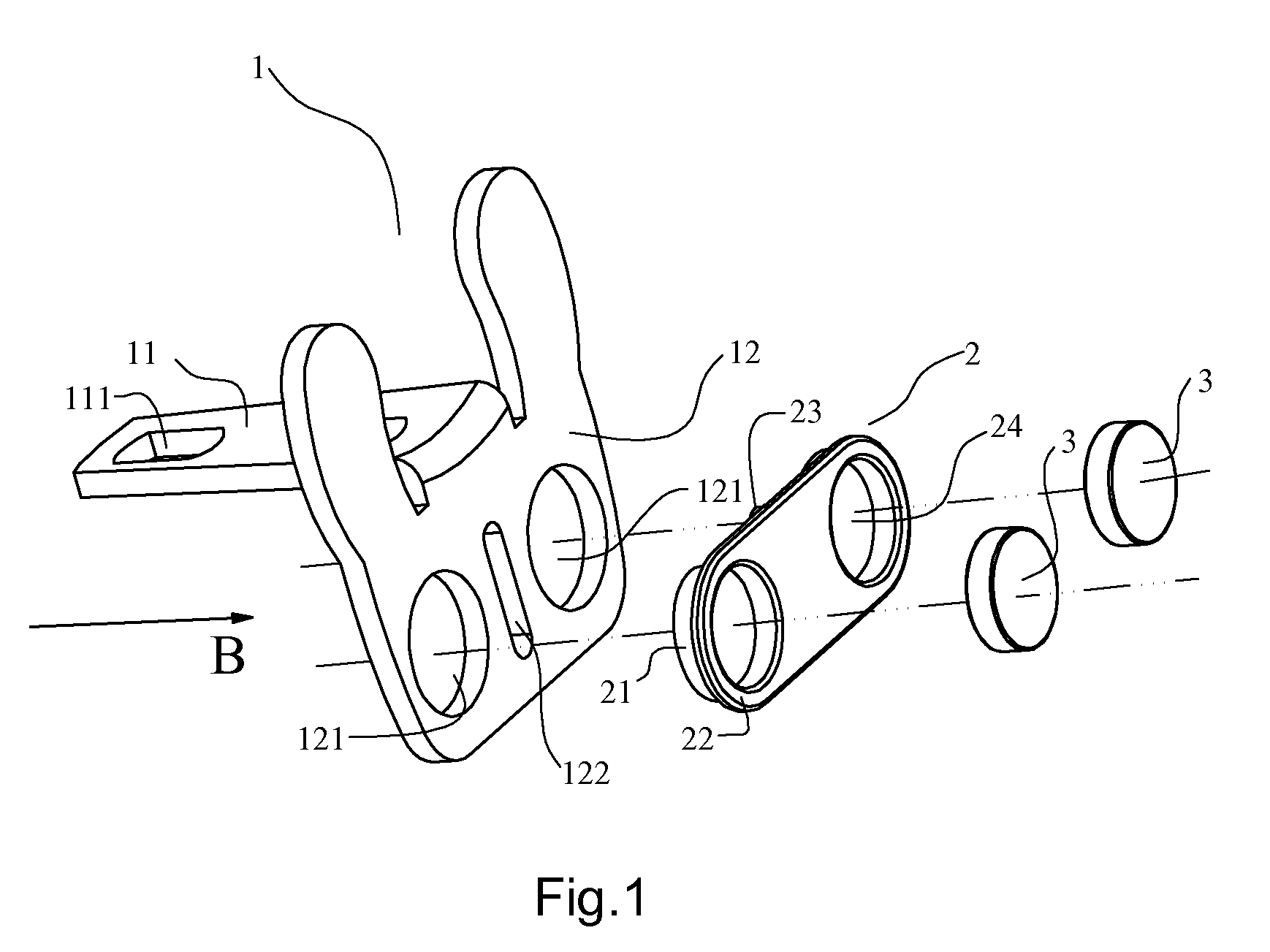

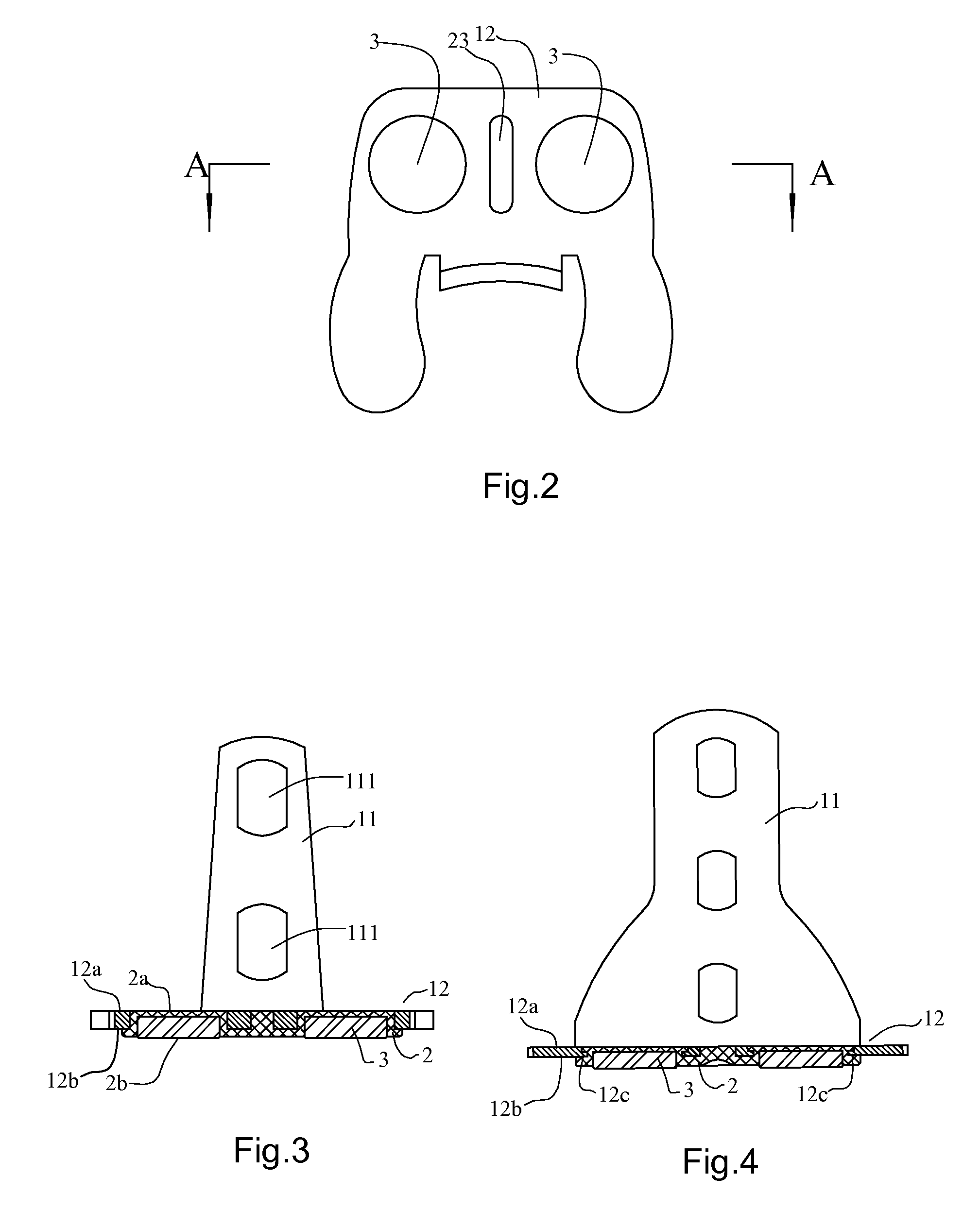

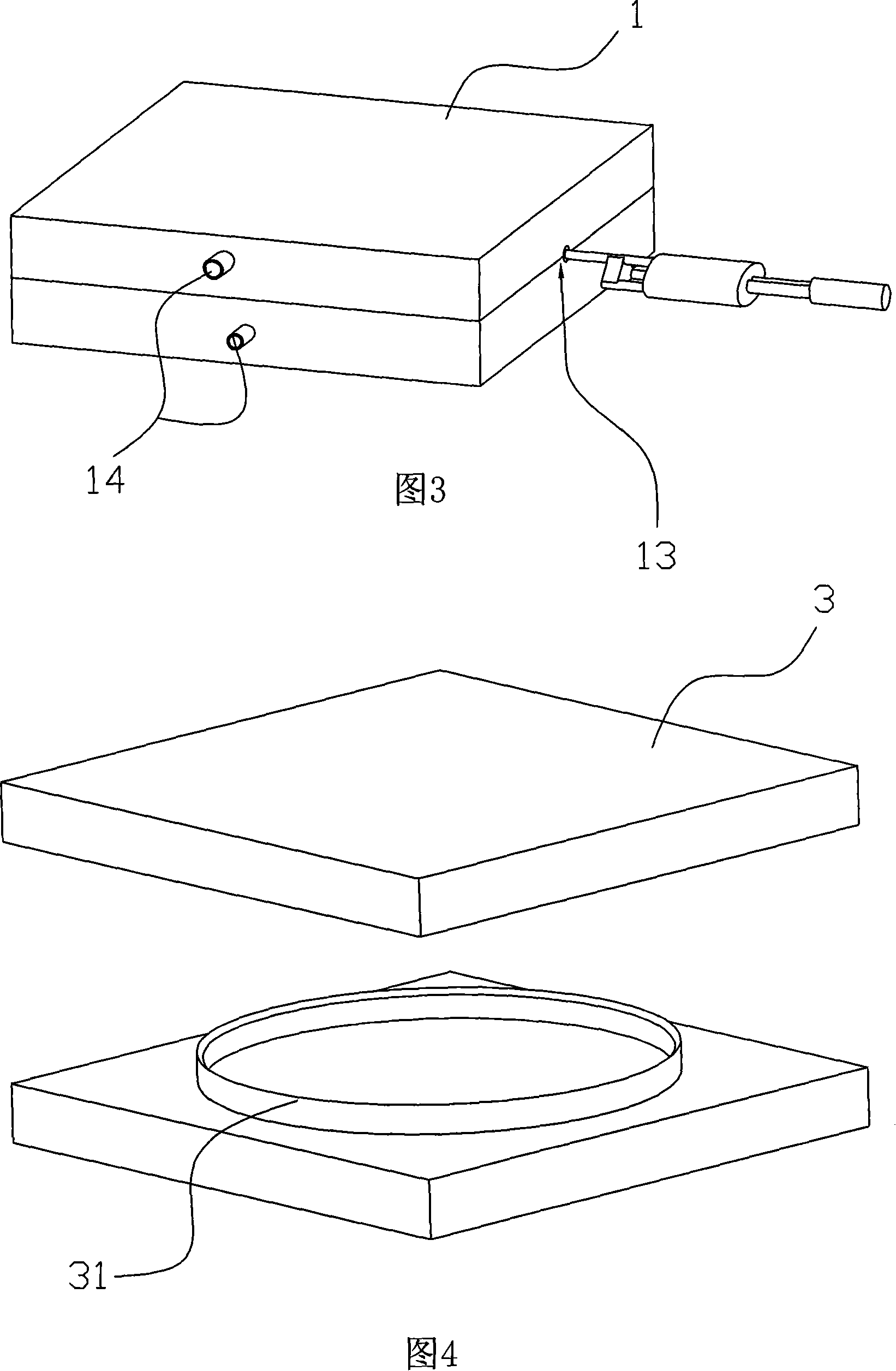

Magnetic End Hook for Tape Measure, Manufacture Method and Application Thereof

InactiveUS20090288307A1Improve production efficiencyGuaranteed accuracyMeasuring tapesEngineeringMagnet

A magnetic end hook on tape measure, comprises a magnet (3) and a main body (1) of the end hook which includes a horizontal portion (11) jointed with a tape blade, a vertical portion (12) having a front surface (12b), a rear surface (12a) and at least one hole (121) for setting said magnet (3); wherein the magnetic end hook further comprising an gasket (2), said gasket has an adapted hole or groove (24) for receiving said magnet (3). A method of manufacture and an application are also described. Compared with the prior art, in this invention, the gasket, additionally set between the hole of the end hook and the magnet on the magnetic end hook, is resilient and can adjust the preferred distance between the magnet and the inner wall of the hole. Therefore, the magnet is mounted more firmly and the probability of falling or breaking is reduced.

Owner:ZHOU XIAOGANG

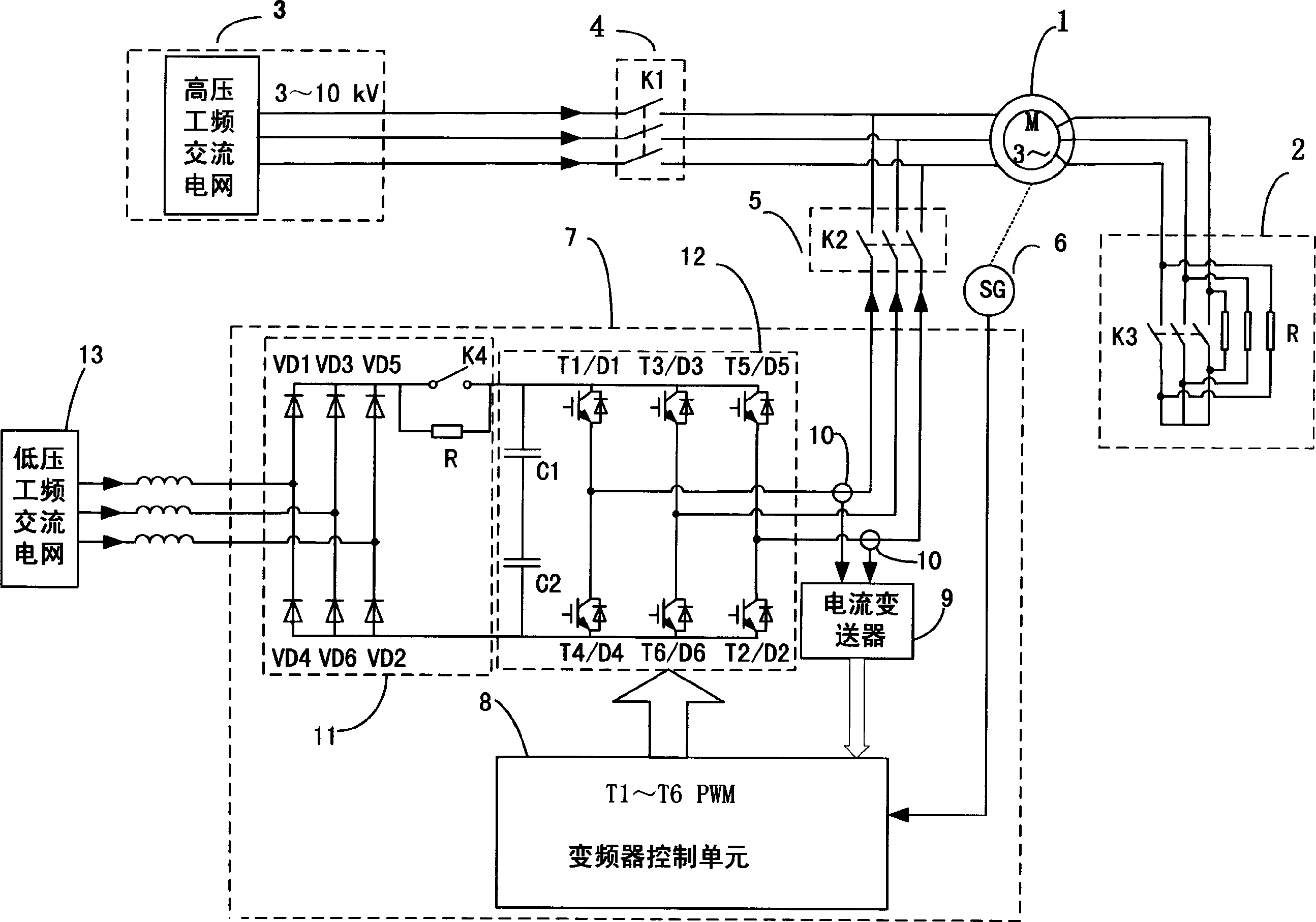

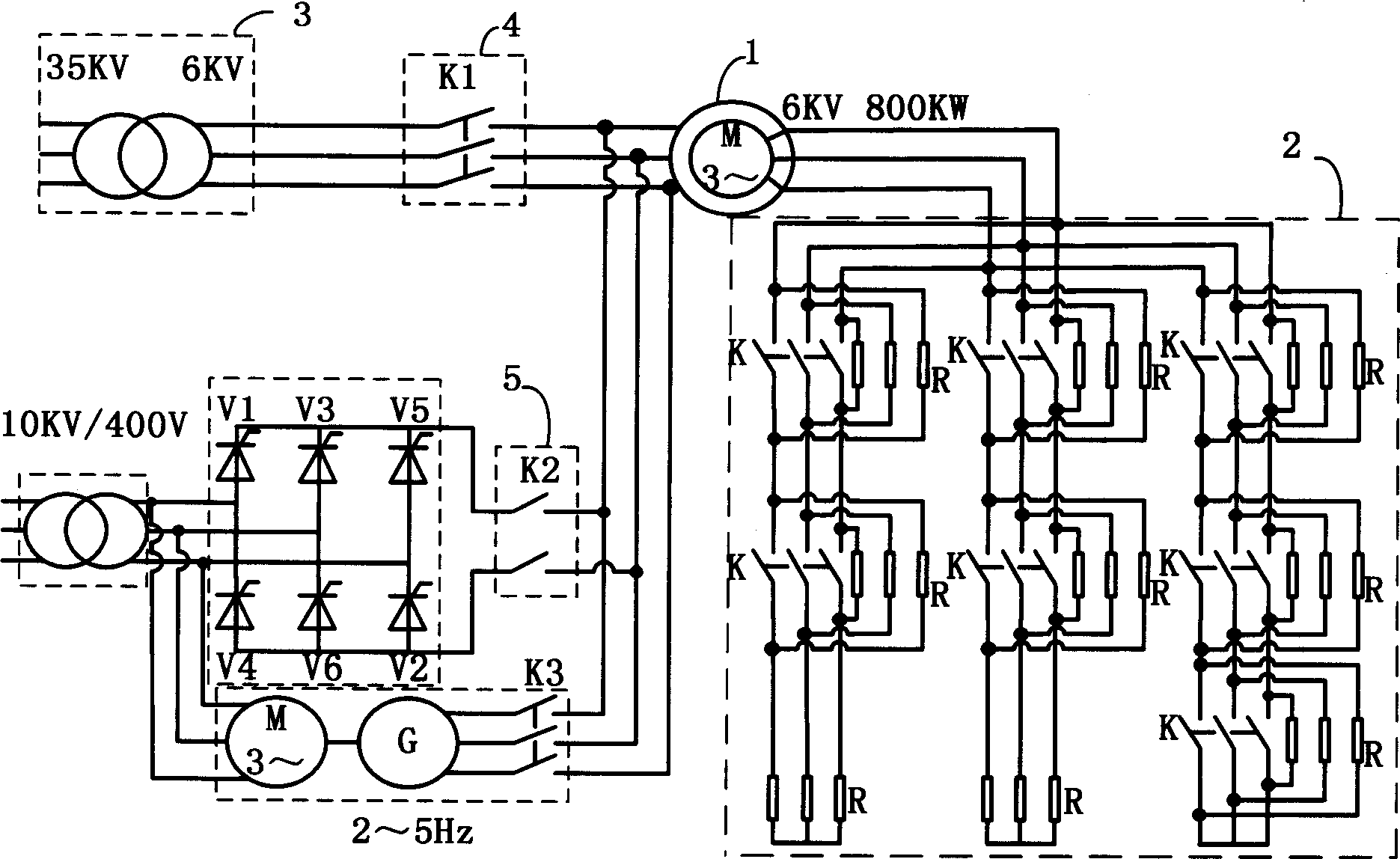

Low-voltage low-frequency transformer of high-voltage wound asynchronous motor for drining mine hoister

InactiveCN1641994ASolve the problem of frequency conversion speed regulationIncrease total daily outputElectronic commutation motor controlAC motor controlLow voltageTransformer

The invention relates to a low voltage low frequency transducer that is used to drive mine winder high voltage winding asynchronous motor. It comprises rectification circuit, inverter circuit, and frequency transducer control unit. The control system of the invention is in the transducer and the output voltage is especial PWM low DC voltage and low voltage low frequency PWM AC. It adopts discontinuity switching operation mode and only connects to the high voltage winding asynchronous motor to drive the motor directly by high voltage switch when the motor is in retarding braking stage and retarding crawling stage. The invention has the advantage of great DC dynamic brake moment and low frequency crawling dynamic moment, as well as low cost.

Owner:ZHONGYUAN ENGINEERING COLLEGE

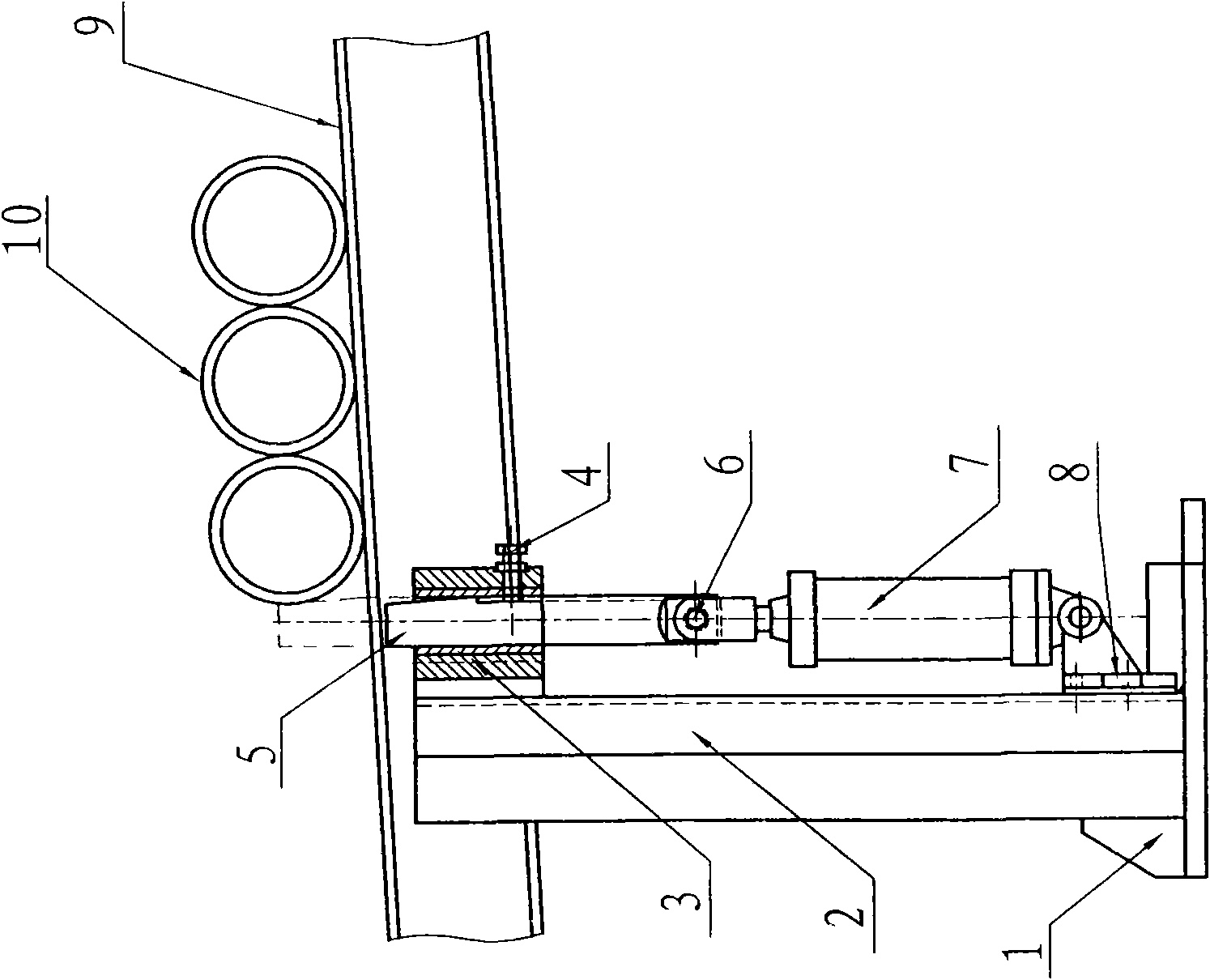

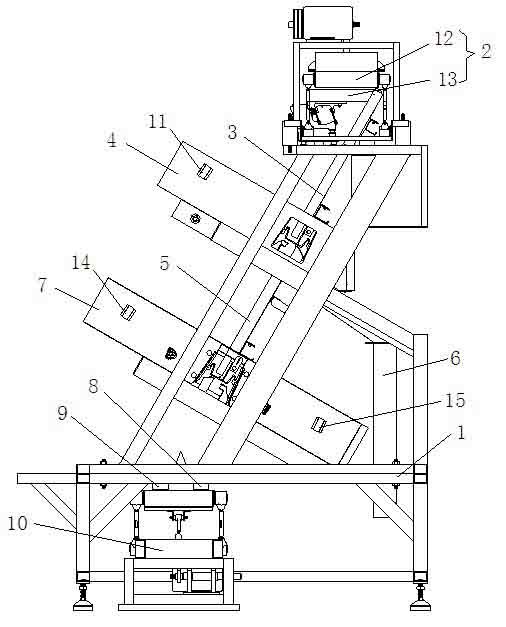

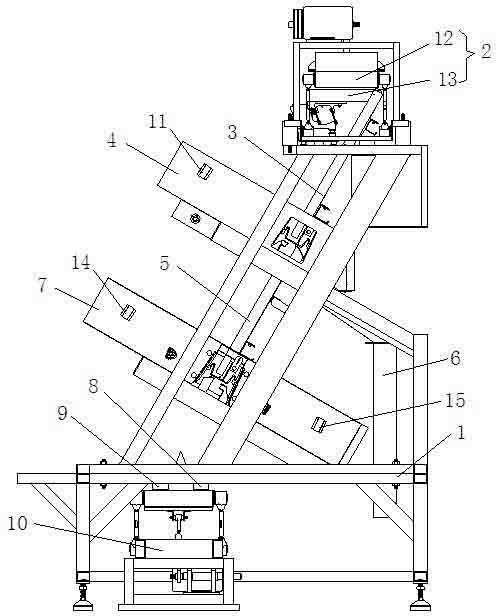

Steel pipe stop and feed device

InactiveCN101602212ASave time on one-by-one shipmentsIncrease daily outputMetal working apparatusEngineeringMechanical engineering

A steel pipe stop and feed device comprise an inclined beam and a lifting stop mechanism, wherein the lifting stop mechanism comprises a base, an upright post, a guiding base, a stop bar, a movable connecting sleeve, a cylinder, a lug; the upright post is fixed on the base, the guiding base is mounted on the upper section of the upright post, the stop bar is sleeved in the guiding base, the lug is fixed on the upright post or the base, a telescopic bar of the cylinder is in movably hinged connection with the stop bar through the movable connecting sleeve, the cylinder body of the cylinder is in movably hinged connection with the lug. Due to the steel pipe stop and feed device, the finished and leveled steel pipe can roll down from the inclined beam only through one lifting and conveying, the lifting stop mechanism can control the steel pipe to roll down simultaneously dependent on deadweight without the other lifting and conveying, thereby not only saving conveying time of the steel pipe one by one, but also saving energy, increasing the daily output of steel pipe cutting process by about 15%, and having remarkable energy-saving effect with 8kw saved per hour.

Owner:JIANGSU CHANGBAO PLS STEEL TUBE

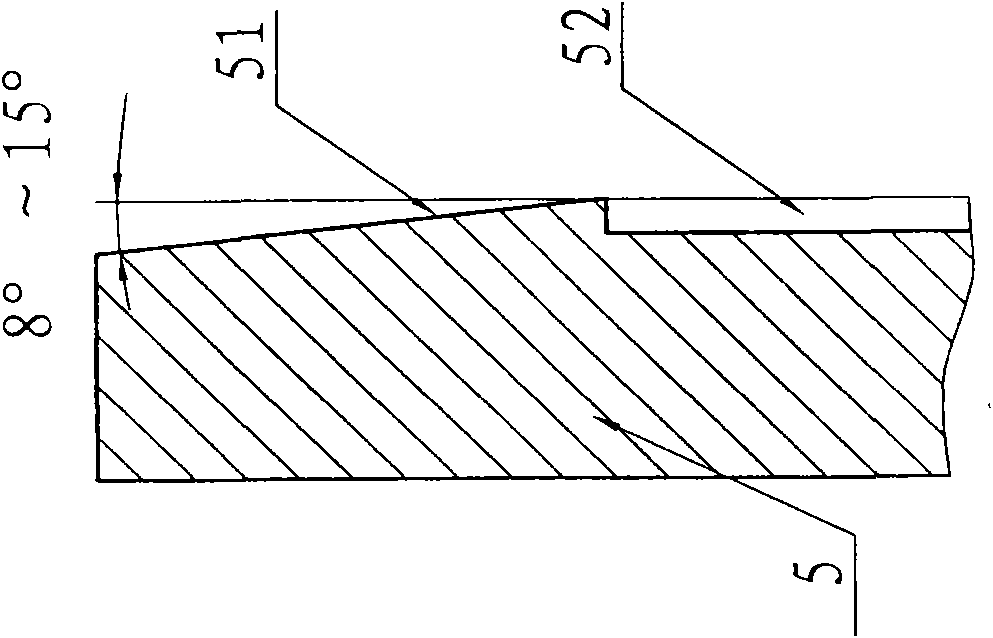

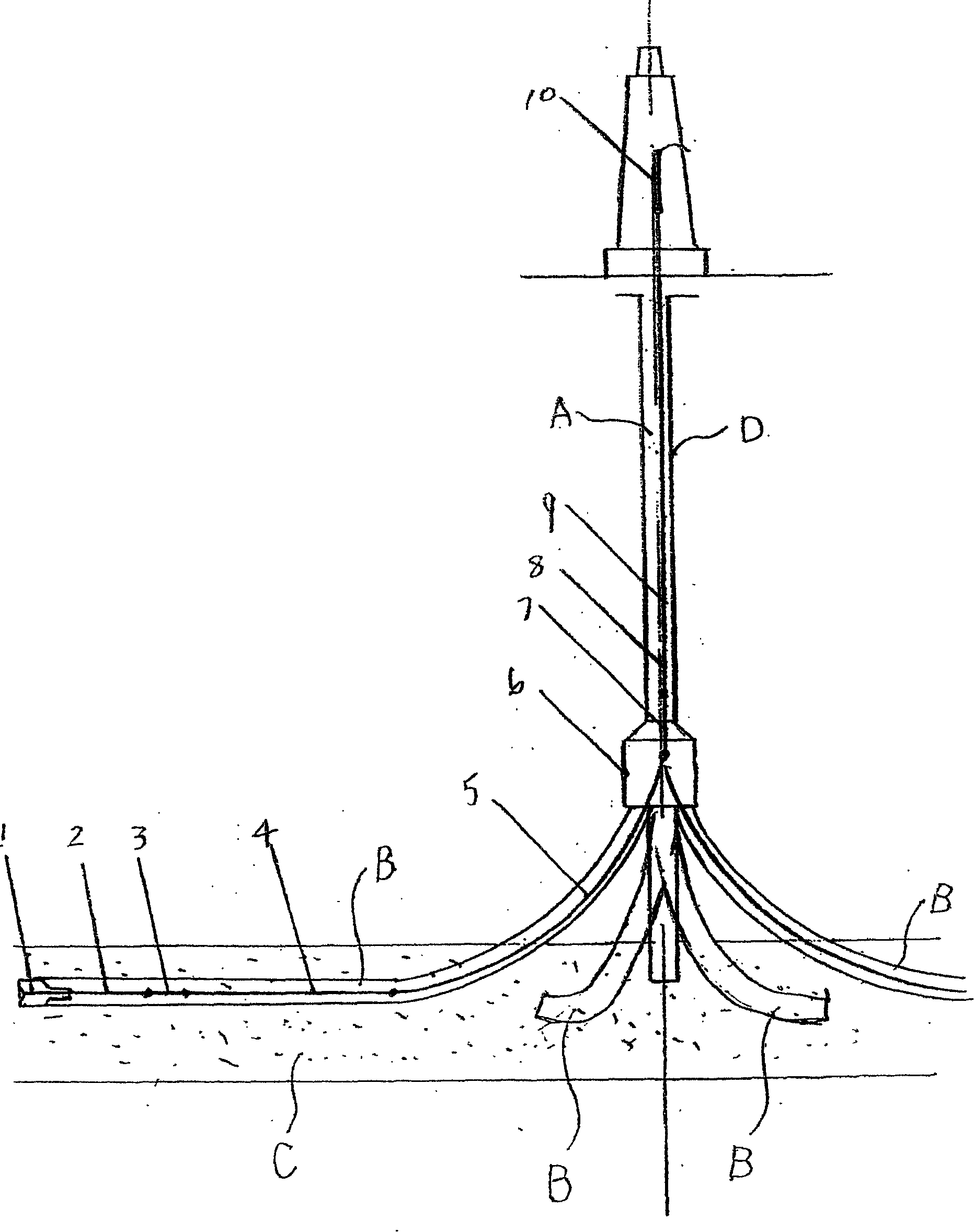

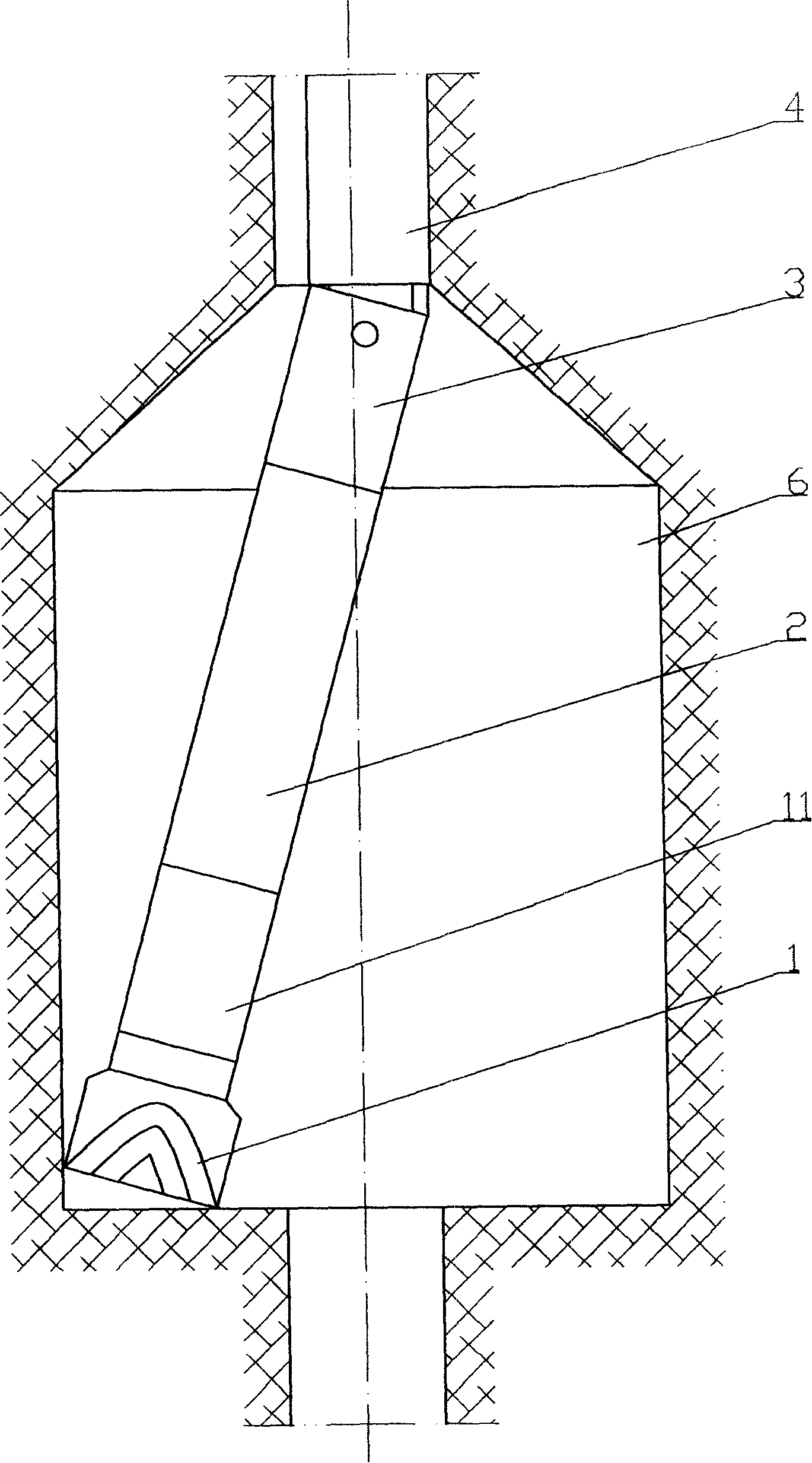

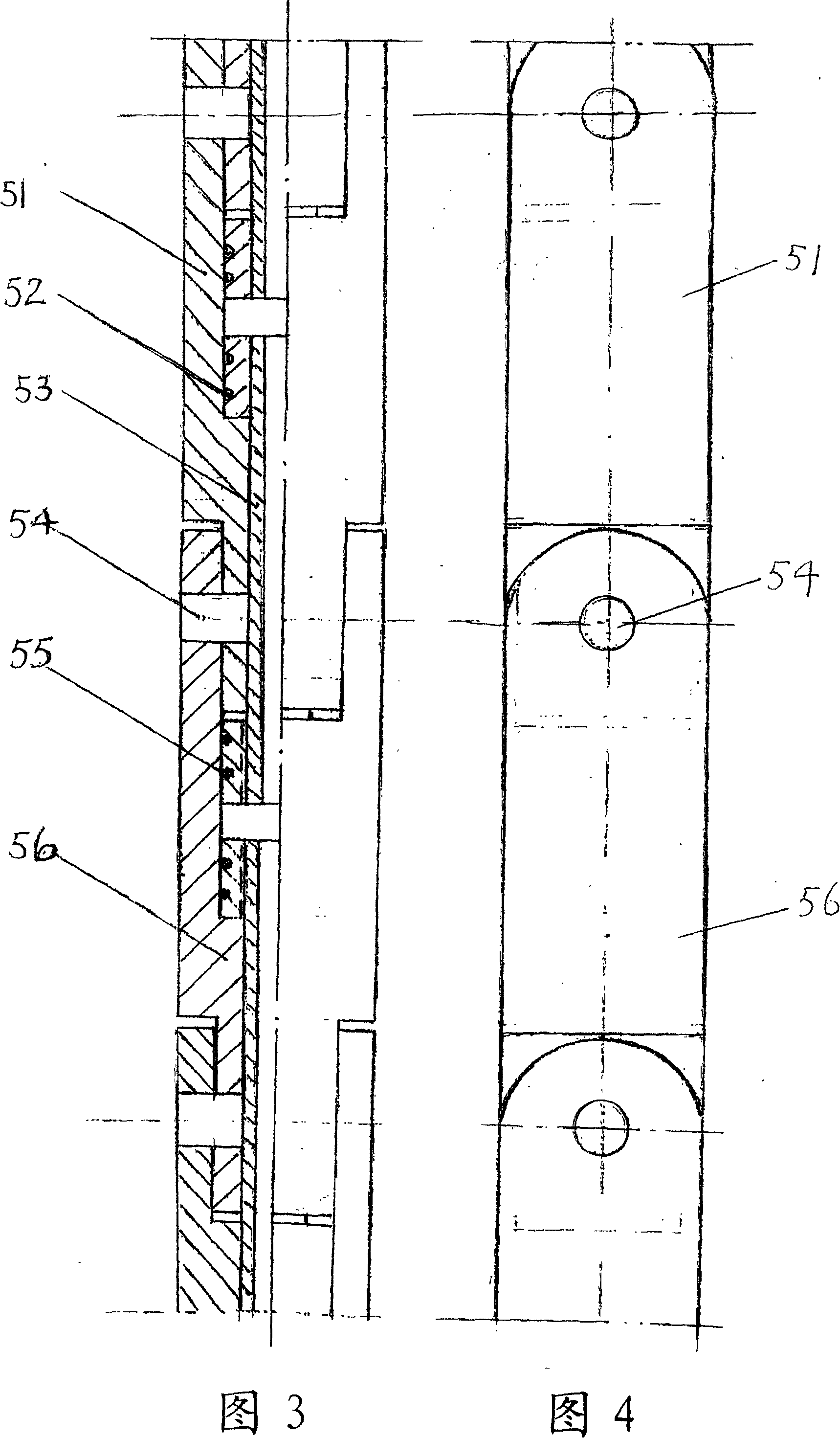

Large curvature radiation horizontal well drilling technique and device

InactiveCN101210481AIncrease permeable areaIncrease daily outputDirectional drillingWell drillingEconomic benefits

The invention discloses a large-curvature radioactive level horizontal drilling process and device includes drilling vertical well to oil layer, lowering the sleeve, drilling sleeve shoe, building up angle directionally, washing well, lifting the drill, lowering special sieve vessels, filling with gravels, decoupling the hanger for circulated well washing, lifting the hanger de-coupler and all drilling tools above, drilling other radial wells, etc. Through drilling a plurality of radial wells, the invention enlarges seepage area, expanding seepage range, increasing the daily production for single well and raises final recovery ratio, so as to achieve the purposes of making full use of energy, increasing economic benefits and benefiting the society.

Owner:杜晓瑞

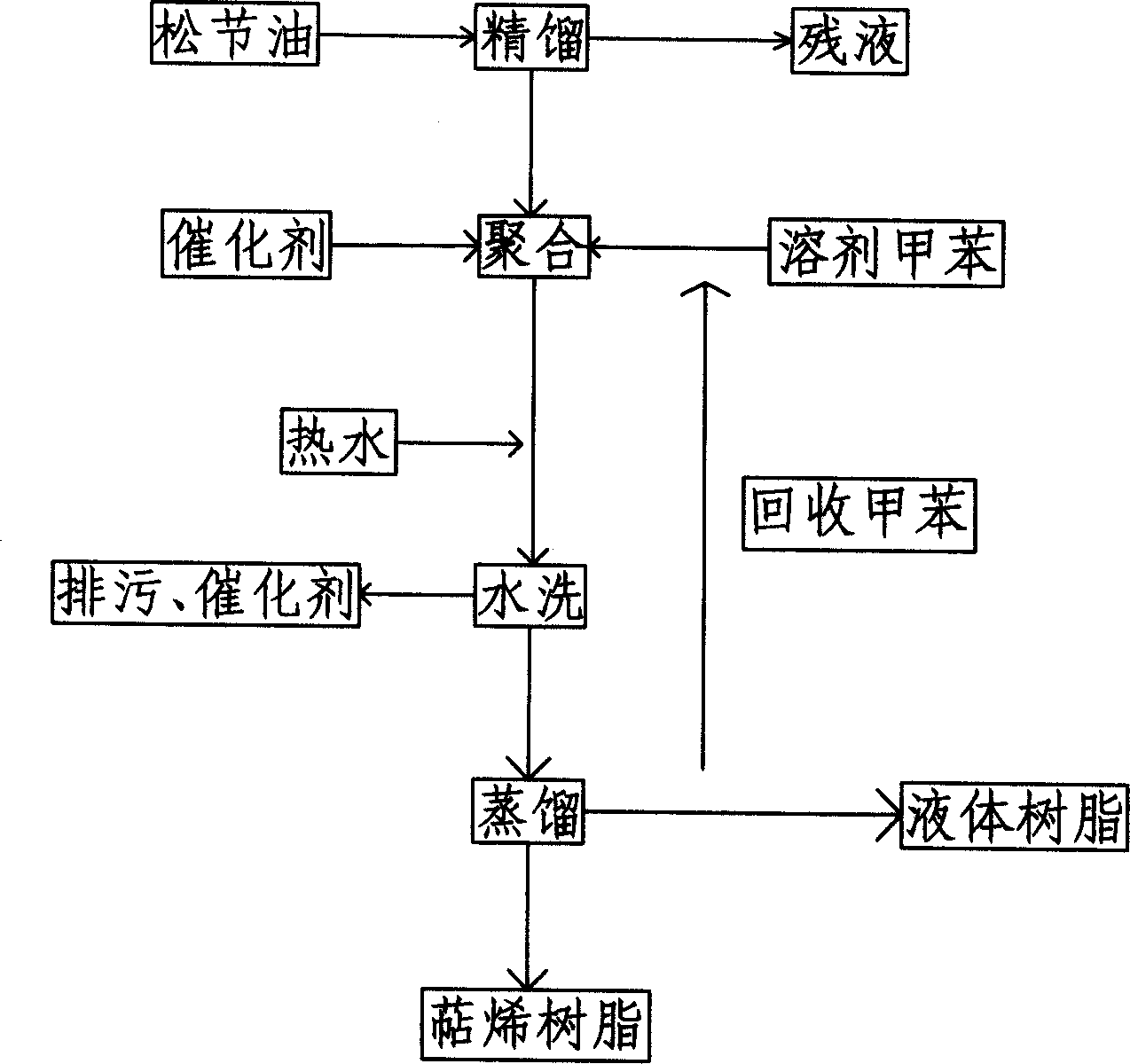

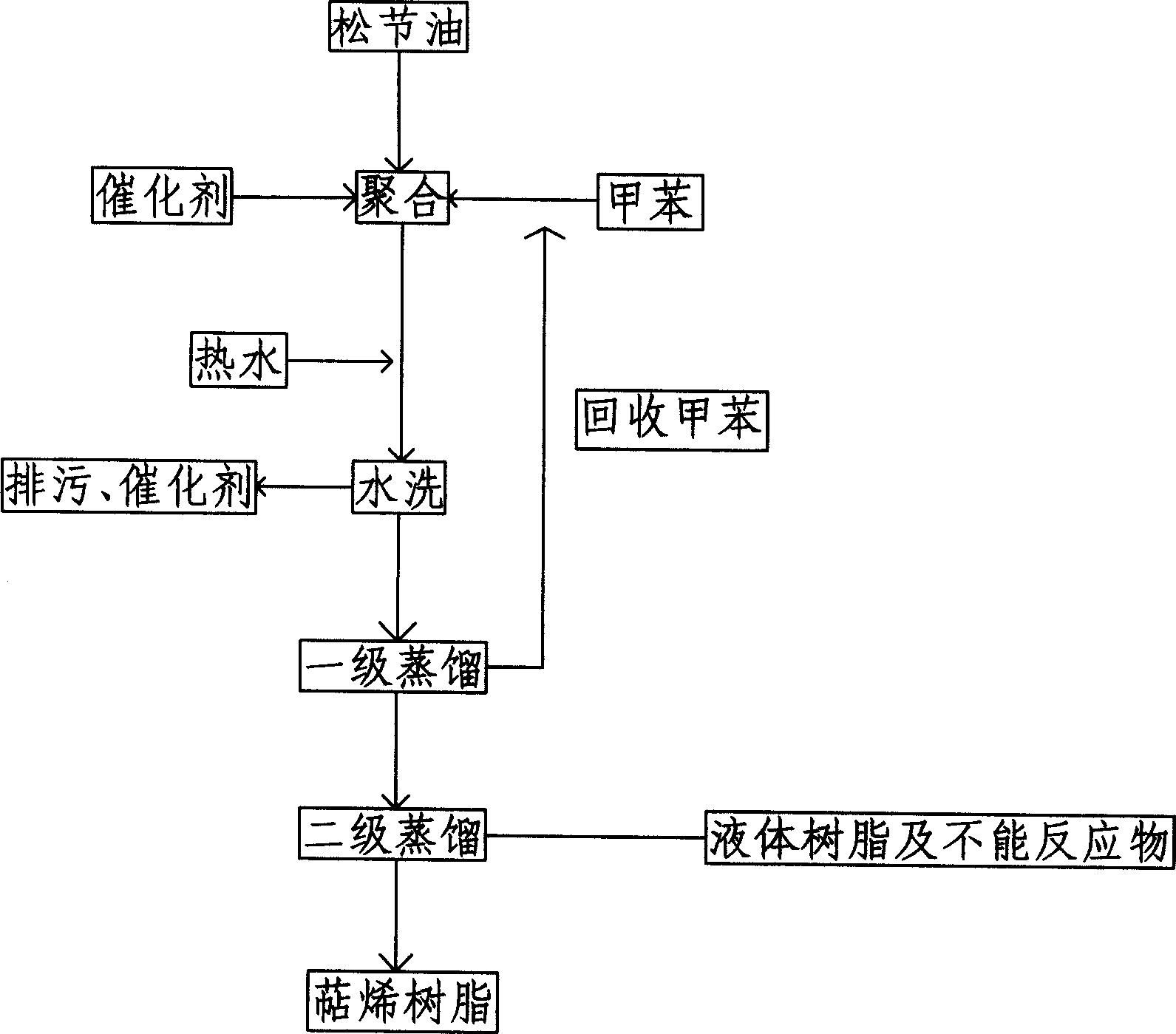

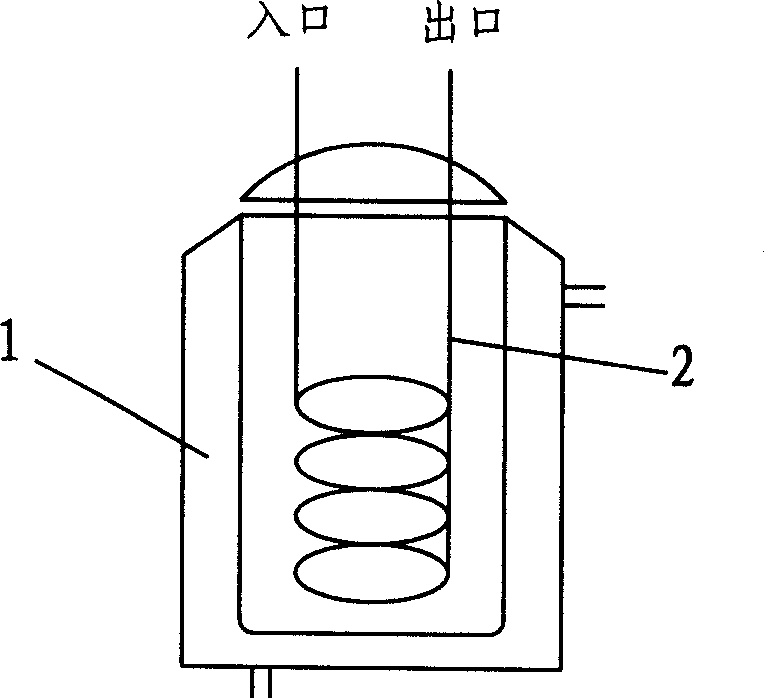

Production method of terpene resin

InactiveCN1631916AMild and even reactionThe reaction temperature fluctuation range is smallAluminium chlorideDistillation

A method for producing terpine resin has the steps follows: turpentine oil, toluene, catalyst aluminium chloride have polymerization in the wash the mixed outcome with hot water for draining the catalyst and waste out, then distil the outcome, recycle toluene and clear the liquid resin and the material which did not join the reaction in the course of distillation, then the toluene is made. The reactor includes enamel glass and inside cooling device which is steelless pipe groups filled with saturated salt solution of indoor temperature in the polymerization. The invention has friendly reaction, small fluctuating range of temperature, stable operation, productiving being raised by 20%, fewer equipments, low cost fir energy and production good economic benefit.

Owner:蓝运泉

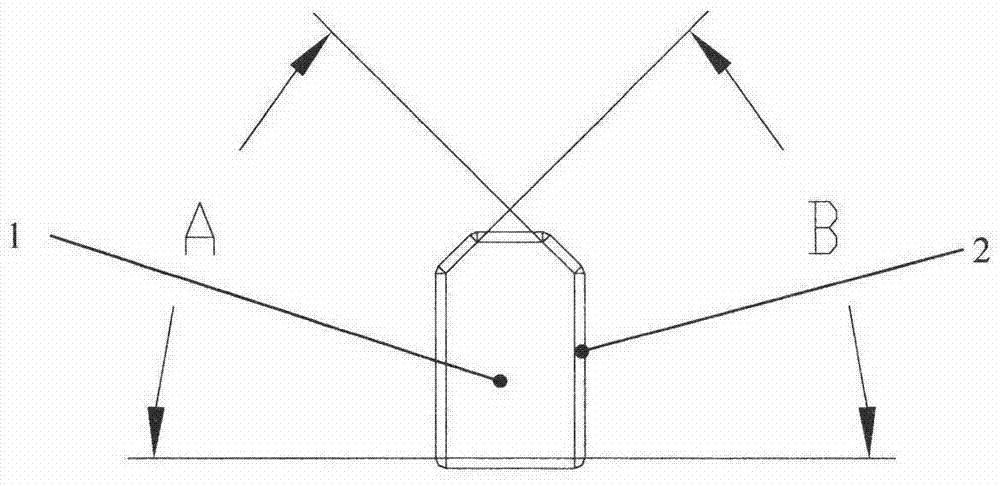

Tea sorting method and sorting machine

The invention relates to a tea sorting method and a sorting machine. The end of the first chute is provided with a first optical sorting chamber, and a first pneumatic actuator system is provided between the outlet of the first optical sorting chamber, the second chute and the first hopper, and the second optical sorting A second pneumatic actuator system is provided between the discharge port of the chamber and the second discharge hopper and the third discharge hopper, and the discharge port of the second optical separation chamber is connected with the second discharge hopper and the third discharge hopper respectively. The first imaging system is a single-sided camera imaging, the second imaging system is a double-sided camera imaging, and the first and second pneumatic execution systems are connected with the signal processing system. It can be seen from the above technical solution that the second imaging system of the present invention adopts double-sided camera imaging, which can observe the front and back sides of the material at the same time, without missing the material with defects on one side, improving the sorting accuracy of the material, and at the same time improving the Daily output.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

Environment-protection type coated release-controlled urea and preparing method

InactiveCN1850742AImprove channel propertiesReduce dosageUrea compound fertilisersFertilizer mixturesChemical compositionControl release

This invention discloses environmental protection style envelope control release urea and its preparation method. It solves problem of high cost and hard degradation of film in existing fertilizer. It is consisted by urea core and external layer envelope, the envelope is made up by natural silicate mineral powder, natural grease raw material and control releasing additive. Particle urea occupies 89.9-94.9 percent of the product; envelope material occupies 5.1-10.1 percent. Preparation procedures are that urea sieving, drying, envelope liquor and envelope powder preparation, enveloping, drying and packaging. The cost is low; its price is large lower than homogeneous product in and out country, nothing chemical components are contained in the enveloping material. Material, generating process and product using are environmental protected, and there is no solid and liquid and gas waste discharging. If it is used long time, it can change soil structure, and make soil loosen and enhance soil water keeping ability, it can preferably absorb and store moisture at certain time after nutrition releasing, generating equipment and technique are simple, and easy to large scale generating, nitrogen content is 41.1-43.7 percent.

Owner:中国民用航空学院

Production technology of fresh zanthoxylum oil

ActiveCN101606676AHigh extraction rate of active ingredientsSimple processEdible oils/fatsFood preparationFruit juiceVegetable oil

The invention relates to a production technology of fresh zanthoxylum oil and aims at the defects of deficient and incomplete squeezing caused by an existing method that the fresh bunge prickly ash and edible vegetable oil after being mixed are squeezed, high residual oil content of waste residues and larger labor intensity. By the optimized procedures of material selection, pulverized manufacture of fruit juice, mixing, filtration, colloid removal, waxing, deposits and trace moisture thereof, the invention improves the production efficiency, shortens the production procedure, enhances the daily yield, lowers the rate of waste materials, lowers the cost, is timesaving and laborsaving, has better mouth feel, is more scientific and reasonable, improves the quality and the storage stability of a product, reflects the diversity of the product, increases the selectivity for consumers and enlarges the application range of production raw materials.

Owner:重庆市树上鲜食品(集团)有限公司

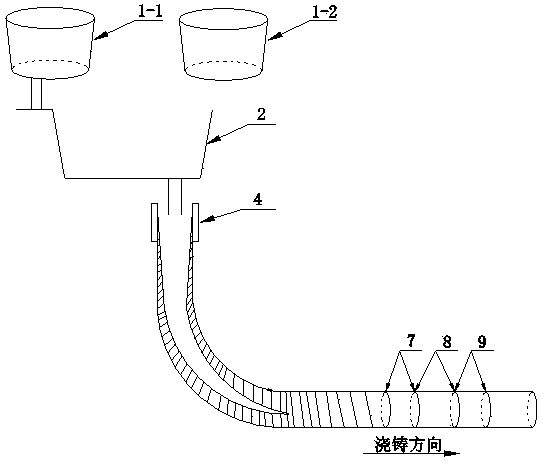

Continuous-casting big round billet dissimilar steel mixed casting production method

The invention discloses a continuous-casting big round billet dissimilar steel mixed casting production method. The method comprises the following steps that when molten steel of a prior melt is casted into a medium ladle, a certain amount of molten steel is left in a big ladle of the melt, and the casting speed is decreased; when the molten steel, left in the medium ladle, of the prior melt is decreased to a certain liquid level, casting is started on a big ladle of molten steel of a later melt, and a steel ladle covering agent in the medium ladle is replaced; after the big ladle of the latermelt is cast for a certain time, covering slag of a crystallizer is replaced; after the big ladle of the later melt is cast for 25 t, the liquid level of the medium ladle is kept, and the casting speed is increased; after the big ladle of the later melt is cast for 30 t, the liquid level of the medium ladle is slowly increased to the normal full liquid level, and then casting is conducted; and after the big ladle of the later melt is cast for 40 t, the casting speed is decreased to that corresponding to normal superheat degree, and then normal casting is conducted. According to the continuous-casting big round billet dissimilar steel mixed casting production method, when dissimilar steel is produced in the same medium ladle in a continuous casting manner, the thermal shutdown time can beshortened, the production efficiency of a continuous casting machine can be met, and the continuous casting billet yield can be increased.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Cold-formed steel joist

ActiveUS20100139201A1Easy to customizeEasy to useFloorsLoad-supporting pillarsJoistCold-formed steel

An upper chord bearing joist comprising a top chord member and a bottom chord member, each having a flange portion and a web receiving portion including two web receiving tabs, each made from a unitary piece of metal; a generally planar steel web, a portion of the web being attached to the the top chord member and to the bottom chord member, wherein a top portion of the web is between the two web receiving tabs of the top chord member and a bottom portion of the web is between the two web receiving tabs of the bottom chord member; and a first and second pair of support members, each support member including a shoe portion, a web attaching portion, and an angled portion, the web attaching portion portion being attached to the web receiving tabs and the angled portion being in contact with the web. The joist may be cambered, have reinforcement stiffeners, and have a rotatable joint at either end. The joists may be used in composite with concrete or with wood.

Owner:ISPAN SYST LP

A production process for carbon electrode containing scale graphite

InactiveCN1571593AReduce consumptionIncrease productionElectric discharge heatingGraphite carbonAnthracite

The invention discloses a producing technics of squama graphite carbon electrode, its material use following powder gravity percentage: 0.075-0.15mm petroleum coke powder after calcining 23-28%, 0.075-0.15mm squama graphite powder 2-8%, 0.5-4mm petroleum coke after calcining 18-23%, 4-10mm petroleum coke after calcining 11-19%, 4-10mm electric calcining anthracite 6-14%, 10-16mm petroleum coke after calcining 2-10%, warm pitch of binder 16-20%, pugging, forming, baking the above material, then machining, the carbon electrode smelt industry silicon which is produced by the invention, the yield can be improved greatly, the consuming of electrode and electric energy can be reduced, so does the producing cost.

Owner:河北顺天电极有限公司

Production technique of yellow phosphorus appropriation electrode

InactiveCN1446774AMeet the technical requirements of the smelting industryMeet technical requirementsPhosphorus compoundsElectrodesElectric consumptionAnthracite

A special electrode for producing yellow phosphorus is prepared from (0.05-0.075)-mm calcined petroleum coke powder, (0.5-4)-mm graphite particles (4-10)-mm graphite particles, (4-10)-mm electricallycalcined anthracite, (10-16)-mm electrically calcined anthracite and medium-temp coal asphalt as adhesive through proportional mixing, kneading, shaping, calcining and machining. Its advantages are high output of yellow phosphorus, and less electric consumption.

Owner:涞水县长城电极有限公司

Production method of zanthoxylum oil

InactiveCN103749742AKeep the original tasteRich in nutrientsEdible oils/fatsZanthoxylum leprieuriiVegetable oil

The invention discloses a production method of zanthoxylum oil. The method comprises the following steps: selecting dried zanthoxylum and vegetable oil; baking and sauting the vegetable oil for 10-60 minutes at 60-100 DEG C, adding the dried zanthoxylum accounting for 6-12wt% of the vegetable oil when cooling the vegetable oil to 50-80 DEG C and maintaining for 2-10 minutes so as to obtain mixed oil; adding the mixed oil obtained in the mixing and sauting manner into an oil presser, maintaining the temperature within 70-100 DEG C and performing initial squeezing so as to obtain the zanthoxylum oil; performing preliminary filtration on the initially-squeezed zanthoxylum oil by using a filter screen so as to filter a majority of impurities; introducing the zanthoxylum oil subjected to the preliminary filtration into a vacuum filter; performing filtration on zanthoxylum oil again under the condition that the oil temperature is maintained within 75 DEG C to 105 DEG C so as to improve the filtration efficiency; adding the zanthoxylum oil subjected to the vacuum filtration into a centrifugal oil filter and performing rotating precipitation and filtration again, thereby obtaining the zanthoxylum oil. The method is high in production efficiency, wide in raw material resource, low in cost and pure in zanthoxylum oil taste.

Owner:安顺市西秀区百岁陈德文牌食品加工厂

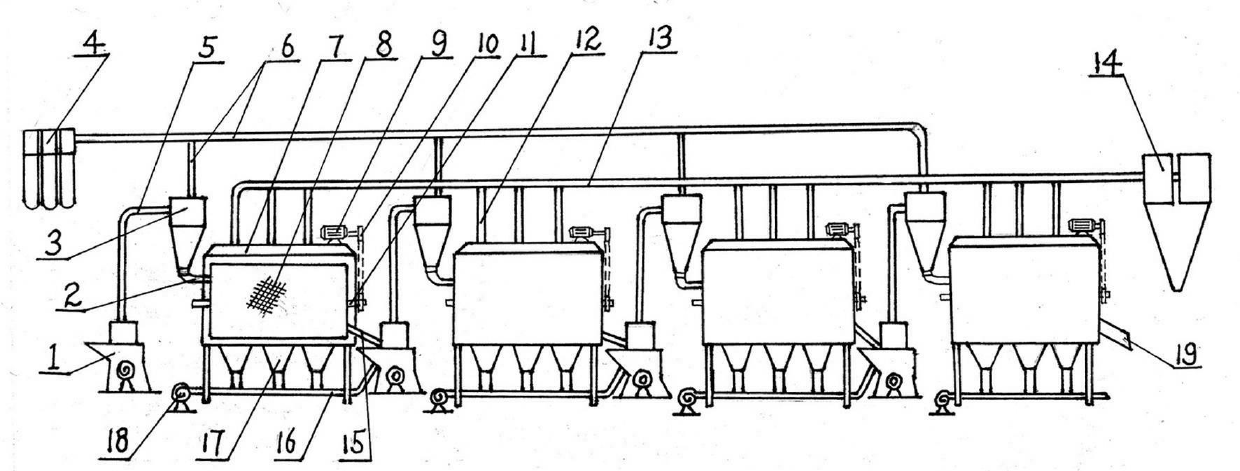

Negative-pressure dustless moxa extracting equipment and production process thereof

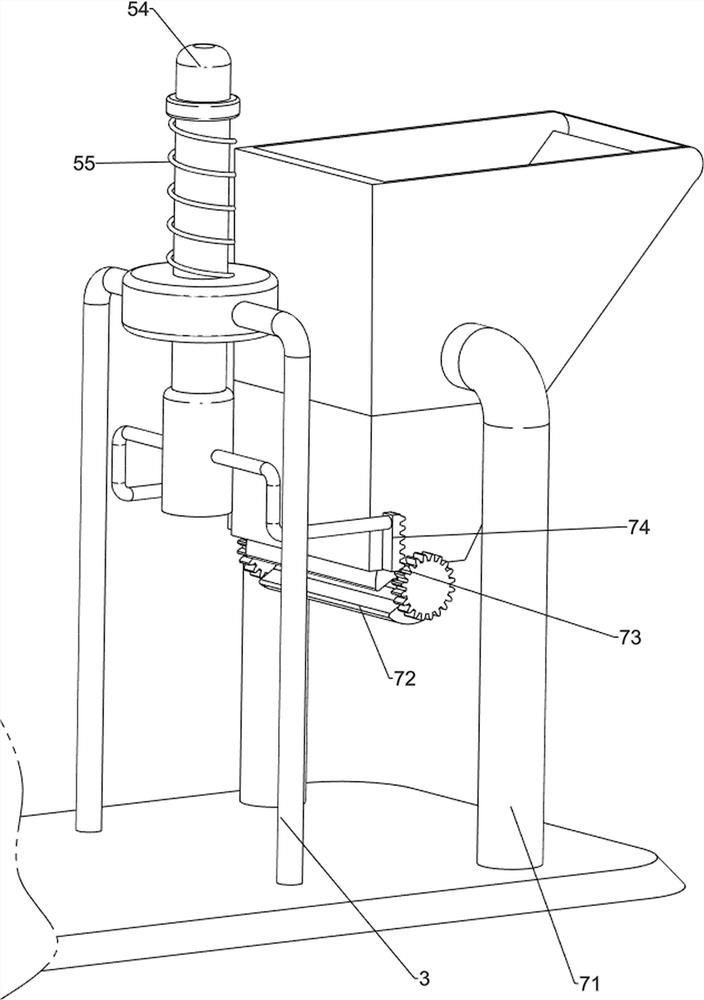

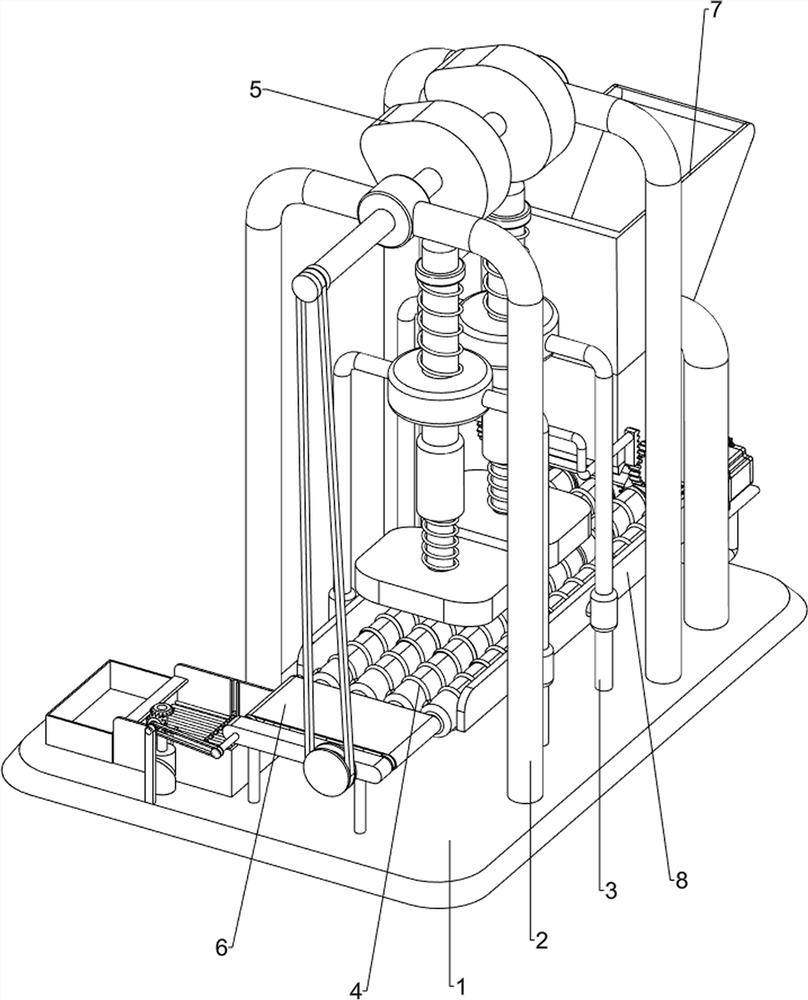

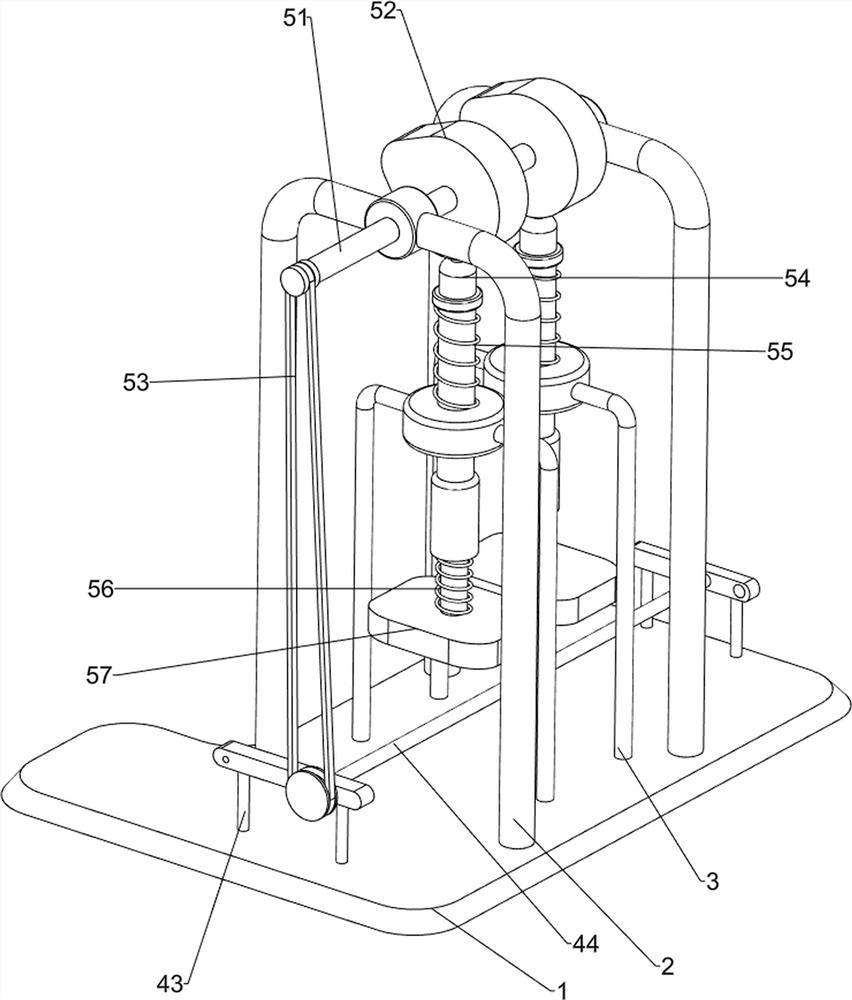

ActiveCN102560691AHigh purityImprove automationMechanical fibre separationWorking environmentProcess engineering

The invention relates to negative-pressure dustless moxa extracting equipment and a production process thereof. The negative-pressure dustless moxa extracting equipment comprises a fine fleece collector, a dust collector and four moxa extracting devices, wherein the four moxa extracting devices are connected in sequence. Each moxa extracting device consists of a grinder, a separator and a moxa remover, the grinder is sequentially connected and communicated with the separator and the moxa remover through conveying pipelines, the moxa remover is connected with the fine fleece collector through a negative-pressure moxa suction pipe and a fine fleece conveying pipeline, and the separator is communicated with the dust collector through a dust collecting pipeline. The negative-pressure dustless moxa extracting equipment is applicable to large-scale industrialized continuous production of moxa extraction, is capable of extracting high-purity moxa in a short time and simplifying production process, and simultaneously guaranteeing product quality reliably, improving working environment and reducing waste of folium artemisiae argyi.

Owner:南阳仙草健康集团有限公司

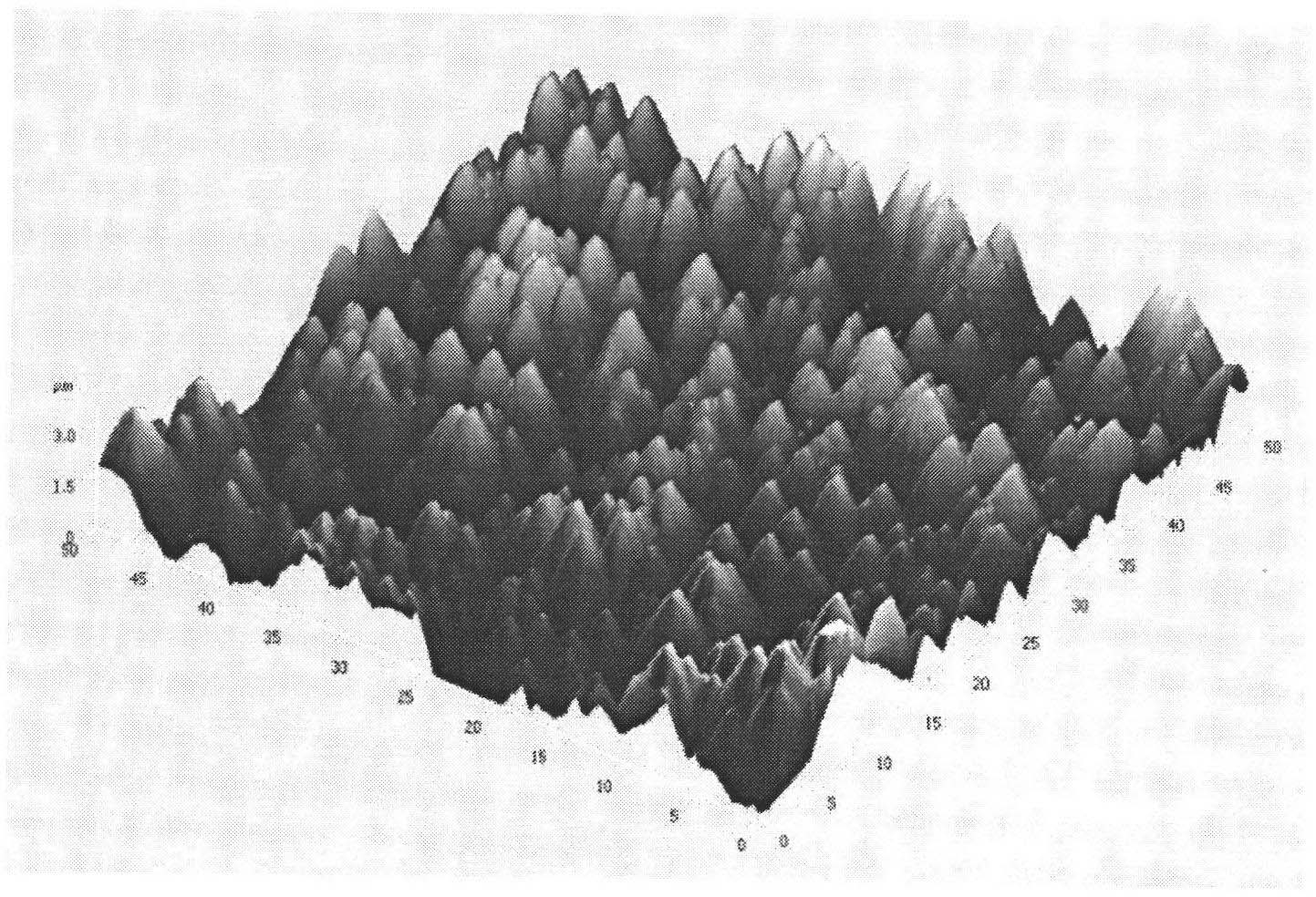

Polycrystalline silicon etching solution in solar cell and polycrystalline silicon etching process

InactiveCN102330156AShort corrosion timeIncrease daily outputAfter-treatment detailsPolycrystalline siliconSolar cell

The invention relates to a polycrystalline silicon etching wafer solution in a solar cell. The solution is characterized by comprising the following components in parts by weight: 6 to 7 parts of hydrofluoric acid, 64 to 68 parts of nitric acid, and 26 to 28 parts of deionized water. An etching process of the polycrystalline silicon in the solar cell is characterized by comprising the following steps: injecting the deionized water into an etching tank; slowly pouring the hydrofluoric acid into the etching tank along the etching tank wall; slowly pouring the nitric acid into the etching tank along the etching tank wall; starting a cooling system of the etching tank to circularly cool a liquid in the etching tank for 10 to 15 minutes until the temperature of the liquid in the etching groove to be between 4 and 8 DEG C to obtain etching solution; and etching a polycrystalline silicon wafer in the etching solution for 280 to 320 seconds. According to the polycrystalline silicon wafer etching solution, the etching time is shortened; the polycrystalline etching effect is improved; the texture of the silicon wafer is uniform, fine and constant, the surface is clean, has good accordance without black lines; and the conversion efficiency and the quality of a solar cell are improved.

Owner:无锡尚品太阳能电力科技有限公司

Hydrophobic and oleophobic fluorine-containing group-modified drag reducer for hydraulic fracturing of inverse emulsion

The invention relates to a hydrophobic and oleophobic fluorine-containing group-modified drag reducer for hydraulic fracturing of an inverse emulsion, and belongs to the technical field of application of chemical agents in oil-gas field engineering. The hydrophobic and oleophobic fluorine-containing group-modified drag reducer is prepared by initializing inverse emulsion polymerization with a water-soluble monomer A1, a fluorine-containing monomer A2, a mutual solvent A3, water A4, an oil phase B and a free radical initiator C. According to the drag reducer, a water-phase mixture is dispersed into an oil phase represented by mineral oil or paroline to form a 'W / O' inverse emulsion; a small fluorine-containing segment with low surface energy and friction coefficient and the minimal surface tension in a solid material is introduced; the drag-reducing property of an original drag reducer is reserved; the drag reduction efficiency can reach 70% when the drag reducer is applied to hydraulic fracturing; meanwhile, the affinity between drag reducer molecules and the affinity between the drag reducer molecules and a reservoir rock are reduced by introduction of the fluorine-containing group; the drainage assisting performance and the reservoir protection performance after the hydraulic fracturing process are improved; and the problems that the drag reducer for shale oil and gas development at present is poor in flowback performance, serious in reservoir damages and high in biotoxicity are solved.

Owner:YANGTZE UNIVERSITY

Method for preparing briquetting furnace burden fro calcium carbide production from hydrated lime powder and coking coal powder

The invention discloses a method for preparing briquetting furnace burden fro calcium carbide production from hydrated lime powder and coking coal powder. The method comprises: taking hydrated lime powder and coking coal powder as raw materials; determining the amount of the coking coal powder according to the fixed carbon content required by a calcium carbide smelting process and the fixed carbon content of the coking coal powder; determining the amount of the hydrated lime powder according to the CaO content required by the calcium carbide smelting process and the CaO content of hydrated lime; and adding water to the hydrated lime powder and the coking coal powder, mixing well, briquetting and drying the obtained product. Compared with conventional processes, the method has the advantages of reducing costs for raw materials by about 50 percent, improving the quality of calcium carbide products, reducing the power consumption per unit weight of calcium carbide and increasing daily output and production efficiency of submerged arc furnaces.

Owner:张至德

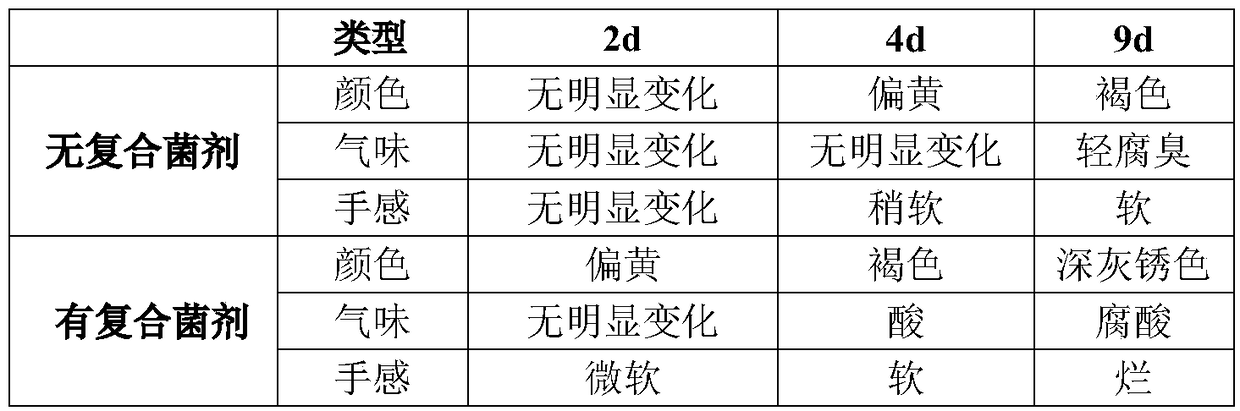

Low-temperature degradation straw composite microbial agent containing Saccharomyces cerevisiae and application thereof

ActiveCN108795795AMaturity days increasedImprove palatabilityFungiBio-organic fraction processingBiotechnologyCellulose

The invention provides a low-temperature degradation straw composite microbial agent containing Saccharomyces cerevisiae. The composite bacterial agent uses 6 strains, so that the corn stalk maturitydays can be increased by 2 to 3 days in an environment with the outdoor temperature of 1 to 6 DEG C, and then the composite bacterial agent is particularly suitable for northern regions. Compared withthe control group, the average milk yield of cows fed with corn straw treated with compound bacteria is increased by 8.9kg, the content of crude fibers in cow manure is decreased by 3.4%, and the average daily intake is increased by 2.3kg, because the compound bacteria for degrading lignocelluloses is added, and a large amount of Saccharomyces cerevisiae is contained in the compound bacteria, thecorn straw has soft texture and acid aroma, and the palatability is obviously improved to increase the appetite of livestock. Furthermore, the Saccharomyces cerevisiae can promote animal growth, regulate normal gastrointestinal flora and maintain microecological balance, thereby having the effects of improving gastrointestinal functions, increasing food digestibility and biological values, reducing serum cholesterol, controlling endotoxin, inhibiting the growth of spoilage bacteria in intestinal tracts and improving the immunity of bodies and the like so as to further increase the daily output.

Owner:JILIN AGRICULTURAL UNIV

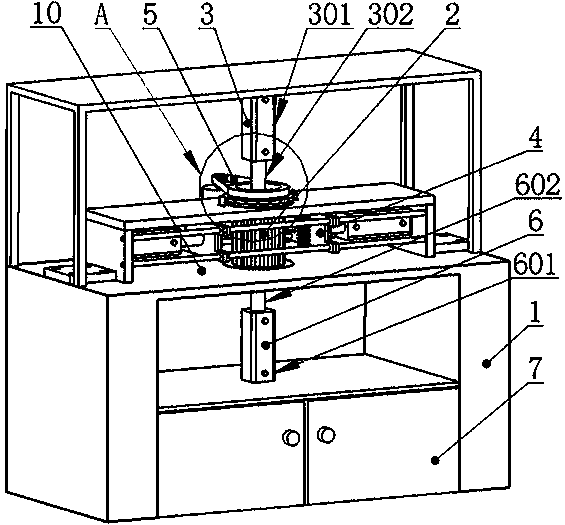

Anastomosis nail preparation device

The invention relates to an anastomosis nail preparation device which comprises a core rod, a core rod support and a broken nail stamping die. The broken nail stamp die comprises an upper die set and a lower die set. The upper die set comprises an upper template, a left slider push rod, a right slider push rod and a core rod pressing block. The lower die set comprises a core rod stand positioning module, a left slider, a right slider, a left broken nail stamping knife and a right broken nail stamping knife. The anastomosis nail preparation device improves the yield, reduces the labor cost and avoids the problems that the anastomosis nails produced in a manual manner are poor in consistency, the nail tips are blunt, the nail bodies deform, burrs exist on the head parts of the nails and that damages are caused to the nail bodies when the manual filing technique is adopted to produce the anastomosis nails.

Owner:FENGH MEDICAL CO LTD

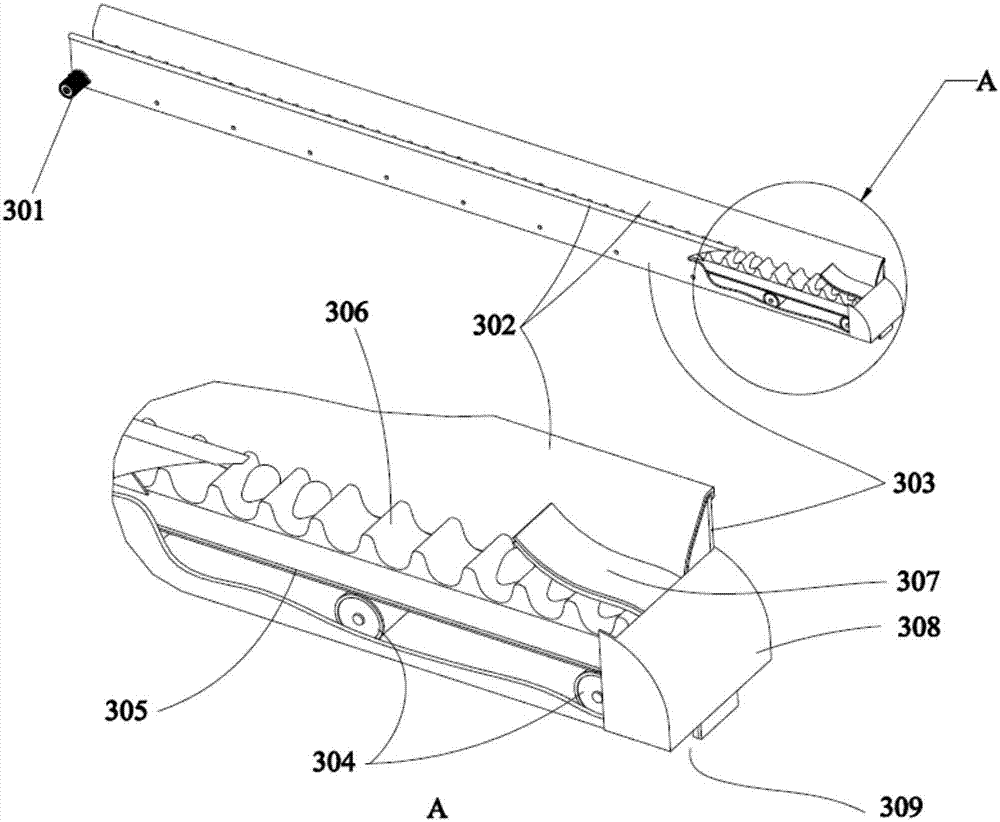

Semiautomatic strawberry harvesting and packing equipment and strawberry packing bag thereof

InactiveCN107572030AAvoid problems such as inconsistencies in the actual total weightReduce labor intensityPackaging automatic controlPackaging fruits/vegetablesEngineeringLoad cell

The invention discloses semiautomatic strawberry harvesting and packing equipment and a strawberry packing bag thereof. The equipment consists of a strawberry conveying groove and an automatic packingsystem, wherein the strawberry conveying groove consists of a conveying groove frame, a conveying belt motor, a roller, a conveying belt, side sponge, conveying belt sponge, a conveying belt end cover and end cover sponge; and the automatic packing system consists of a packing bag bottom rubber wheel, a packing bag lower box wheel, a packing bag upper cover wheel, a packing system driving motor,a packing bag guide wheel, a reflective photoelectric sensor, a weighing sensor, a bar code scanner, a packing system frame and a strawberry packing strip. When the equipment is used for manually harvesting strawberries, the manual box loading action of each picked strawberry can be saved, so that the labor intensity is greatly reduced, and the daily output is increased; and each harvested strawberry owns independent package, so that the strawberries can be loaded in boxes for sales, and can be sold in a scattered manner according to the weight unit price under the condition of not weighing, and the problem of different actual total weight of each box of strawberries in box loading sales is prevented.

Owner:SOUTHWEST UNIV

Free forging process for sector plate forge piece

InactiveCN106040931ALow technical requirementsLow skill level requiredMetal-working apparatusEngineeringForge

The invention discloses a free forging process for a sector plate forge piece. The free forging process includes the following steps that G0 is equal to [alpha / 360piR<2>L-1 / 2(R-h1)L+B(H-h1)L]*rho; the fire consumption is calculated, wherein G1 two-fire forming is conducted, and the fire consumption rate is 5%, that is, G1 is equal to G0*0.05; head cutting is conducted, wherein G2 is equal to 1.8*B2*H*2; the discharging weight is calculated, wherein G is equal to G0+G1+G2; flat square blank forming is conducted through an upper flat anvil and a lower flat anvil, and a sector-shaped groove is machined through a planing machine; and a forged sector-shaped concave blocking narrow anvil of a blank is drawn out, and the width and the size are adjusted properly to accord with the conditions indicated in a drawing. According to the free forging process, the requirement for the skill of workers is not high, operation is easy and convenient, and production efficiency is high; the embryo die forging shape is precise, and size precision is high, so that the number of process accessorial blocks is small, and the allowance for machining is small; and according to the forged sector-shaped face of the forge piece, a great number of raw materials are saved, the machining time is shortened, the requirement for the technological level of the workers is lowered, and the daily output is increased greatly.

Owner:ANHUI RUIJIE FORGING

Cold-formed steel joist

An upper chord bearing joist comprising a top chord member and a bottom chord member, each having a flange portion and a web receiving portion including two web receiving tabs, each made from a unitary piece of metal; a generally planar steel web, a portion of the web being attached to the top chord member and to the bottom chord member, wherein a top portion of the web is between the two web receiving tabs of the top chord member and a bottom portion of the web is between the two web receiving tabs of the bottom chord member; and a first and second pair of support members, each support member including a shoe portion, a web attaching portion, and an angled portion, the web attaching portion being attached to the web receiving tabs and the angled portion being in contact with the web. The joist may be cambered, have reinforcement stiffeners, and have a rotatable joint at either end. The joists may be used in composite with concrete or with wood.

Owner:ISPAN SYST LP

Full-automatic molded pulp four-workstation integrated equipment and production process for same

InactiveCN103556546AImprove work efficiencyIncrease daily outputTextiles and paperMolded pulpShell molding

The invention discloses full-automatic molded pulp four-workstation integrated equipment and a production process for the same. The full-automatic molded pulp four-workstation integrated equipment comprises a suction filtration forming device and four hot-pressing shaping devices, wherein the suction filtration forming device comprises a forming frame, a pulp tank, a forming mold plate, a transferring mold plate, a forming and transferring mold gas-storing tank, a forming and transferring mold supporting plate moving cylinder, a transferring cylinder, an overturning oil cylinder and an overturning spindle; the four hot-pressing shaping devices are matched with the suction filtration forming device; each hot-pressing shaping device comprises an upper mold plate, a lower mold plate, an upper mold pressurizing cylinder, a lower mold moving cylinder, a shaping and transforming mold gas-storing tank and a shaping and transferring mold supporting plate moving cylinder; the transferring cylinder is arranged on a transferring mold supporting plate; a transferring mold is fixed on the transferring mold plate; and the transferring mold plate is guided by a mold plate guiding shaft, and is driven by the transferring cylinder to vertically move along the mold plate guiding shaft. By the full-automatic molded pulp four-workstation integrated equipment, the mold utilization rate is increased, and the quality of products and the labor productivity are improved.

Owner:张宝华

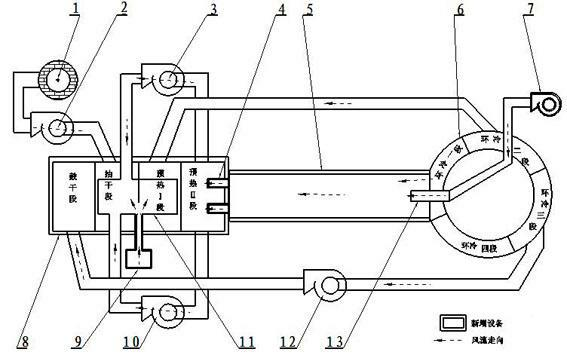

Method and system for optimizing drying grate-rotary kiln oxidate pellet thermal regulation

A method and a system for optimizing a drying grate-rotary kiln oxidate pellet thermal regulation are characterized in that a blower is adopted to pressurize the combustion air of a center burner; the pressure of the combustion air is increased to 18 to 25 KPa; the length of the flame of the center burner of a rotary kiln is controlled to be 15 to 17 m; a heat source point is added in a gas hood to increase the temperature of the preheating segment II of a drying grate by 100 to 150 DEG C; hot air of 500 to 1,000 DEG C are supplied to an air drying segment and a preheating segment I; and the system comprises a pressurizing device, the heat source point and a hot air supply device. The invention has the advantages that reasonable drying and preheating temperature gradient is formed, the drying and preheating effect is improved, energy is saved, the proportion of production of hematite is improved from the highest 40 percent to 100 percent, the hot air volume of the drying grate is sufficient, the hot air temperature is standard, the drying and preheating effect of fresh pellets is remarkably improved, the yield is increased, the consumption of coal gas is lowered, the powder entering the kiln is reduced, and the phenomenon that ring forming is liable to be caused by high-temperature powder feeding of the rotary kiln.

Owner:LIUZHOU IRON & STEEL

Automatic filter element hole pricking equipment

InactiveCN109834753AAvoid force deformationAvoid torqueMetal-working feeding devicesMetal working apparatusBiochemical engineeringFilter element

The invention discloses automatic filter element hole pricking equipment. The automatic filter element hole pricking equipment comprises a machine frame, a clamp, a pressing device, hole pricking devices, a rotating device, an ejecting device, a control device and an operation table, wherein the clamp, the pressing device, the hole pricking devices, the rotating device, the ejecting device, the control device and the operation table are installed on the machine frame; the clamp is installed in the center of the operation table, the pressing device is arranged right above the clamp, the hole pricking devices are symmetrically arranged on the left side and the right side of the mouse cage of the clamp; the rotating device is arranged right behind the clamp; the ejecting device is arranged under the clamp; the control device is arranged below the ejecting device. According to the automatic filter element hole pricking equipment, when the equipment works, the filter element to be puncturedis fixed by the pressing device in the clamp, the hole pricking devices are matched with the rotating device to realize 360-degrees rapid and uniform hole pricking of the filter element, the deformation of the filter element is small, and the working efficiency and the hole pricking quality are greatly improved.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Building ceramic plate/brick and preparation method thereof

The invention discloses a building ceramic plate / brick, which is prepared from a base material and an additive, wherein the base material comprises 5-25 wt% of a plastic raw material, 40-60 wt% of a fluxing raw material, and 25-45 wt% of wollastonite and / or wollastonite fiber, and relative to the base material, the addition amount of the additive is 0.01-6 wt%, and the additive comprises one or a combination of an organic reinforcing agent and a water reducing agent. Correspondingly, the invention also discloses a preparation method of the building ceramic plate / brick. According to the invention, through formula design, wollastonite and / or wollastonite fibers are introduced into a green body for reinforcement and toughening while low-temperature fluxing raw materials are introduced to realize low-temperature firing and avoid high-temperature melting failure of inorganic fibers, so that the product performance is remarkably improved, and the energy consumption and the production cost are reduced.

Owner:况学成 +1

Patting type quick quail egg shelling device

The invention relates to a shelling device, in particular to a patting type quick quail egg shelling device. The patting type quail egg quick shelling device provided by the invention can automatically shell quail eggs and meanwhile conveniently collect the shelled quail eggs. The patting type quail egg quick shelling device comprises a base, first supports symmetrically arranged on the base, L rods symmetrically arranged in the middle of the base, a patting mechanism arranged on the first supports, and a conveying mechanism arranged in the middle of the base. Through the design of the conveying mechanism, automatic movement of the quail eggs can be achieved, the quail eggs do not need to be moved manually, and meanwhile operation of the patting mechanism is better matched; and through thedesign of a cleaning mechanism, the quail eggs in a water discharging frame can be moved into a collecting frame, so that automatic collection of the quail eggs is achieved, and meanwhile the effectof preliminary cleaning of the shelled quail eggs is achieved.

Owner:李璐璐

Polyurethane cushion and production technique thereof

A polyurethane mat and its manufacturing process, which is composed of the following two parts: a. 40-70% polyether polyol, 25-55% polyester polyol, butanediol or / and ethylene glycol or / and propylene glycol Neopentyl glycol or / and hexanediol or / and diethylene glycol or / and dipropylene glycol 0.1-5%, stannous octoxide or / and dibutyltin dilaurate or / and bismuth isooctanoate 0.09-1.5%; b .Polyether polyol 30-60%, polyester polyol or / and polycarbonate diol 5-30%, isocyanate 30-60%, adipoyl chloride or / and phosphoric acid or oleic acid 0.001-0.1%, butanediol 0.3-5% of alcohol or / and neopentyl glycol or / and hexanediol, the above-mentioned percentages are by weight. Its production process includes batching, feeding into the mold, forming in the mold and trimming processes. It has the advantages of easy preparation, good product performance, low production cost, simple production process and large output. It is a very practical product. Promote apps.

Owner:汪士抗

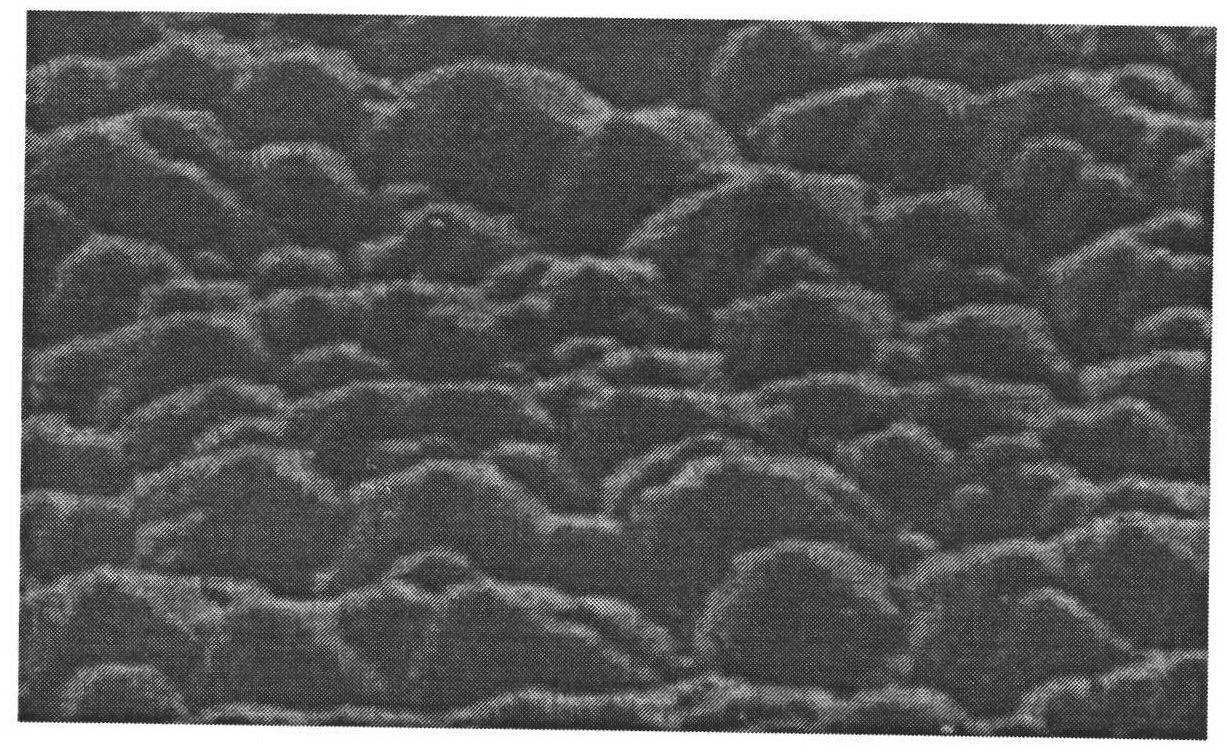

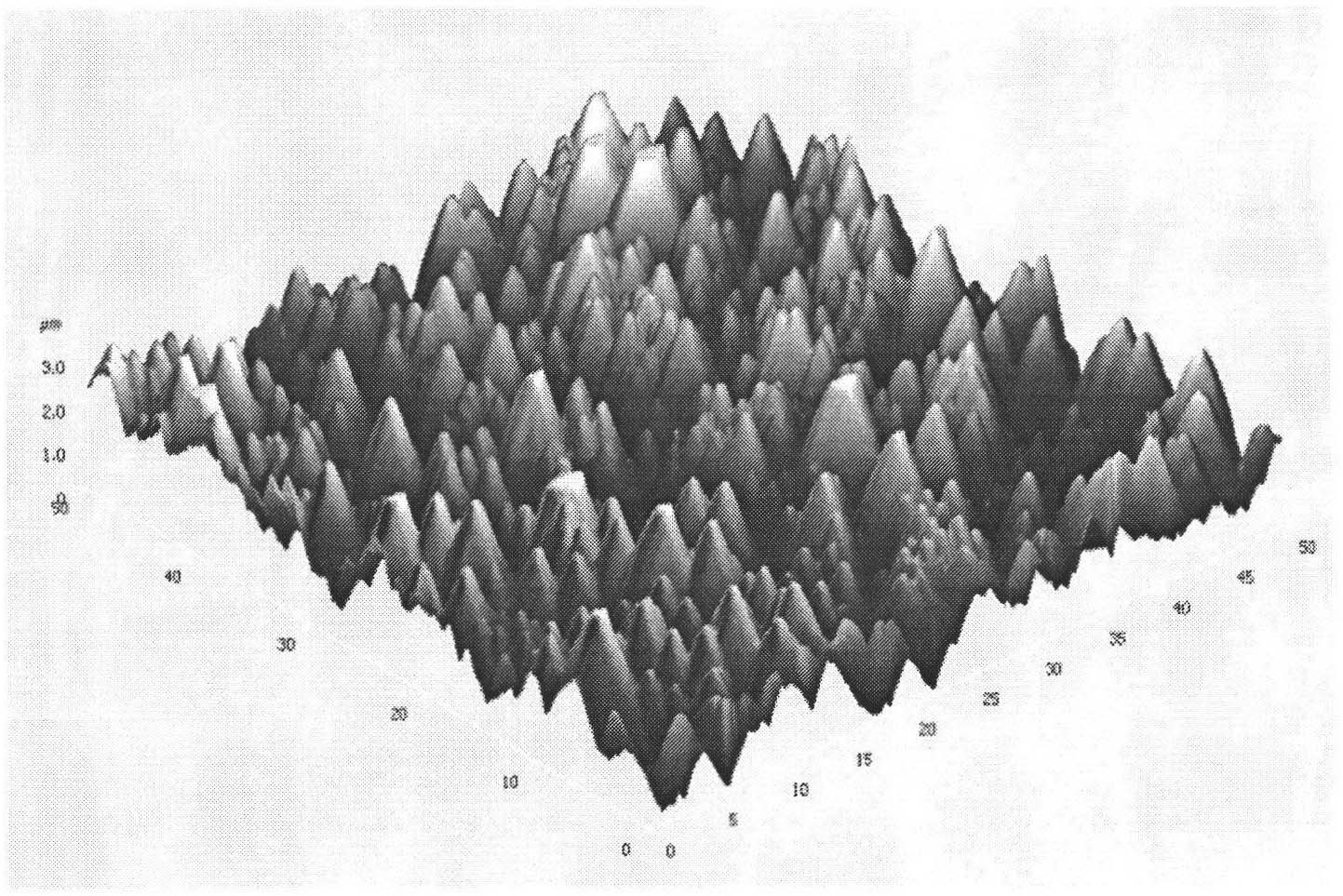

Texture etching solution of monocrystaline silicon solar cell, preparation method, and application thereof

InactiveCN102400225AOvercome timeOvercome uniformity issuesAfter-treatment detailsFinal product manufactureTetramethylammonium hydroxideSilicon solar cell

The invention relates to a texture etching solution of a monocrystaline silicon solar cell, a preparation method, and an application thereof. Raw materials of the texture etching solution comprise the following components, by weight, 1-3% of tetramethylammonium hydroxide, 7-9% of isopropyl alcohol and 88-92% of deionized water. The preparation method comprises: adding the deionized water to a texture etching groove, then adding the tetramethylammonium hydroxide and the isopropyl alcohol, controlling a temperature to 75-85 DEG C, completely and uniformly stirring to obtain the texture etching solution, which is applicable for treatment of silicon wafers. Compared to the prior art, with the present invention, the texture etching solution has a good anisotropic etching characteristic and high etching rate, the etching surface has good homogeneity, the etching solution does not contain free-alkali metal ions, has advantages of no toxicity and easy operation and control, and can provide compatibility with the microelectronic technology.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com