Anastomosis nail preparation device

A technology for preparing devices and staples, which is applied in the field of medical devices, can solve the problems of easy wear and tear of mandrels, unsharp nail tips, and high defect rate, so as to avoid premature damage and scrap, reduce labor costs, and eliminate problems of poor consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing. The numerical value of the angle involved in the present invention is the absolute value of the angle, and the positive and negative signs of the angle are omitted.

[0032] A staple preparation device includes a mandrel assembly 3, a mandrel support 4 and a broken nail die.

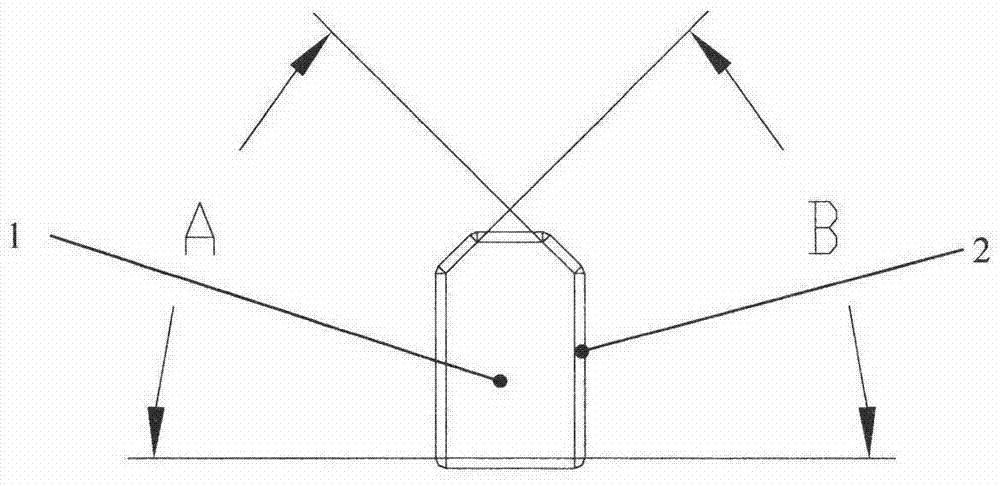

[0033] The staple is made of titanium wire 2, the material of which is pure titanium, and the specific grade is TA1 or TA2, wherein TA1 and TA2 are standard grades of pure titanium. Pure titanium has the appropriate hardness and toughness required by staples, and the staples made are not easy to be brittle. Use a winding machine to tightly wind the titanium wire 2 on the mandrel 1. The effect after winding is as follows: figure 1 shown. The meaning of the tight winding is: a titanium wire 2 is helically and continuously wound on the mandrel 1 by a winding machine, and the titanium wire 2 forms a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com