Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

286results about "Needles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lancet and method of manufacturing the same

InactiveUS20050171567A1Minimal discomfortSufficient amountSurgical needlesCatheterEngineeringTissue skin

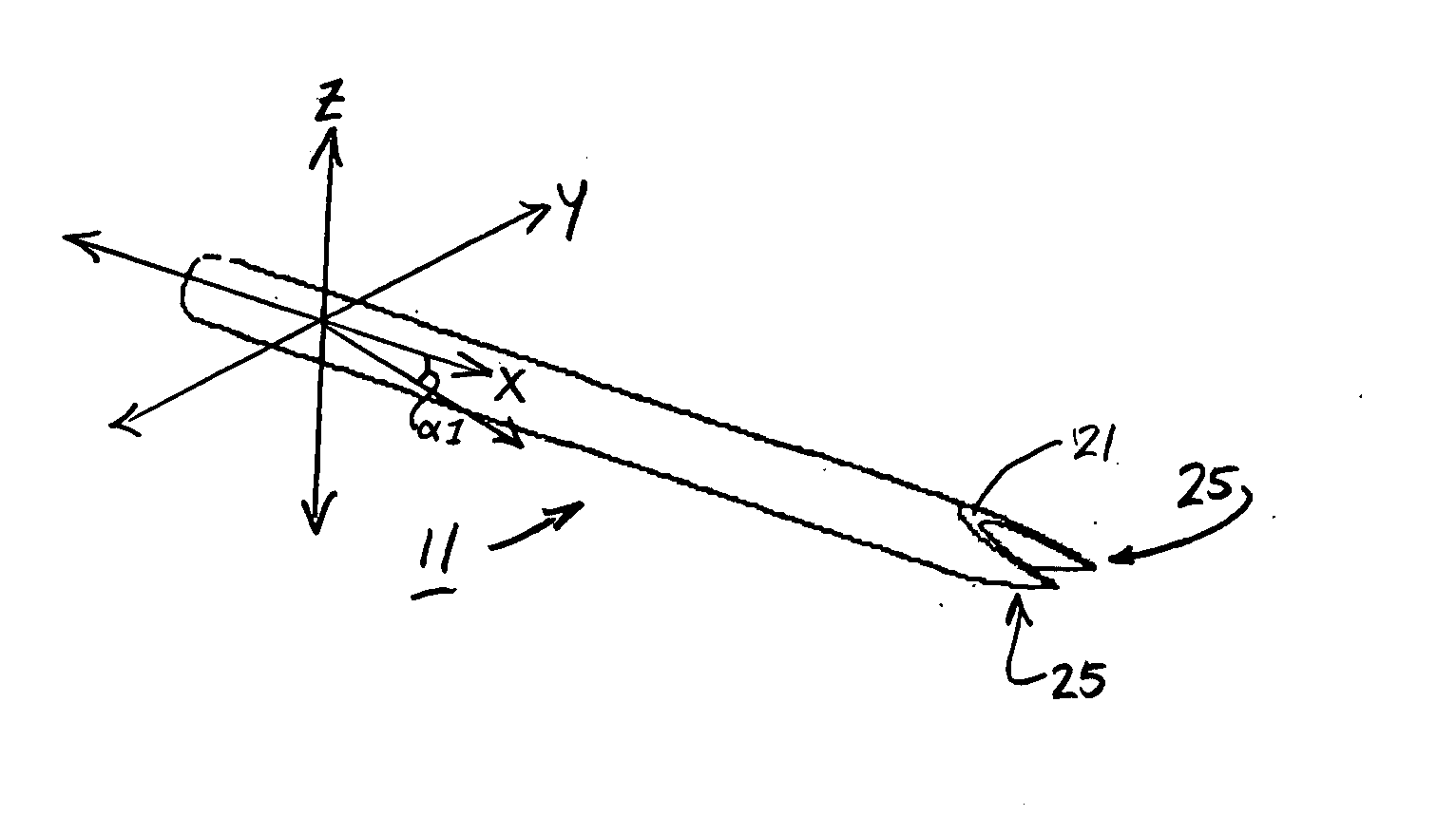

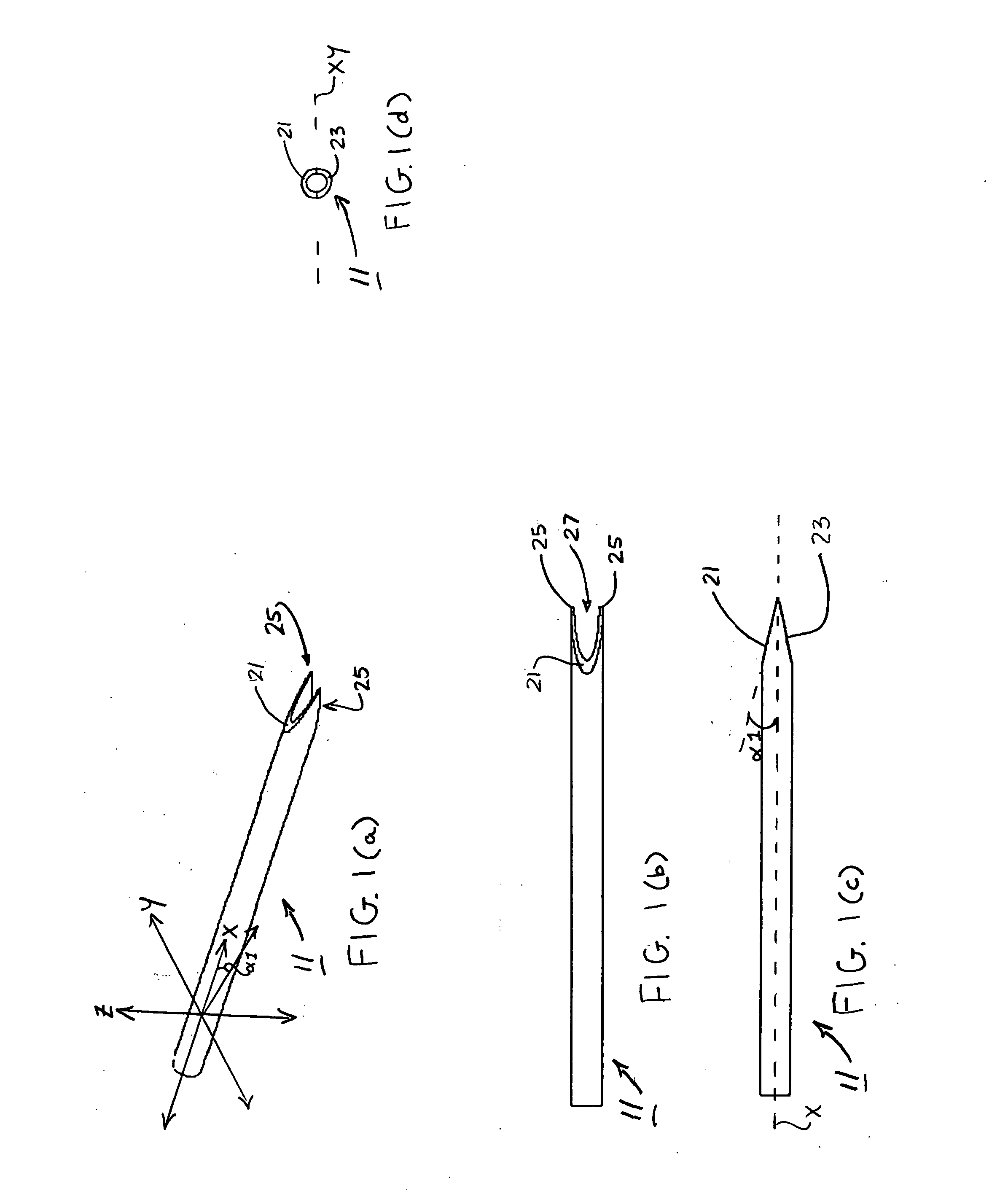

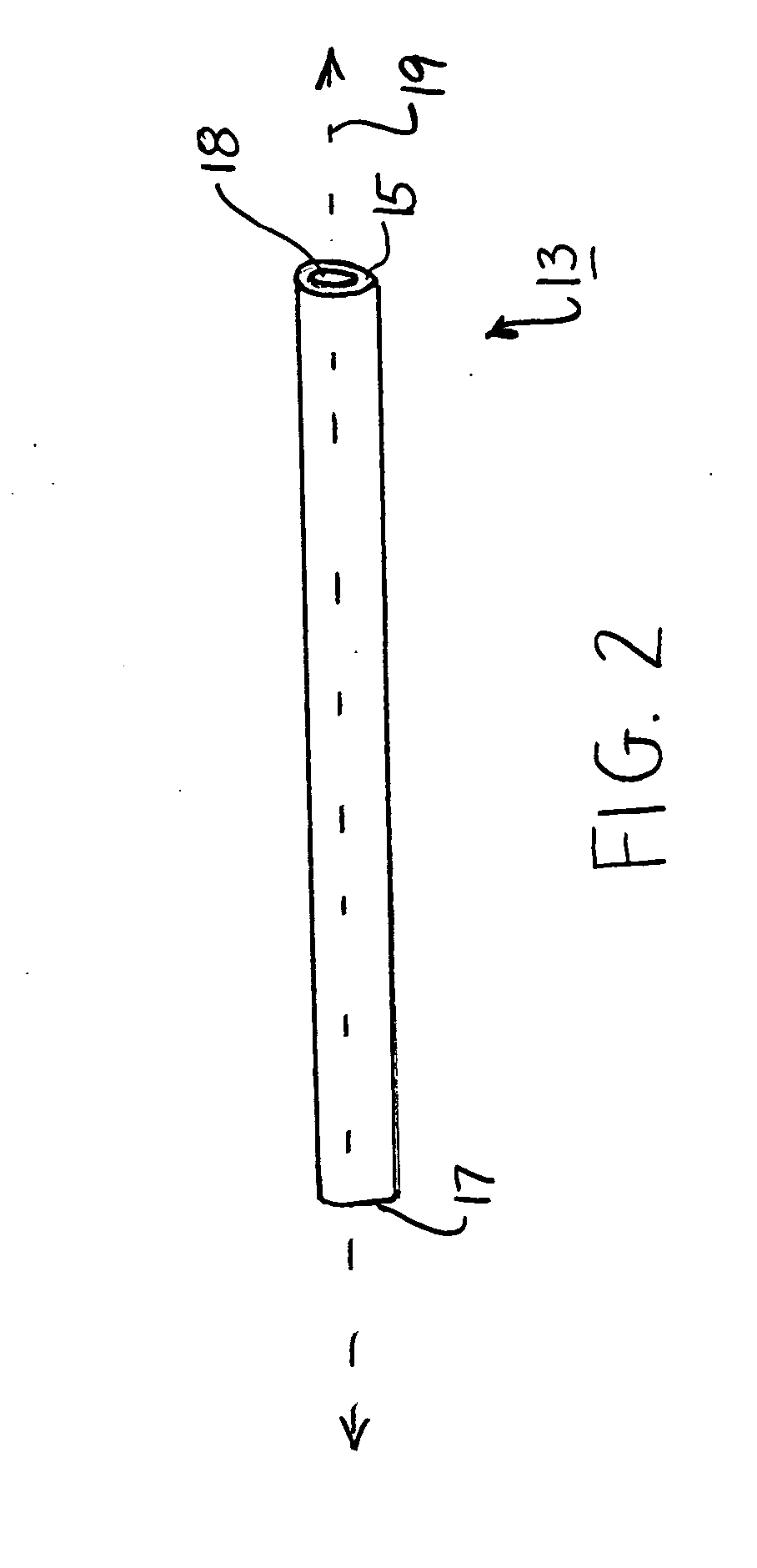

A lancet for acquiring a blood sample includes a unitary member which is hollow along at least a portion of its length. Preferably, the unitary member is in the form of a seamless cylindrical tube which is constructed out of a rigid and durable material, such as stainless steel. During the lancet manufacturing process, a series of individual grinding processes are performed on one end of the unitary member to yield a lancet which includes a plurality of skin-penetrable tips. In one embodiment, one end of the unitary member is subjected to a pair of single angle planar grinds to yield a lancet which includes a pair of sharpened tips. In another embodiment, one end of the unitary member is subjected to four compound angle planar grinds to yield a lancet which includes a pair of sharpened tips. In another embodiment, one end of the unitary member is subjected to three single angle planar grinds to yield a lancet which includes three equidistantly spaced sharpened tips.

Owner:ABBOTT LAB INC

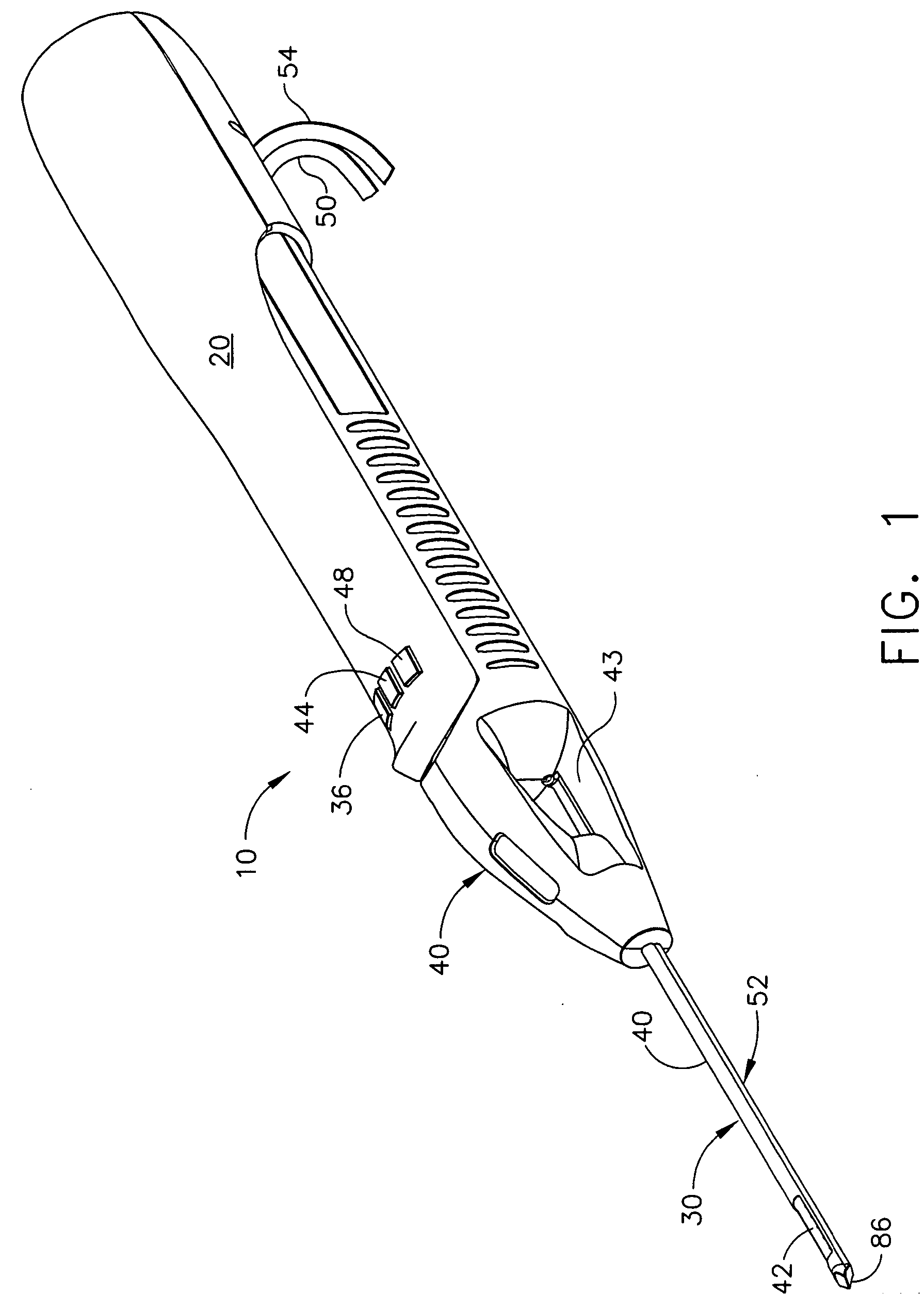

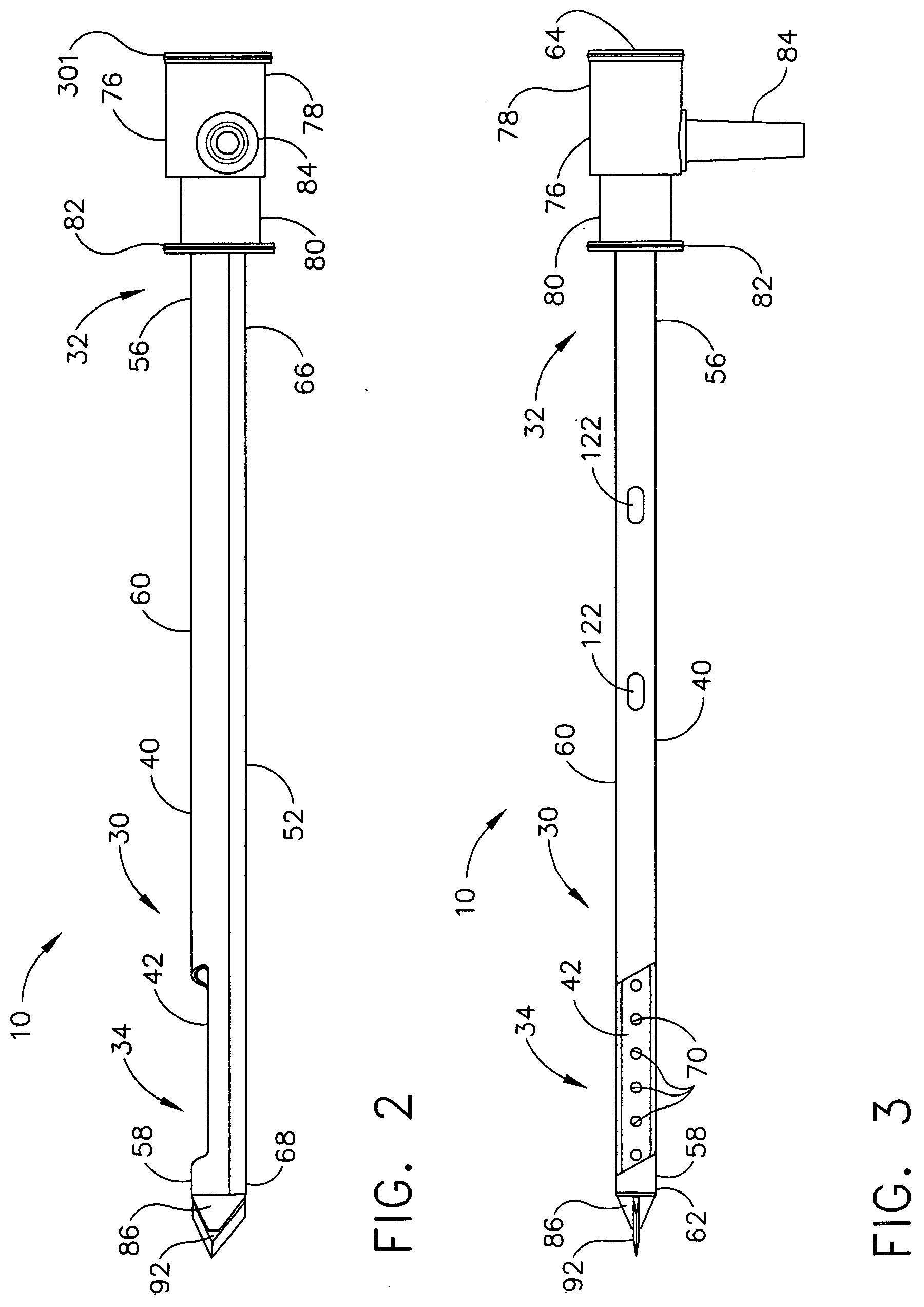

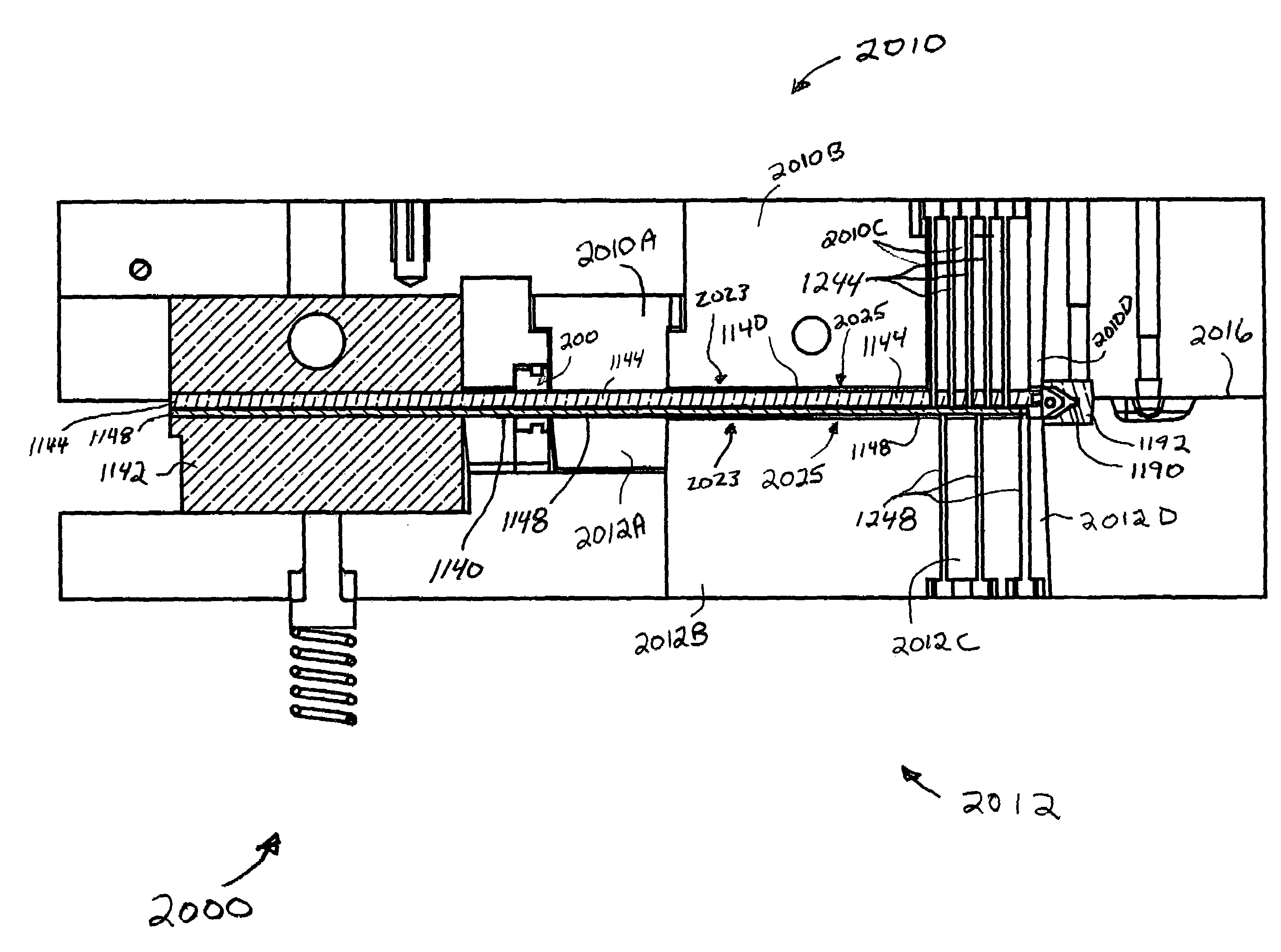

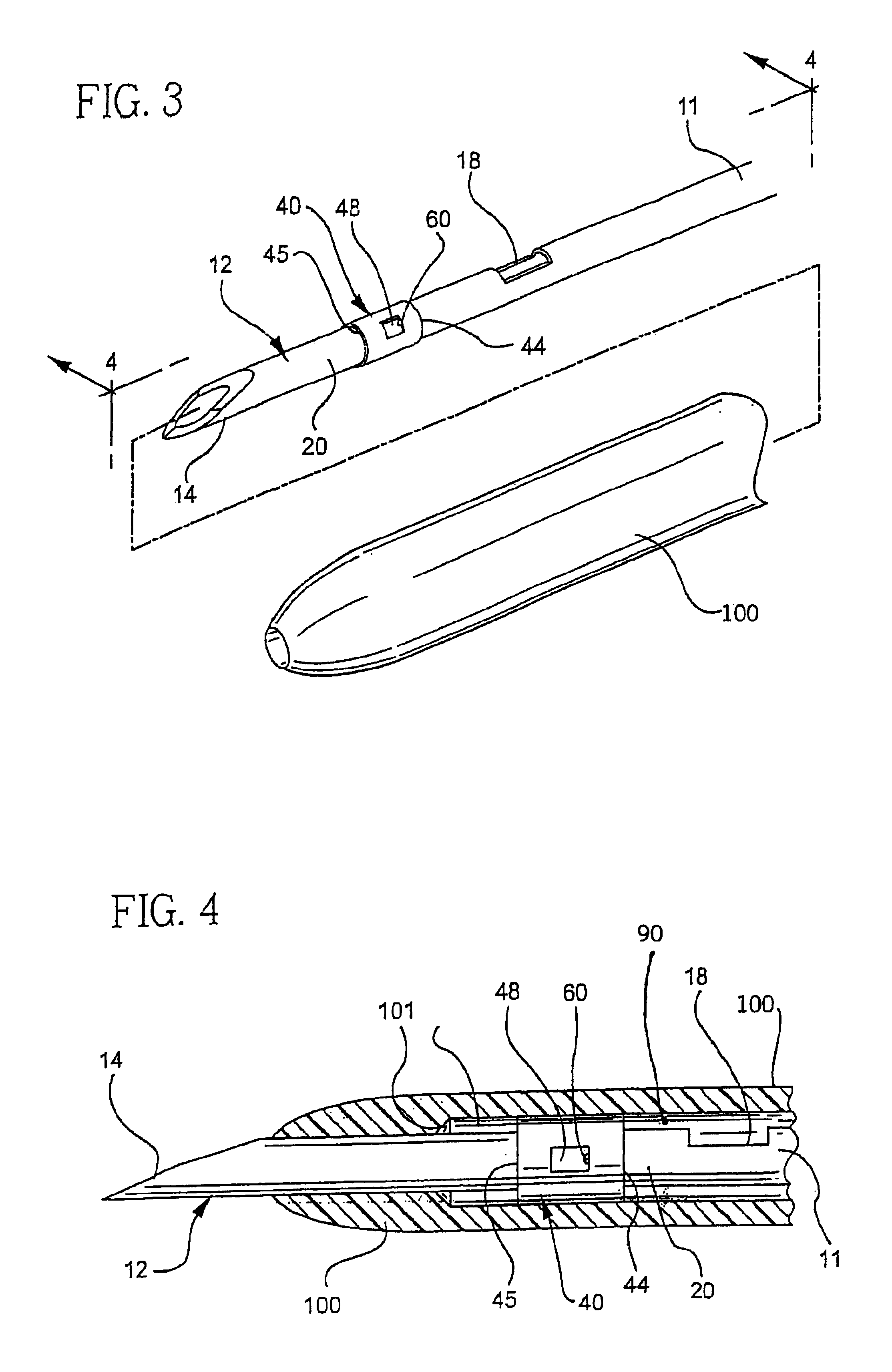

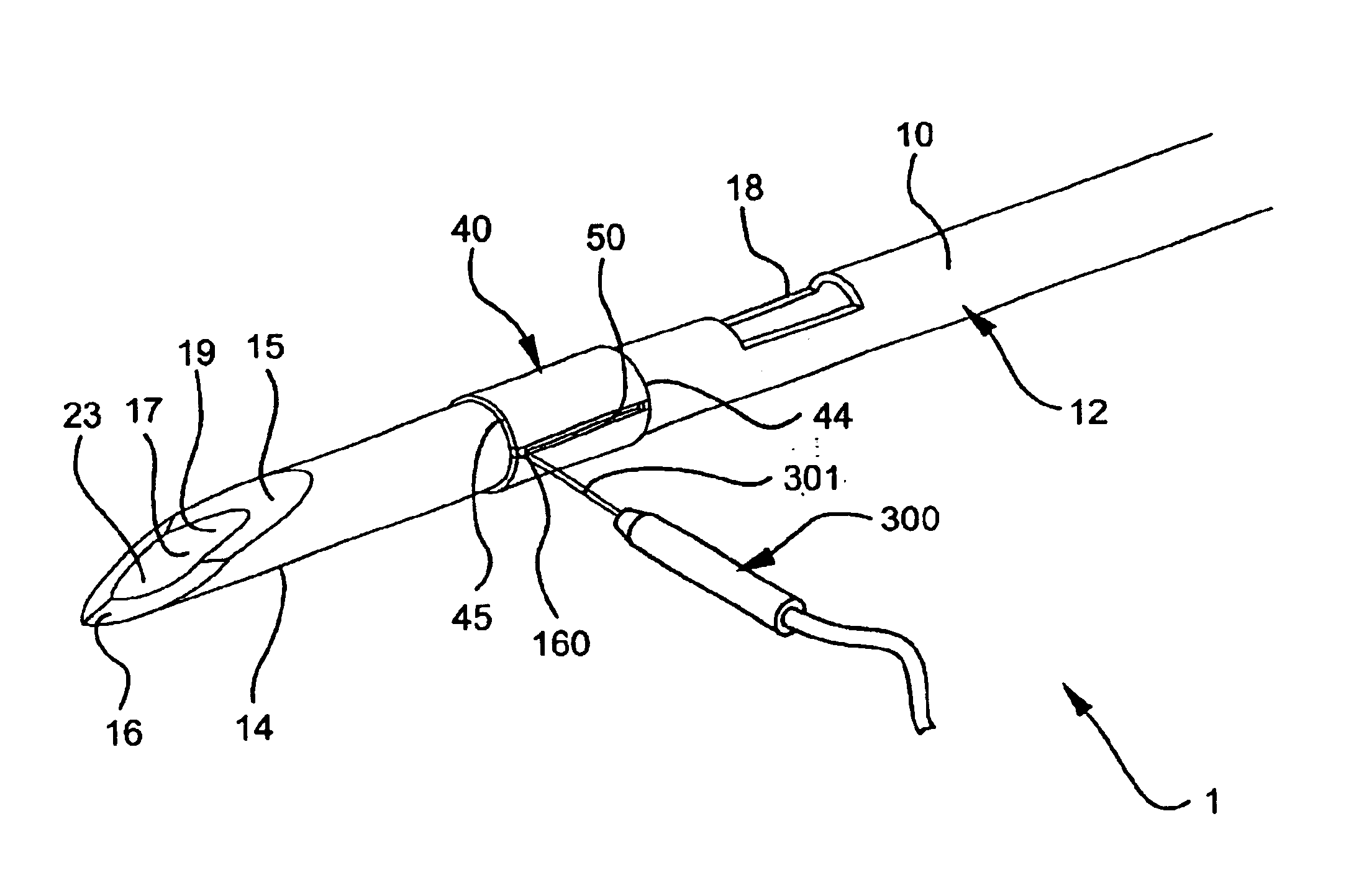

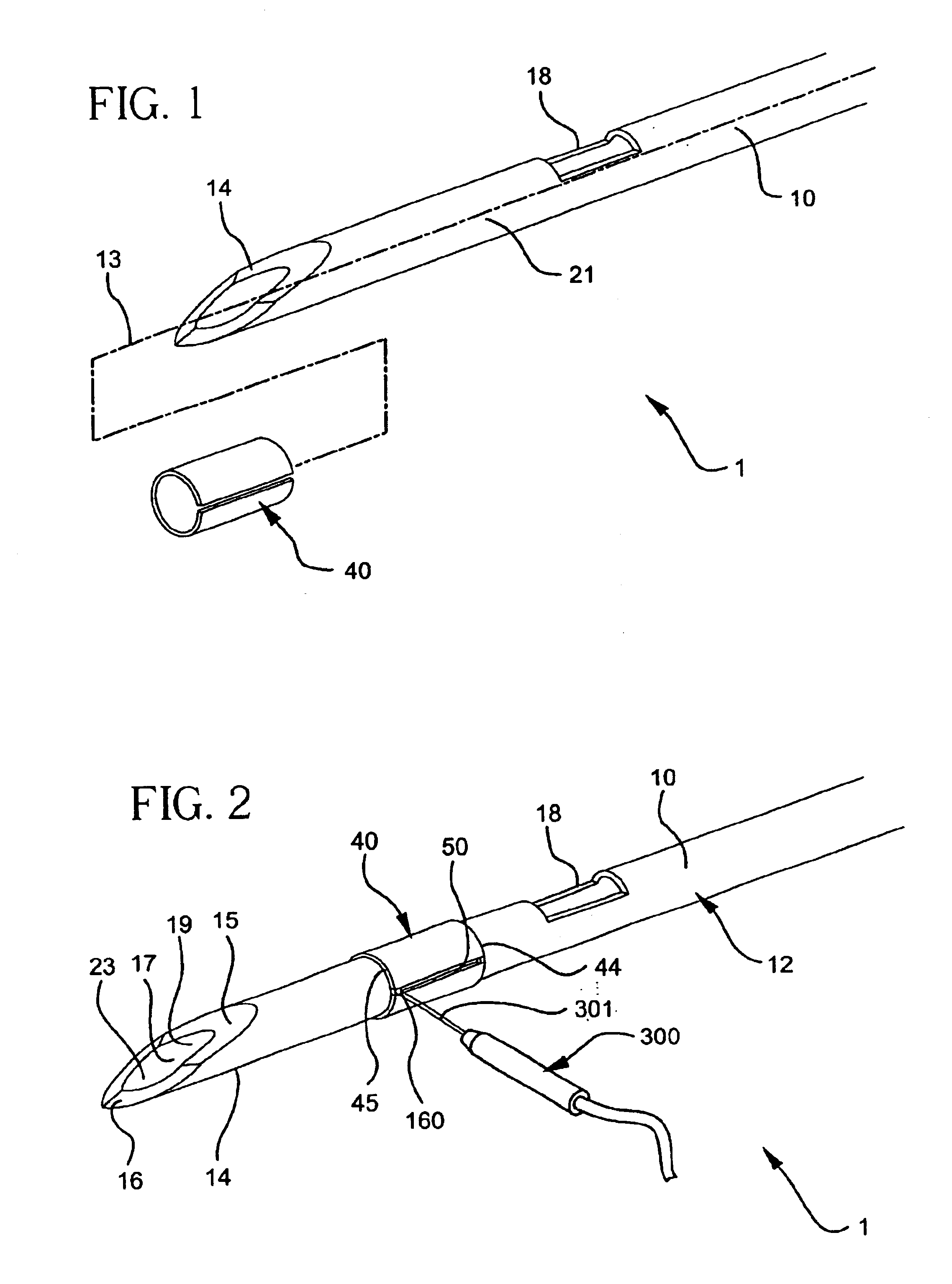

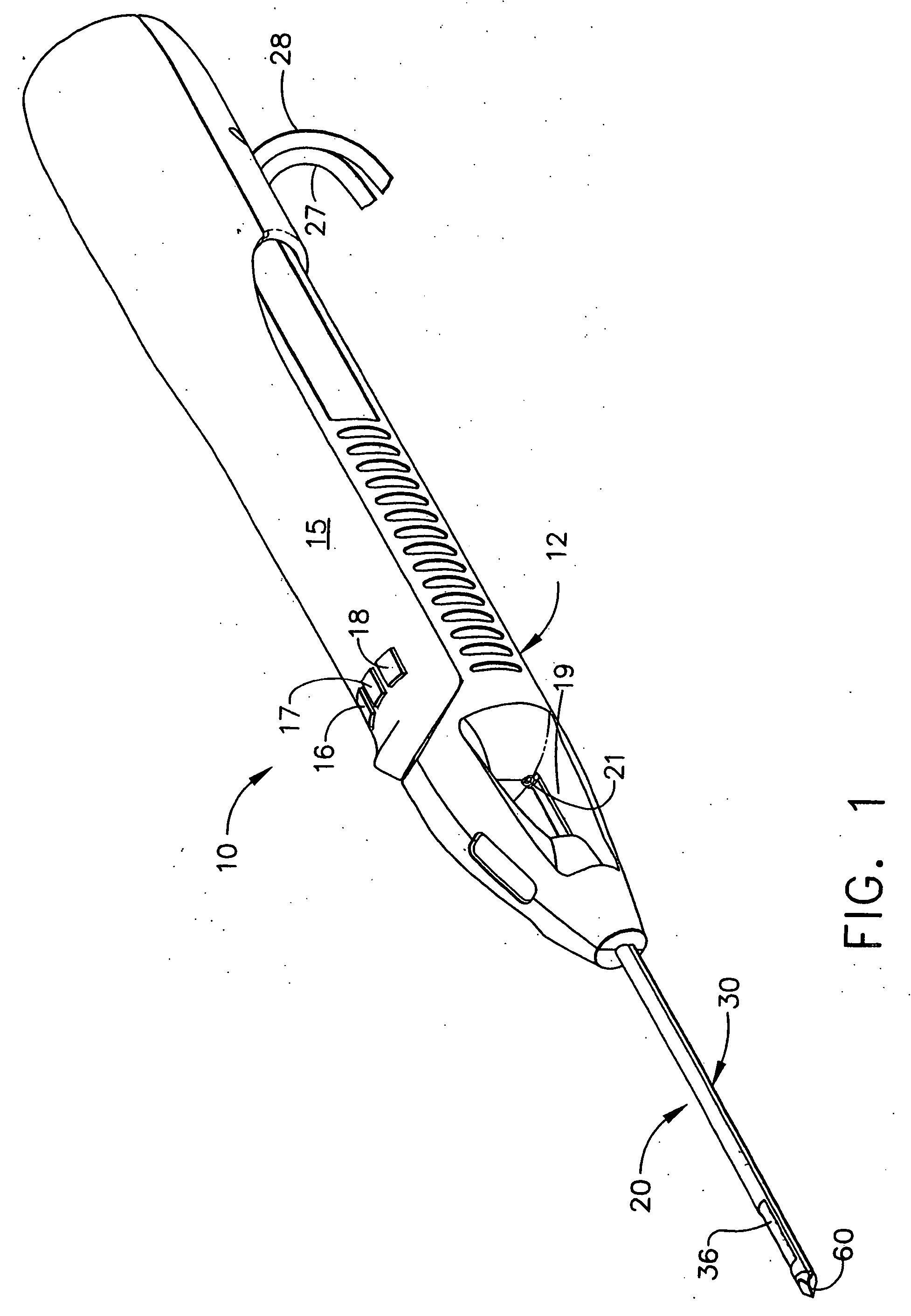

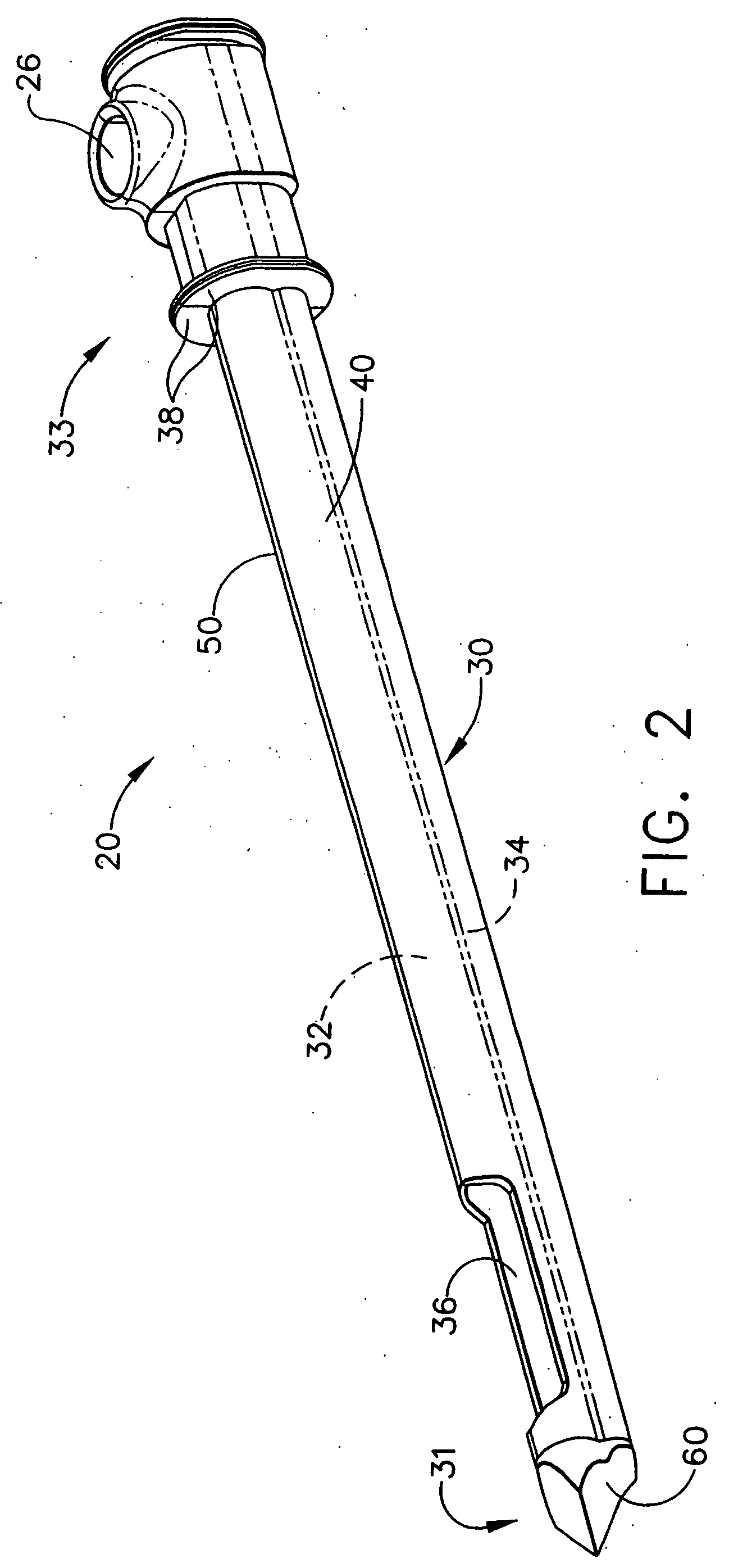

Method of manufacturing a needle assembly for use with a biopsy device

InactiveUS20060144548A1Low costMaintain propertiesSurgical needlesVaccination/ovulation diagnosticsDistal portionMedicine

An improved process for manufacturing a biopsy needle assembly is provided. The process may comprise the steps of forming an aperture for receiving tissue to be sampled in an exterior surface of an elongated tube for receiving a cutter, wherein the elongated tube comprises a proximal portion and a distal portion; forming a hole in the exterior surface of the elongated tube; and applying a coating of material over the elongated tube to form a lumen for receiving vacuum on the exterior surface of the elongated tube, wherein the hole in the exterior surface of the elongated tube provides communication between an interior of the elongated tube and an interior of the lumen. In one version, the elongated tube may be placed in a mold configured to form the vacuum lumen when material is injected into the mold. A proximal hub may advantageously be formed by overmolding.

Owner:DEVICOR MEDICAL PROD

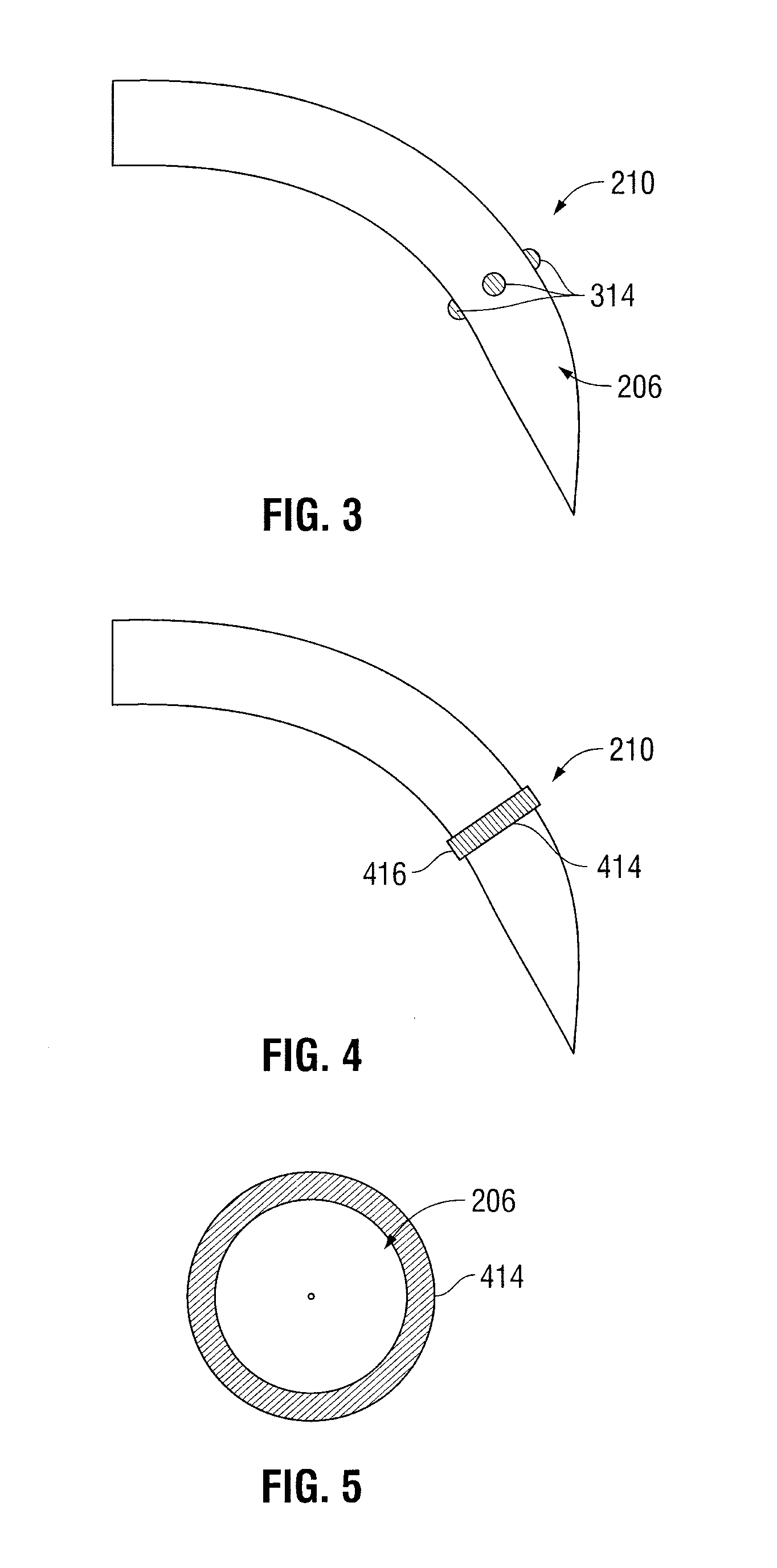

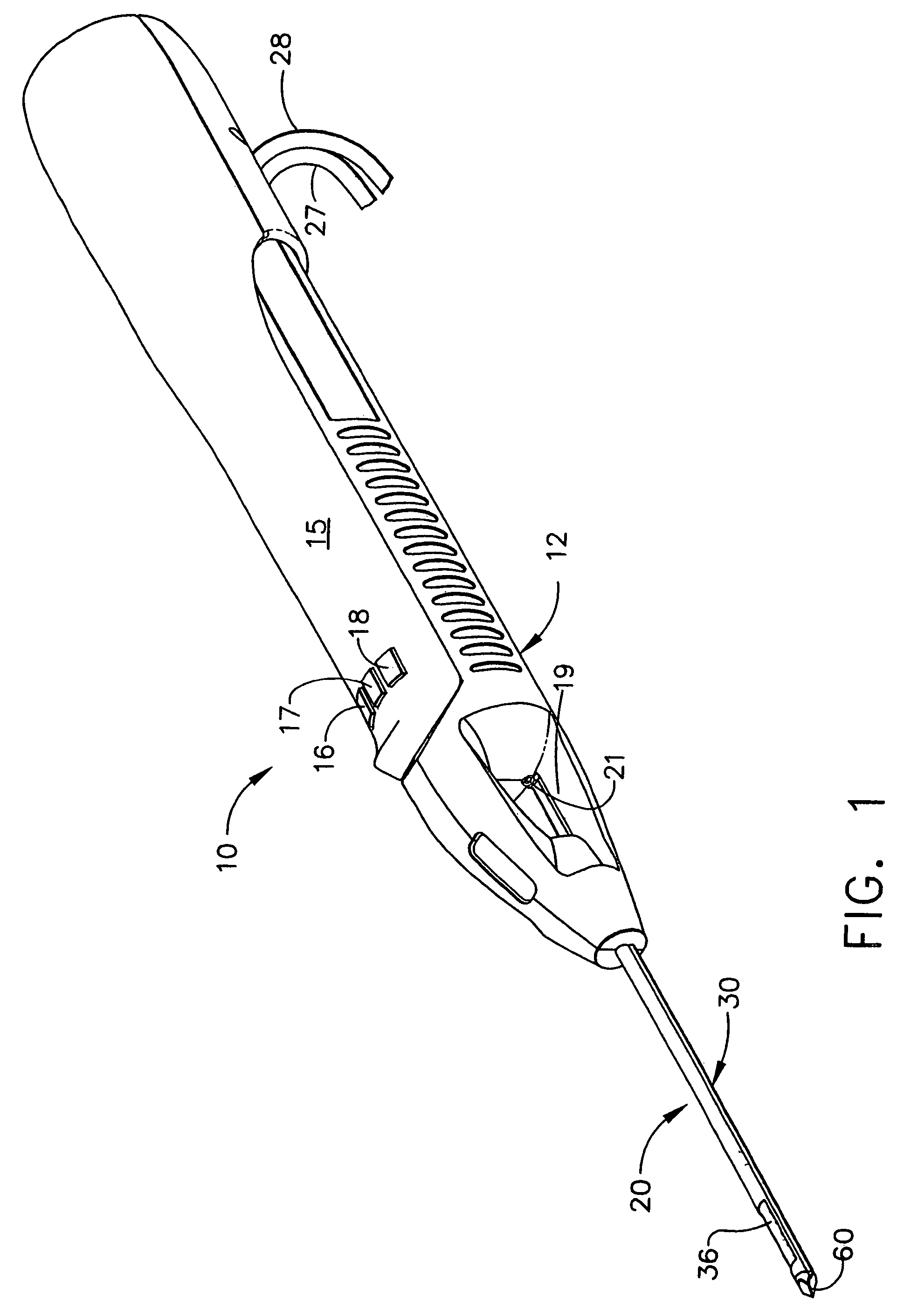

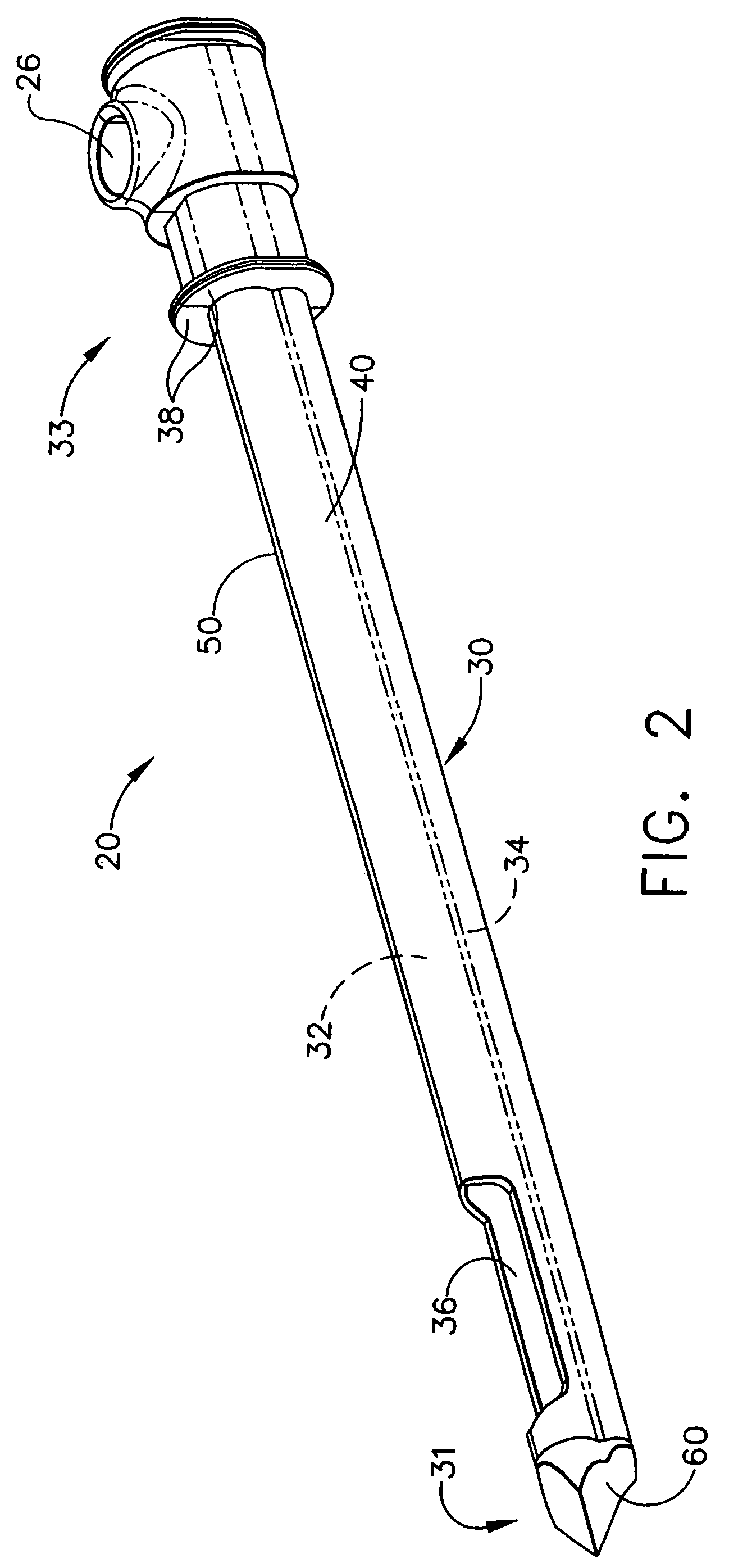

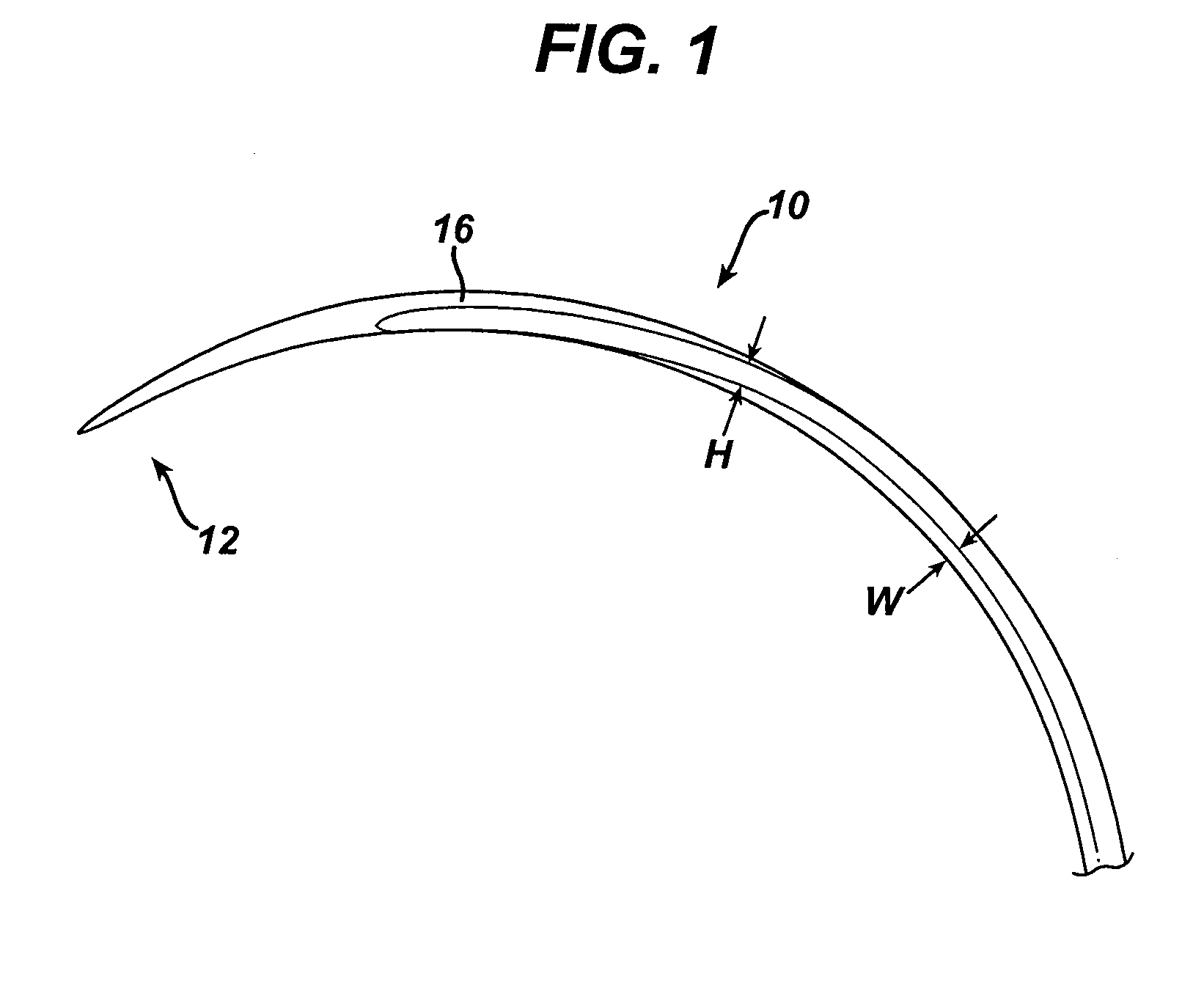

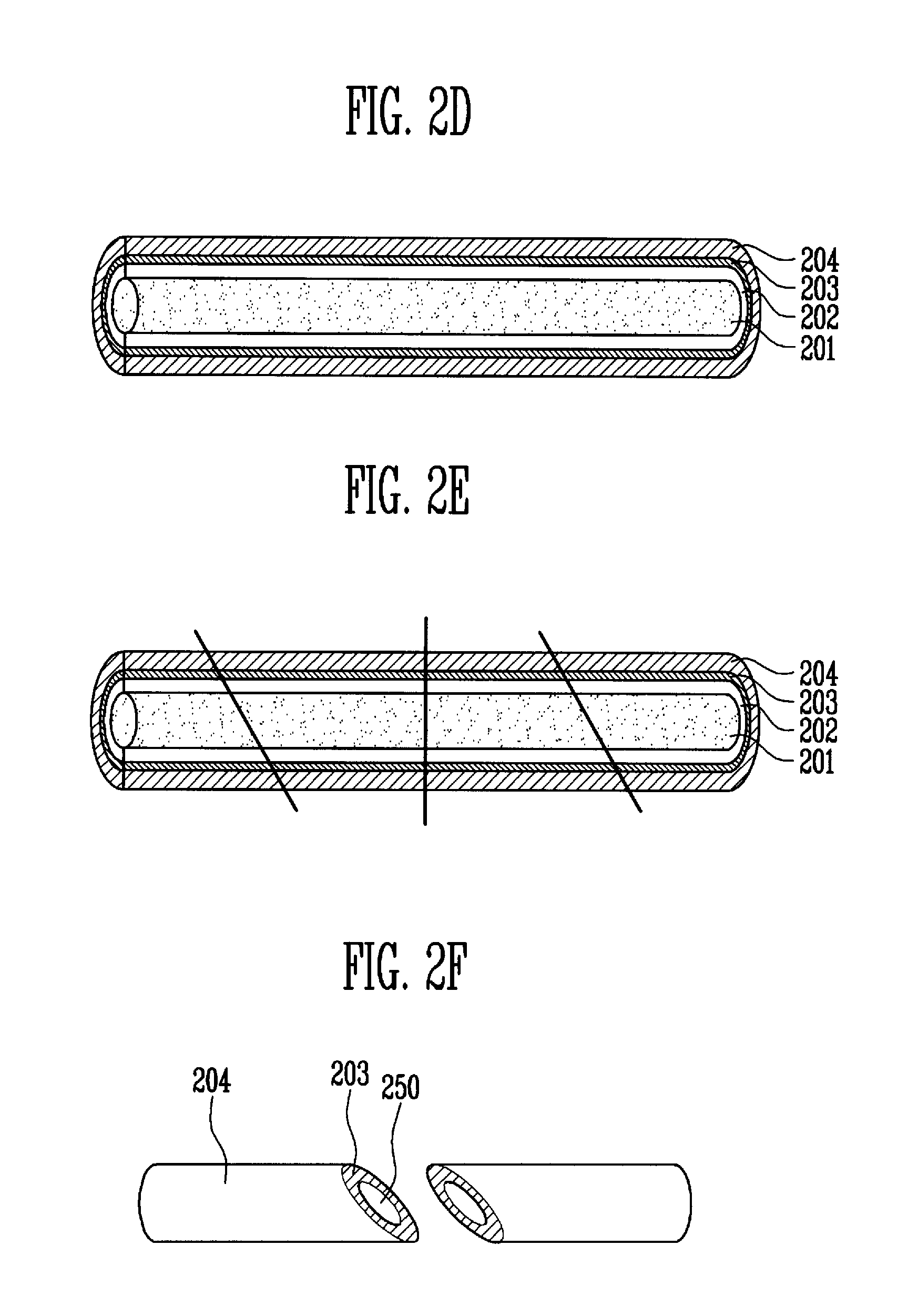

Surgical needle with reduced contact area

InactiveUS20100036415A1Reduce exposureFacilitate atraumatic insertionSurgical needlesNeedlesSurgical operationSurgical department

The present disclosure relates to a surgical needle that includes a proximal end adapted for attachment to a surgical filament, a distal end, and a shaft extending therebetween. An outer surface of the shaft includes reduction structure configured and dimensioned to reduce contact between the outer surface and tissue without unnecessarily compromising the structural integrity or strength of the needle. Additionally, the configuration and dimensions of the reduction structure facilitate atraumatic insertion and passage of the surgical needle through the tissue during use.

Owner:TYCO HEALTHCARE GRP LP

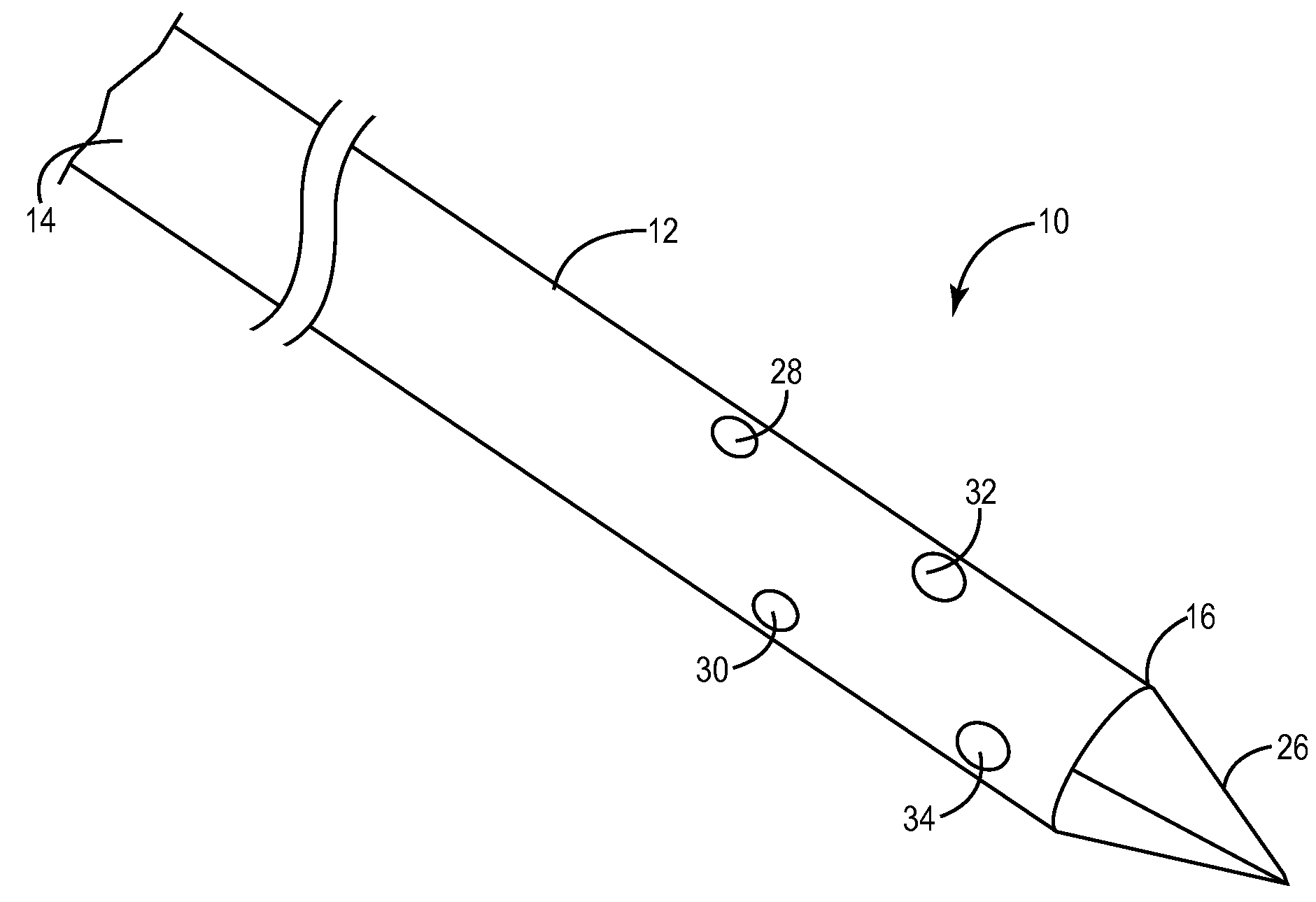

Injection needle having lateral delivery ports and method for the manufacture thereof

An injection needle comprises an elongated body having an outer surface and an inner surface defining a longitudinal channel through the tubular body. The elongated body further comprises a distal end and at least one lateral delivery port extending from the inner surface to the outer surface proximate the distal end and fluidly coupled to the longitudinal channel. A distal tip is coupled to the distal end and comprises a radio-opaque material.

Owner:MEDTRONIC INC

Thermal forming of refractory alloy surgical needles

A method of thermal forming of refractory alloy suture needles is disclosed. Needle blanks made from refractory alloys are used to form surgical needles, which are heated to a temperature above the ductile to brittle transition temperature but below the recrystallization temperature of the refractory alloy. The heated needle blanks are then mechanically formed into a surgical needle.

Owner:ETHICON INC

Method of forming a biopsy device

InactiveUS7445739B2Maintain stiffnessMaintain strengthButtonsSurgical needlesDistal portionBiopsy device

A method for forming a needle assembly is provided. A distal portion of the needle can be formed of a first material which does not interfere with MRI imaging of a tissue receiving port disposed in the distal needle portion. A proximal needle portion can be formed of a second, different material, such as a metal. The proximal needle portion can provide strength and stiffness.

Owner:DEVICOR MEDICAL PROD

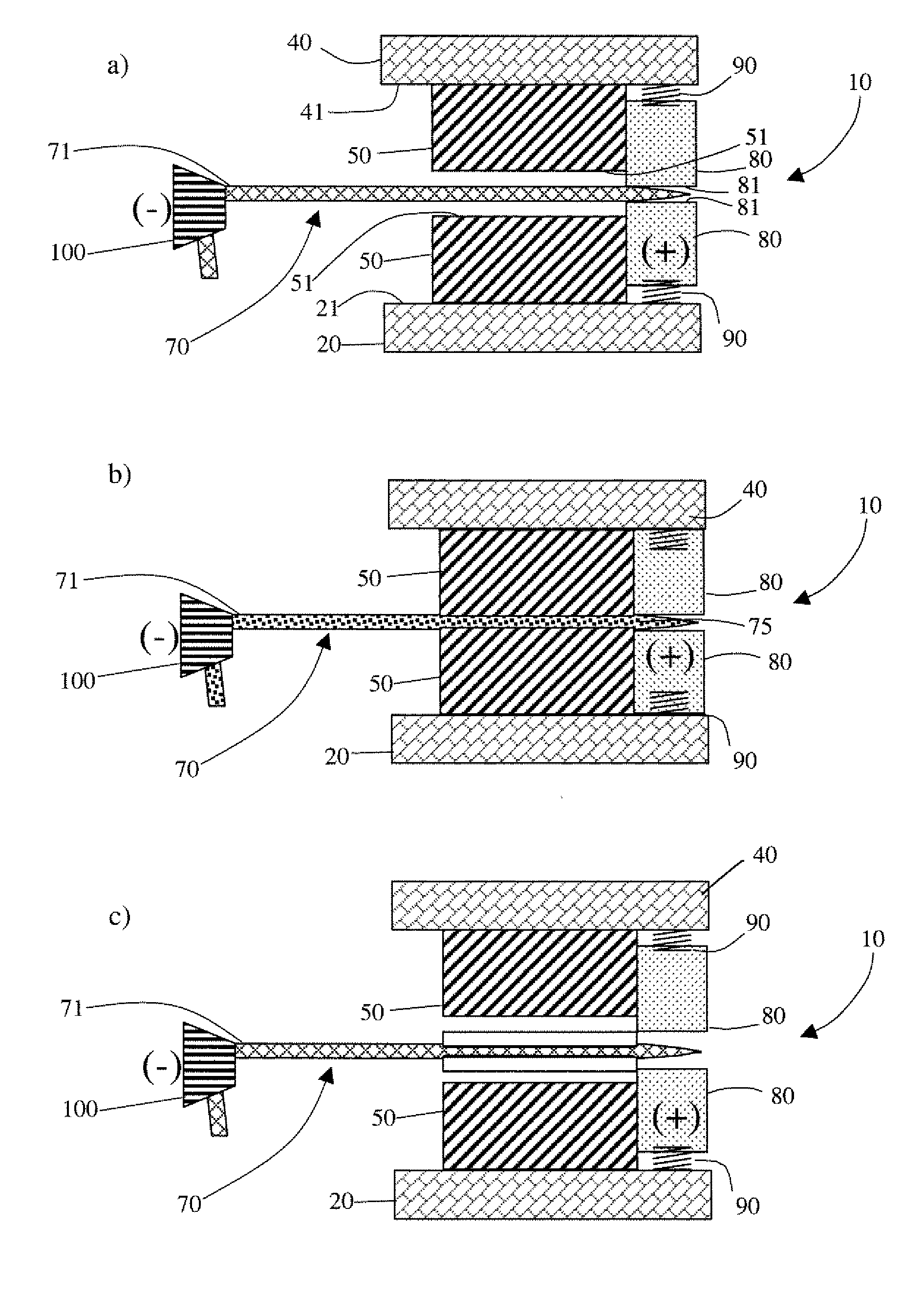

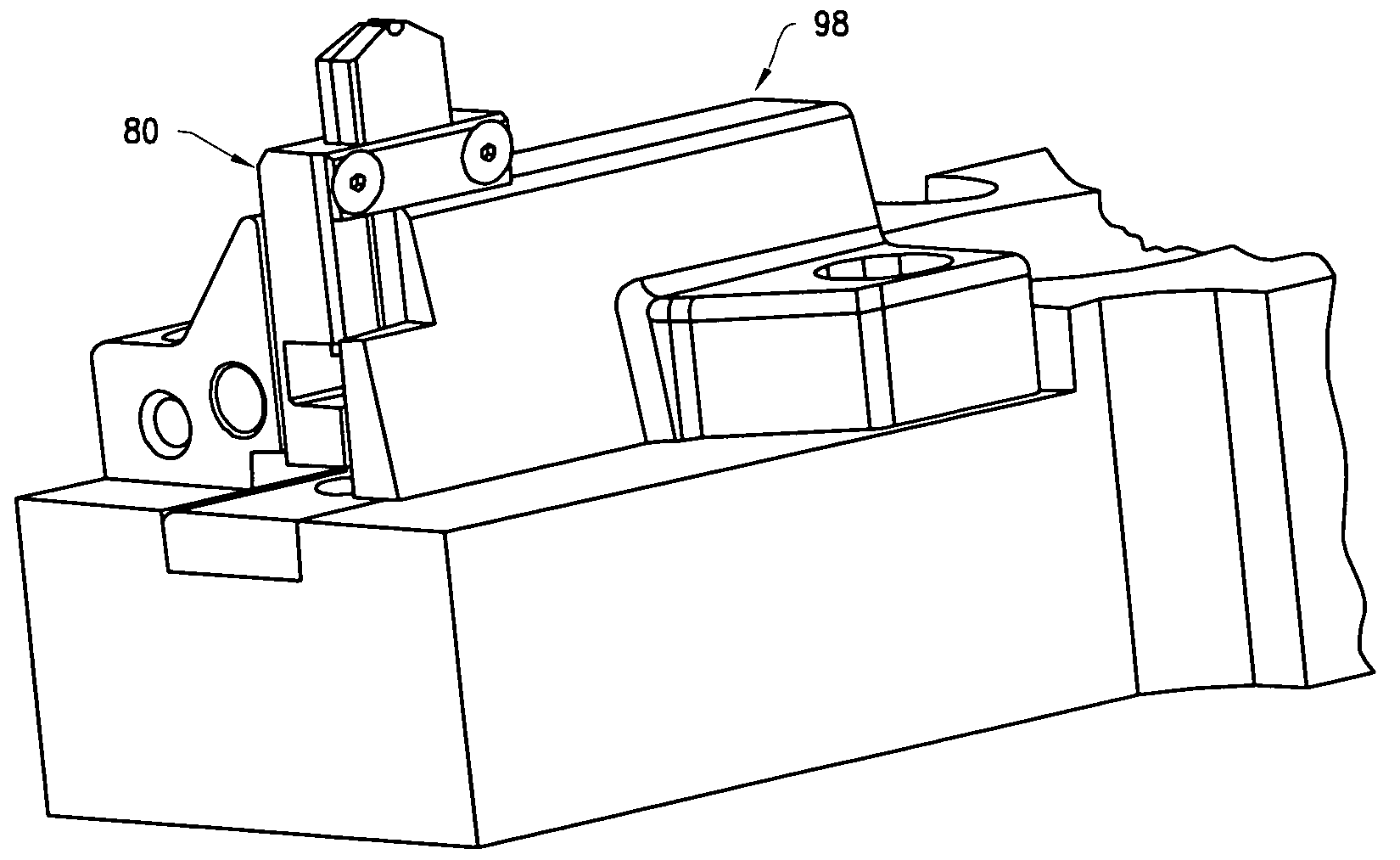

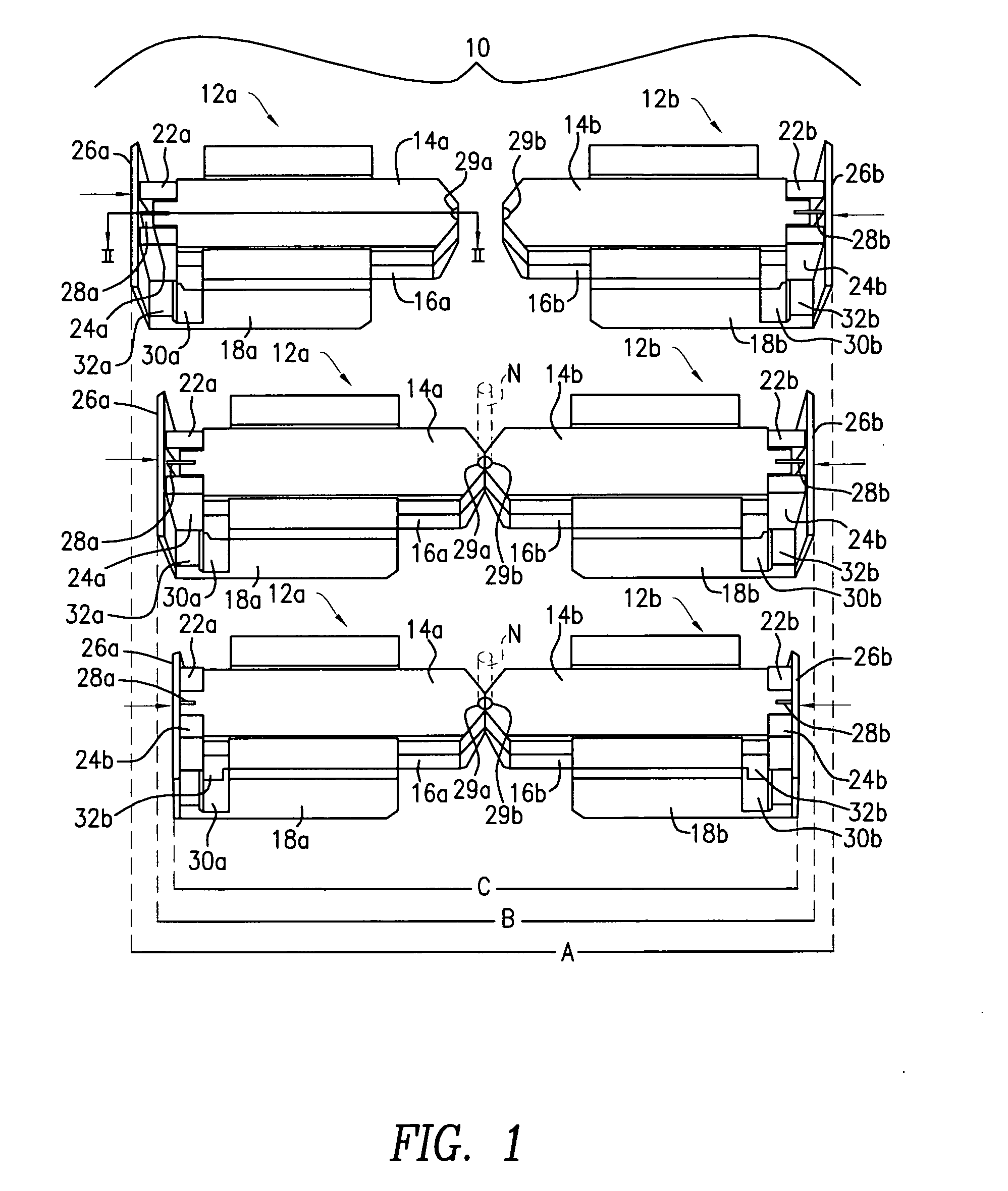

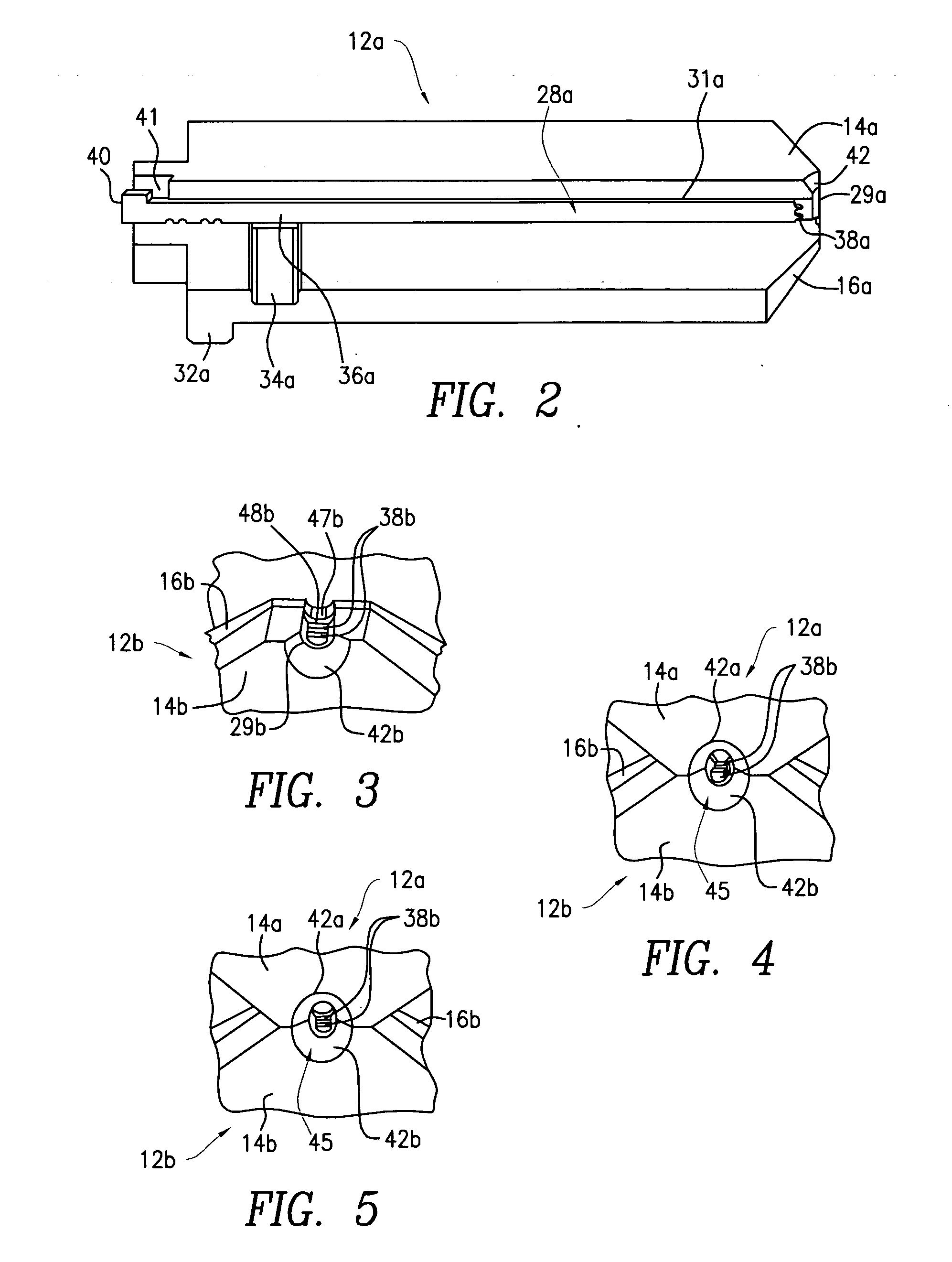

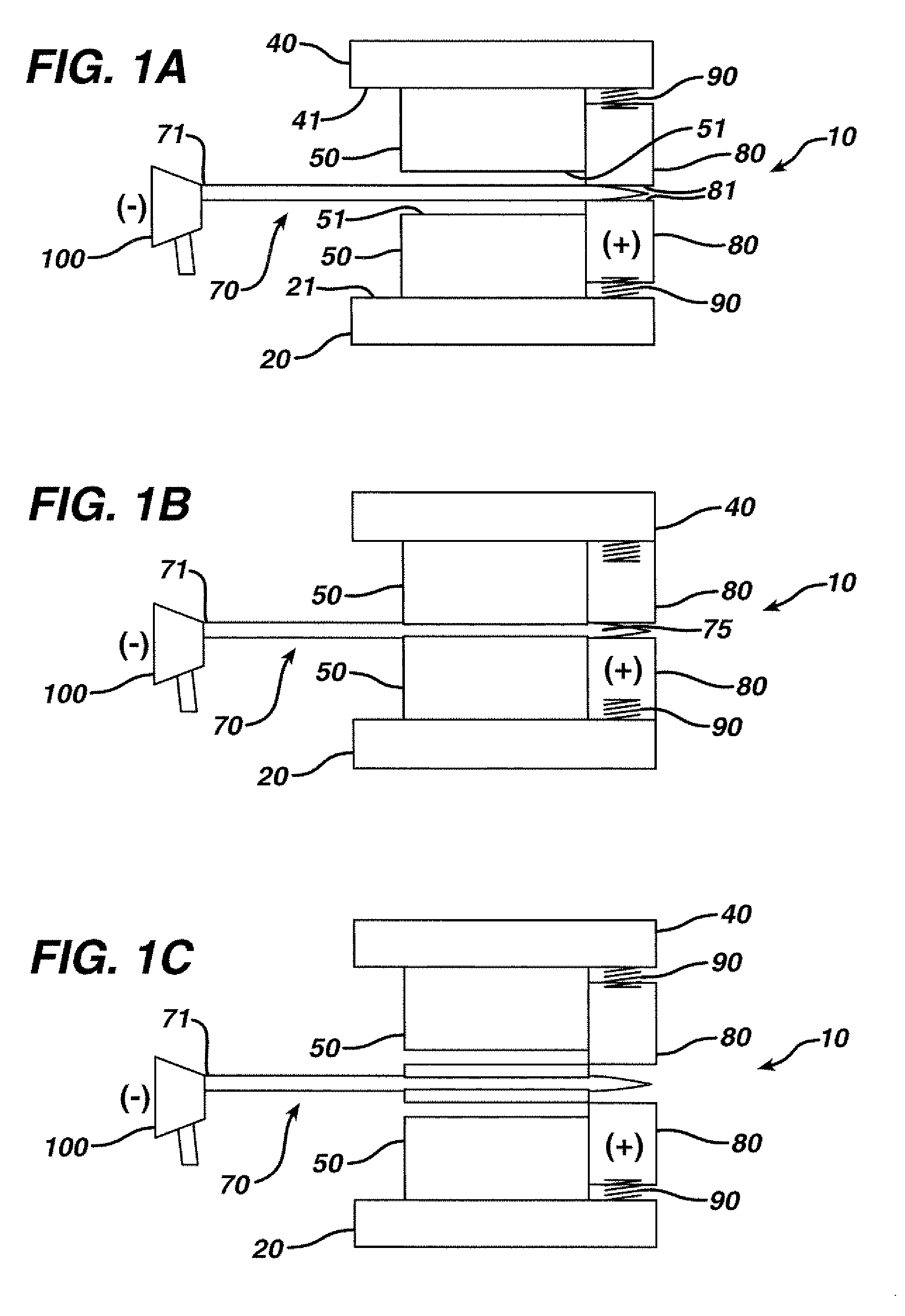

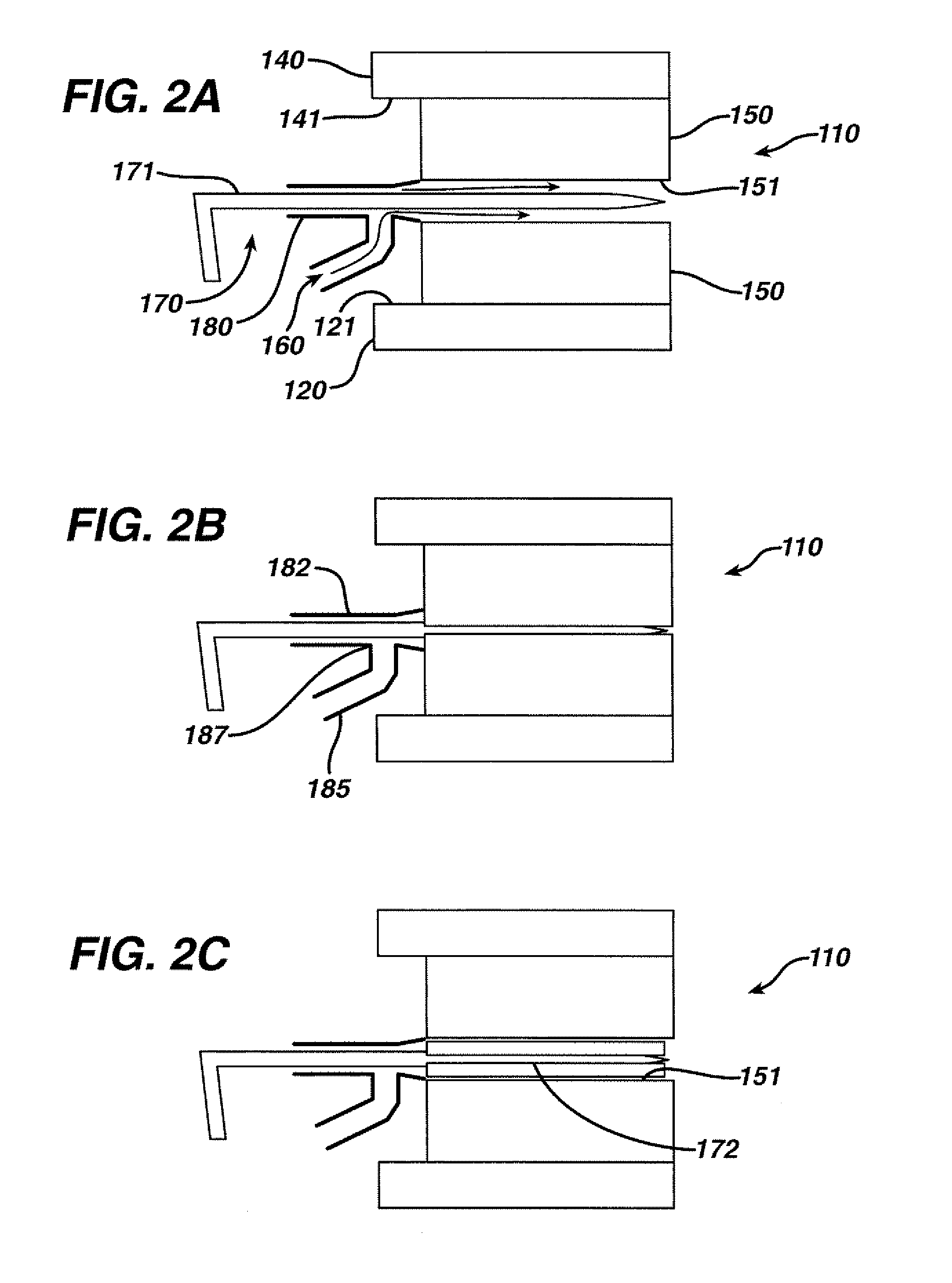

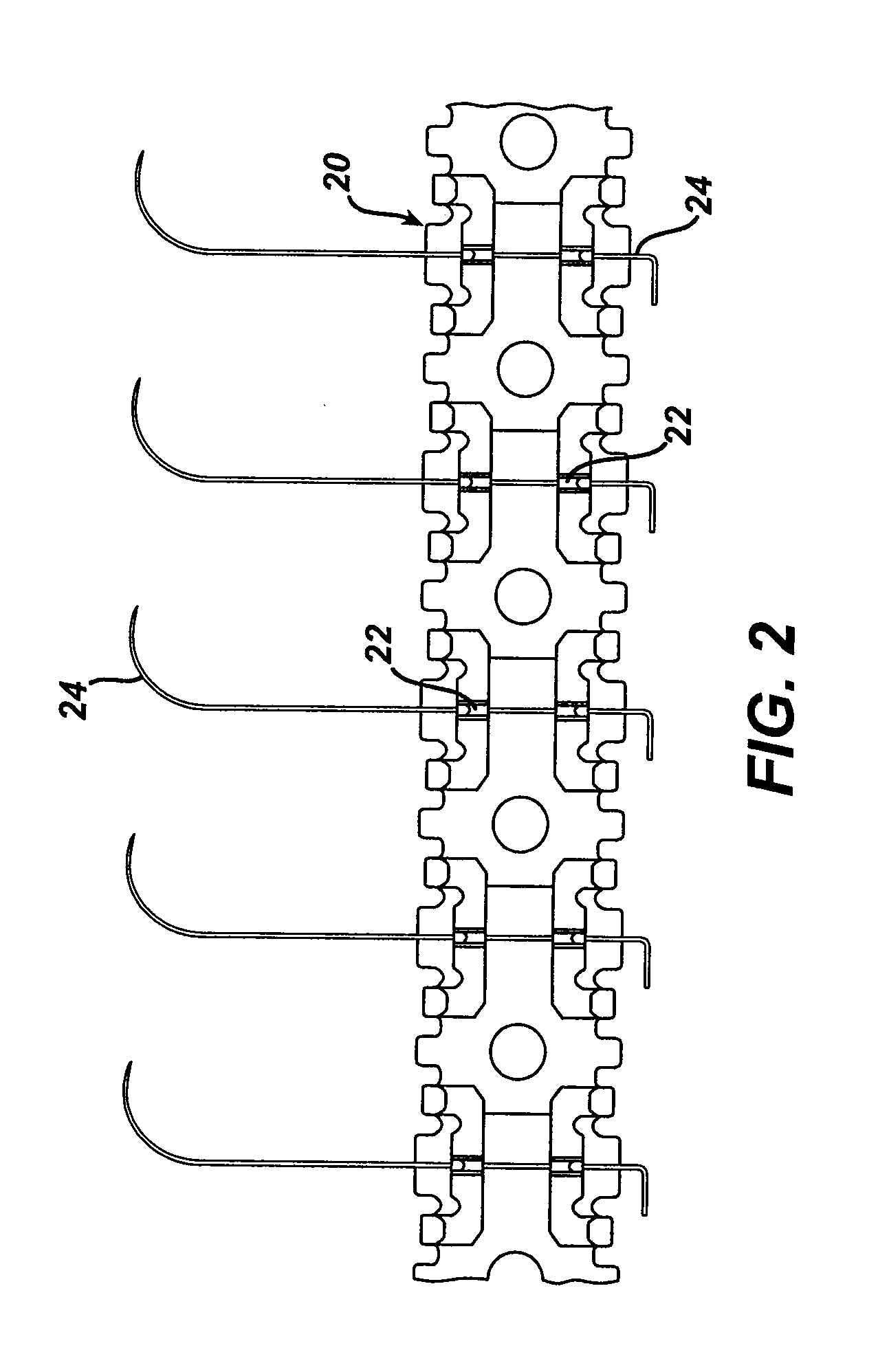

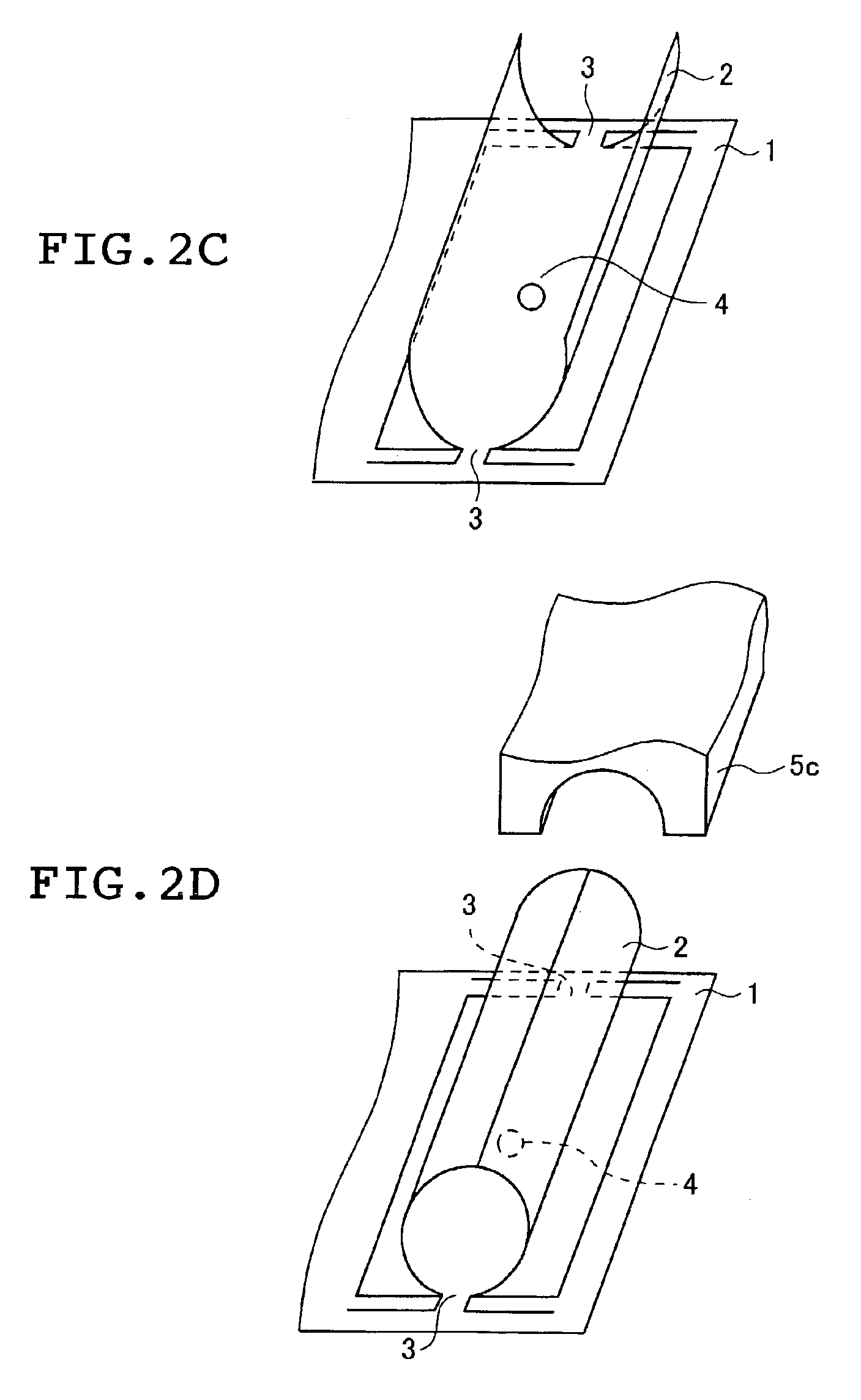

Apparatus and method for swaging needles

ActiveUS20080119876A1Overcome disadvantagesOvercome problemsSuture equipmentsSurgical needlesSuturing needleEngineering

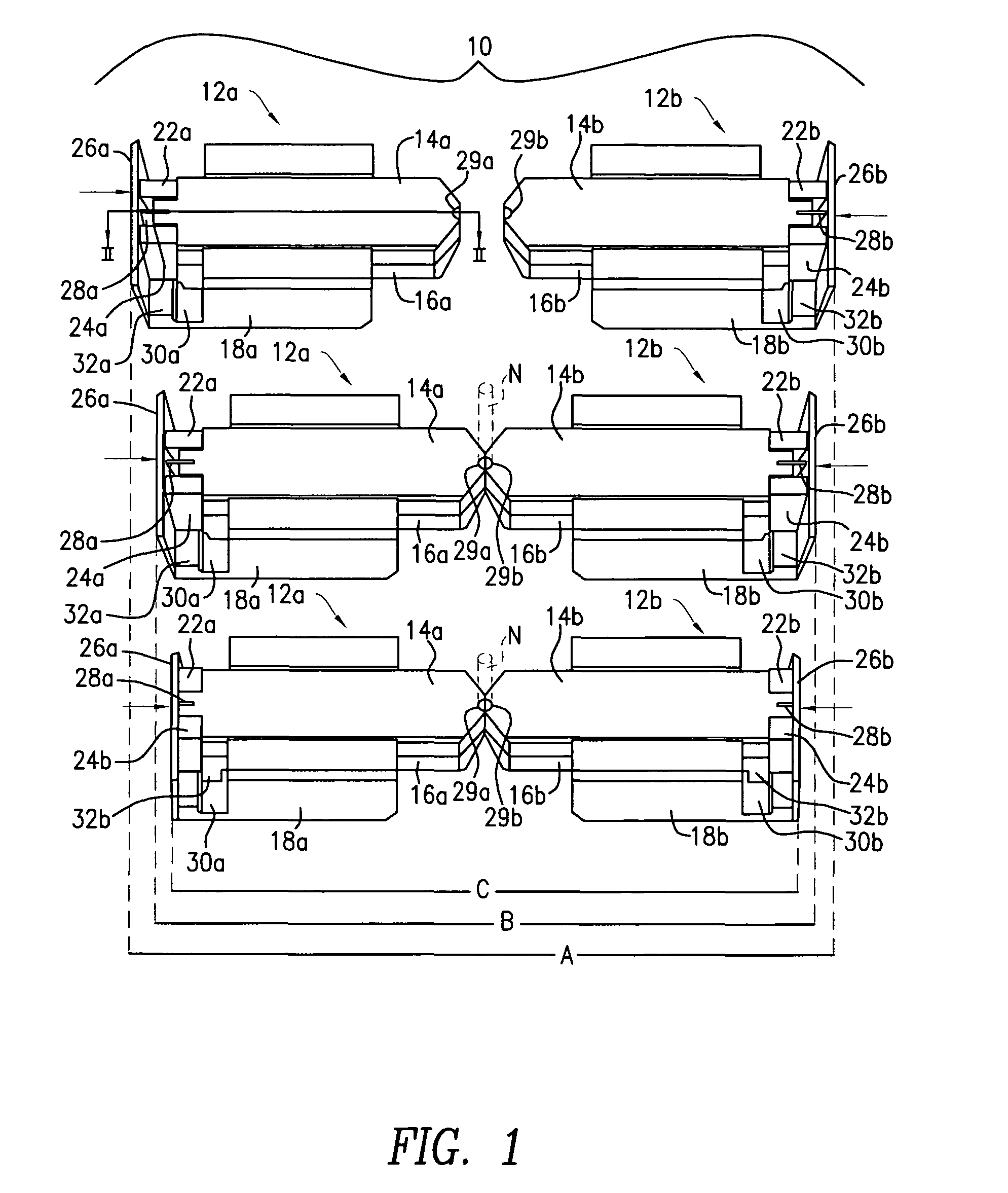

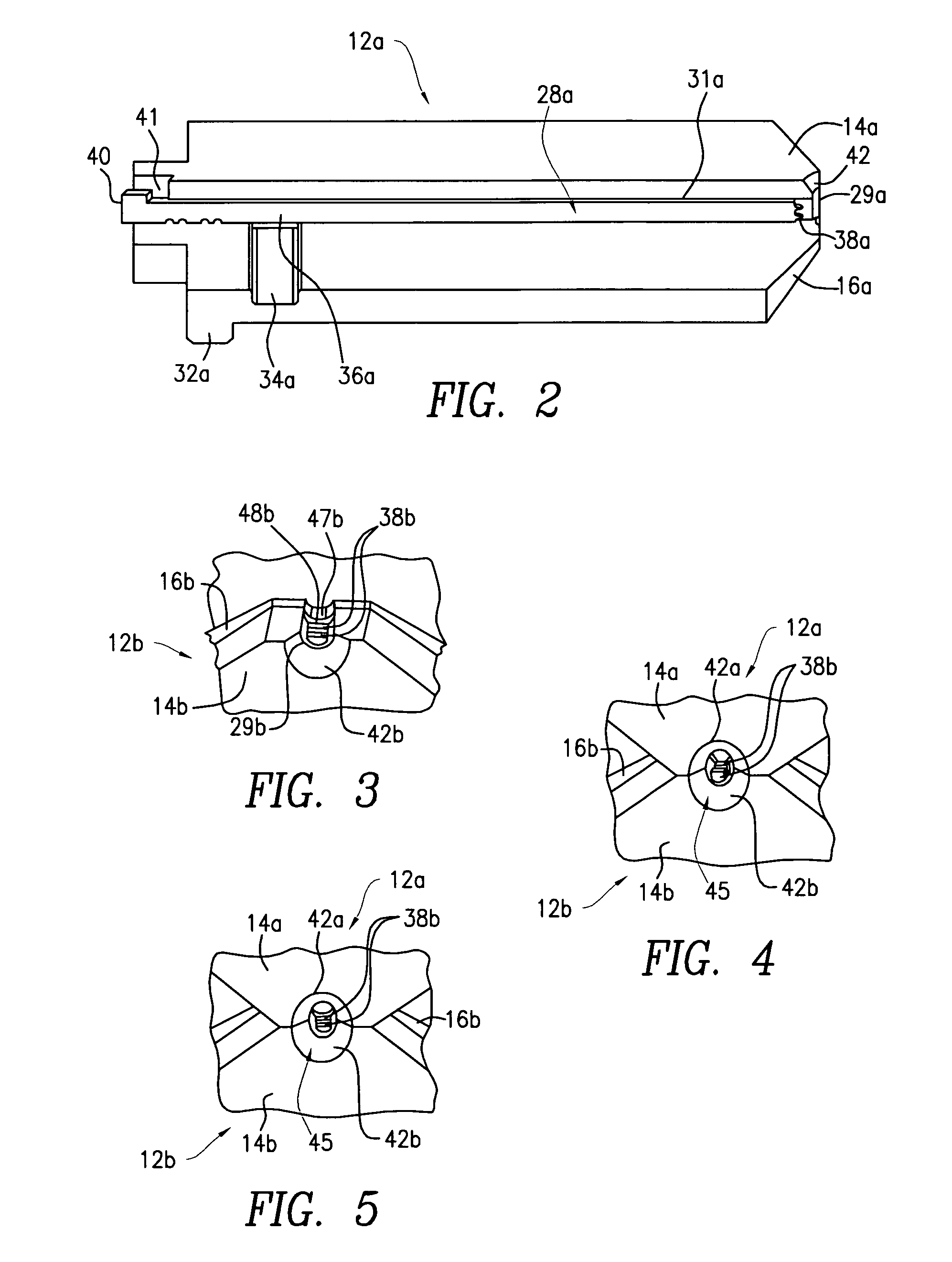

A method and apparatus for making armed sutures has a pair of opposed die assemblies that may be driven by actuating surfaces of a swaging machine to hold and swage a needle on a suture. The dies grip and confine the needle in the area of the suture receptacle. A pair of opposed swaging elements with offset stakes insert through passageways in the dies and impinge on the captured needle making a plurality of indentations in the needle barrel and gripping the suture in the suture receptacle. The indentations are offset and aligned generally in alternating peak-to-valley relationship, causing the suture receptacle and the contained suture to assume a serpentine configuration. The stakes and the resulting indentations can be dimensioned to result in a converging suture receptacle, which exhibits increasing shear force being exerted on the suture with increasing depth into the suture receptacle. The apparatus and method permit reliable suture-needle attachment over a larger range of tolerances, such that a single die setup can be used on a plurality of needle and suture materials. The resulting product exhibits a serpentine suture / needle attachment interface with reliable attachment and smooth outer dimensions.

Owner:ETHICON INC

Method of making a needle and a needle

A method is provided for forming a feature on a needle. In particular, a hollow, metal cannula has a first end, a second end and a substantially constant outer diameter extending over at least a portion of its length. An annular metal sleeve is provided that has a proximal shoulder and a distal shoulder. The length of the annular sleeve is less than the length of the constant diameter portion of the cannula. The sleeve has an inner diameter approximately equal to or less than the outer diameter of the constant diameter portion of the cannula. Two edges extend axially along the length of the sleeve, from the proximal shoulder to the distal shoulder, thereby defining a slit. The sleeve is positioned on the cannula at the constant outer diameter portion in an interference fit. An additional mechanical junction may be provided to secure the sleeve to the cannula. For example, the sleeve may be welded to the cannula using a laser welder at at least one edge of the sleeve near one of either the proximal face or the distal face. Alternatively and additionally, the sleeve may be crimped or glued to the cannula. In accord with another aspect of this invention, a needle is provided made in accord with this method.

Owner:BECTON DICKINSON & CO

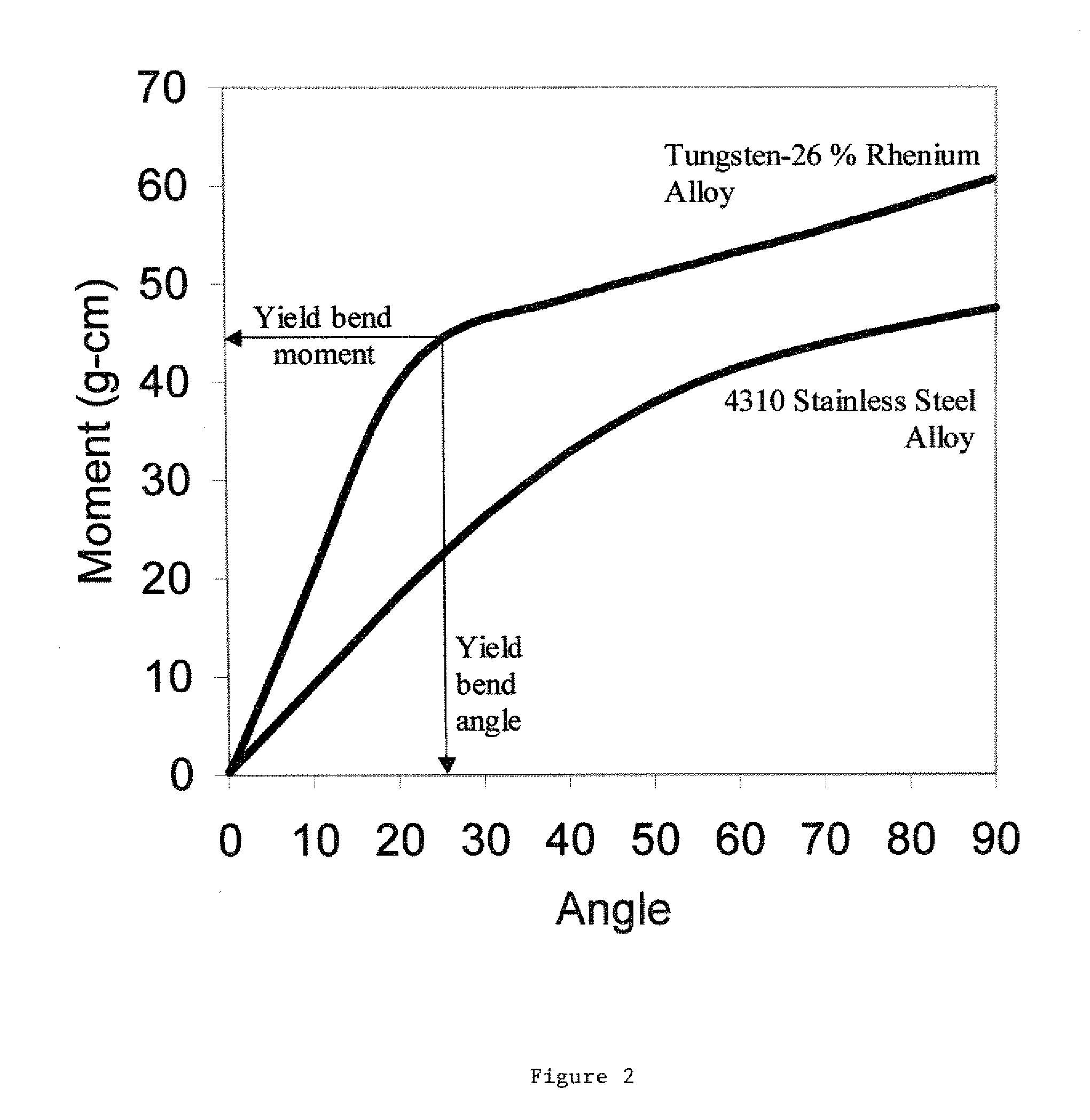

Tungsten alloy suture needles

A method for making a curved tungsten alloy suture needle comprising the step of heating tungsten alloy needle blanks or a tungsten alloy suture needle to a temperature below the recrystallization temperature of the alloy. The tungsten alloy suture needles described herein have a desirable combination of stiffness, strength, ductility, and surface color.

Owner:ETHICON INC

Thermal Forming of Refractory Alloy Surgical Needles

A method of thermal forming of refractory alloy suture needles is disclosed. Needle blanks made from refractory alloys are used to form surgical needles, which are heated to a temperature above the ductile to brittle transition temperature but below the recrystallization temperature of the refractory alloy. The heated needle blanks are then mechanically formed into a surgical needle.

Owner:CICHOCKI FR R +2

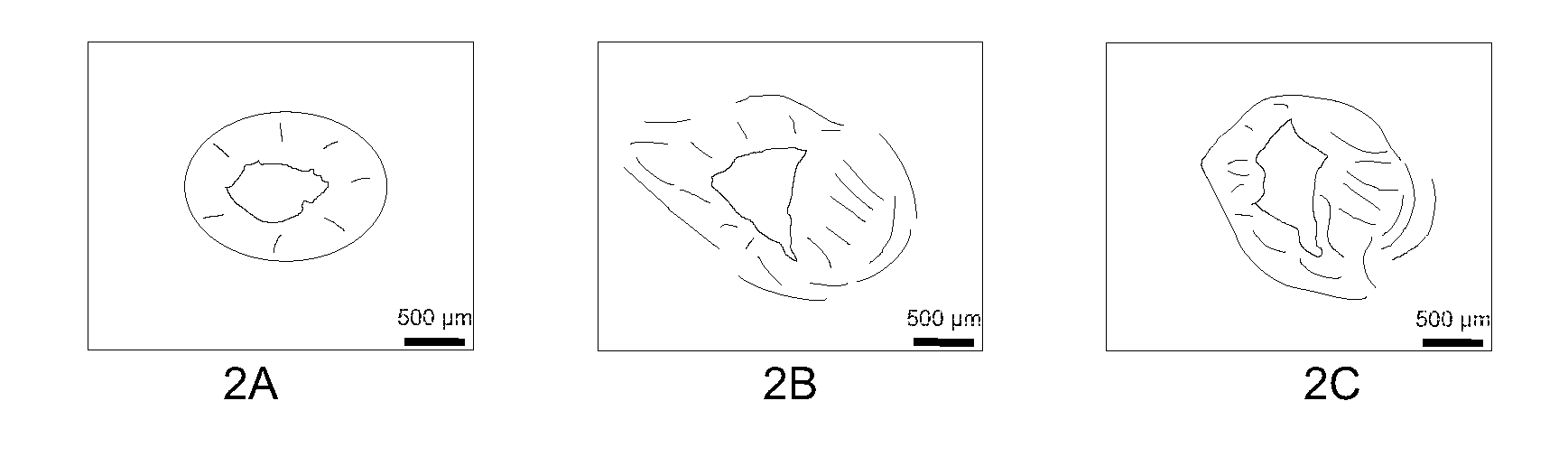

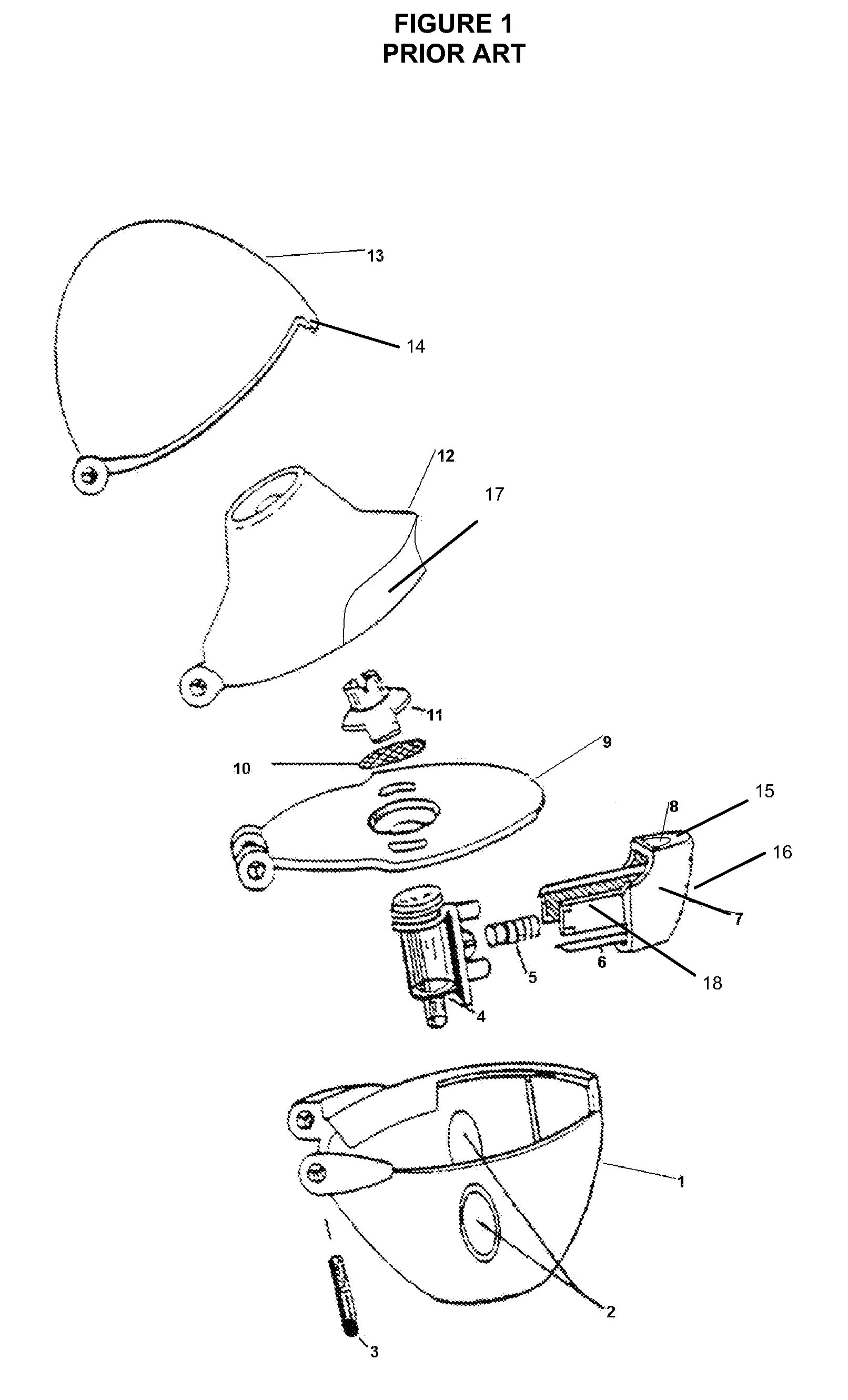

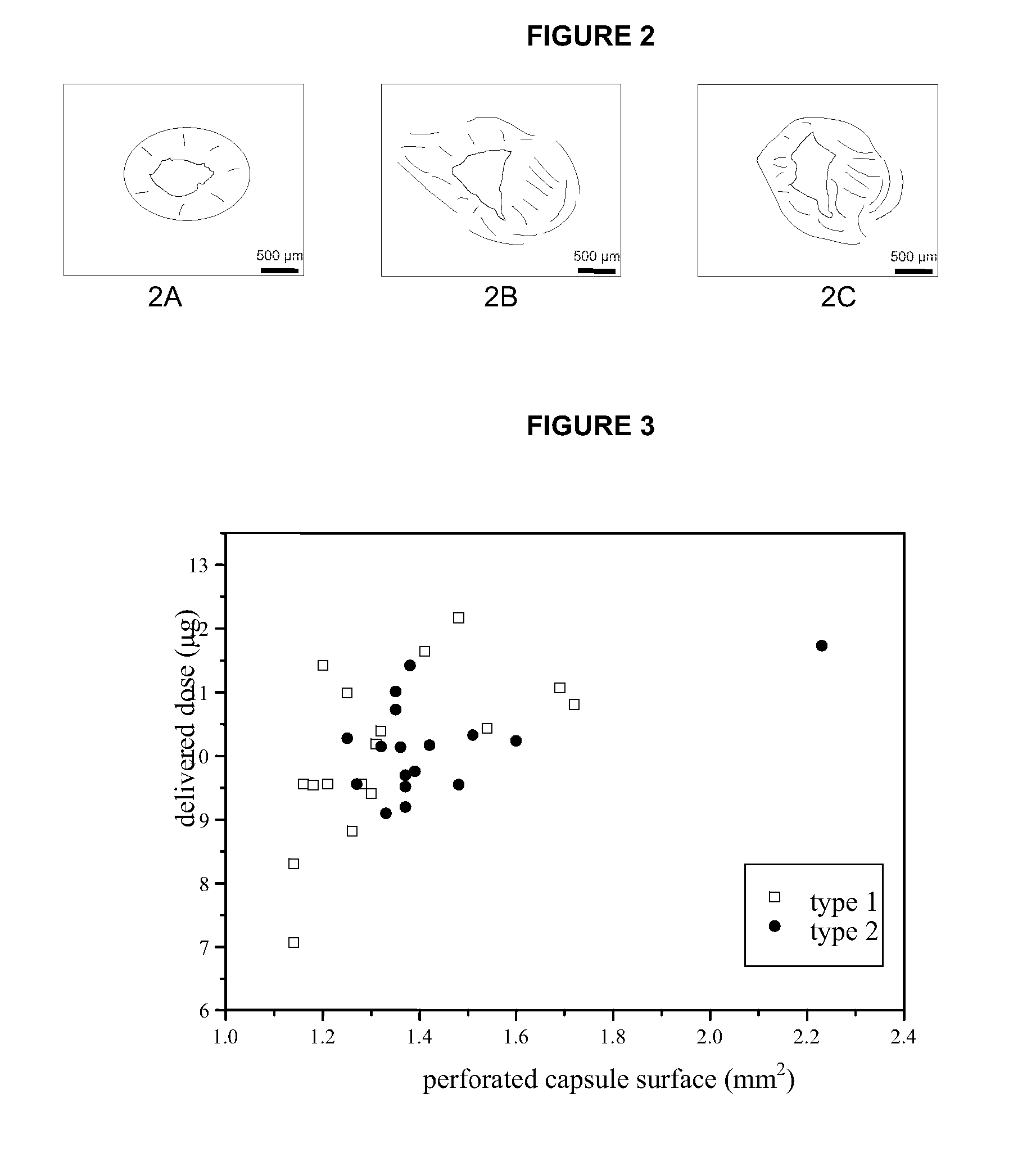

Needle for piercing a powder capsule for inhalation

ActiveUS20070107722A1Enhances expulsionReduce effortRespiratorsLiquid surface applicatorsPowder InhalerInhalation

The invention relates to a powder inhaler with at least one specially sharpened needle, to ensure the precise piercing or cutting open of capsules and hence the optimum delivery of powdered medicament compositions, medicament formulations or medicament mixtures, as well as ensuring that little effort is needed to perforate or cut open the capsule.

Owner:BOEHRINGER INGELHEIM PHARM KG

Thermal forming of refractory alloy surgical needles and fixture and apparatus

A method of thermal forming of refractory alloy suture needles is disclosed. Needle blanks made from refractory alloys are used to form surgical needles, which are heated to a temperature above the ductile to brittle transition temperature but below the recrystallization temperature of the refractory alloy. The heated needle blanks are then mechanically formed into a surgical needle. A Fixture and an apparatus for forming refractory alloy surgical needles using this method are also disclosed.

Owner:ETHICON INC

Method of making a needle and a needle

A method is provided for forming a feature on a needle. In particular, a hollow, metal cannula has a first end, a second end and a substantially constant outer diameter extending over at least a portion of its length. An annular metal sleeve is provided that has a proximal shoulder and a distal shoulder. The length of the annular sleeve is less than the length of the constant diameter portion of the cannula. The sleeve has an inner diameter approximately equal to or less than the outer diameter of the constant diameter portion of the cannula. Two edges extend axially along the length of the sleeve, from the proximal shoulder to the distal shoulder, thereby defining a slit. The sleeve is positioned on the cannula at the constant outer diameter portion in an interference fit. An additional mechanical junction may be provided to secure the sleeve to the cannula. For example, the sleeve may be welded to the cannula using a laser welder at at least one edge of the sleeve near one of either the proximal face or the distal face. Alternatively and additionally, the sleeve may be crimped or glued to the cannula. In accord with another aspect of this invention, a needle is provided made in accord with this method.

Owner:BECTON DICKINSON & CO

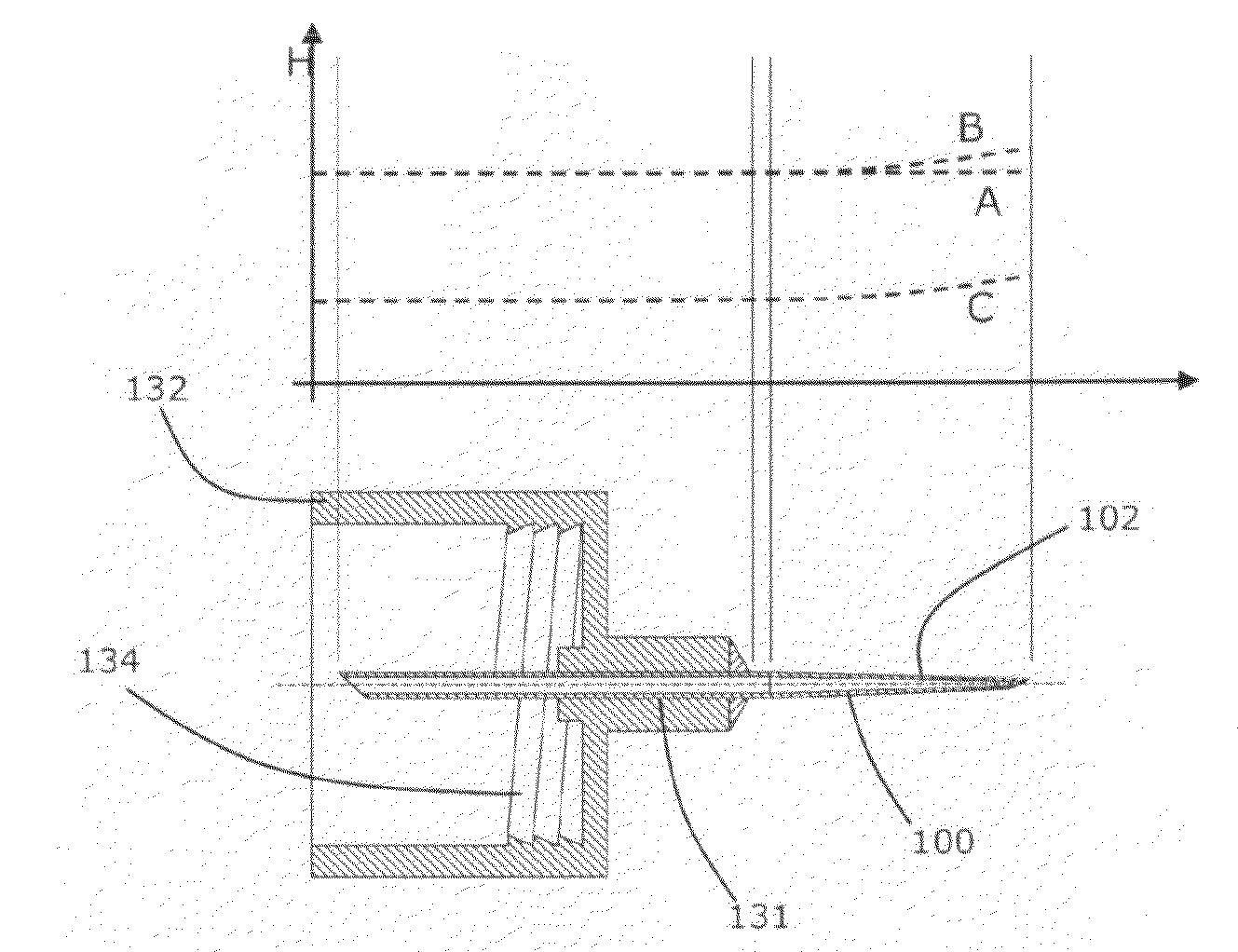

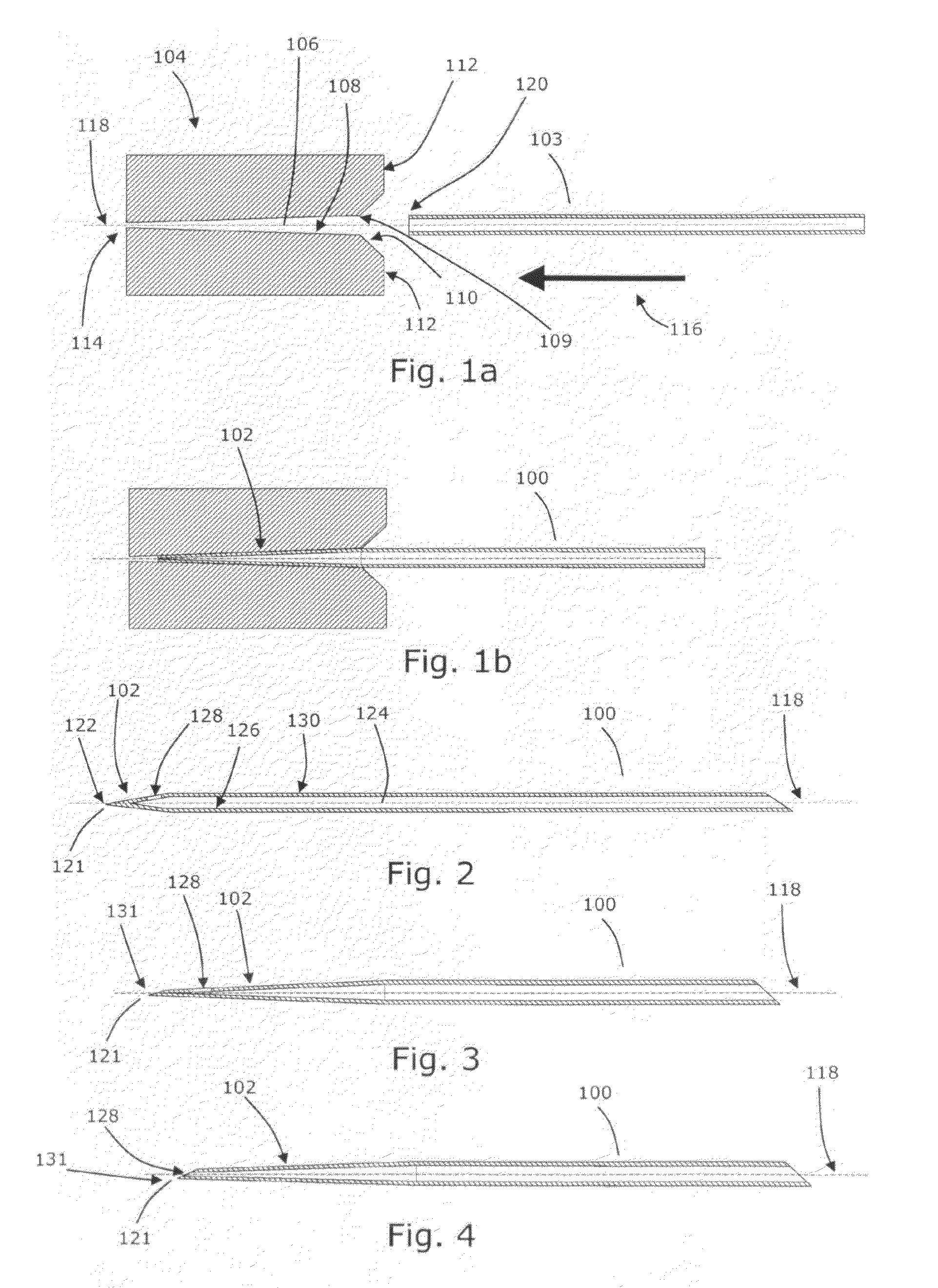

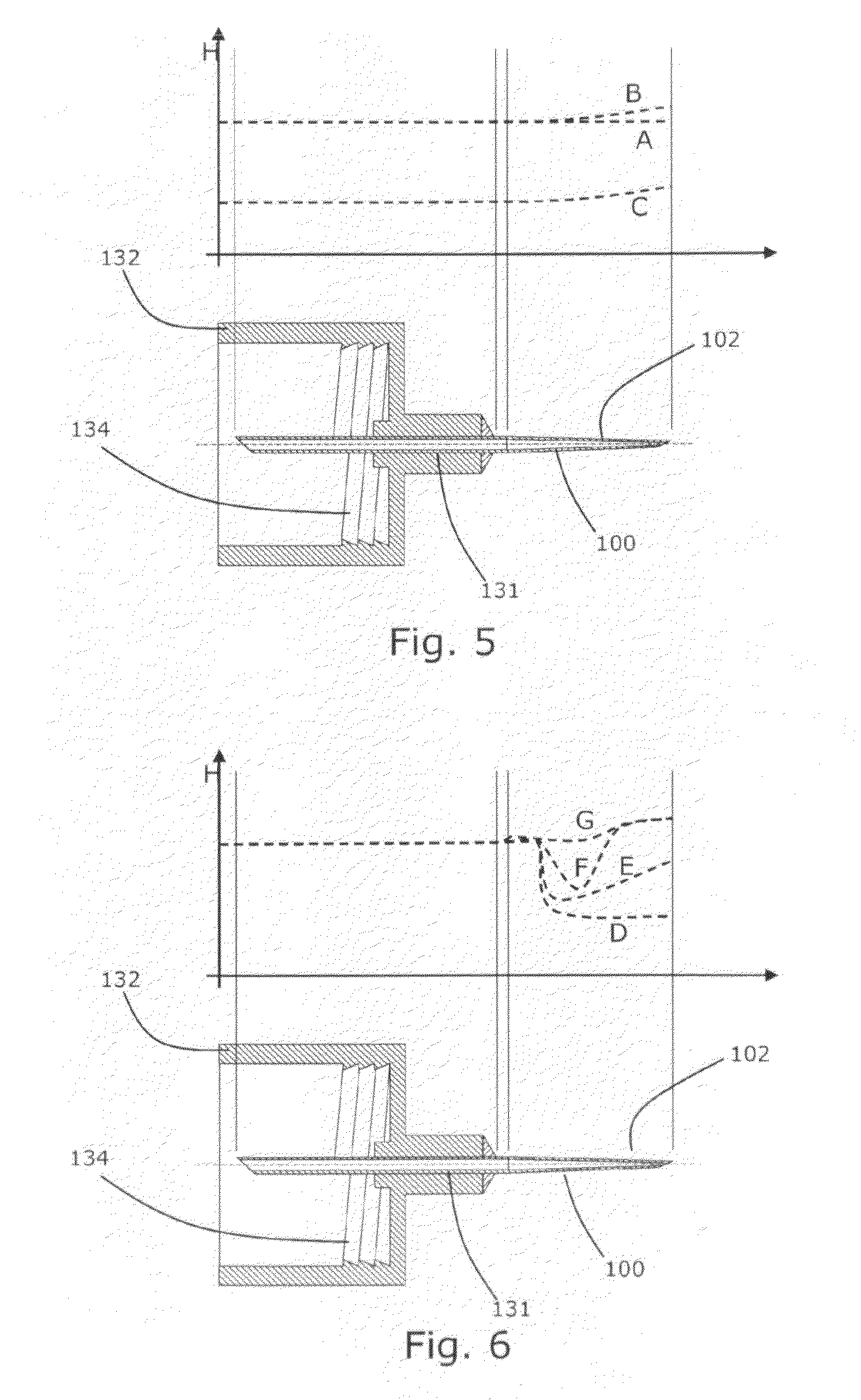

Cannula For An Injection Device, The Cannula Having A Tapered End, And A Method For Manufacturing the Same

InactiveUS20090163877A1Reduce partRelieve pressureInfusion syringesInfusion needlesBiological bodyHardness

A cannula (100) for an injection device, the cannula defining a tapered end part termination (102) in a distal end for insertion into the tissue of a living being, wherein the hardness of the cannula decreases in the direction of the distal end. A tool (104) for providing a tapered portion of a cannula, the tool defining a tapered cavity (106). A method of manufacturing a cannula defining a tapered end part, by forcing a distal end of an tubular element into a tapered cavity of a tool.

Owner:NOVO NORDISK AS

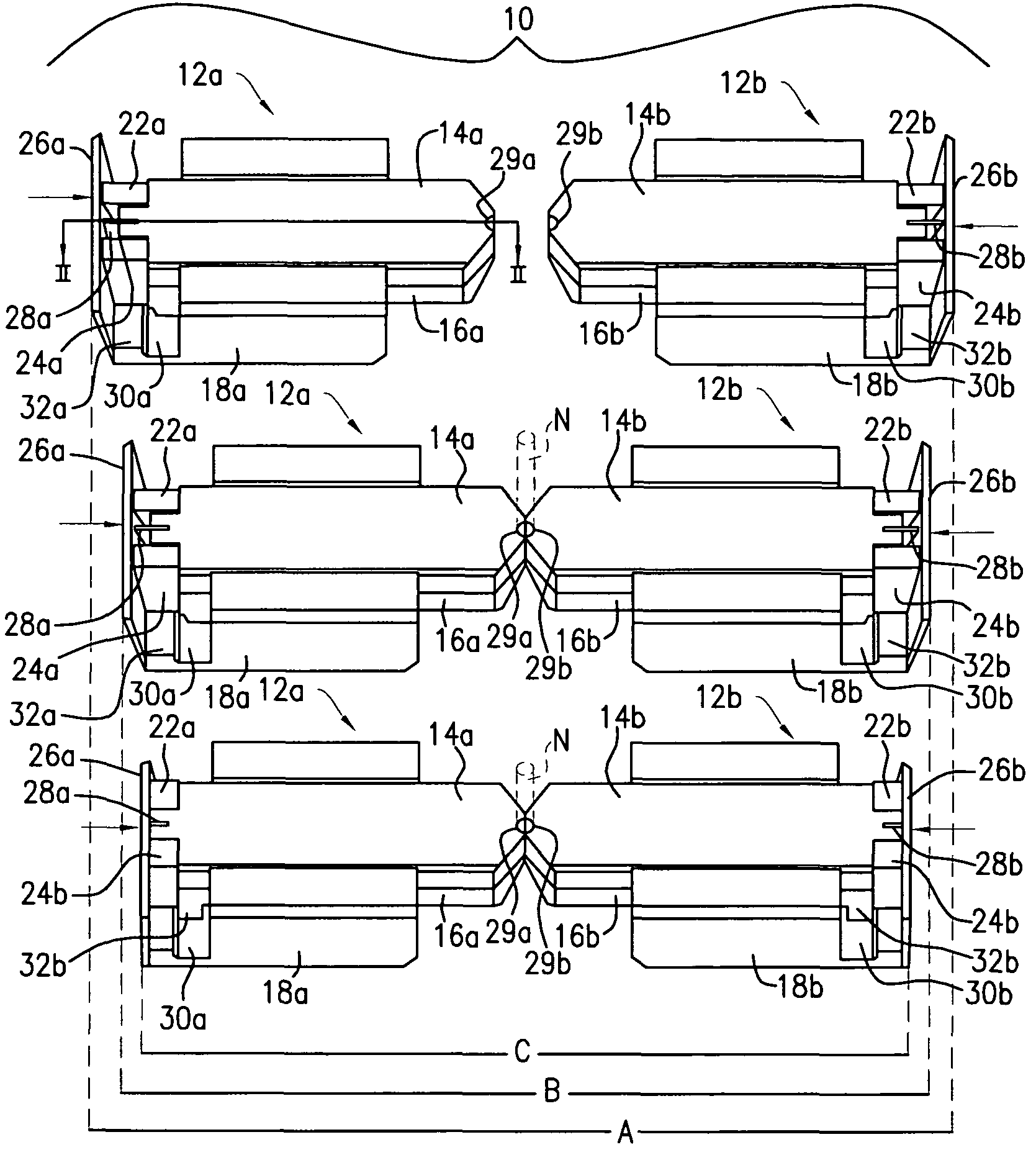

Apparatus and method for swaging needles

A method and apparatus for making armed sutures has a pair of opposed die assemblies that may be driven by actuating surfaces of a swaging machine to hold and swage a needle on a suture. The dies grip and confine the needle in the area of the suture receptacle. A pair of opposed swaging elements with offset stakes insert through passageways in the dies and impinge on the captured needle making a plurality of indentations in the needle barrel and gripping the suture in the suture receptacle. The indentations are offset and aligned generally in alternating peak-to-valley relationship, causing the suture receptacle and the contained suture to assume a serpentine configuration. The stakes and the resulting indentations can be dimensioned to result in a converging suture receptacle, which exhibits increasing shear force being exerted on the suture with increasing depth into the suture receptacle. The apparatus and method permit reliable suture-needle attachment over a larger range of tolerances, such that a single die setup can be used on a plurality of needle and suture materials. The resulting product exhibits a serpentine suture / needle attachment interface with reliable attachment and smooth outer dimensions.

Owner:ETHICON INC

Method of forming a biopsy device

InactiveUS20050212175A1Maintaining stiffness characteristicMaintain strengthButtonsSurgical needlesDistal portionBiopsy device

A method for forming a needle assembly is provided. A distal portion of the needle can be formed of a first material which does not interfere with MRI imaging of a tissue receiving port disposed in the distal needle portion. A proximal needle portion can be formed of a second, different material, such as a metal. The proximal needle portion can provide strength and stiffness.

Owner:DEVICOR MEDICAL PROD

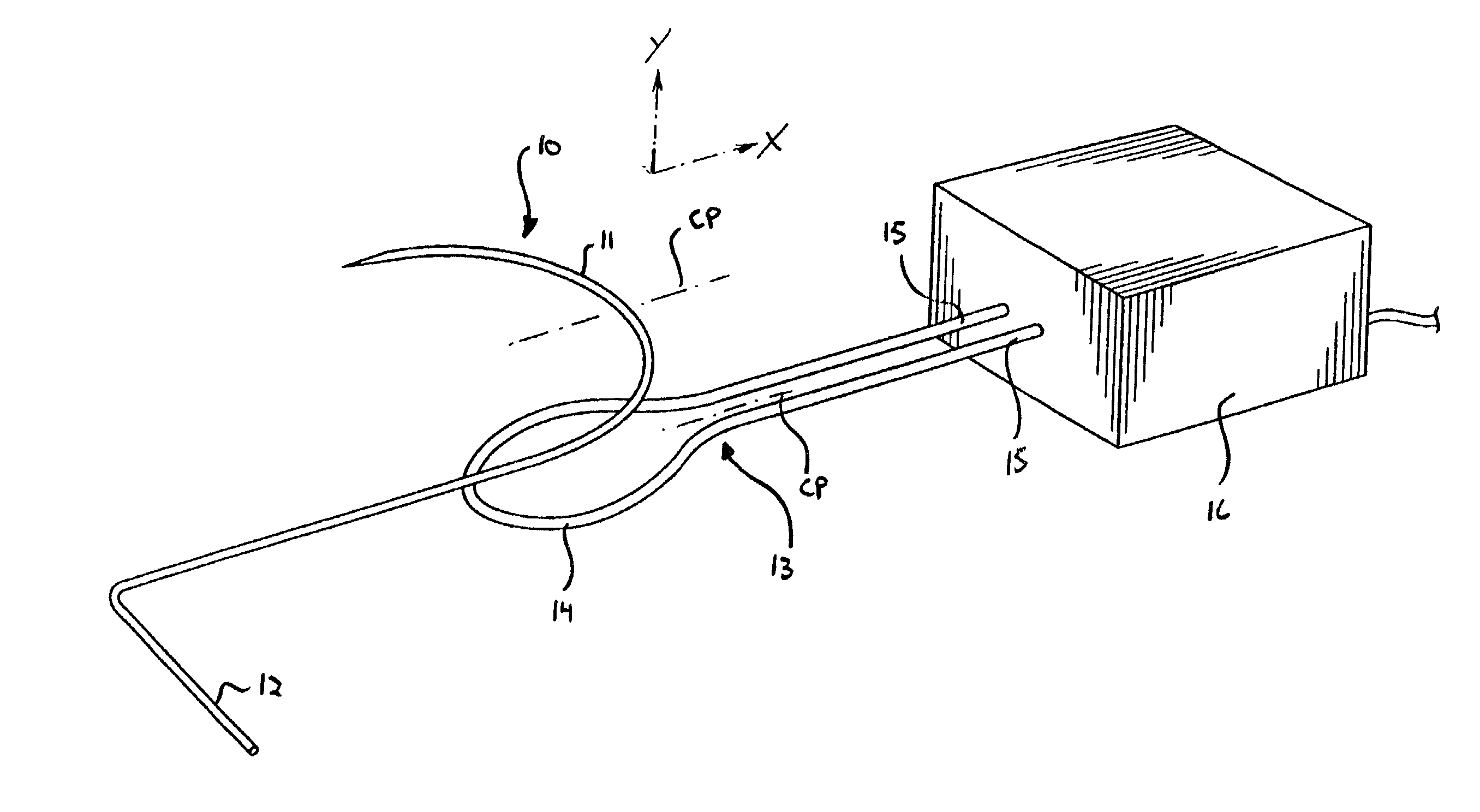

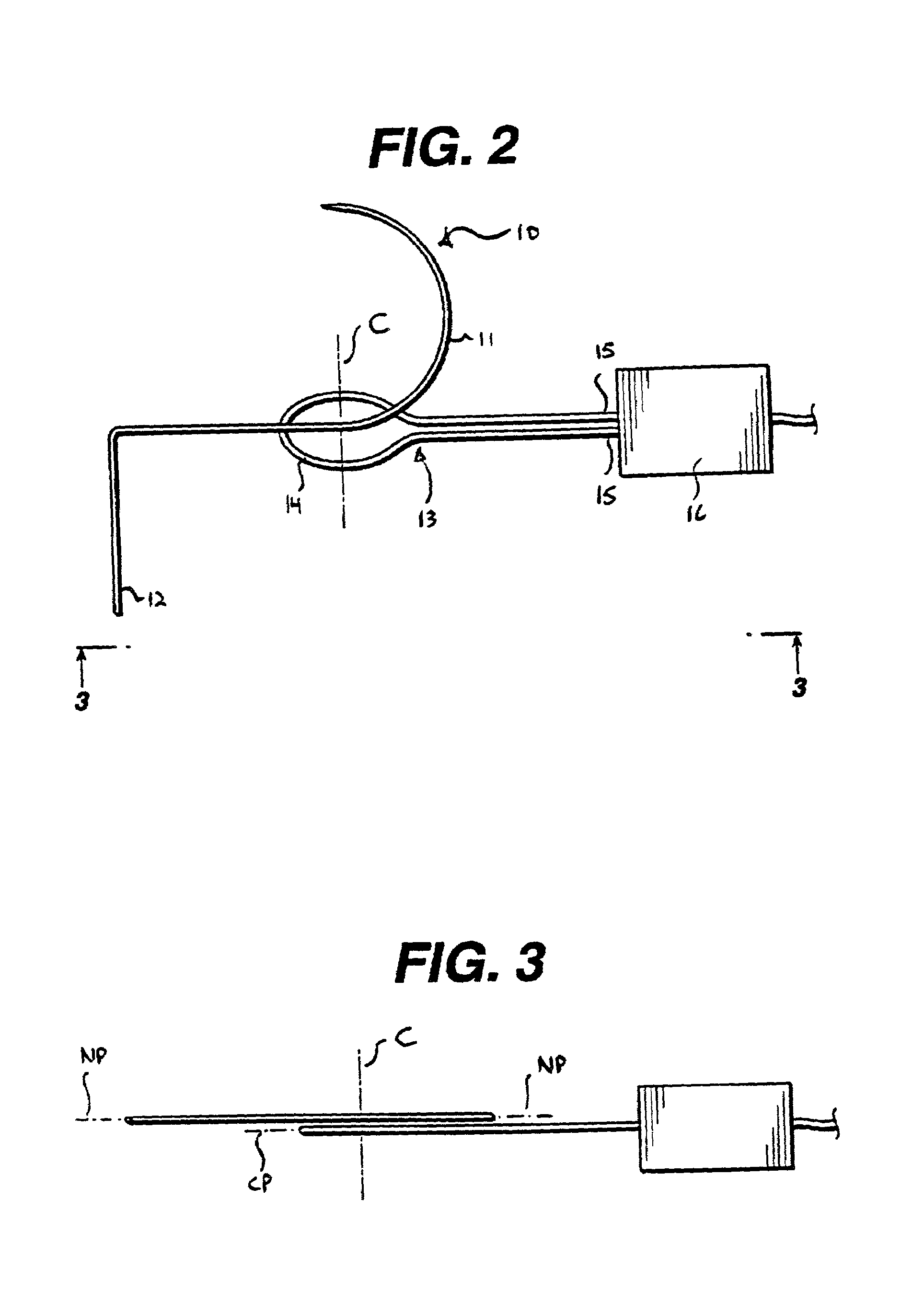

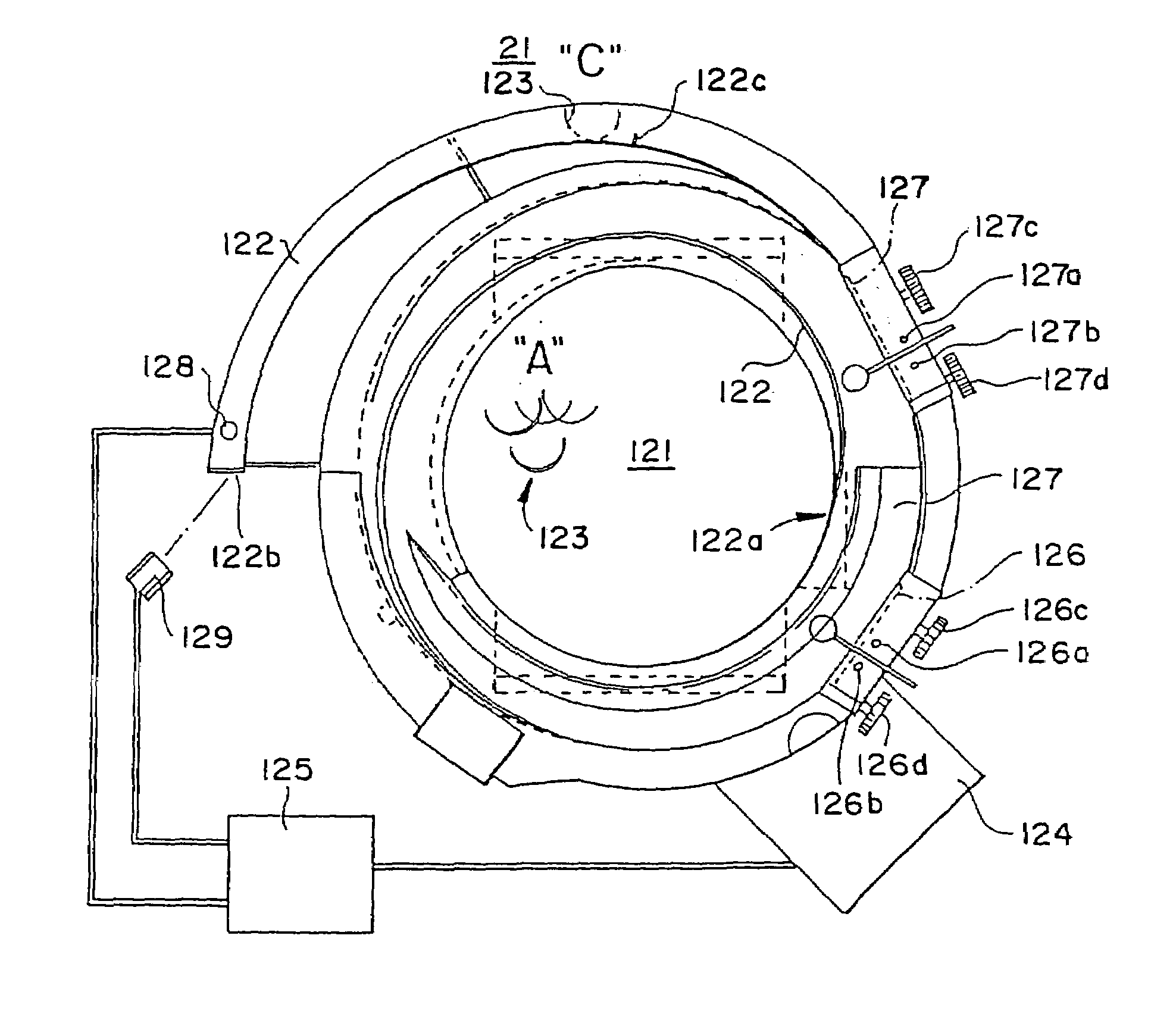

Method of selectively annealing a needle

InactiveUS7001472B2Facilitate selective hardeningPromote softeningSurgical needlesFurnace typesPower flowImproved method

An improved method of selectively annealing a needle and the needle prepared by the improved method is disclosed. A curved needle is positioned adjacent a flat electromagnetic induction coil. The curved body of the needle is positioned in a plane parallel with the coil plane of the flat induction coil. A current is delivered through the coil to selectively heat and consequently selectively anneal a portion of the needle. The improved method enables the selective annealing of curved needles, and is especially useful for the manufacture of surgical needles.

Owner:ETHICON INC

Surgical Needle Coatings and Methods

ActiveUS20110111116A1Increased durabilityEfficiently provideSurgical needlesPharmaceutical delivery mechanismImproved methodMedical device

The present invention provides improved medical devices for use in surgical procedures and methods for manufacturing improved medical devices. In some embodiments, the improved medical devices can include improved surgical needles that are capable of being repeatedly passed through tissue using minimal force. More particularly, the improved surgical needles can be manufactured with two or more different coatings that provide the surgical needles with both durability and lubricity for ease of repeated and successive passes through tissue. Improved methods for manufacturing the surgical needles and for providing and applying coatings to the surgical needles are also provided.

Owner:CILAG GMBH INT

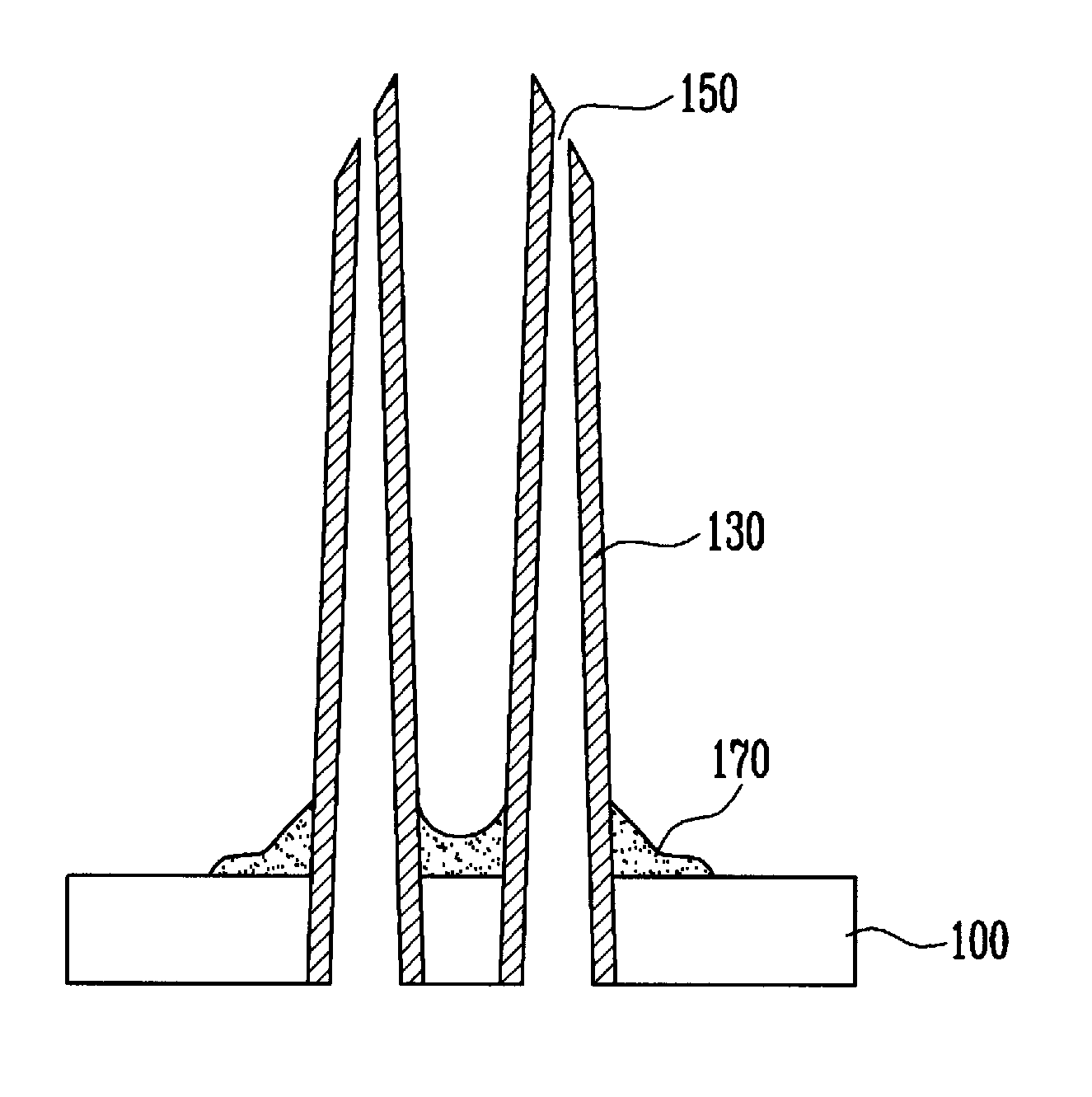

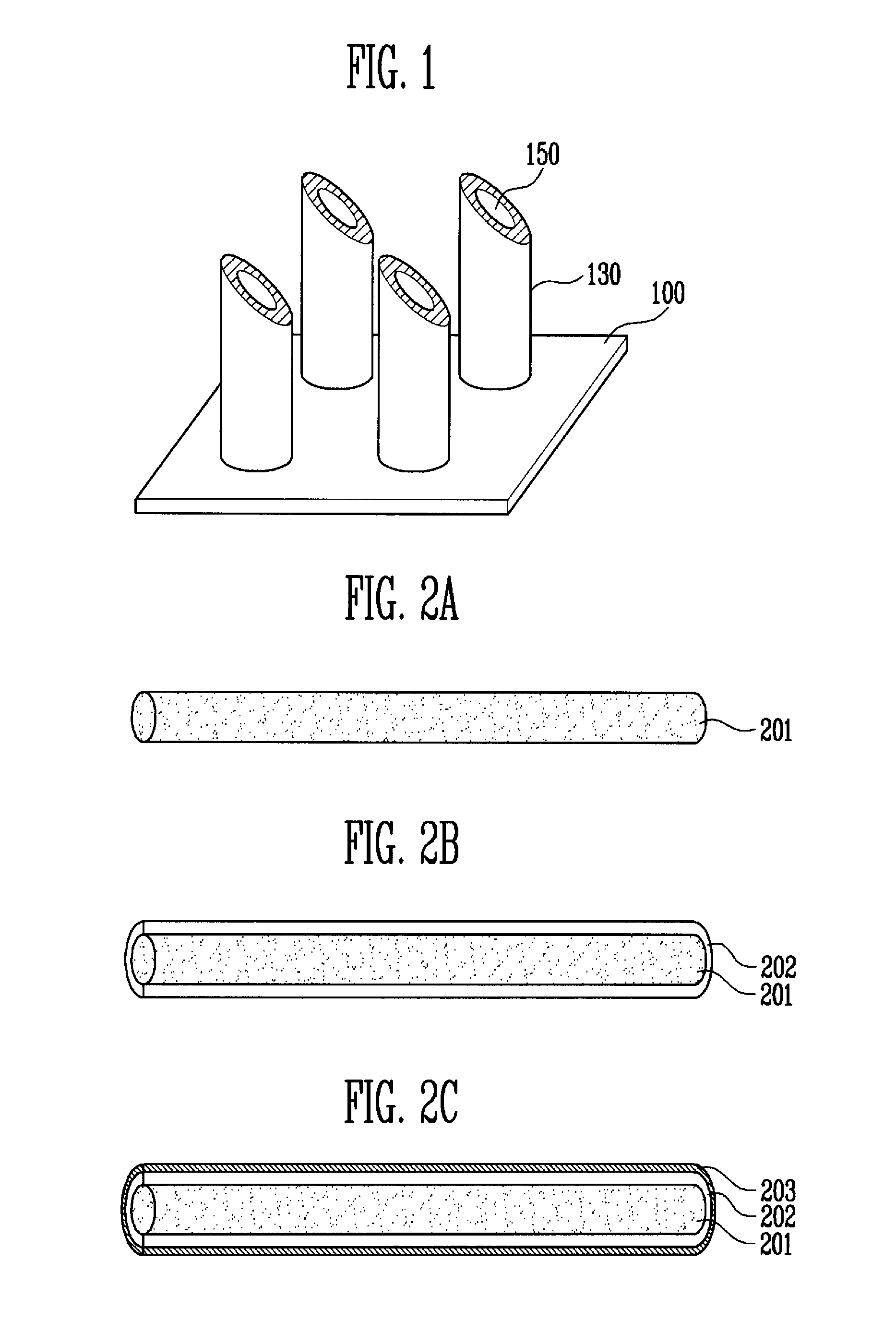

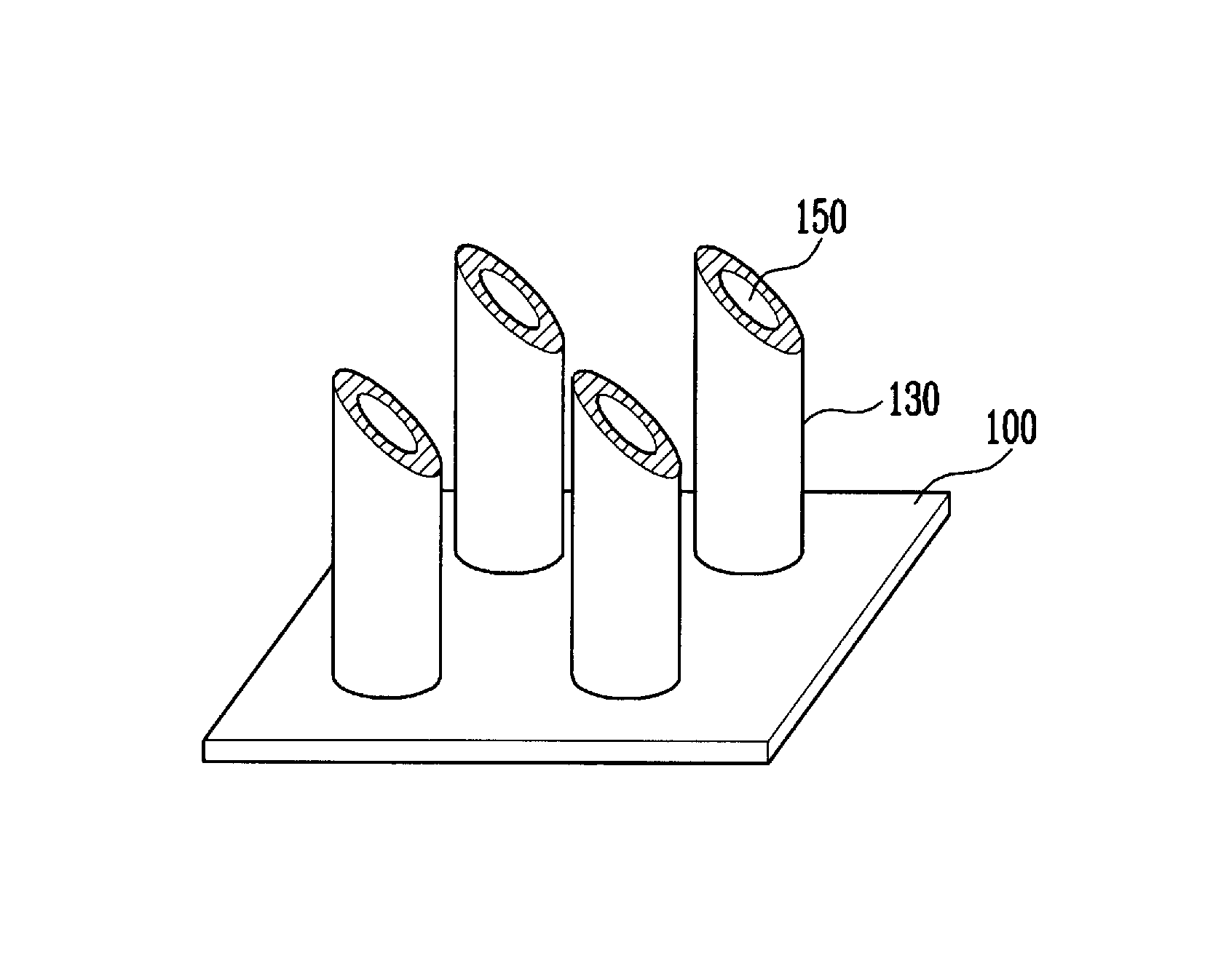

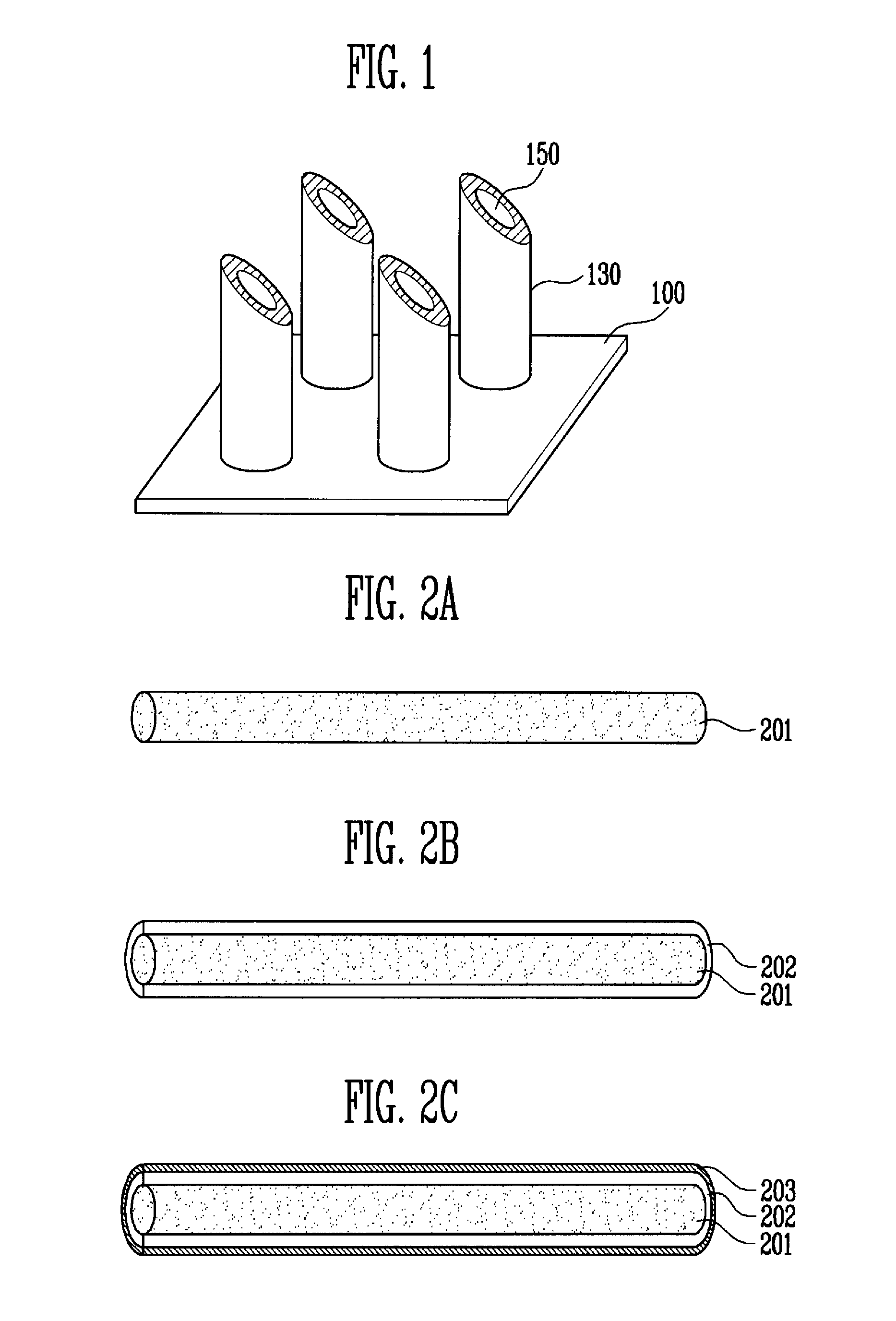

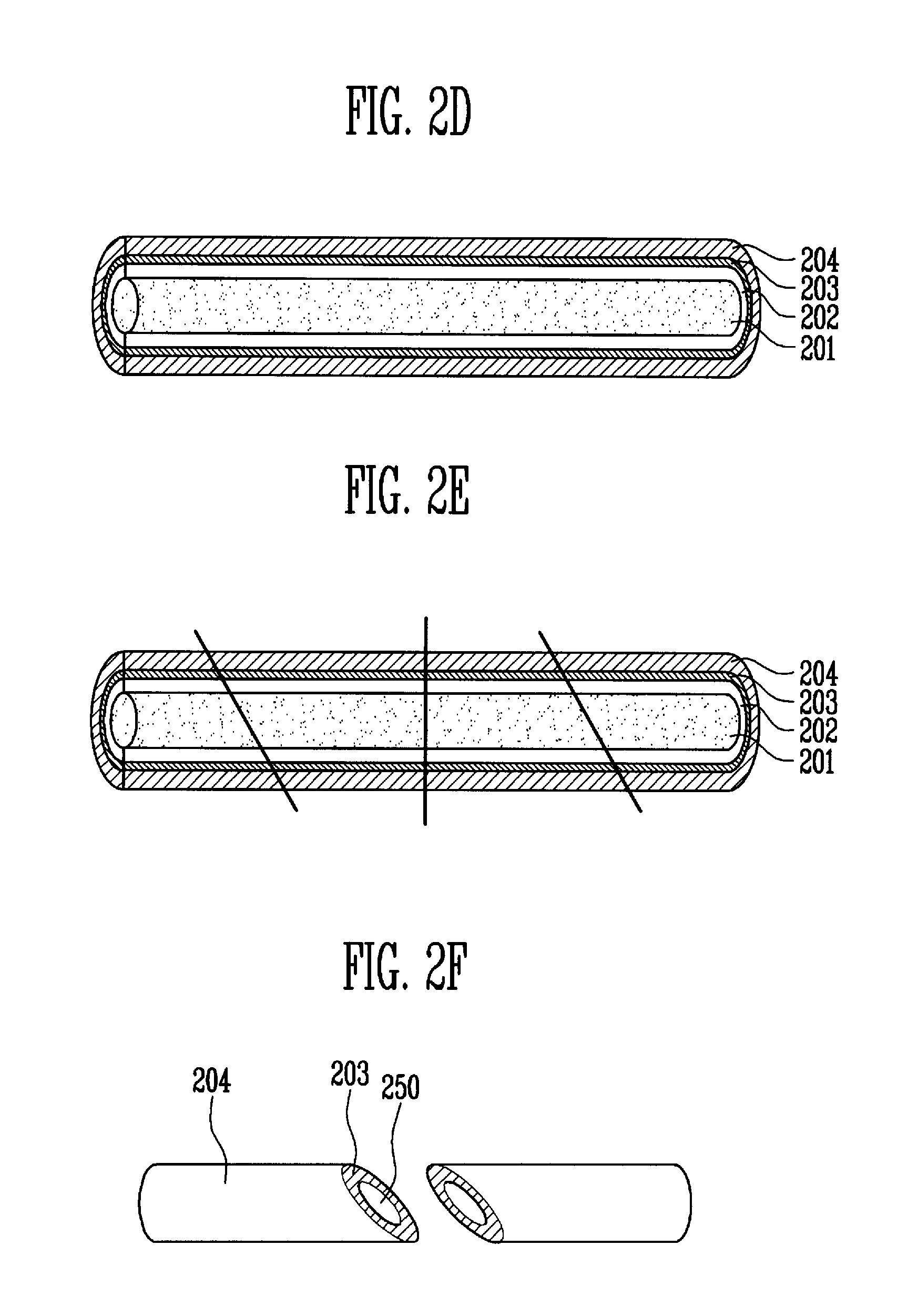

Method of manufacturing hollow microneedle structures

InactiveUS20110005669A1Uniform inner diameterSimple processGlovesPretreated surfacesHardnessMinimizing pain

Provided is a method of manufacturing a hollow microneedle structure. The method includes coating a hollow core having a predetermined section and being long in a lengthwise direction with a coating solution, and solidifying the coating solution to form a coating layer, depositing a metal seed layer on the coating layer, plating the seed metal layer with a metal to form a plated layer, cutting the hollow core having the plated layer at an inclination angle with respect to the lengthwise direction to form a surface inclination, and removing the hollow core and the coating layer to form a hollow. Thus, the hollow microneedle structure can be manufactured to have such diameter, length, hardness, and inclination angle as to minimize pain. By use of the hollow core, the microneedle structure can have vertical microneedles with a uniform inner diameter.

Owner:ELECTRONICS & TELECOMM RES INST

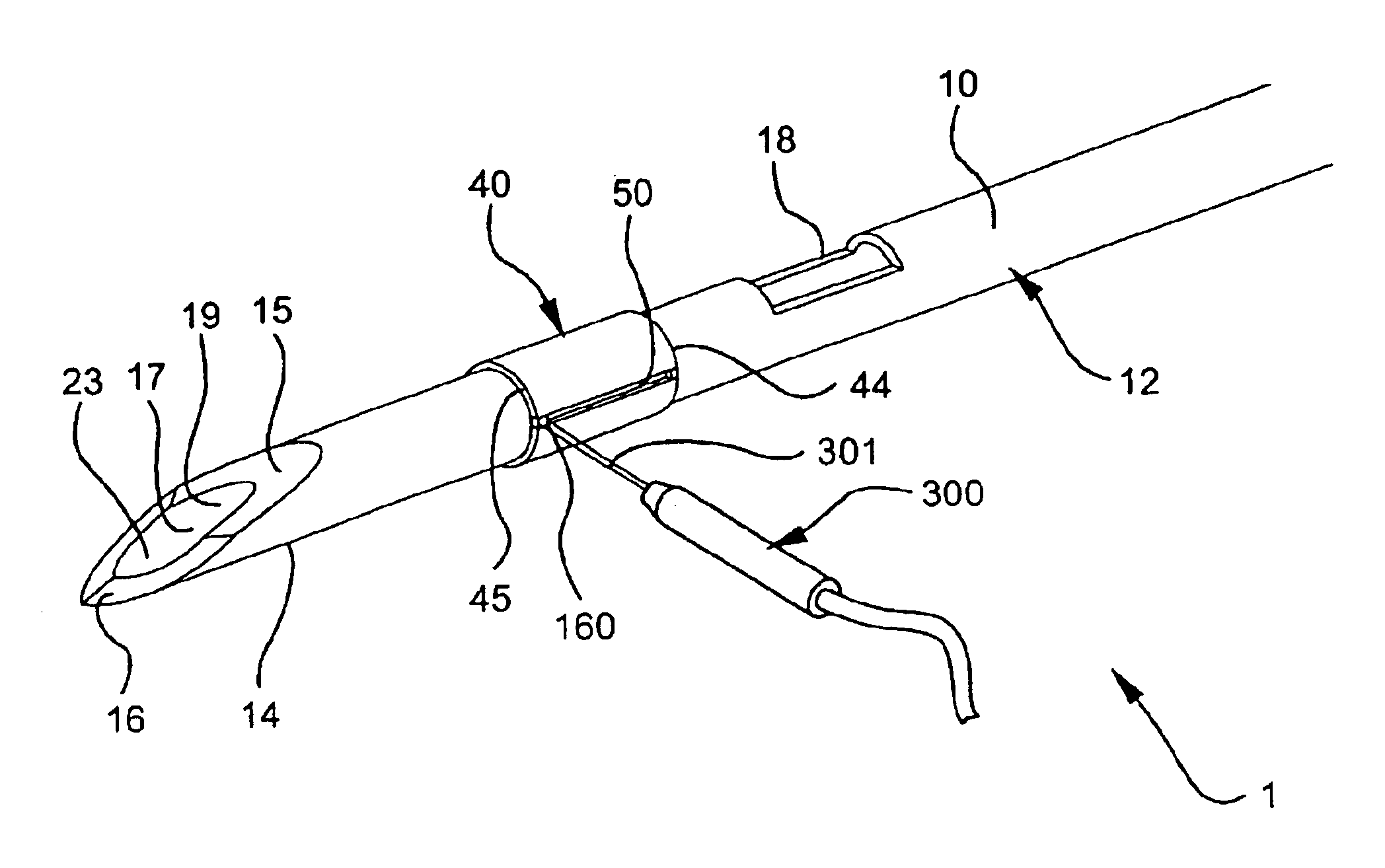

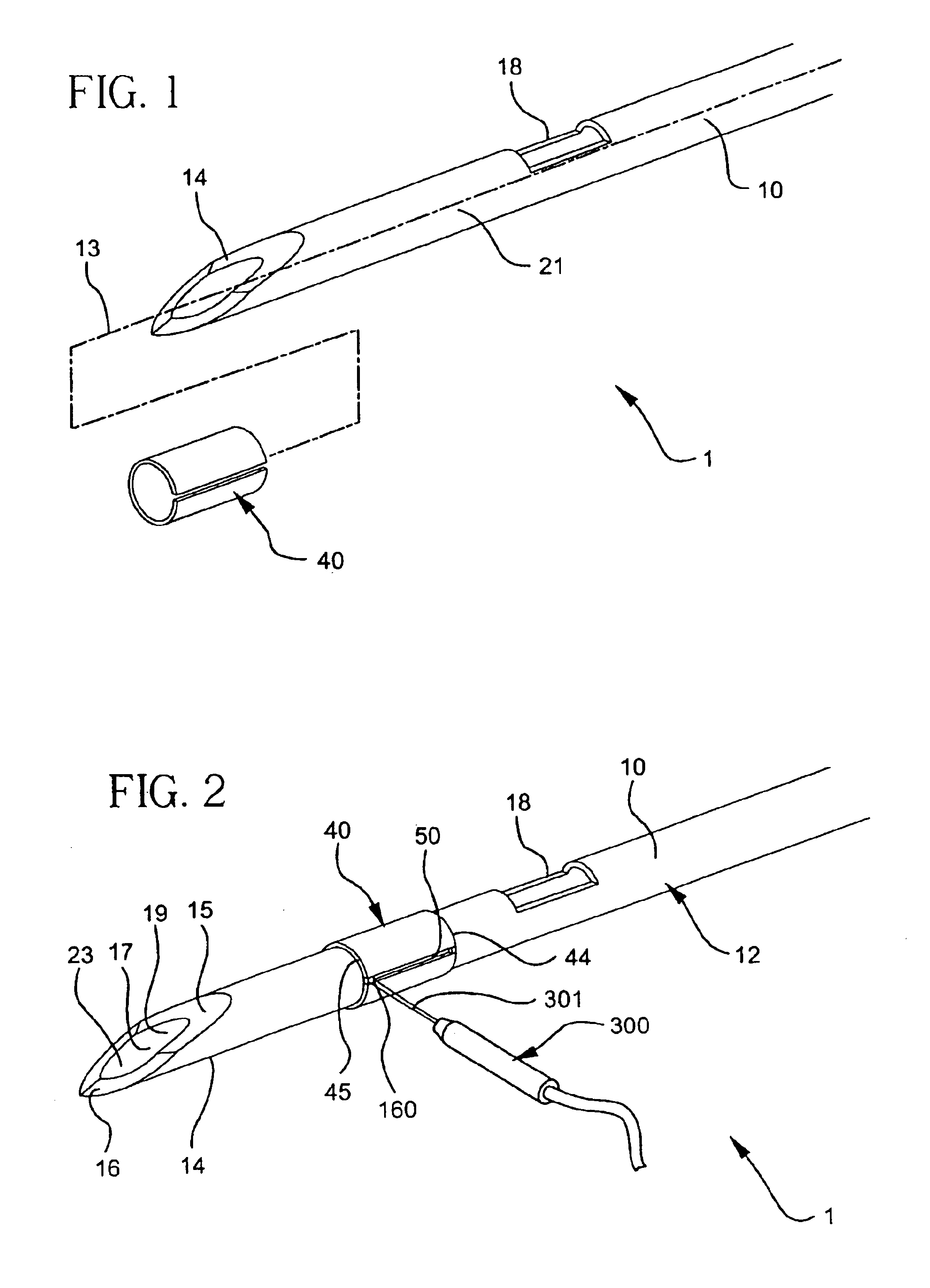

Microsurgical probe

Owner:ALCON INC

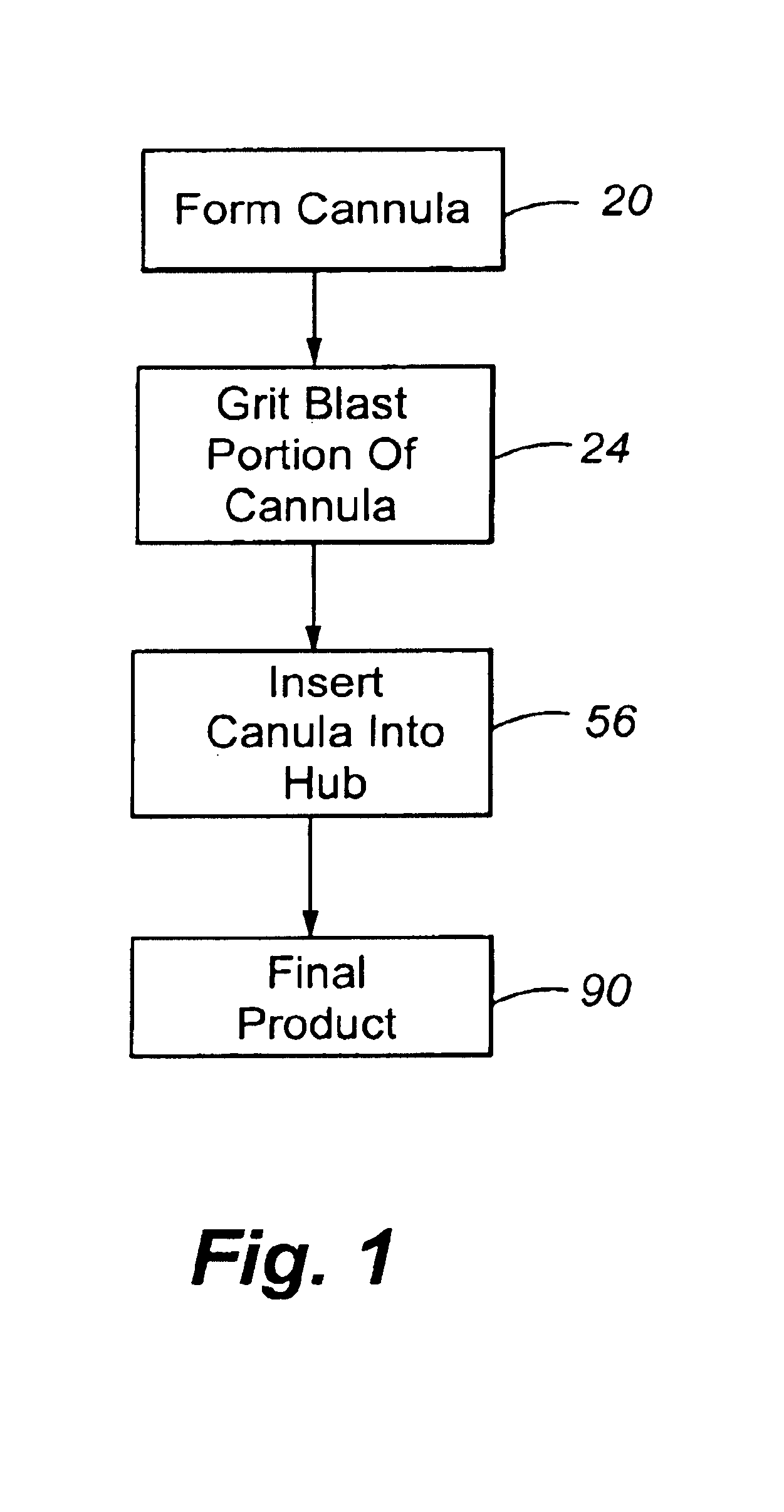

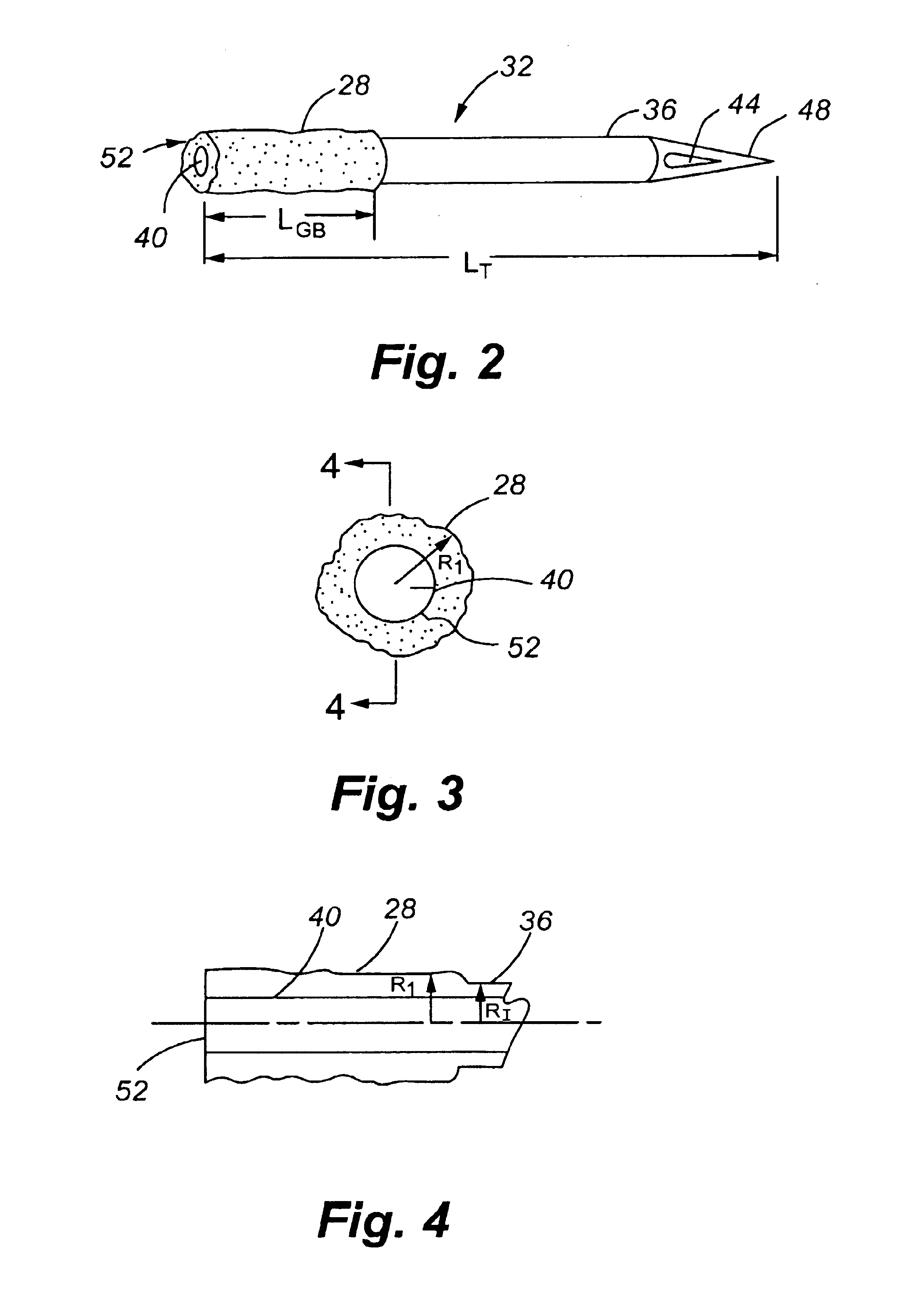

Method for manufacturing a cannula assembly

InactiveUS7024749B2High strengthReduce manufacturing costSurgical needlesAssembly machinesHypodermic needleInterference fit

The present invention is directed to a novel process for inserting a cannula, such as a hypodermic needle, into a hub member by roughening a first portion of the cannula while leaving a second portion substantially smooth such that the first portion forms an interference fit and the second portion a line-to-line fit with the hub bore. In the absence of an adhesive, the second portion is passed through the hub bore followed by the first portion. The first portion is forced into the hub bore to provide an adhesive-free interference fit that is capable of resisting puncturing forces during normal use.

Owner:FENWAL

Surgical needle swage tool

In a method of attaching a suture to a needle barrel, a first compression stroke compresses the radially-defined top of the barrel against a suture in the bore of the barrel while restraining the bottom and sides of the barrel against deformation. A second compression stroke compresses the bottom of the barrel against the suture while restraining the sides against deformation. In another method, the top and bottom are compressed concurrently while the sides are restrained against deformation. An apparatus for attaching a suture to a needle barrel includes two die sets, each including a die with a groove therein. In one die set, the groove protects the bottom and sides of the barrel from deformation while the top is compressed. In the other die set, the groove protects the sides of the barrel from deformation while the bottom is compressed.

Owner:ETHICON INC

Tungsten alloy suture needles with surface coloration

A medical device, particularly a suture needle, comprising a tungsten alloy and having a blue, yellow or black surface coloration.

Owner:ETHICON INC

Metal tubular body and manufacturing method thereof

InactiveUS6877652B2Improve penetration resistanceLow costSoldering apparatusCatheterPunchingMetal sheet

Side hole-bearing tubular bodies made of metal and having an inside diameter of up to 2 mm are manufactured by a method which includes punching from a metal sheet a sheet blank in the developed shape of a tubular body and punching in the sheet blank a hole which corresponds to the side hole in the tubular body and / or notches which form the side hole when the sheet blank is pressed into, a tubular shape, in such a way that the metal sheet and the sheet blank remain partly joined; pressing the sheet blank into a tubular shape; and cutting apart the metal sheet and the sheet blank where they remain joined. Metal tubular bodies manufactured in this way can have one or more side holes of any shape, position or number thereon, and are highly suitable for use in medical devices such as syringe needles.

Owner:TERUMO KK

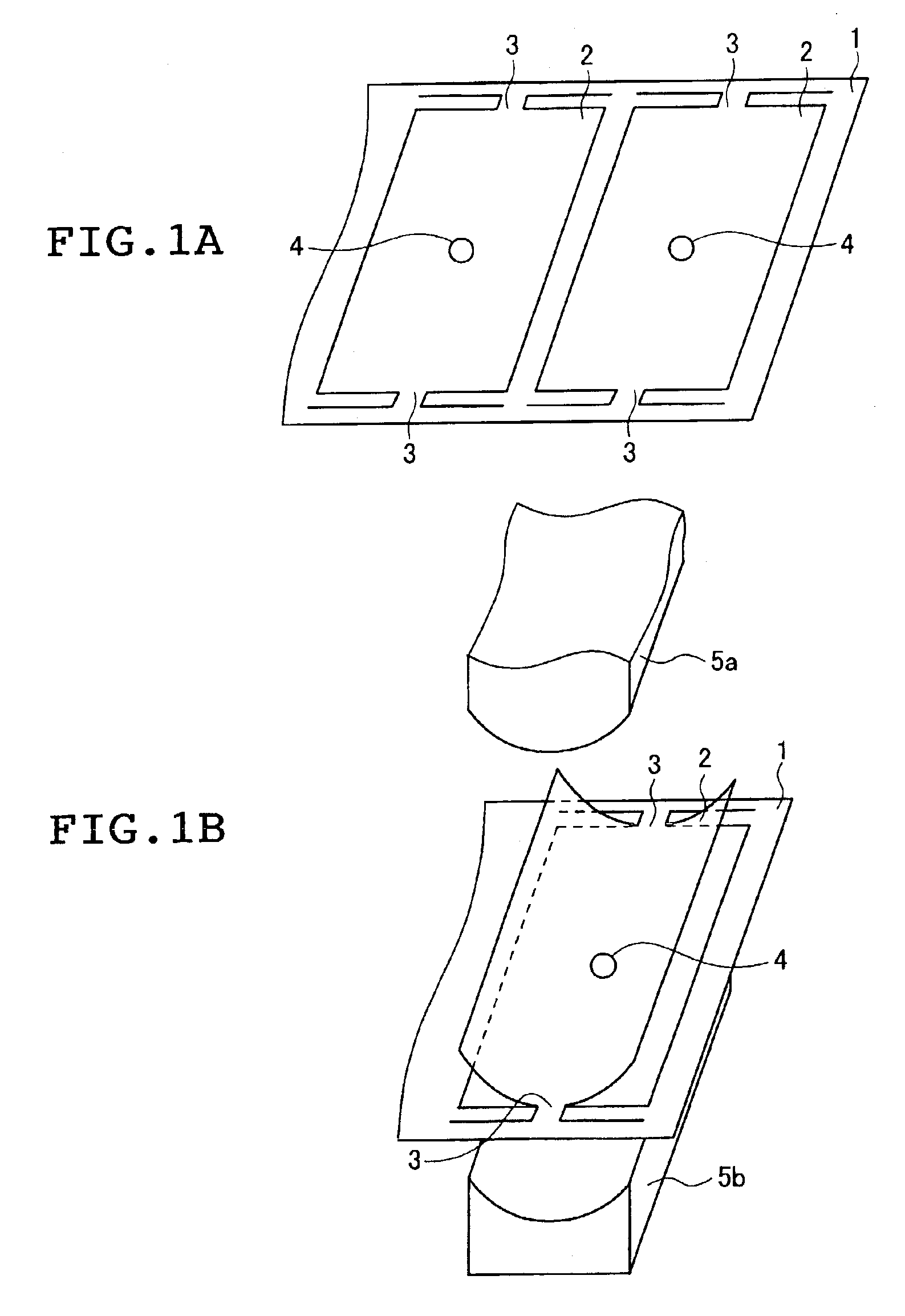

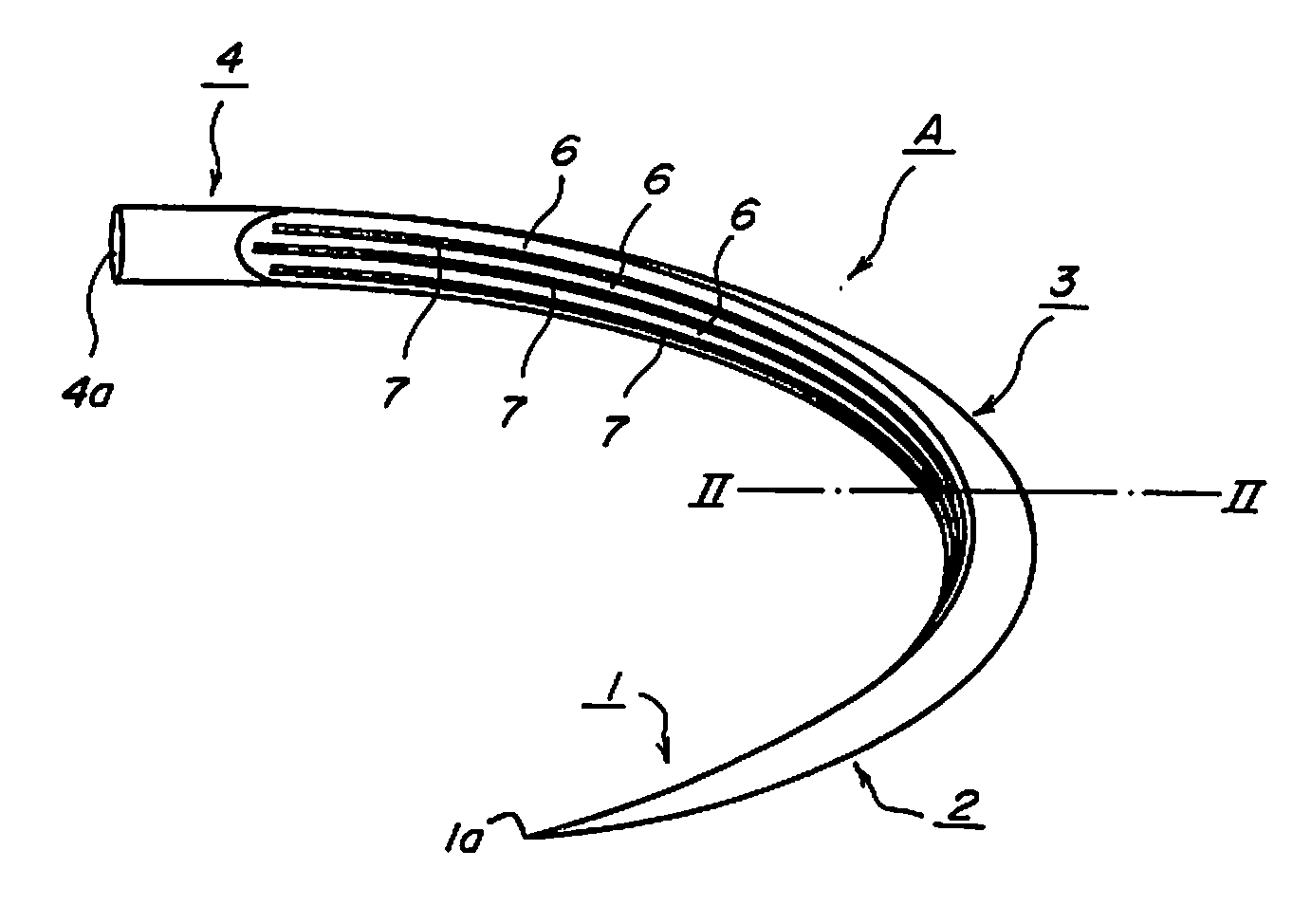

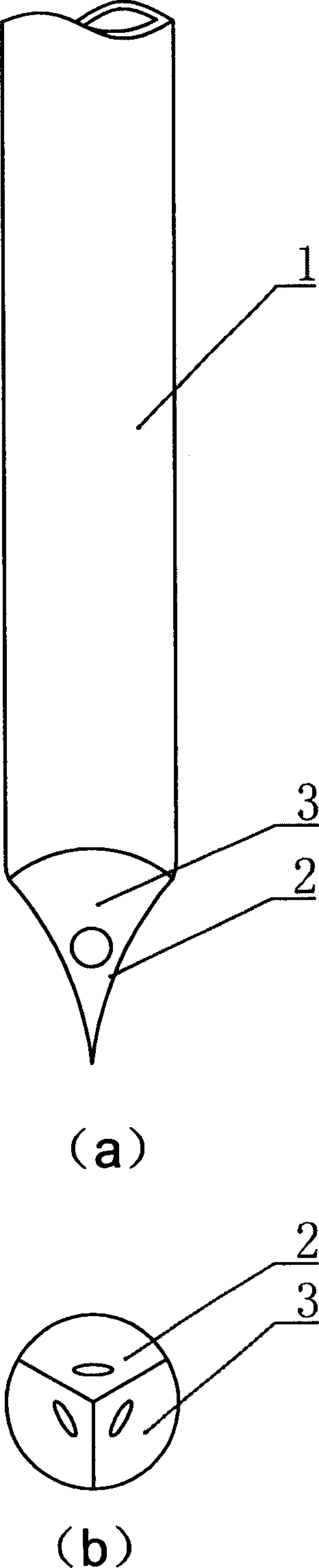

Suturing Needle

ActiveUS20100023054A1Increase resistanceReduce distortionSurgical needlesMetal-working apparatusSuturing needleWave shape

Provided is a suturing needle, which can be reliably held by a needle holder, which can transmit a high thrust, and which can reduce the fear of damaging a patient and the deformation when a strong force acts. The suturing needle has a representative constitution including a needle tip portion (1) having a needle tip (1a) for piercing the tissues, a tapered portion (2) continuing to the needle tip portion (1), a trunk portion (3) continuing to the tapered portion (2), and a thread attaching portion (4) continuing to the trunk portion (3) for connecting the suturing thread. The suturing needle is characterized in that the needle tip portion (1) is formed to have a circular section continuing to the sharp needle tip (1a), an angular section continuing to the sharp needle tip (1a), a circular section continuing to the blunt needle tip (1a) or an angular section continuing to the blunt needle tip (1a), in that the tapered portion (2) is formed to become gradually thicker from the needle tip portion (1) to the trunk portion (3), in that the trunk portion (3) is formed to have a substantially triangular section, the upper face of which is formed of a wave shape having at least two ridges and the slopes of which are formed of two flat faces, in that the trunk portion (3) is also formed to have relations of R1≧R2≧R3, when a peak (5) or the joint portion between the two flat faces has a diameter of R1, when the crest of the ridges has a roundness of R2, and when a valley (7) has a roundness of R3, in that the valley (7) is formed to correspond partially to the peak (5), and in that the thickness becomes continuously larger from the tapered portion (2) to the trunk portion (3).

Owner:MATSUTANI SEISAKUSHO CO LTD

Grindless surgical needle manufacture

InactiveUS20050044922A1High retention rateSharp and durablePinsSurgical needlesBiomedical engineeringGrinding process

A method for manufacturing a surgical needle devoid of a grinding process includes the steps of swaging a needle blank to define a substantially tapered or conical needle end, pressing the tapered needle to form a plurality of intersecting surfaces and forming cutting edges along the lines of intersection of the intersecting sides. The needle may be subjected to an etching process (e.g., an acid bath) to sharpen the cutting edges and / or provide a matte finish on the needle. The needle produced by the novel process is extremely sharp and durable, and exhibits an enhanced retention of sharpness relative to conventional ground needles over periods of prolonged use.

Owner:TYCO HEALTHCARE GRP LP

Disposable Needle for Syringes and Infusions and the Manufacture Thereof

InactiveUS20090099535A1Reduce the possibilityAvoid harmInfusion needlesNeedlesSyringe needleDisposable Needle

A disposable needle for syringes and infusions includes a tubular needle body (1), one end of which consists of a pyramid needle tip (2), a conical needle tip (4) or the combination of a pyramid needle tip and a conical needle tip, a through-hole (3) communicating with the inner hole of the needle body (1) is provided on the tubular needle body (1) and the conical needle tip (4), or on the other part. The said conical needle tip (4) is solid, hollow or locally hollow. A manufacture of the said needle is also provided.

Owner:WANG YUEAN +1

Needle sorting device

InactiveUS6997305B2Eliminate exposureCost effectiveSuture equipmentsProgramme controlBiomedical engineeringDischarger

A device for singulating surgical needles from a bulk supply of needles includes a vibratory bowl for receiving the supply of needles. The bowl has a floor to receive the needles, a track extending from the floor to a needle discharge point and a selectively vibrating motor to vibrate the surgical needles into a single file along the track. A discharge device has first and second needle receiving pockets, and positions the first and the second needle receiving pockets below the needle discharge point. A controller selectively vibrates the vibratory bowl and selectively positions the first and second needle pockets below the needle discharge point, the controller singulating individual needles from the single file of needles into the first and second needle receiving pockets. A discharger discharges the singulated needles in a spaced relationship on a conveyor for subsequent imaging at an inspection station.

Owner:ETHICON INC

Method of manufacturing hollow microneedle structures

InactiveUS8402629B2Uniform inner diameterSimple processGlovesPretreated surfacesHardnessMinimizing pain

Provided is a method of manufacturing a hollow microneedle structure. The method includes coating a hollow core having a predetermined section and being long in a lengthwise direction with a coating solution, and solidifying the coating solution to form a coating layer, depositing a metal seed layer on the coating layer, plating the seed metal layer with a metal to form a plated layer, cutting the hollow core having the plated layer at an inclination angle with respect to the lengthwise direction for form a surface inclination, and removing the hollow core and the coating layer to form a hollow microneedle structure. Thus, the hollow microneedle structure can be manufactured to have such diameter, length, hardness, and inclination angle as to minimize pain. By use of the hollow core, the microneedle structure can have vertical microneedles with a uniform inner diameter.

Owner:ELECTRONICS & TELECOMM RES INST

Disposable syringe and transfusion system needle head and its production method

ActiveCN1814313AReduce the likelihood of injuryAvoid harmInfusion needlesNeedlesInfusion setSyringe needle

This invention discloses a one-off injector and pinhead, it includes tubular pin. The pin is made by pyramid type, conic pin, or pyramid and cone. Liquor via holes is set on the pin or other part. The conic pinhead is solid, hollow or part hollow. This invention also discloses the manufacturing method of the pinhead. Because the included angle of foreside of axial backoff conical surface of the conic pin or backside of bulge and axial is small, so the radial size of liquor via hole at corresponding part is small, and the damage of pin to body tissue is greatly reduced. The possible damage of aperture to body is absolutely avoided by set liquor via hole on pipe body near the conic pin. Otherwise, when the pin rotating, damage to body is hard to form, especially the large diameter infusion pin.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com