Large curvature radiation horizontal well drilling technique and device

A horizontal well and large curvature technology, applied in drilling equipment, directional drilling, earthwork drilling and production, etc., can solve the problems of high investment and low efficiency, and achieve the goal of increasing daily production, improving recovery, and reducing artificial blockage and restrictions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

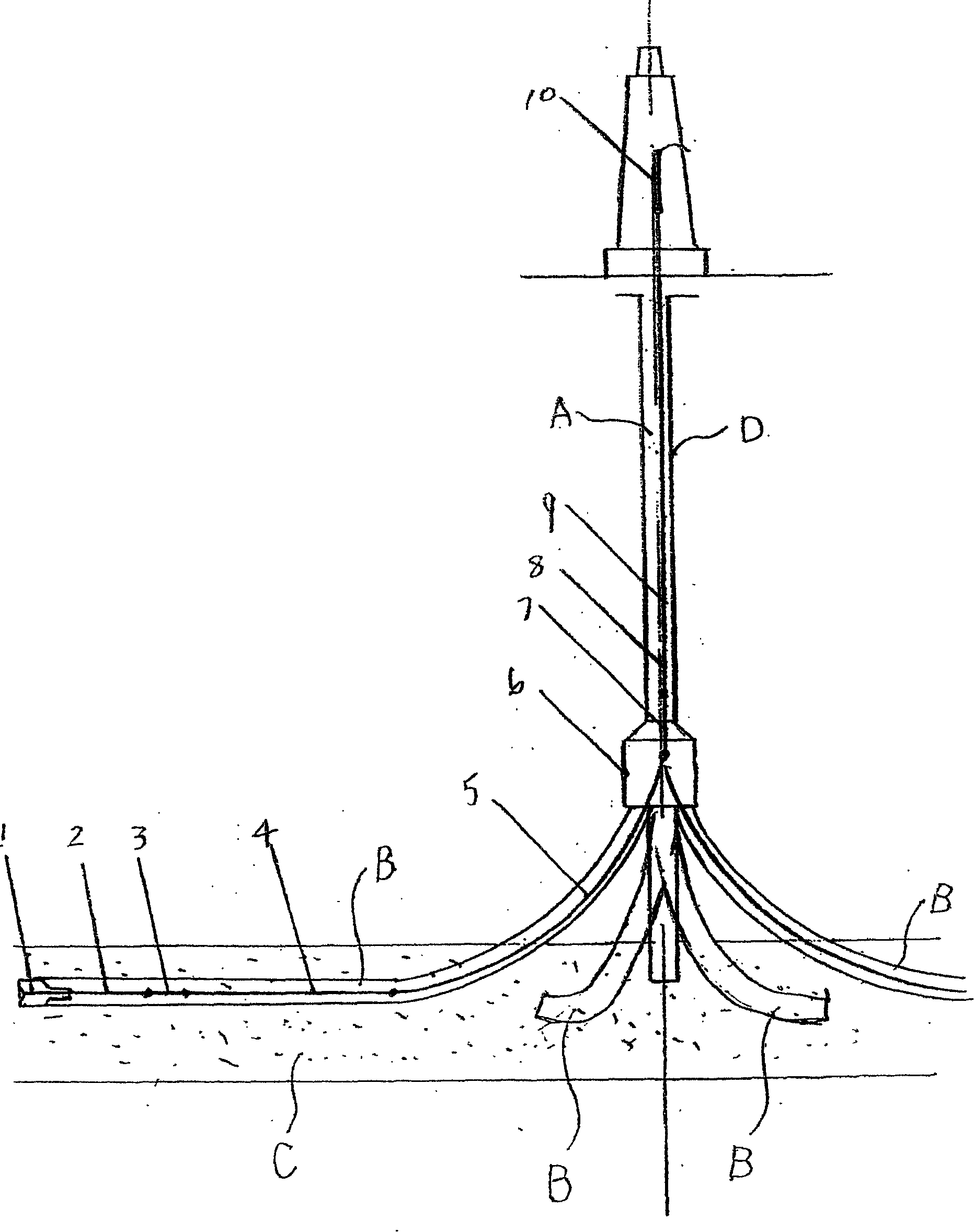

[0046] See figure 1 ~ Figure 8, the specific scheme and steps of the present invention are as follows:

[0047] (1) Drilling a vertical well to the oil layer: newly designed well position, drill a vertical well A into oil layer C according to the conventional method.

[0048] (2) Run casing: run casing 9 in vertical well A, and its lower end is 20 meters ± 2 meters from the top of thin oil layer C; for thick oil layers, casing 9 can be lowered to the top of oil layer C.

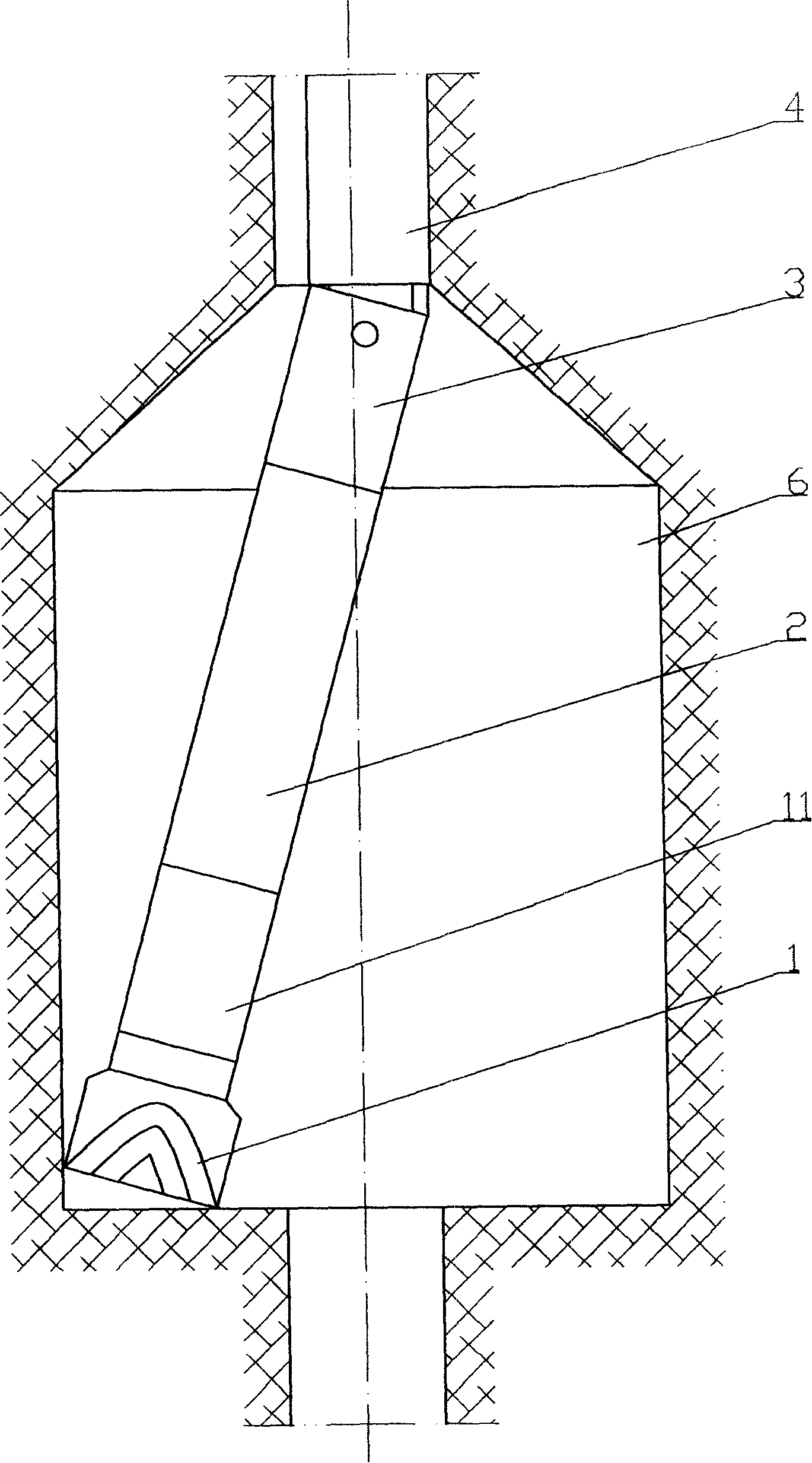

[0049] (3) Drilling out casing shoes: the next example figure 1 The reaming drill bit shown in -0 drills the casing shoe (enlarged wellbore) 6, and expands the borehole diameter of the 215 mm vertical well A to 600-1000 mm, and the footage is 3-4 meters (that is, the casing is formed). The length of the shoe 6).

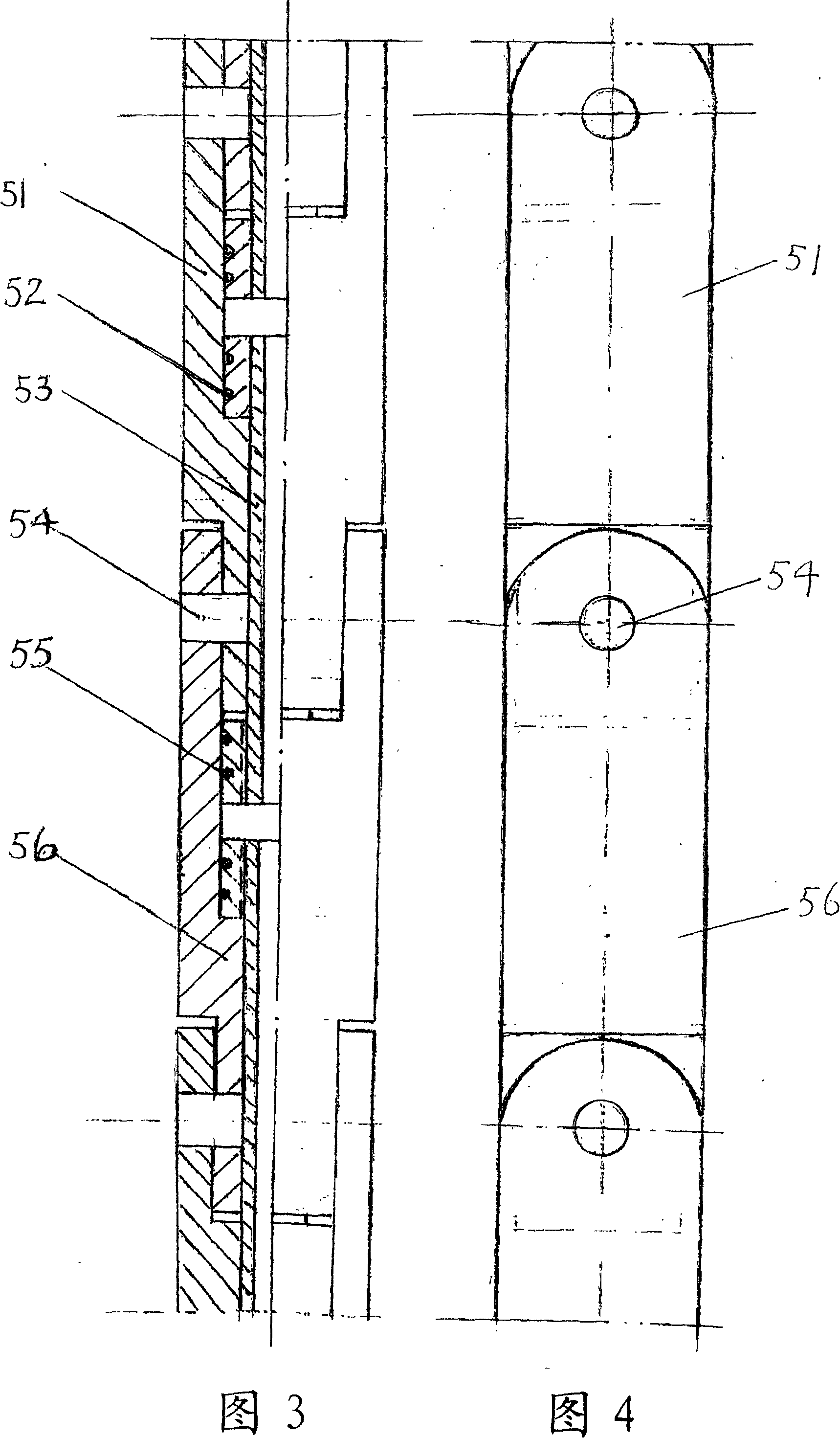

[0050] (4). Directional build-up: run down the build-up tool and drill out such as figure 1 The radial well B (including the curved transition section) shown in the marks 1 to 5, the tilting tool inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com