Dual-cone spiral forced feeding device

A technology of forced feeding and double-cone barrels, which is applied in the petroleum industry, coking ovens, direct heating and dry distillation, etc., can solve the problems of material accumulation or hysteresis, and achieve high filling rate and high material level, high working efficiency and safe operation reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

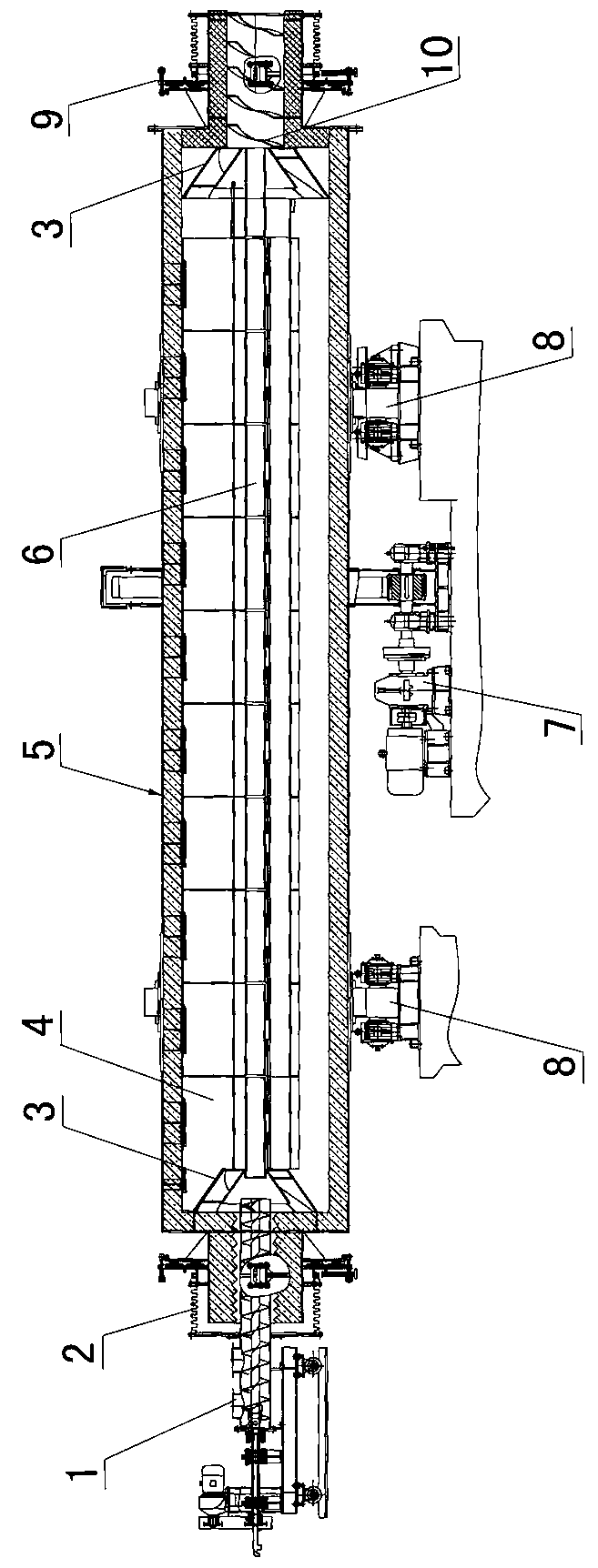

[0033] see figure 1 As shown, the rotary retort includes a rotary cylinder 5, a screw feeder 1 arranged at the tail of the rotary cylinder 5, and a discharge screw mechanism 10 arranged at the head of the rotary cylinder 5 to drive the rotary cylinder 5 The rotating power unit 7 and the support unit 8 supporting the rotating cylinder 5 . A tail sealing device 2 is provided between the screw feeder 1 and the rotary cylinder 5 , and a head sealing device 9 is provided between the discharge screw mechanism 10 and the rotary cylinder 5 . The support device 8 can be a support device with retaining wheels, or a support device without retaining wheels.

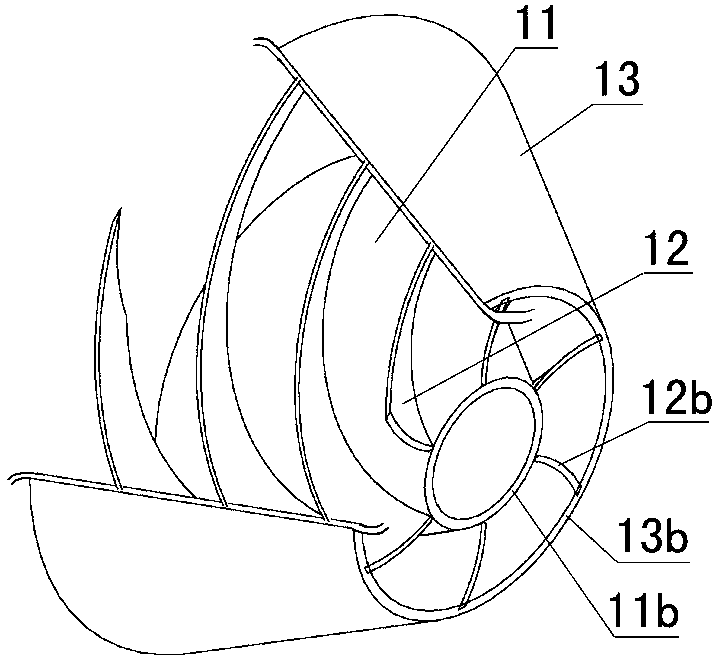

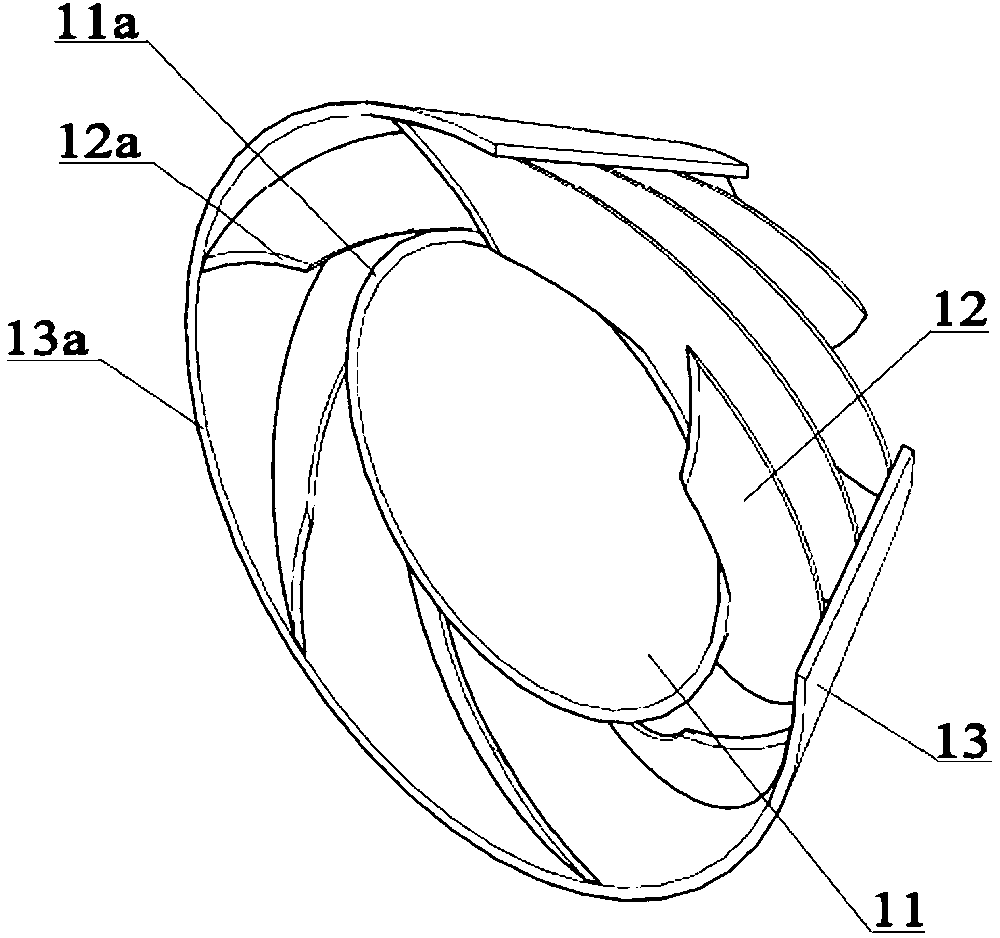

[0034] see Figure 7 , Figure 8 , the inside of the rotary cylinder 5 is provided with a rotary cylinder shaft 6, and the rotary cylinder 5 is welded between the rotary cylinder shaft 6 and the inner circumferential side wall of the rotary cylinder 5 to divide the interior of the rotary cylinder 5 into a plurality of compartment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com