Environment-friendly polyester color-modifying agent and preparation method thereof

An environment-friendly, color-repairing agent technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of potential toxicity and irritation, alcohol solvents are flammable and irritating, and achieve degreasing and oligomer Excellent removal performance, reduced content of additives, and reduced COD value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

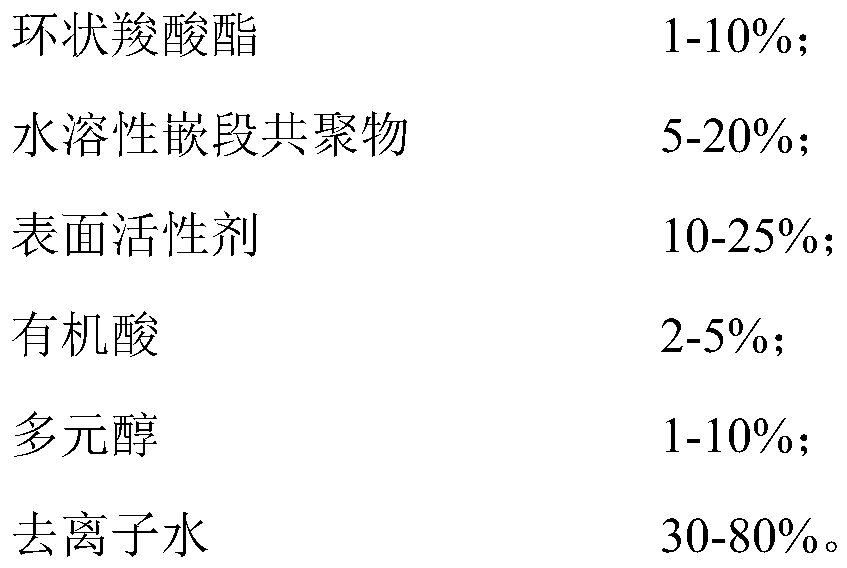

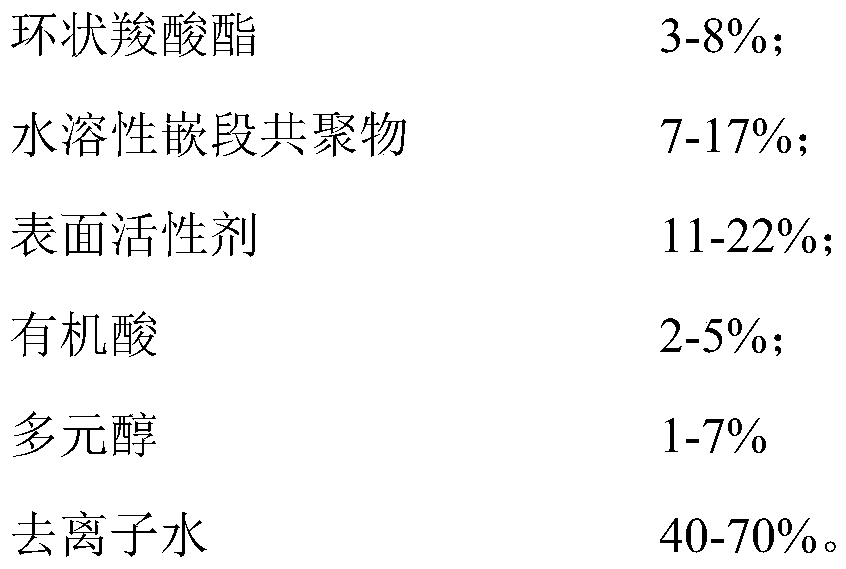

Method used

Image

Examples

Embodiment 1

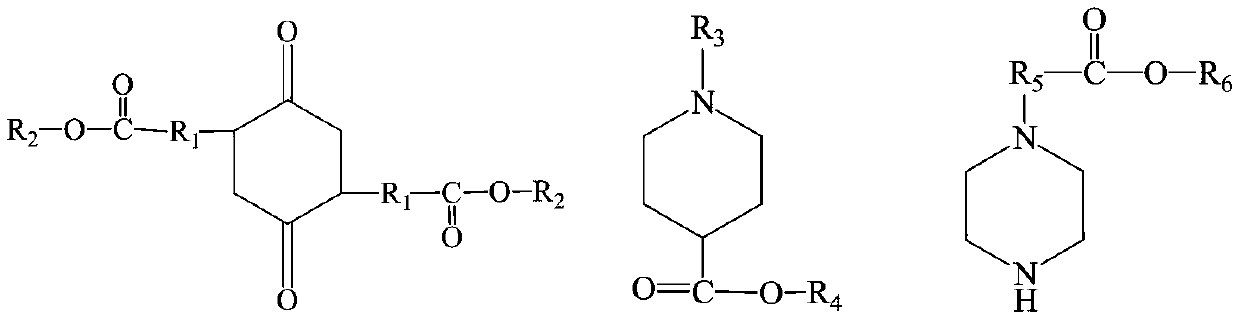

[0054] Add 2.9 grams of malic acid, 4.4 grams of mannitol, and 7.5 grams of deionized water into a three-necked flask, and stir at 95°C for 20 minutes. After cooling down to 60°C, add sodium methylbutene sulfonate-vinyl butyrate block copolymer (weight average molecular weight 4800) 10.4 grams, tartrate bis (sodium tetradecyl diester sulfonate) 6.4 grams, butanediol bis (succinic acid diester) 12.1 grams, stirred for 45 minutes, then added 1,4-cyclo 3.6 grams of diethyl hexanedione-2,5-dicarboxylate and 52.5 grams of deionized water were stirred for 15 minutes, and then cooled to room temperature to prepare environmentally friendly polyester color repair agent 1#. The measured solid content was: 40.7% .

Embodiment 2

[0056] Add 4.4 grams of glycine, 1.8 grams of xylitol, and 6.5 grams of deionized water into a three-necked flask, and stir at 85°C for 25 minutes. After cooling down to 60°C, add sodium methacrylate-vinyl crotonate block copolymer (weight average molecular weight 7800) 7.2 grams, ethylenediamine bis (sodium dimethyl heptane sulfonate) 8.1 grams, butanediol bis (succinic acid diester) 13.3 grams, stirred for 55 minutes, then added 1,4 - 2.3 grams of dimethyl cyclohexanedione-2,5-dicarboxylate, 3.5 grams of methyl 4-piperidinecarboxylate and 53.5 grams of deionized water, after stirring for 15 minutes, cool to room temperature to prepare an environmentally friendly polyester color repair agent 2#, the measured solid content is: 40.5%.

Embodiment 3

[0058] Add 2.2 grams of glutamic acid, 2.2 grams of glucitol, and 5 g of deionized water in a three-necked flask, stir at 95°C for 15 minutes, and after cooling to 50°C, add allyl potassium sulfonate-vinyl n-hexanoate block copolymer ( Weight-average molecular weight 3200) 16.1 grams, dimethylene bis (decyl amidomethyl propionate polyoxyethylene ether sulfonate, 9EO) 11.6 grams, stirred for 50 minutes, then added 1-methyl-4-piper 2.9 grams of ethyl picolinate, 4.6 grams of methyl 1-piperazinecarboxylate and 55 grams of deionized water, after stirring for 15 minutes, were cooled to room temperature to obtain environmental protection polyester color repair agent 3#, and the recorded solid content was: 40.8 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com