Hydrocarbons hydrocracking method

A hydrocracking and hydrocarbon technology, applied in the field of hydrocarbon hydrocracking, can solve the problems of hydrocracking catalyst deactivation, etc., and achieve the effects of promoting deep cracking, reducing load and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

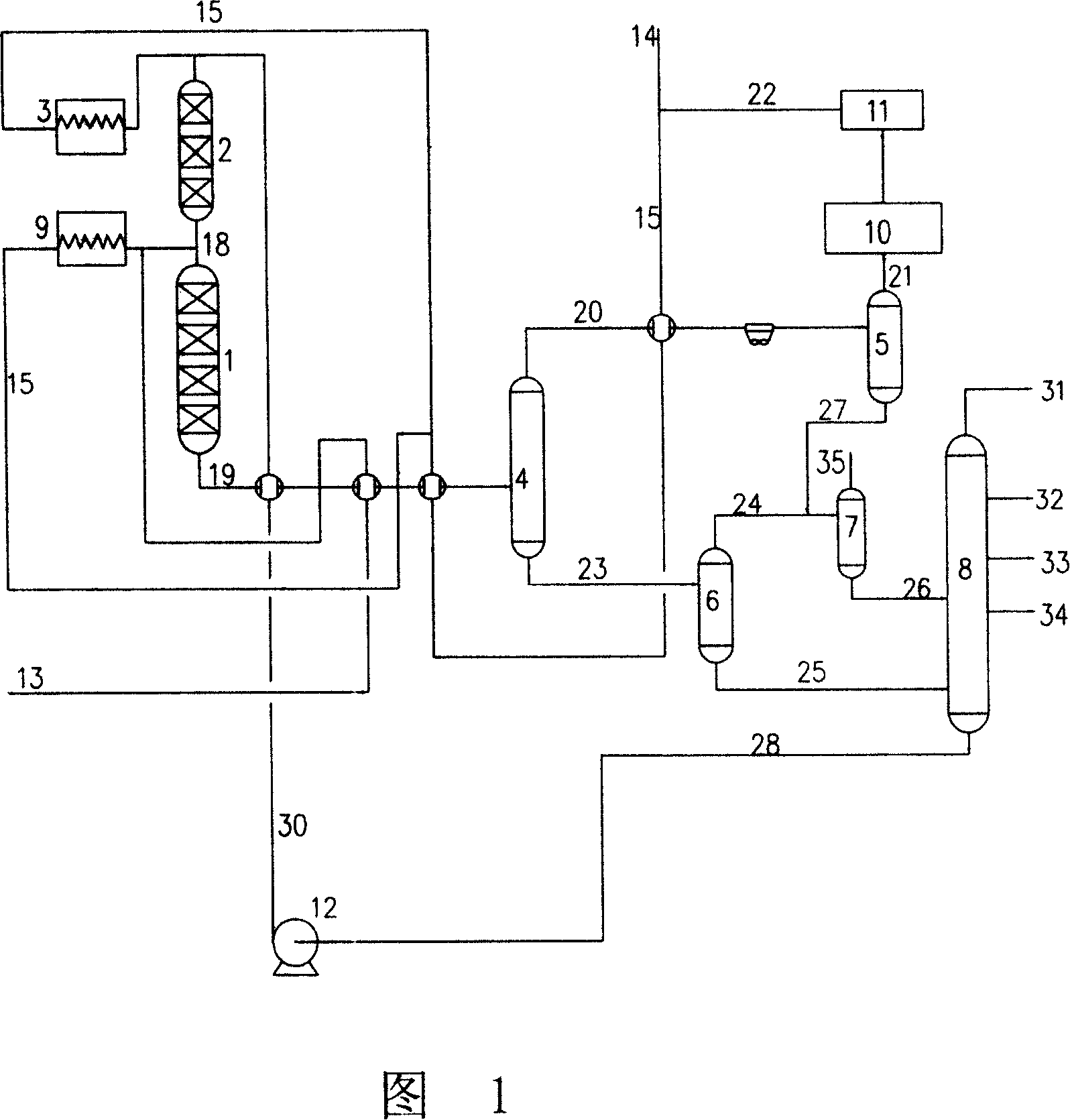

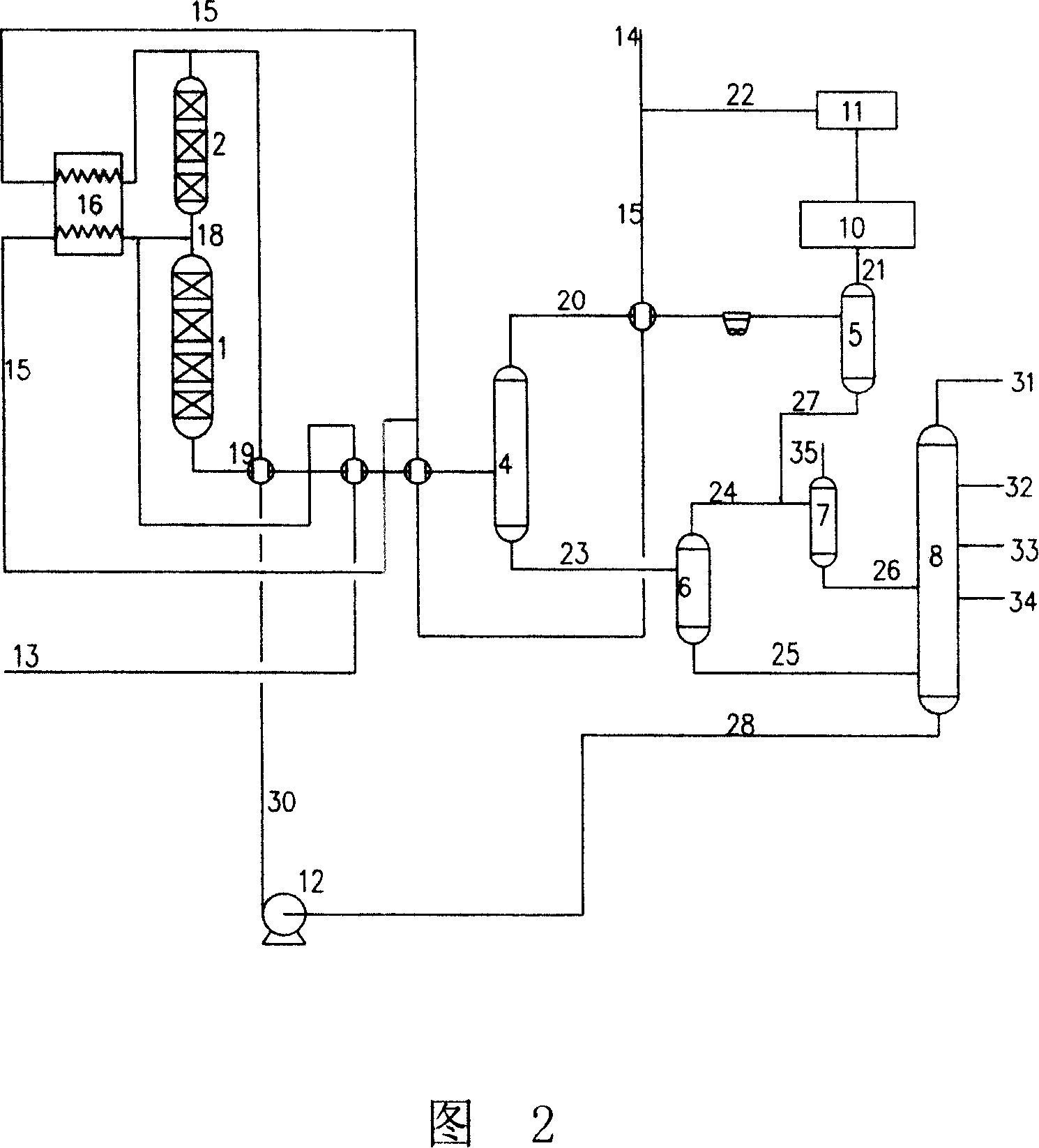

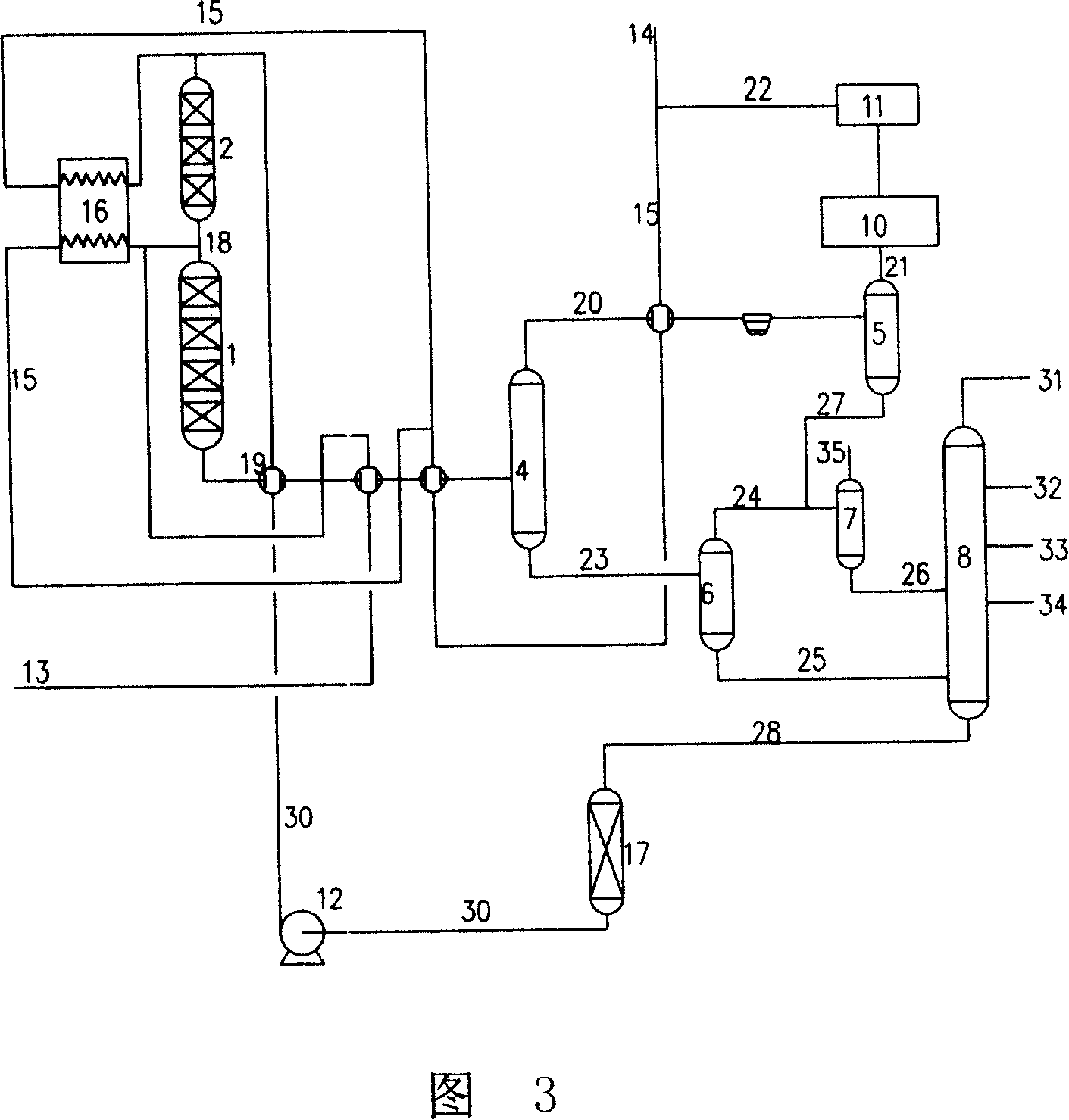

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only drawn to illustrate the basic content of the present invention, and do not limit the scope of the present invention.

[0031] As shown in Figure 1, raw oil 13 enters the device, and after exchanging heat with the first reactor effluent 19, it is mixed with the following mixed hydrogen 15 and the second reactor effluent 18 to enter the first reactor 1, and the first reaction The reactor 1 is usually operated under the conditions of a pressure of 14.0-18.0 MPa and a temperature of 350-450°C. The first reactor 1 is filled with a hydrofinishing catalyst or the upper part is filled with a hydrofinishing catalyst and the lower part is filled with a hydrocracking catalyst. After heat exchange with the effluent 19 of the first reactor, the circulating oil 30 is mixed with the following mixed hydrogen 15 and enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com