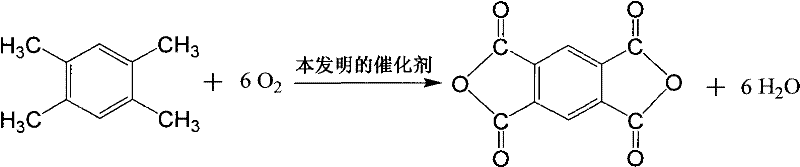

Catalyst for preparing pyromellitic dianhydride from durene through gaseous catalytic oxidation and preparation method thereof

A technology of pyromellitic dianhydride and gas-phase catalytic oxidation, which is applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve problems such as low yield, restriction of PMDA, and complex active components, and achieve Improve yield and purity, reduce production cost, and reduce resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A) Prepare ammonium vanadyl oxalate solution, the molar ratio of oxalic acid to distilled water is 1:21, put the weighed oxalic acid into a container filled with distilled water and equipped with a heating device and a stirrer, stir and heat up to 90°C, wait After the oxalic acid is fully dissolved, slowly add ammonium metavanadate, the molar ratio of ammonium metavanadate to oxalic acid is 0.4:1, and continue to stir and react to obtain ammonium vanadyl oxalate solution;

[0036] B) Preparation of spray liquid, according to V 2 o 5 :TiO 2 (Anatase): P 2 o 5 The molar ratio=1:3.8:0.125 will (NH 4 ) 2 VO 3 、TiO 2 and (NH 4 ) 2 HPO 4 Join by step A) in the ammonium vanadyl oxalate solution obtained, ammonium vanadyl oxalate solution and TiO 2 The weight is 4.6: 1 and stirred evenly to obtain the spraying liquid;

[0037] C) Spraying, spraying the spraying solution obtained in step B) evenly on the surface of SiC spheres with a diameter of 4-6 mm as an inert ca...

Embodiment 2

[0041] A) Prepare ammonium vanadyl oxalate solution, the molar ratio of oxalic acid to distilled water is 1:23, put the weighed oxalic acid into a container filled with distilled water and equipped with a heating device and a stirrer, stir and heat up to 60°C, wait After the oxalic acid is fully dissolved, slowly add ammonium metavanadate, the molar ratio of ammonium metavanadate to oxalic acid is 0.5:1, and continue to stir and react to obtain ammonium vanadyl oxalate solution;

[0042] B) Preparation of spray liquid, according to V 2 o 5 :TiO 2 (Anatase): P 2 o 5 The molar ratio=1:15:0.313 will (NH 4 ) 2 VO 3 、TiO 2 and (NH 4 ) 2 HPO 4 Join in the ammonium vanadyl oxalate solution obtained by step A), wherein, the ammonium vanadyl oxalate solution and TiO 2 The weight ratio is 4.6: 1, and stir evenly, obtain spraying liquid;

[0043] C) Spraying, the spraying solution obtained by step B) is evenly sprayed onto the surface of a ceramic ring with a diameter of 4-6 ...

Embodiment 3

[0047] Prepare catalyst and evaluate catalyst activity with the same method as example 2, put the 50ml catalyst that obtains in the fixed-bed reaction tube of Φ 25mm, control reaction hot spot temperature at 440-450 ℃, feed durene, use air to carry out oxidation, React for 2 hours. Catalyst load 60~80g / L·h, space velocity 4000~4600h -1 , the furnace temperature is 355-375° C., the weight yield of PMDA is 97%-103%, and the purity is more than 95.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com