A kind of dry desulfurization filter for diesel engine exhaust and preparation method thereof

A filter and diesel engine technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of weakened power performance, small desulfurization capacity, and reduced combustion efficiency of diesel engines, and achieve improved desulfurization performance and desulfurization capacity. , the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of dry desulfurization filter that is used for diesel engine exhaust, thickness is 0.5mm, is made of MnO 2 Composed of adhesive silica gel, its preparation method is as follows:

[0023] ① Put 6g MnO 2 , 1g of silica gel and 0.5g of carboxymethyl cellulose are mixed, then add 3ml of water, and ultrasonically mix them evenly in an ultrasonic pool with a power of 100W; after adding water, carboxymethyl cellulose forms a high-viscosity transparent solution , the powdered MnO 2 stick together;

[0024] ② Fill the ultrasonic mixture into a metal vessel and extrude it with a pressure of 30kN;

[0025] ③The circular shape of the honeycomb hole is made by CNC machine tool.

[0026] ④ Then put it into a muffle furnace and bake it at 723K to form it, remove carboxymethyl cellulose, and make a carrier-free desulfurization filter.

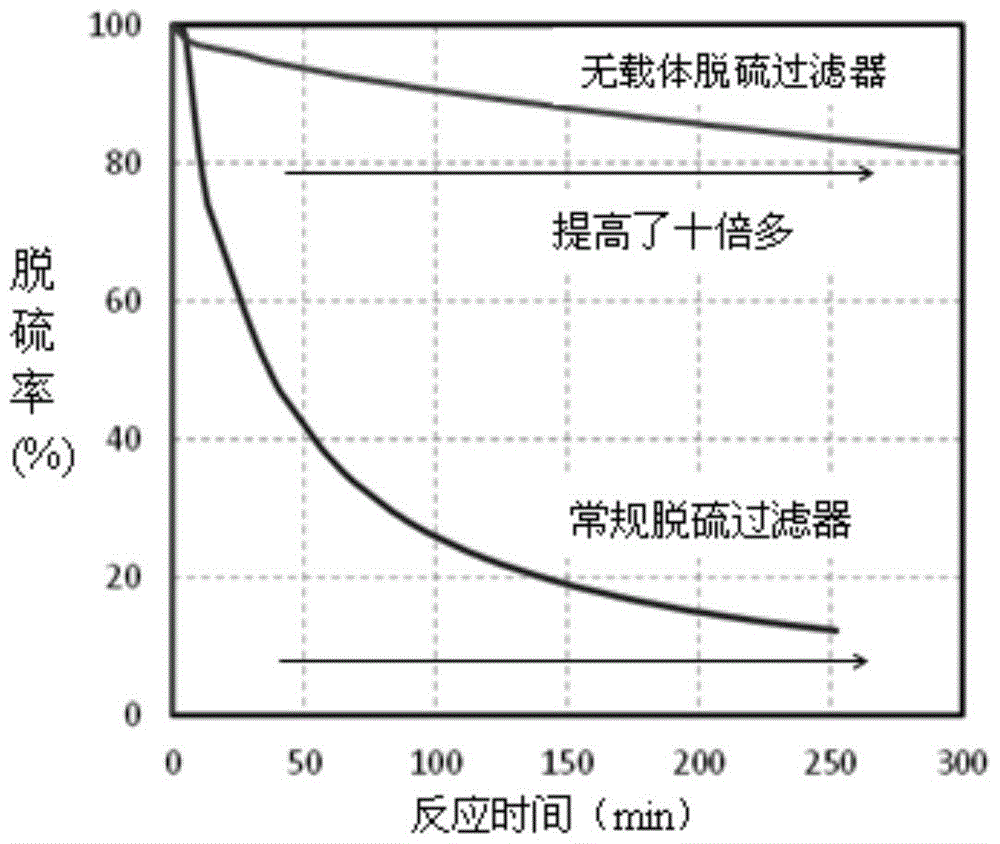

[0027] figure 1 It is a graph showing the desulfurization rate of the unsupported desulfurization filter of this embodiment ...

Embodiment 2

[0029] Embodiment 2: a kind of dry type desulfurization filter that is used for diesel engine exhaust, thickness is 0.1mm, is made of CaCO 3 Composed of adhesive silica gel, its preparation method is as follows:

[0030] ① Put 18g CaCO 3 , 2g of silica gel and 1g of carboxymethyl cellulose were mixed, then 2ml of water was added, and ultrasonically mixed in an ultrasonic pool with a power of 100W to make it evenly mixed. After adding water, carboxymethyl cellulose formed a high-viscosity transparent solution. Powdered CaCO 3 stick together;

[0031] ② Fill the ultrasonic mixture into a metal vessel and extrude it with a pressure of 50kN;

[0032] ③The circular shape of the triangular hole is made by CNC machine tool.

[0033] ④ Then put it into a muffle furnace and bake it at 873K to form it, remove carboxymethyl cellulose, and make a carrier-free desulfurization filter.

Embodiment 3

[0034] Embodiment 3: a kind of dry desulfurization filter that is used for diesel engine exhaust, thickness is 5mm, is made of MnO 2 , Fe 2 o 3 Composed of adhesive silica gel, its preparation method is as follows:

[0035] ① Put 20g Fe 2 o 3 , 4g MnO 2 , 16g of silica gel and 2g of carboxymethyl cellulose were mixed, then 5ml of water was added, and ultrasonically mixed in an ultrasonic pool with a power of 100W; after adding water, carboxymethyl cellulose formed a high-viscosity transparent solution, Powdered Fe 2 o 3 stick together;

[0036] ② Fill the ultrasonic mixture into a metal vessel and extrude it with a pressure of 5kN;

[0037] ③The hexagonal hole structure is made by CNC machine tools.

[0038] ④ Then put it into a muffle furnace and bake it at 573K to form it, remove carboxymethyl cellulose, and make a carrier-free desulfurization filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com