Recovery system and recovery technology of desulfuration seawater

A recovery system and seawater desulfurization technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dispersed particle separation, etc., can solve the problem of low pH and heavy metal content control of discharge water and large footprint , Low oxidation efficiency and other issues, to achieve the effect of improving seawater desulfurization rate, easy operation, and increasing desulfurization capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

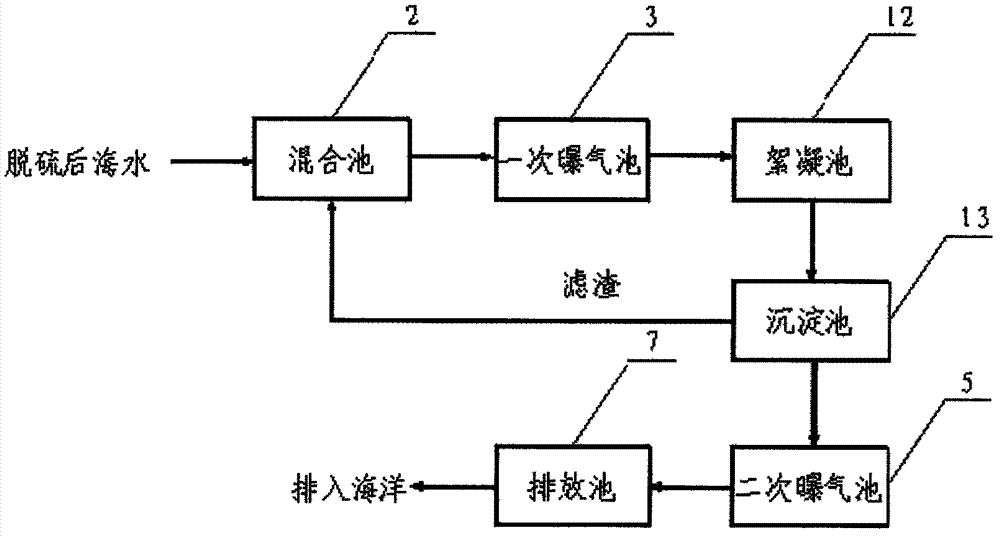

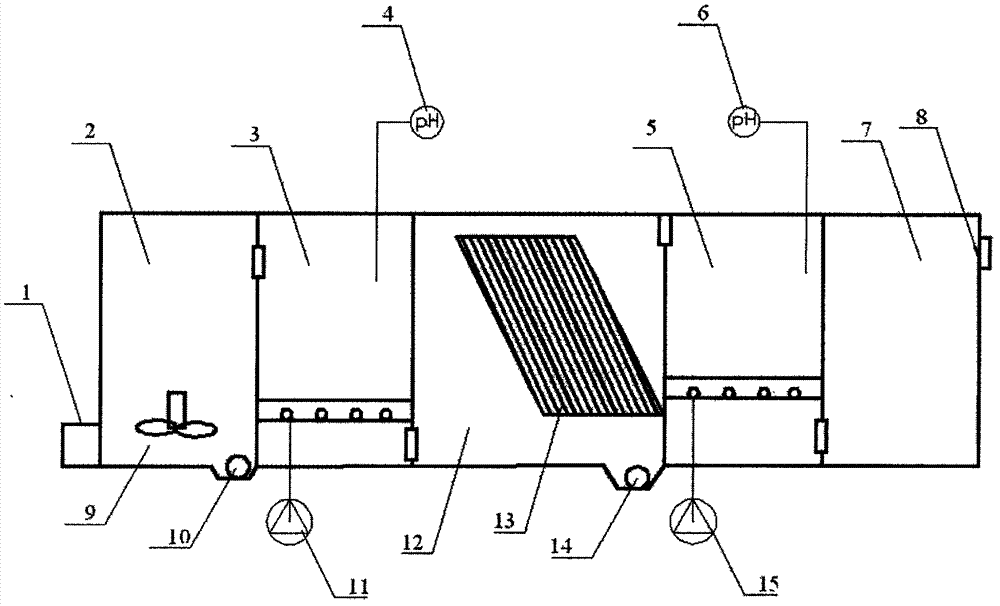

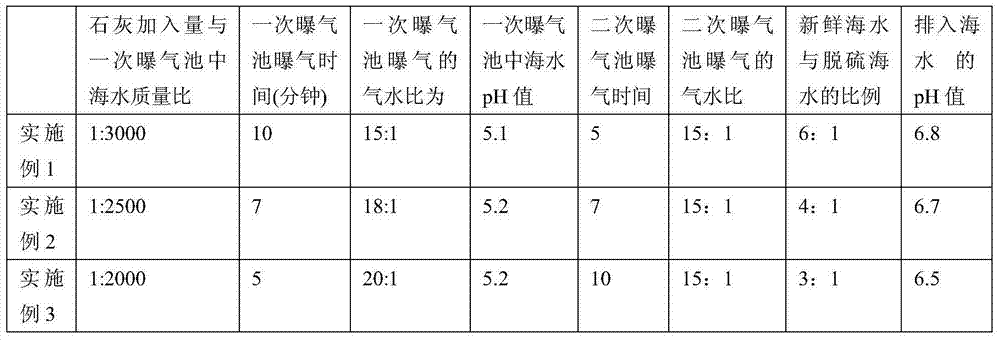

[0016] Such as figure 2 As shown, the whole recovery system of the present invention is arranged in a tank body, and the mixing tank 2, the primary aeration tank 3, the flocculation tank 12, the sedimentation tank 13, the secondary aeration tank 5, and the discharge tank are successively separated by interlayers in the tank body. 7. A stirring device 9 is installed in the mixing tank 2, an aeration head is installed in the primary aeration tank 3 and the secondary aeration tank 5, and the aeration time of the desulfurized seawater in the primary aeration tank is 5-10 minutes, and the aeration gas The water ratio is 15:1-20:1. The lower part of the mixing tank 2 is equipped with a mixing tank slag discharge pipe 10, which is regularly pumped and discharged; the lower part of the sedimentation tank 13 is connected with the flocculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com