Nitrogen-rich porous carbon desulfurizer and preparation method thereof

A desulfurizer, porous carbon technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as low nitrogen-containing functional groups, and achieve rich nitrogen-containing functional groups, high desulfurization efficiency, and improved desulfurization capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

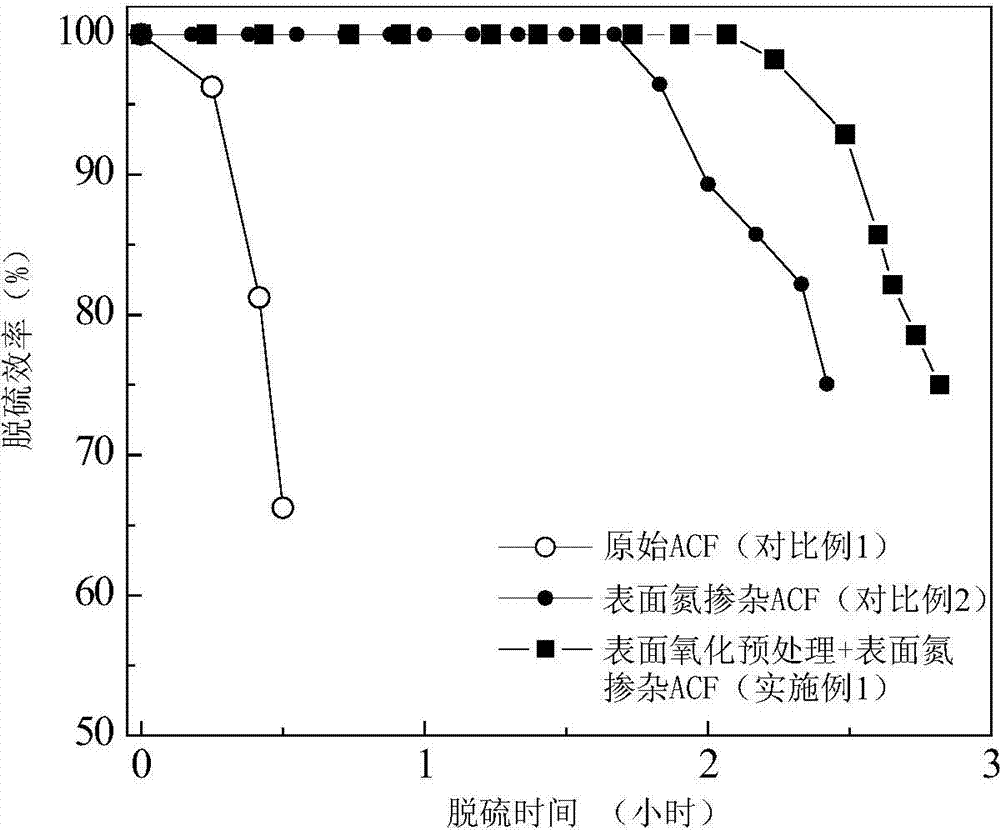

Embodiment 1

[0033] Soak the activated carbon fiber in a nitric acid solution with a mass concentration of 30%, stir it in a constant temperature water bath at 60°C for 2 hours, take it out, rinse the activated carbon fiber with deionized water to pH=6-7, and then dry it in an oven at 105°C overnight . Dissolve 100 grams of dicyandiamide in 200 milliliters of ethanol solution with a mass concentration of 50% to form a dicyandiamide solution. Pour 100 grams of acid-washed activated carbon fibers into the above-mentioned dicyandiamide solution, heat while stirring at 60° C., slowly evaporate ethanol and moisture, and then dry overnight at 105° C. in an oven. Put the activated carbon fiber loaded with dicyandiamide into a high-temperature calcination furnace, under the condition of nitrogen protection, raise the temperature from room temperature to 750°C at a rate of 5°C / min, and keep it at 750°C for 1 hour, then cool Finally, a nitrogen-rich activated carbon fiber desulfurizer with dicyandi...

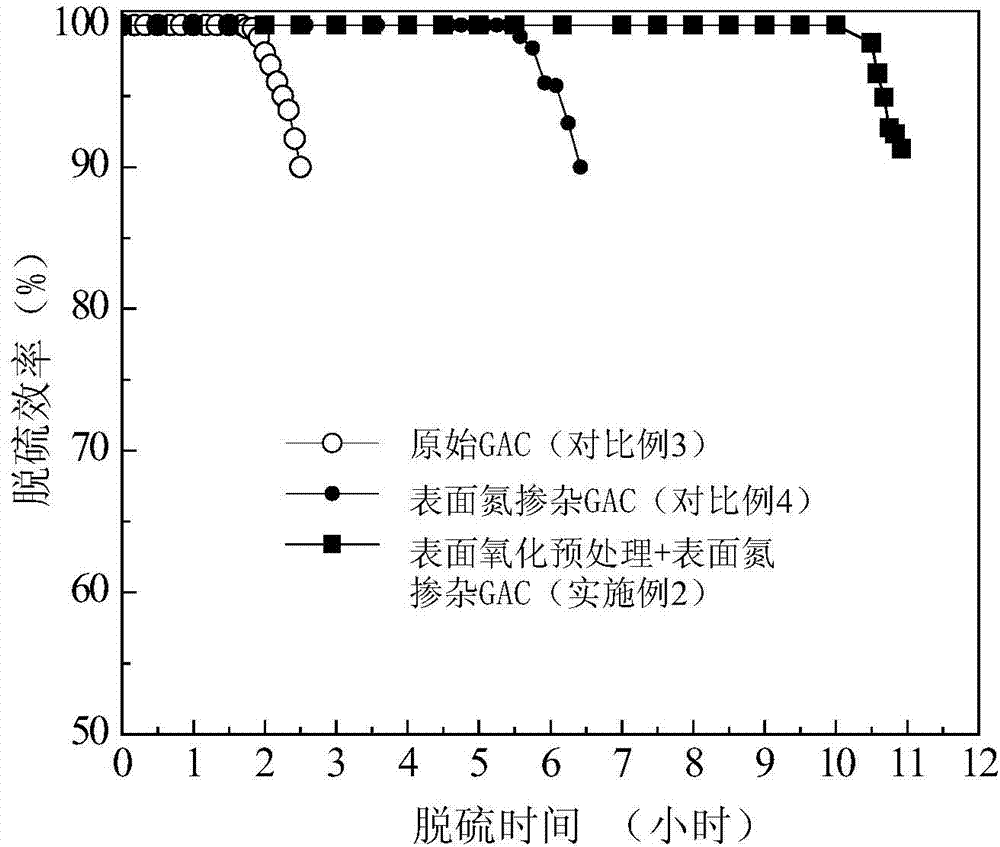

Embodiment 2

[0041] Soak 10-20 mesh granular activated carbon in a nitric acid solution with a mass concentration of 20%, and stir in a constant temperature water bath at 60°C for 3 hours. The acid-washed granular activated carbon was rinsed with deionized water to pH=6-7, and then dried overnight in an oven at 105°C. Dissolve 5 grams of melamine in 100 milliliters of water to make a melamine solution. Pour 30 grams of acid-washed 10-20 mesh granular activated carbon into the above-mentioned melamine solution, heat while stirring at 60°C, slowly evaporate the water, and then dry in an oven at 105°C overnight. The granular activated carbon loaded with melamine was placed in a high-temperature calciner, and under the condition of nitrogen protection, the temperature was raised from room temperature to 800 °C at a heating rate of 5 °C / min, and kept at 800 °C for 1 hour. After cooling, the following Nitrogen-rich granular activated carbon desulfurizer with melamine as nitrogen source and surf...

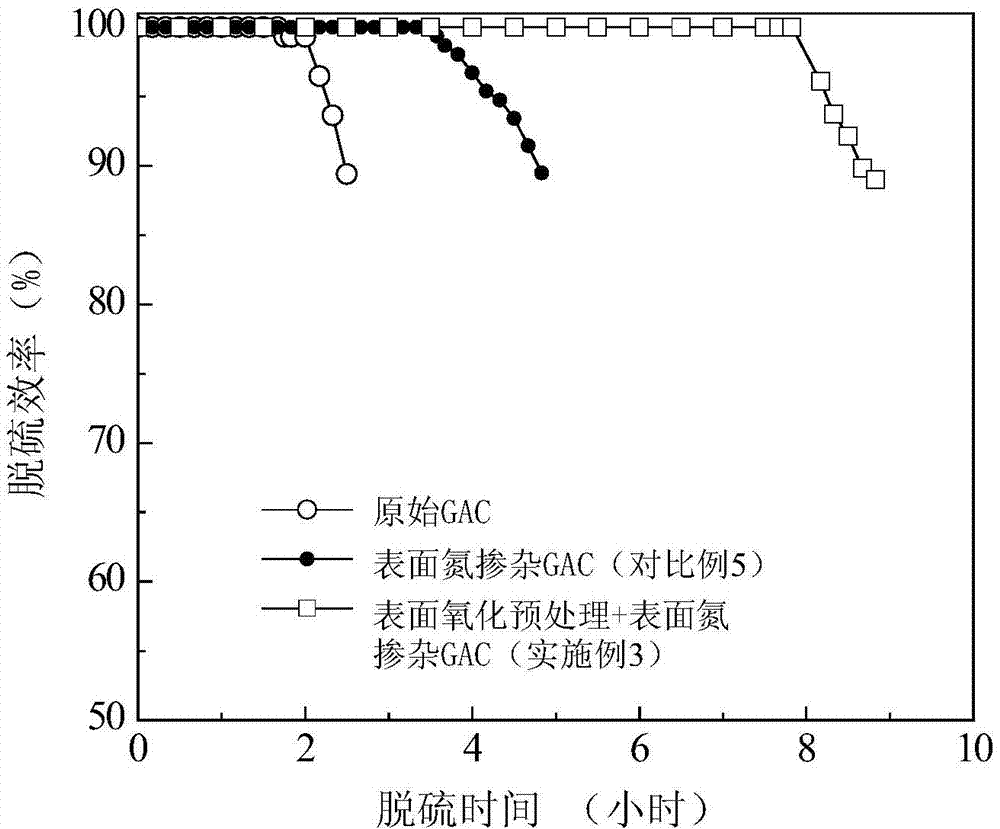

Embodiment 3

[0049] Soak 10-20 mesh granular activated carbon in a nitric acid solution with a mass concentration of 50%, and react at 60°C for 1 hour. The acid-washed granular activated carbon was rinsed with deionized water to pH=6-7, and then dried overnight in an oven at 105°C. Dissolve 200 grams of urea in 1000 milliliters of 50% ethanol aqueous solution to form a urea solution. Pour 100 grams of acid-washed granular activated carbon into the above-mentioned urea solution, heat while stirring at 60°C, slowly evaporate ethanol and water, and then dry in an oven at 105°C overnight. The activated carbon loaded with urea was placed in a high-temperature calciner, and under the condition of nitrogen protection, the temperature was raised from room temperature to 850 °C at a heating rate of 5 °C / min, and kept at 850 °C for 1 hour. After cooling, urea was obtained. Nitrogen-enriched granular activated carbon desulfurizer with surface nitrogen doping as nitrogen source.

[0050] Elemental a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com