Externally heated medium and high pressure process and apparatus for synthesizing material ammonia with methanol and methane

A methanol synthesis tower and methanation technology, which is applied in the production of hydrogen, etc., can solve the problems of large increase in the amount of air released from synthetic ammonia, incomplete refining of raw material gas, and increased air release from ammonia, so as to achieve good catalyst protection and high production capacity. Large, high alcohol-ammonia ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

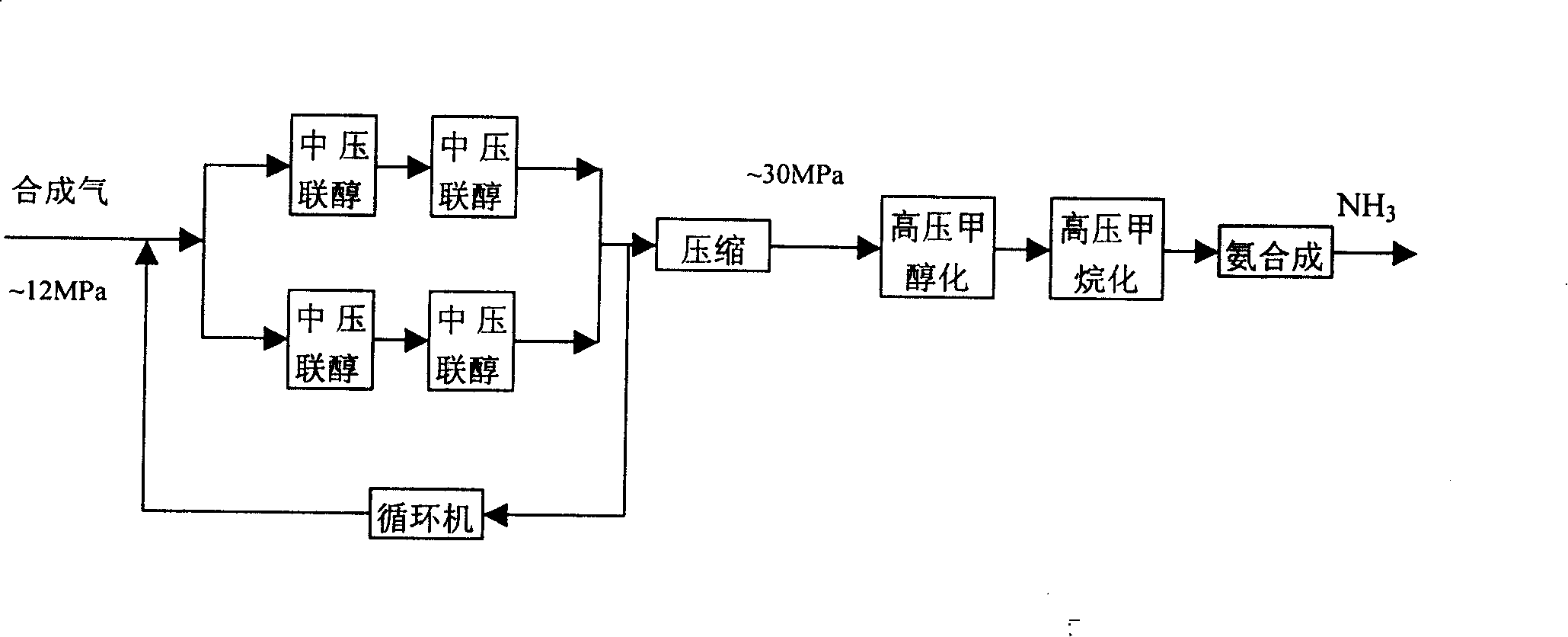

[0037] refer to figure 1 , Fig. 6, a kind of method for the synthesis ammonia raw material gas of external heat formula, high-pressure methanol, methanation, the step of this method comprises:

[0038] (1), medium-pressure co-alcohol: take medium-pressure co-alcohol for the feed gas, the medium pressure is 10-12Mpa, and the synthesis gas mainly includes nitrogen, hydrogen, carbon monoxide and carbon dioxide;

[0039] (2) Compression: compress the outlet gas of the alcohol unit, and the high pressure is ~ 30Mpa;

[0040] (3), high-pressure methanolylation: at low space velocity ~ 6000h -1 1. Under the condition of a high pressure of ~30Mpa, methanol is synthesized in a high-pressure methanol synthesis tower, passed into a methanol separator for separation, and methanol is produced, and the raw material gas is initially refined to produce alcohol gas;

[0041] (4) High-pressure methanation: the post-alcohol gas is passed into the primary inlet of the high-pressure methanation ...

Embodiment 2

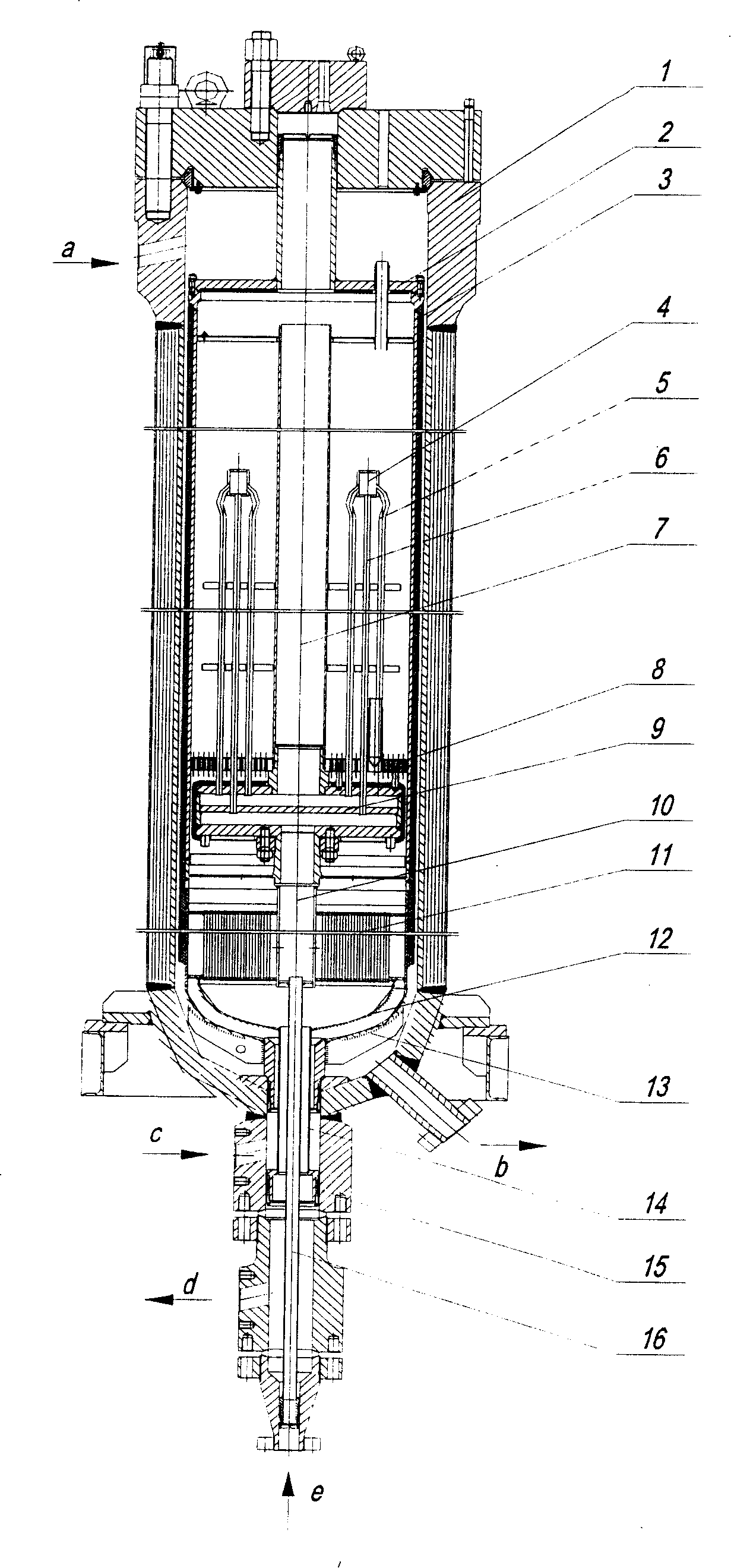

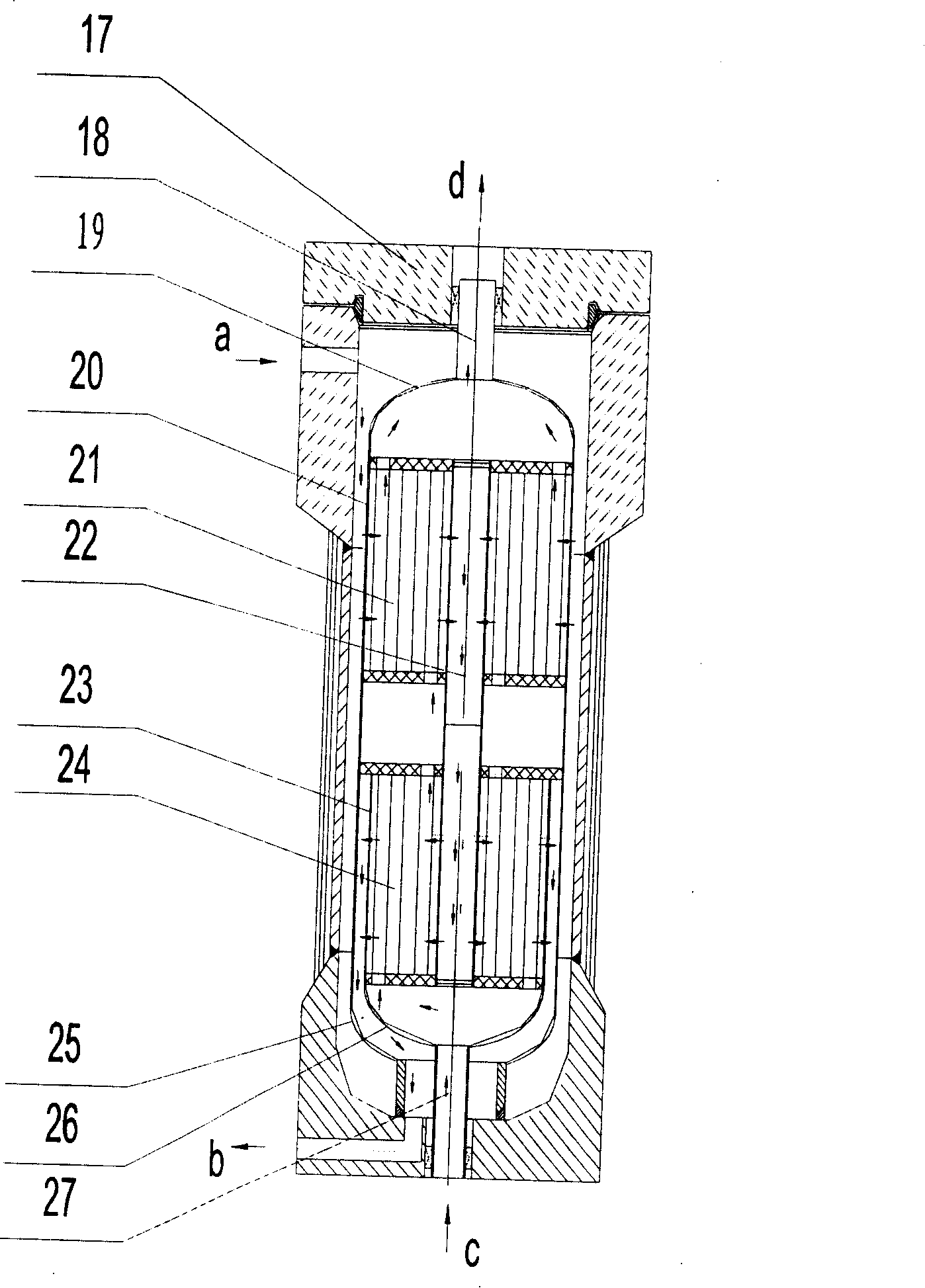

[0051] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Fig. 6, a kind of device of external heating type medium and high pressure methanol, methanation synthesis ammonia raw material gas, described device comprises medium-pressure alcohol-linked equipment, high-pressure machine, high-pressure methanoly equipment, high-pressure methanation equipment and ammonia synthesis equipment, The high-pressure methanation equipment includes a high-pressure methanation tower (A), an external heat exchanger (B) and a heater (C), and the primary outlet of the high-pressure methanation tower (A) is sequentially connected to the external heat exchanger device (B), heater (C), the gas outlet of the heater (C) is connected to the secondary inlet of the high-pressure methanation tower.

[0052] Referring to Fig. 6, the high-pressure methanation equipment also includes a water cooler (D), an ammonia cooler (E) and a gas-water separator (F), and the secondary outlet of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com