Production method of vanadium-aluminum alloy

A vanadium-aluminum alloy and production method technology, applied in the field of metallurgy, can solve the problems of increasing the production cost of vanadium pentoxide, restricting the development of vanadium-aluminum alloy, low recovery rate of vanadium-aluminum alloy, etc., achieving environmental protection of the process, reducing the vanadium content rate, The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

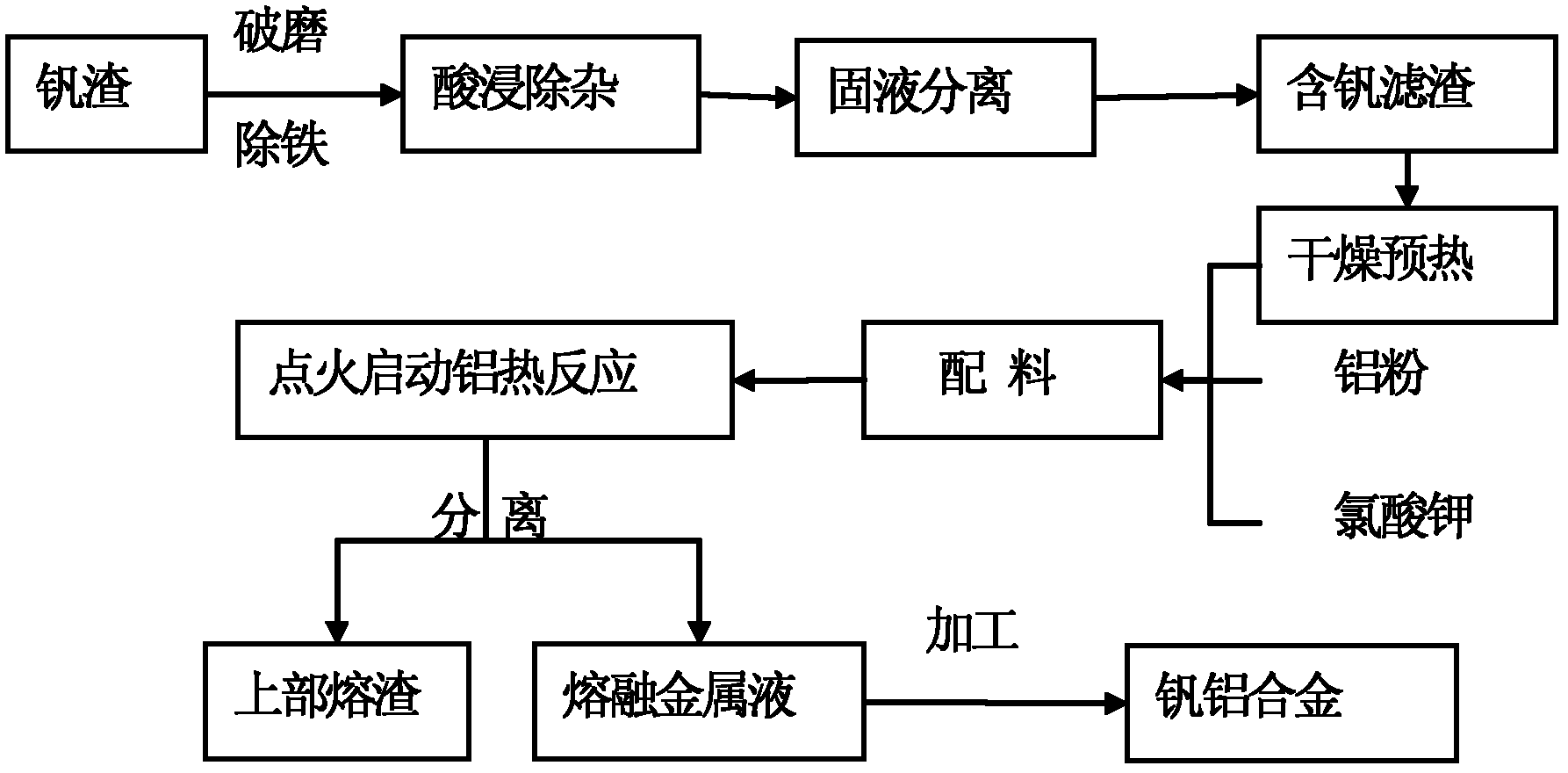

Method used

Image

Examples

Embodiment 1

[0024] A kind of production method of vanadium aluminum alloy, its concrete steps comprise:

[0025] S1-1. Acid leaching: first, pretreat the vanadium slag, including crushing and magnetic separation to remove iron, so that the particle size of the vanadium slag reaches 100 mesh ± 10 mesh; Add dilute sulfuric acid with a concentration of 25%±2% to the vanadium slag. During this process, vanadium and other substances in the vanadium slag, such as impurities containing iron, magnesium, chromium, manganese, silicon, phosphorus, and sulfur, dissolve in the in the acid solution.

[0026] S1-2, impurity removal: adjust the pH value of the acidolysis solution in S1-1 to PH=4±0.5, at this time, the vanadium in the acidolysis solution forms calcium vanadate precipitation, and most of the iron, magnesium, Chromium, manganese, silicon, phosphorus, sulfur and other impurities are leached and enter the supernatant in the state of ions, for example: most of the iron exists in the supernata...

Embodiment 4

[0040] This embodiment is the same as the production process used in implementation one, the difference being the parameters used in each process, specifically as follows:

[0041] S4-1. Acid leaching: the particle size of the pretreated vanadium slag is 110 mesh; under the condition of 105°C, add dilute sulfuric acid with a concentration of 27% to the treated vanadium slag.

[0042] S3-2. Impurity removal: adjust the pH value of the pickling solution to pH=4.5.

[0043] S3-3. Aluminothermic reduction: mix the dry vanadium-containing filter residue with aluminum powder at a ratio of 2.4:1.0, and add industrial potassium chlorate at a mass of 5.5% of the total charge weight. Wherein, 4mm<the particle size of the vanadium-containing filter residue<5mm, 99%<the aluminum content of the aluminum powder<99.5%, the particle size of the aluminum powder is 3mm, and 4mm<the particle size of potassium chlorate<5mm. When adding aluminum powder in stages, a. During the smelting process, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com