Titanium-contained composite alloy reinforcing core-spun yarn and application to HRB400E thread steel

A composite alloy and strengthening package technology, applied in the field of iron and steel materials, can solve the problems of increased production cost of rebar and difficulty in cost control of production enterprises, and achieve the effects of cost saving, stable yield and stable strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

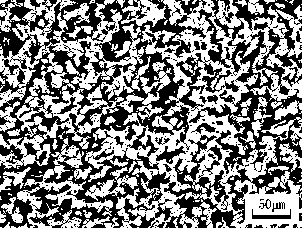

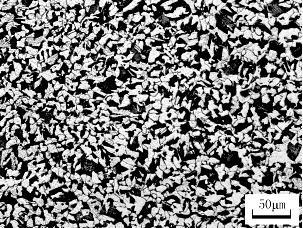

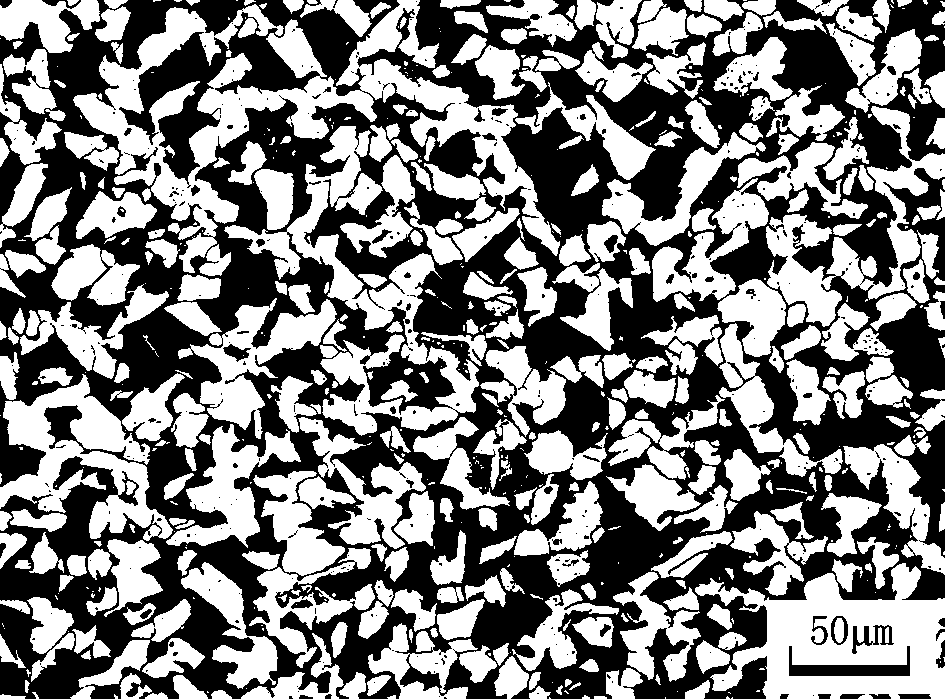

Image

Examples

Embodiment Construction

[0032] In order to better explain the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples. The following examples are only illustrative technical solutions of the present invention, and do not limit the present invention in any form .

[0033] Table 1 below is a list of mass percentage values of chemical components contained in the core powder of the titanium-containing composite alloy reinforced cored wire in Examples 1-5 of the present invention.

[0034] Table 1 Chemical composition of titanium-containing composite alloy reinforced cored wire core powder in Examples 1-5 (Wt, %)

[0035]

[0036] The core powder described in Examples 1-5 is made of titanium nitride, silicon-manganese alloy, silicon nitride, copper powder, iron powder, and silicon-zirconium alloy. During preparation, each raw material is firstly ground into 200 mesh dry powder, After calculatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com