Method for recovering vanadium from vanadium precipitation waste water

A vanadium precipitation wastewater and contact reaction technology, applied in the field of vanadium recovery, can solve the problems of long vanadium precipitation time, complicated process, low vanadium precipitation rate, etc., achieve energy saving and cost saving, simple operation, good social and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

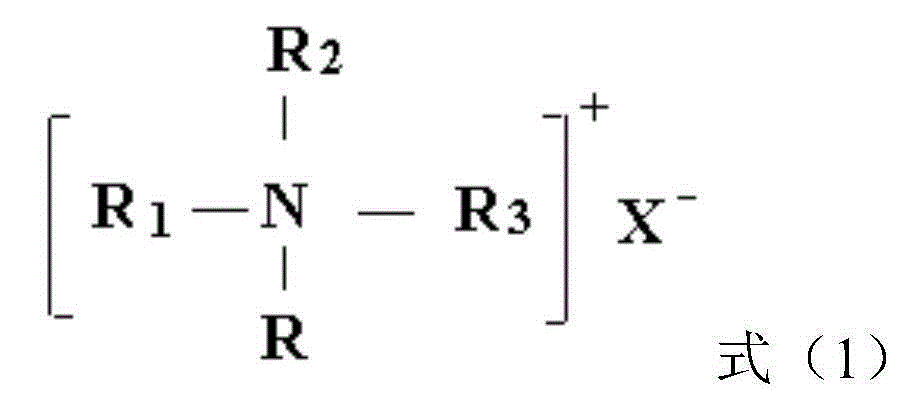

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is used to illustrate the method for recovering vanadium from vanadium precipitation wastewater provided by the present invention.

[0034] In the clean beaker of 2000mL, add 1000mL pH shown in table 1 to be the vanadium deposition waste water of 3.0, be 0.5:1 to add ethanol according to the mol ratio of vanadium in ethanol and vanadium deposition waste water, stir at normal temperature and carry out the first contact reaction, reaction After 5 minutes, add the above solution according to the mass ratio of cetyltrimethylammonium chloride and vanadium in the vanadium precipitation wastewater of 0.05:1, stir at normal temperature to carry out the second contact reaction, after reacting for 5 minutes, filter to obtain low vanadium waste water.

[0035]After testing, the vanadium content in the obtained low-vanadium wastewater is 0.003g / L, and the vanadium deposition rate is 99.41%.

Embodiment 2

[0037] This embodiment is used to illustrate the method for recovering vanadium from vanadium precipitation wastewater provided by the present invention.

[0038] In the clean beaker of 2000mL, add 1000mL pH shown in table 1 to be the vanadium precipitation waste water of 3.0, be 0.05:1 to add ethanol according to the mol ratio of ethanol and vanadium in the vanadium precipitation waste water, stir at normal temperature and carry out the first contact reaction, reaction After 10min, add the above solution according to the mass ratio of dodecyltrimethylammonium chloride and vanadium in the vanadium precipitation wastewater of 0.5:1, stir at normal temperature to carry out the second contact reaction, react after 10min, filter to obtain low vanadium waste water.

[0039] After testing, the vanadium content in the obtained low-vanadium wastewater is 0.005g / L, and the vanadium deposition rate is 99.01%.

Embodiment 3

[0041] This embodiment is used to illustrate the method for recovering vanadium from vanadium precipitation wastewater provided by the present invention.

[0042] In the clean beaker of 2000mL, add the vanadium deposition waste water shown in 1000mL table 1, use sulfuric acid or sodium hydroxide to regulate the pH of vanadium deposition waste water to be 2.5, be 0.1:1 to add ethanol according to the mol ratio of vanadium in ethanol and vanadium deposition waste water, Stir at 20°C to carry out the first contact reaction. After 1 minute of reaction, add the above solution according to the mass ratio of octadecyltrimethylammonium chloride to vanadium in the vanadium precipitation wastewater is 0.5:1, and stir at room temperature to carry out the second contact reaction. Contact reaction, after 1 minute of reaction, filter to obtain low-vanadium wastewater.

[0043] After testing, the vanadium content in the obtained low-vanadium wastewater is 0.002g / L, and the vanadium depositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com