Rectangular ingot for anti-corrosion mold and process method of rectangular ingot

A process method and flat steel ingot technology are applied in the field of flat steel ingots for corrosion-resistant molds, flat steel ingots, and flat steel ingots for the production of said corrosion-resistant molds, which can solve the problem of insufficient utilization of waste metals, cumbersome smelting process, and unfavorable resources. Effective Utilize and other problems to achieve the effect of reducing vanadium content, good melting performance, improving nitrogen fixation efficiency and reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0041] The present invention relates to a method for preparing high-nitrogen die steel by composite injection and adding nitrogen-enriched iron-manganese-based materials. The purpose of the present invention is to provide a method for smelting high-nitrogen die steel with normal pressure specifications, so as to solve the problems raised in the above-mentioned background technology question.

[0042] In order to achieve the above object, the present invention provides the following technical solutions: a method for preparing high-nitrogen mold steel by composite injection and adding nitrogen-enriched ferromanganese-based materials, the high-nitrogen plastic mold steel of the present invention, its chemical composition contains the following elements by mass percentage: C0.25~0.65%, Si 0.4~0.8%, Mn 0.4~0.9%, Cr 12~18%, Ni 0.05~0.3%, Mo 0.1~0.3%, N 0.06~0.30%, Al≤0.02%, P≤ 0.020%, S≤0.005%, and the rest are Fe and unavoidable impurity elements. Include the following steps:

[...

Embodiment 1

[0054] In the implementation example of the present invention, the high-nitrogen plastic mold steel contains the following elements in mass percent: C 0.35%, Si 0.48%, Mn 0.51%, Cr 12.5%, Ni 0.12%, Mo 0.16%, N 0.16%, Al : 0.016%, P: 0.017%, S: 0.003%, and the rest are Fe and unavoidable impurity elements. Include the following specific steps:

[0055] 1) Select IF steel billet scraps according to the above chemical composition: C 0.0024%, Si 0.014%, Mn 0.16%, P0.011%, S 0.006, Al 0.013%, the balance is Fe and other unavoidable impurities, and placed in the electric furnace Carry out primary refining, the temperature is 1640±10°C, and the pressure in the furnace is 1 standard atmospheric pressure. Pour low-carbon clean molten steel into the LF furnace, blow argon, and add slagging agents (lime, fluorite, lime sand, aluminum oxide) after 6 minutes to obtain molten steel with a nitrogen content of 38ppm;

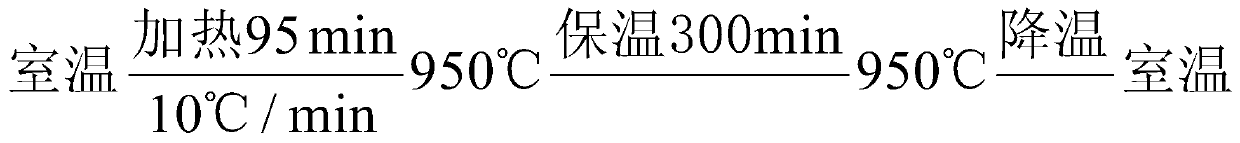

[0056] 2) Use a refining furnace for refining with a large amount of sla...

Embodiment 2

[0064] In the implementation example of the present invention, the high-nitrogen plastic mold steel contains the following elements in mass percent: C0.42%, Si0.54%, Mn0.43%, Cr13%, Ni0.11%, Mo0.15%, N0.21%, Al : 0.018%, P: 0.018%, S: 0.004%, and the rest are Fe and unavoidable impurity elements. Include the following specific steps:

[0065] 1) Select IF billet scraps according to the above chemical composition: C 0.0027%, Si 0.016%, Mn 0.16%, P0.011%, S 0.006, Al 0.013%, the balance is Fe and other unavoidable impurities, and put it in the electric furnace Carry out primary refining, the temperature is 1643±5°C, and the pressure in the furnace is 1 standard atmospheric pressure. Pour low-carbon clean molten steel into the LF furnace, blow argon, and add slagging agents (lime, fluorite, lime sand, aluminum oxide) after 6 minutes to obtain molten steel with a nitrogen content of 42ppm;

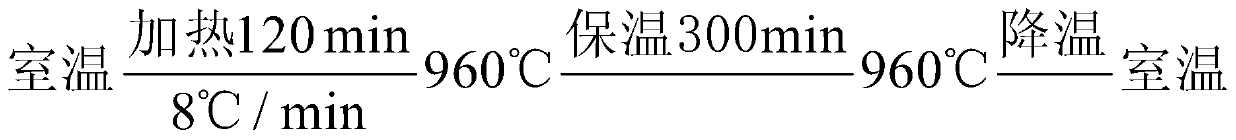

[0066] 2) Use a refining furnace for refining with a large amount of slag. After slaggin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com