Sandblasting perforating annular fracturing ground control system and method

An annular fracturing, sand blasting and perforating technology, which is applied in the directions of drilling with liquid/gas jet, earthwork drilling, and fluid production, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

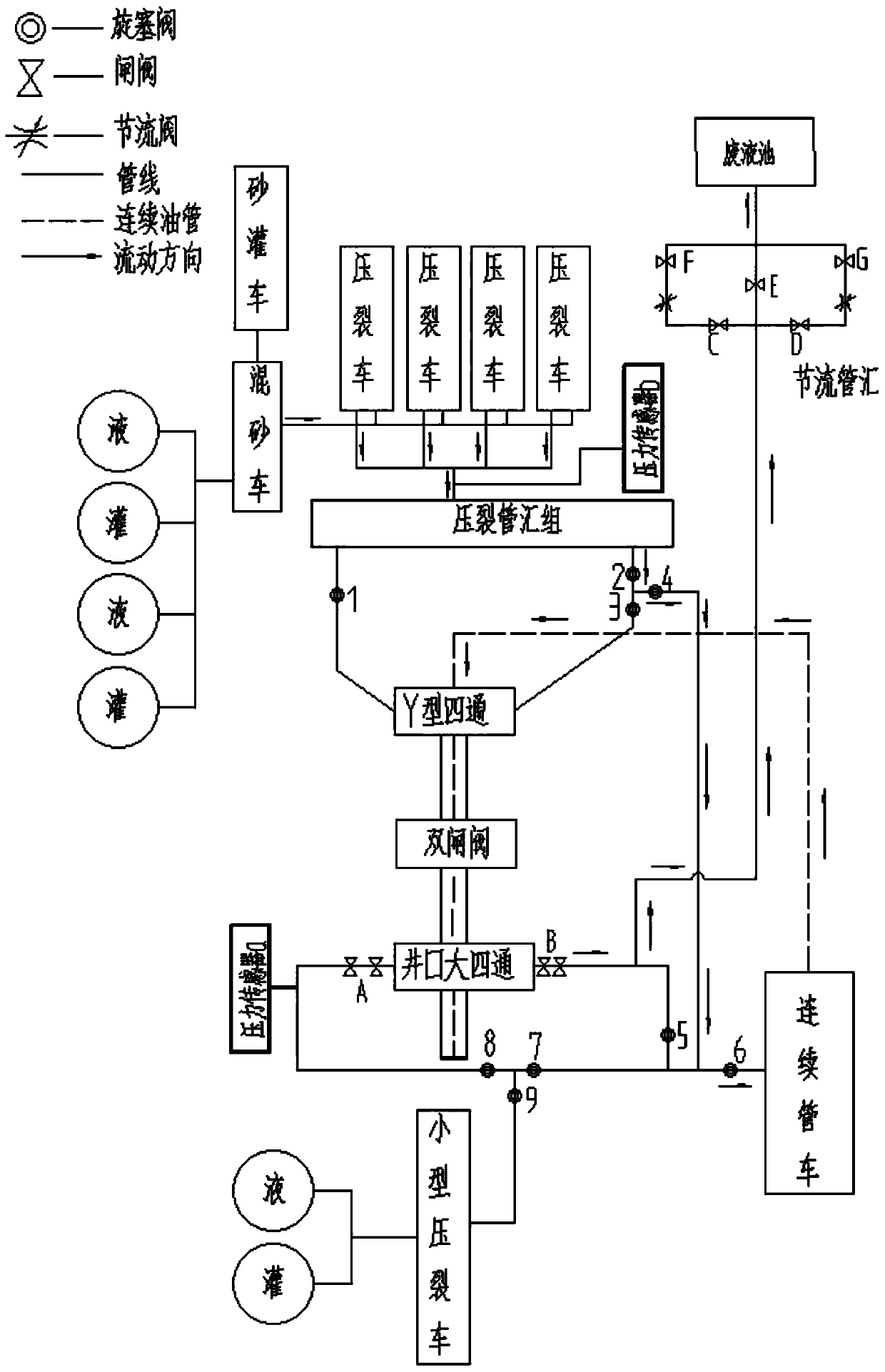

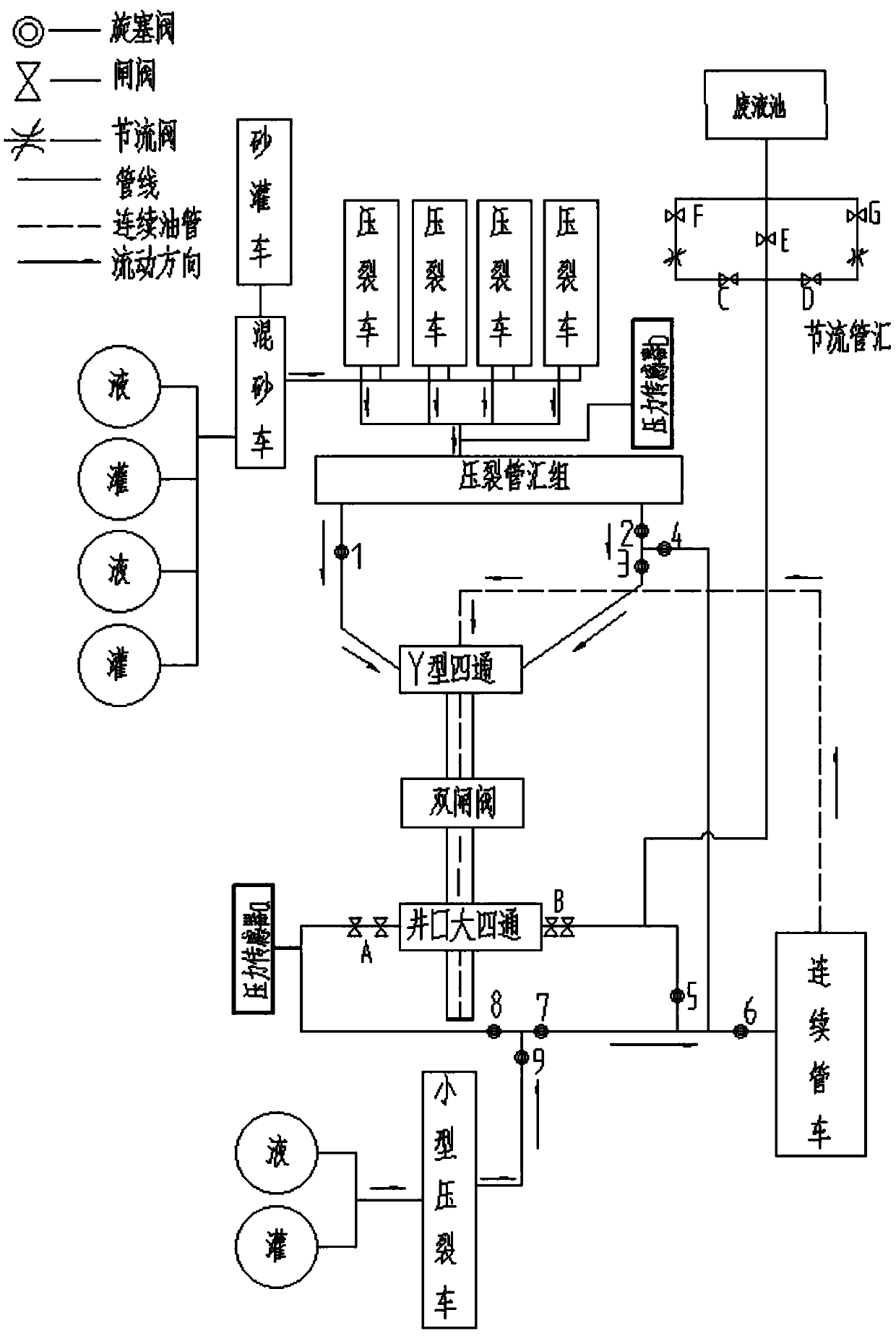

[0041] The present invention is a ground control system for sandblasting and perforating annular space fracturing, comprising a fracturing annular space pumping system, a coiled tubing pumping system, a wellhead device, a wellhead pressure control choke manifold, a coiled tubing vehicle, a coiled tubing, waste Liquid recovery tank, throttling manifold;

[0042] The wellhead device includes a Y-shaped cross, a double gate valve, and a large wellhead cross in sequence. The waste liquid recovery pool is connected to the large wellhead cross through a choke manifold, and one end of the coiled tubing is connected to a coiled tubing truck. The other end runs through the wellhead;

[0043] The pumping system for the fracturing annular space includes liquid irrigation, sand irrigation truck, sand mixing truck, fracturing train unit, and fracturing manifold. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com