Method fo rproducing high pure methane chloride

A technology of monochloromethane and production method, applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry and other directions, can solve problems such as quality and environmental protection problems, and achieve the effects of no environmental pollution, simple process and investment saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

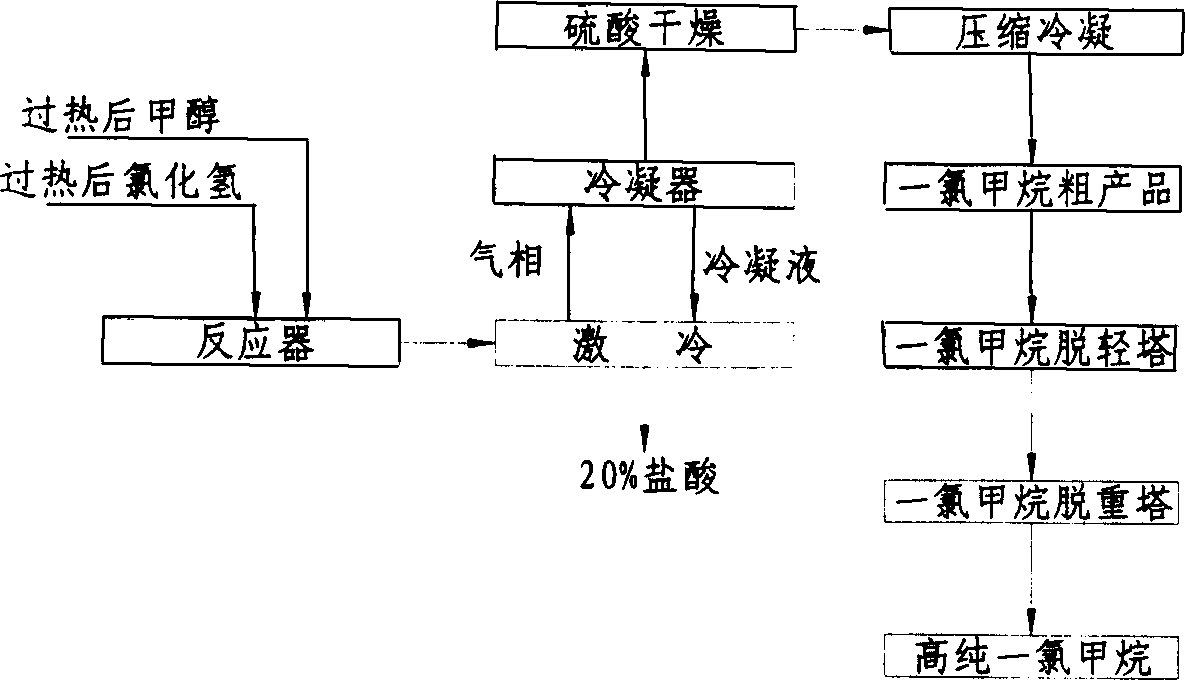

[0011] according to figure 1 As shown, the methanol and hydrogen chloride superheated to 180-220 ° C are 1: 1.1 ~ 1.3 (molar ratio), in the presence of a catalyst, at 280-320 ° C, 0.2-0.4MpaG conditions, the gas phase reaction generates monochloromethane and Water, the high-temperature reaction gas out of the reactor is quenched by dilute hydrochloric acid and the temperature drops to about 120°C. The quenched liquid after separation is 20% hydrochloric acid, which is used to produce 31% industrial hydrochloric acid. After separation, the moisture passes through the condenser Condensate (the condensate is dilute hydrochloric acid for quenching the reaction gas), dry with sulfuric acid, compress and condense to obtain the crude product of monochloromethane. The crude product of monochloromethane passes through the first rectification tower to remove the light components in the crude material of monochloromethane, and then passes through the second rectification tower to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com