Non-saponification extracting and separating method for light rare earth element

A light rare earth element and separation method technology, which is applied in the field of washing and stripping in the process of extracting and separating light rare earth elements, can solve the problems of high acidity, unfavorable product handling or separation, etc., achieve low cost of the method, and shorten washing and stripping time , the effect of shortening the extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

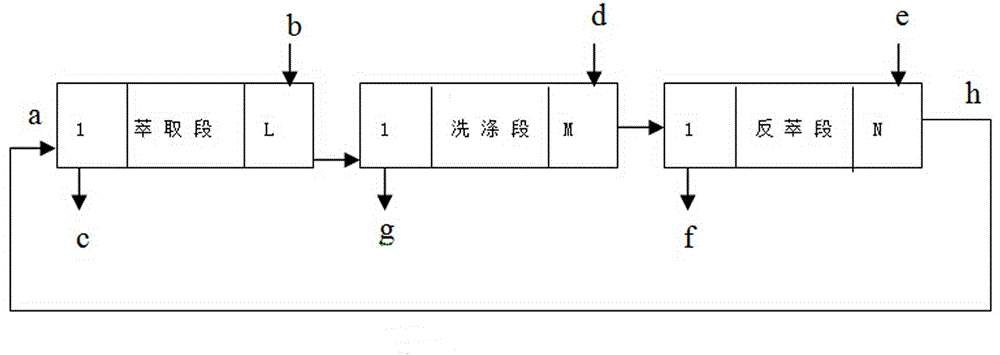

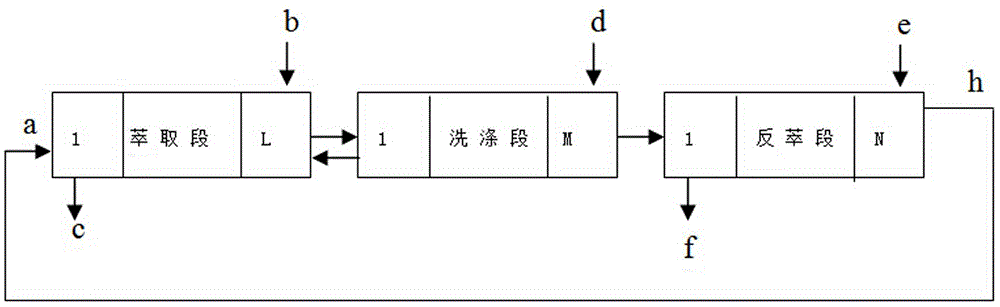

[0016] In the saponification-free extraction and separation method of light rare earth elements, a mixed extractant composed of P507—N235-200# kerosene is added to the first stage of the extraction section, wherein the volume percentage of P507 is 30%, and the volume percentage of N235 is 35%. The volume percentage of 200# kerosene is 35%; the chlorinated light rare earth feed liquid (feed liquid concentration: La 41g / L, Ce 4g / L, Pr 10 g / L, Nd 36 g / L; Feed liquid pH: 1.8), add water in the last stage of stripping section and washing section, according to figure 1 The flow shown is LaCe / PrNd extraction and grouping operation, in which the ratio (O / A) of the extraction section is 1:1, the two-phase residence time is 10min, the ratio (O / A) of the washing section is 2:1, and the two-phase The residence time is 5min, the phase ratio (O / A) of the stripping section is controlled as 1:1.5, and the two-phase residence time is 8min. After 6 stages of extraction, 3 stages of washing, a...

Embodiment 2

[0018] In the saponification-free extraction and separation method of light rare earth elements, a mixed extractant composed of P204—N1923-260# kerosene is added to the first stage of the extraction section, wherein the volume percentage of P204 is 40%, and the volume percentage of N1923 is 30%. The volume percentage of 260# kerosene is 30%; the mixed rare earth chloride feed liquid containing La and Ce is added in the last stage of the extraction section (wherein the concentrations of La and Ce are 40g / L and 4g / L respectively, and the pH of the feed liquid is: 2.3, add water in the last stage of stripping section and washing section, according to the following figure 1 The process shown is for La / Ce separation operation, in which the ratio (O / A) of the extraction section is 2:1, the two-phase residence time is 12min, the ratio (O / A) of the washing section is 2.5:1, and the two-phase residence time is 12 minutes. The time is 3 minutes, the ratio (O / A) of the stripping section...

Embodiment 3

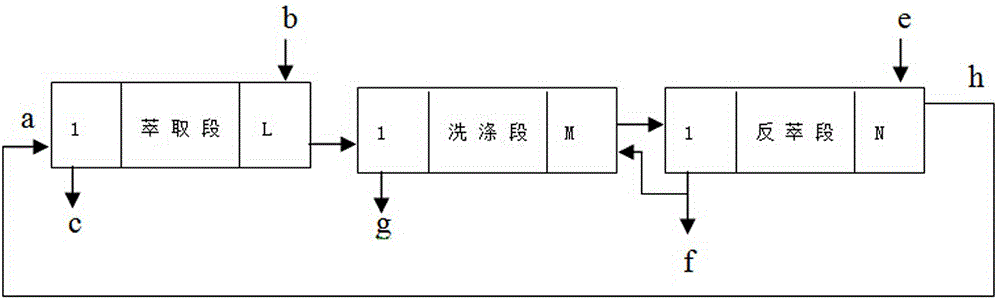

[0020] The non-saponification extraction and separation method of light rare earth elements, adding a mixed type extractant composed of P507—N235-200# solvent oil in the first stage of the extraction section, wherein the volume percentage of P507 is 40%, and the volume percentage of N235 is 25% , the volume percentage of 200# solvent oil is 35%; Add the mixed rare earth chloride feed liquid containing Pr, Nd (wherein the concentration of Pr, Nd is 8g / L and 37g / L respectively, the feed liquid's pH: 4), water is added to the last stage of the stripping section, and 30% (volume %) of the outlet stripping liquid of the last stage of the stripping section is added to the last stage of the washing section, as follows figure 2The process shown is for Pr / Nd separation operation, in which the ratio (O / A) of the extraction section is 3:1, the two-phase residence time is 12min, the ratio (O / A) of the washing section is 1:2, and the two-phase residence time is 1:2. The time is 2 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com