Waterproof construction method for engineering joint of tunnel

A construction method and technology of tunnel engineering, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as poor waterproof reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

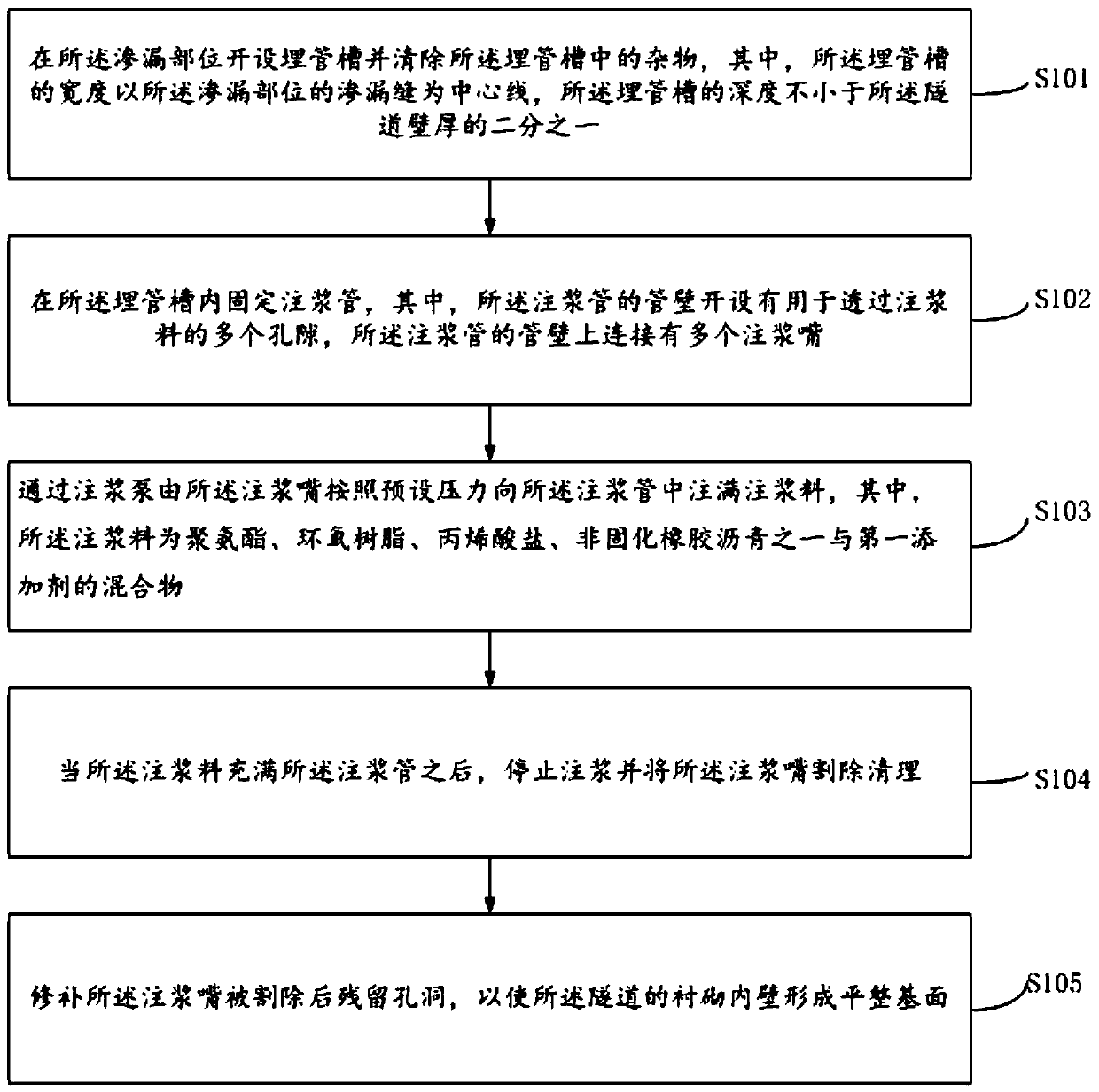

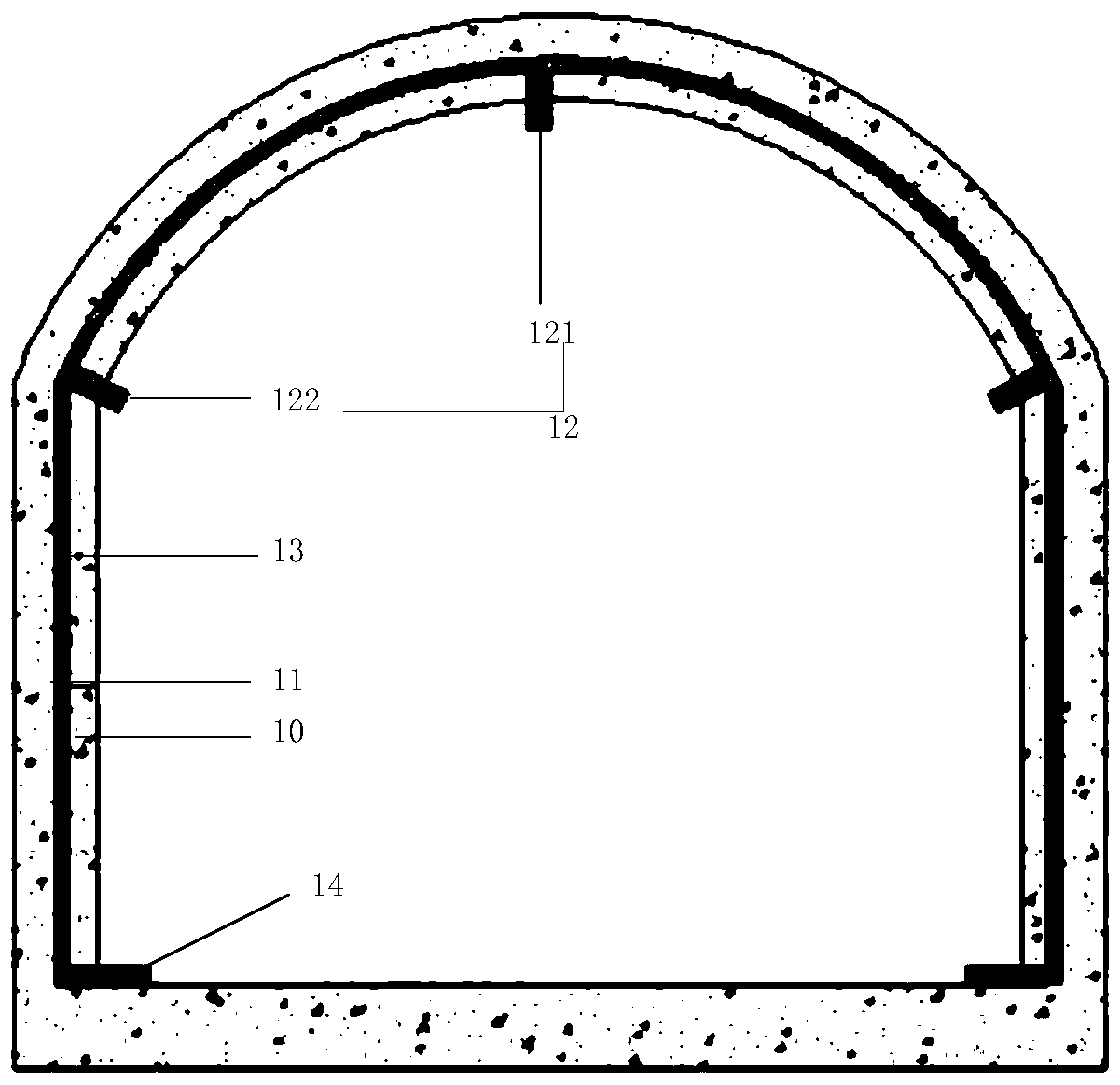

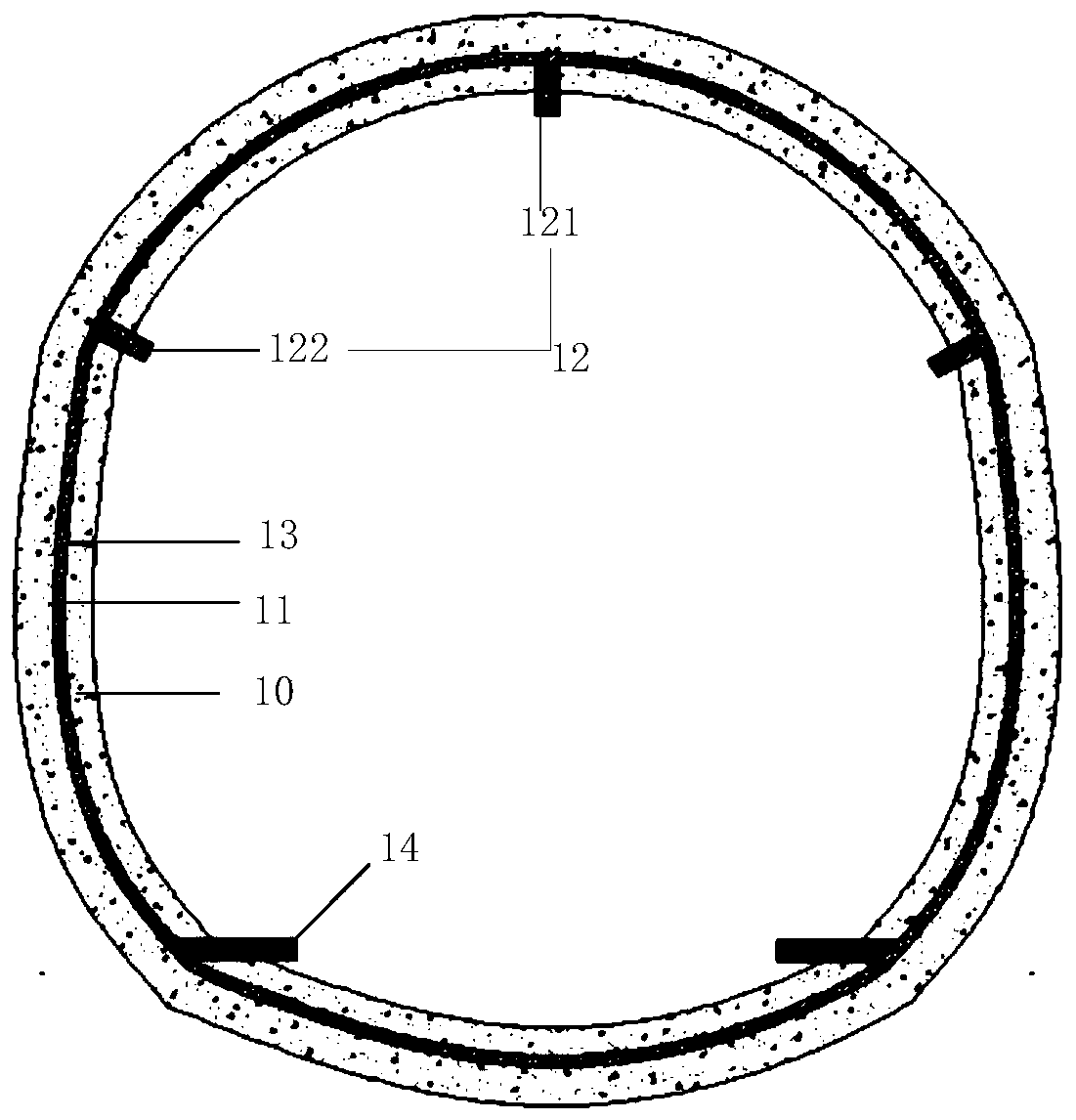

[0045] refer to figure 1 , shows a flow chart of a tunnel engineering joint waterproofing construction method. This method can form figure 2 , image 3 As shown in the tunnel structure, the waterproof structure includes a lining 10, a grouting pipe 11, a grouting nozzle 12, and a buried pipe groove 13. The method may specifically include the following steps:

[0046] S101, setting up a buried pipe groove at the leakage site and clearing the sundries in the buried pipe groove, wherein the width of the buried pipe groove is the centerline of the leakage seam at the leakage site, and the buried pipe groove is The depth of the pipe groove is not less than half of the wall thickness of the tunnel;

[0047] In a specific application, pipe-buried grooves are set up for the circumferential construction joints and deformation joints of the tunnel where water leakage occurs, and the width of the pipe-buried grooves is centered on the leakage seam at the leakage location. For exampl...

Embodiment 2

[0058] refer to Figure 4 , shows a flow chart of another construction method for tunnel engineering joint waterproofing. This method can be applied to figure 2 , image 3 shown in the tunnel structure, forming Figure 5 The waterproof structure shown, combined with Figure 2 to Figure 5 , the waterproof structure includes lining 10, grouting pipe 11, grouting nozzle 12, buried pipe groove 13, drain valve 14, quick-drying cement 15, waterproof reinforcement layer 16, waterproof additional layer 17, waterproof final layer 18, the method is specific May include the following steps:

[0059] S201, setting up a buried pipe groove at the leakage site and clearing the sundries in the buried pipe groove, wherein the width of the buried pipe groove is the centerline of the leakage joint at the leakage site, and the buried pipe groove is The depth of the pipe groove is not less than half of the wall thickness of the tunnel;

[0060] In the specific application, a buried pipe gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com