Method for processing milk dregs

A processing method and technology for milk residue, which are applied in the field of dairy industry manufacturing, can solve the problems of unreported content of physical and chemical components of milk, low yield, difficult to guarantee hygiene and safety, etc., and achieve the improvement of sanitation and preservation conditions, and the improvement of yield and improvement. The effect of the extraction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

[0023] 1 Materials and methods

[0024] 1.1 Time and place

[0025] This experiment was completed from July 20, 2013 to February 10, 2014 in the central laboratory of the College of Food Science and Technology of Yunnan Agricultural University and the laboratory of Kangmei Dairy Co., Ltd. in Shangri-La County, Diqing Prefecture, Yunnan Province.

[0026] 1.2 Experimental materials and instruments

[0027] 1.2.1 Experimental materials

[0028] Three milk samples of yak, Pyak and yellow cow were collected from Shangri-La Ranch in Yunnan

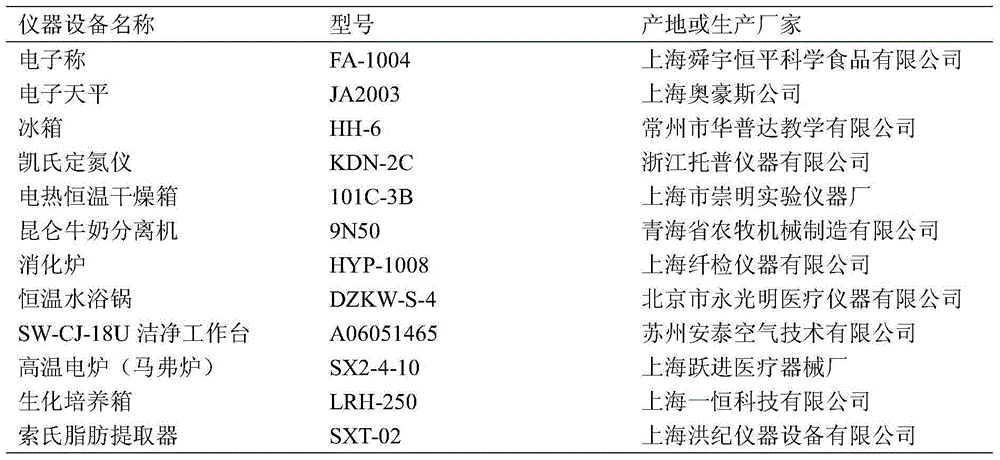

[0029] 1.2.2 Test equipment

[0030] Table 1 Equipment and instruments used in the experiment

[0031] Table1Equipmentsandinstrumentinexperiment

[0032]

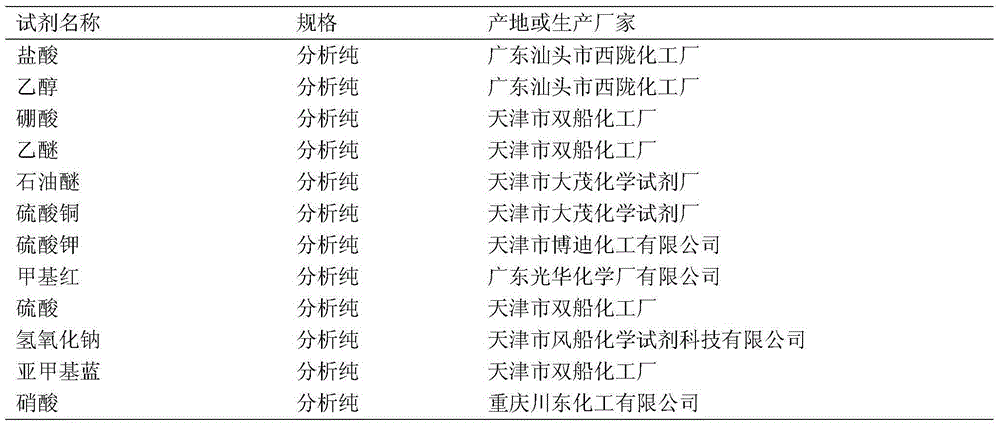

[0033] 1.2.3 Experimental drugs and reagents

[0034] Table 2 Drugs used in this experiment

[0035] Table 2Reagen used in this study

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com