Continuous casting and continuous extrusion device and process of large-plasticity equal channel right-angle copper-steel composite contact wire

A copper-steel composite and extrusion equipment technology, applied in the field of channel right-angle copper-steel composite contact line continuous casting continuous extrusion equipment, can solve the problem of difficulty in establishing continuous industrial production scale, length, weight and shape constraints, and high vacuum production costs. problems, to achieve independent innovation of tooling equipment, increase tensile strength and electrical conductivity, and break through the contradictory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

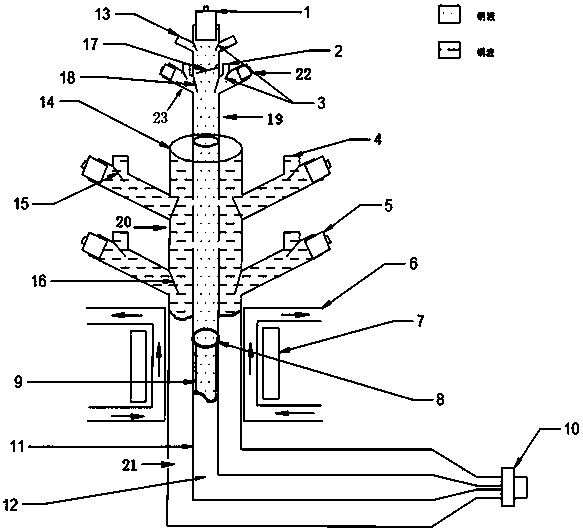

[0059] A kind of continuous casting continuous extrusion equipment of large plastic equal channel right angle copper-steel composite contact wire in this embodiment, such as figure 2 As shown, it includes: a steel mold, a copper mold, a right-angle extrusion device, a cooling circulation system 6 and a coil 7;

[0060] The steel mold mold includes a molten steel longitudinal punch 1, a molten steel inlet channel 2, a molten steel injection valve 3, a molten steel channel 13, a molten steel baffle valve 17, a molten steel circulation valve 18, a steel mold outlet 8, and a steel mold Mold pipeline 19, molten steel oblique punch 22 and molten steel oblique punch pipeline, wherein the molten steel injection valve 3 is divided into the molten steel injection valve 3 located above the molten steel baffle valve 17 and the molten steel injection valve 3 below , the molten steel injection valve 3 on the top communicates with the molten steel inlet channel 2, and the molten steel injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com