A kind of vanadium nitrogen microalloy and preparation method thereof

A technology of micro-alloying and vanadium-nitrogen, which is applied in the production and preparation of vanadium-nitrogen micro-alloys, can solve the problems of no significant increase in product yield, product quality, furnace cavity scaling, ball cracking, ball sticking, etc., and achieve improvement Maturation and reduction speed, improvement of labor productivity, effect of quality and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

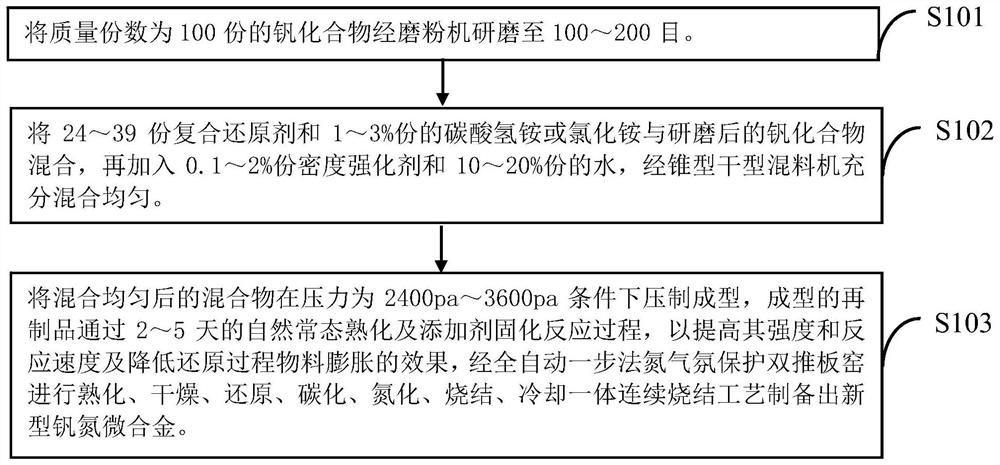

[0054] Such as figure 1 As shown, the preparation method of vanadium-nitrogen microalloy provided by the embodiment of the present invention comprises:

[0055] S101: Grinding 100 parts by mass of the vanadium compound to 100-200 meshes by means of a pulverizer.

[0056] S102: Mix 24-39 parts of composite reducing agent and 1-3% of ammonium bicarbonate or ammonium chloride with the ground vanadium compound, then add 0.1-2% of density enhancer and 10-20% of water , fully mixed evenly by a cone-type dry mixer.

[0057] S103: Press the uniformly mixed mixture under the condition of pressure of 2400pa ~ 3600pa, and the molded re-product goes through 2 ~ 5 days of natural normal aging and additive curing reaction process to improve its strength and reaction speed and reduce the reduction process. The effect of expansion, the vanadium-nitrogen microalloy is prepared by the continuous sintering process of curing, drying, reducing, carbonizing, nitriding, sintering and cooling in a ...

Embodiment 1

[0060] The preparation method of vanadium-nitrogen microalloy formulation using vanadium pentoxide as raw material comprises:

[0061] Grind flake or powdery vanadium pentoxide to 150 mesh through a pulverizer, weigh the vanadium pentoxide that is 100g in mass fractions, and add 35g of composite reducing agent. This implementation selects 290 biological charcoal powder reducing agent, The dosage is based on the following reaction equation, prepared according to the chemical reaction, and the amount of carbon is adjusted appropriately.

[0062] V 2 o 5 +6C+1 / 2N 2 =VC+VN+5CO.

[0063] Add 0.1g of density enhancer Fe powder, add 1~3% of ammonium bicarbonate or ammonium chloride, mix well through the cone dry mixer, and add 12g of water to the wet mixer for wet mixing , mixed evenly and then pressed into shape. The molding pressure is 2400pa. The size of the formed product is 40×40×35mm octagonal prism. The strength and reaction speed and the effect of reducing the expansion ...

Embodiment 2

[0066] The preparation method of vanadium-nitrogen microalloy formulation using vanadium trioxide as raw material comprises:

[0067] Grind flake or powdery vanadium trioxide to 200 mesh through a pulverizer, take vanadium trioxide with a mass ratio of 100g as the base, and add 24g of composite reducing agent. This implementation selects 290 biological charcoal powder reducing agent, The dosage is based on the following reaction equation, prepared according to the chemical reaction, and the amount of carbon is adjusted appropriately.

[0068] V 2 o 3 +4C+1 / 2N 2 =VC+VN+3CO

[0069] Add 2g of density enhancer Mn powder, add 1-3% of ammonium bicarbonate or ammonium chloride, mix well through the cone dry mixer, and then enter the wet mixer to add 12g of water for wet mixing. After mixing evenly, press molding. The molding pressing pressure is 3600pa. The size of the formed product is octagonal prism with a size of 40×40×35mm. The formed product undergoes 5 days of natural nor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com