Acetylene sodium hypochlorite cleaning waste liquid circulating zero-discharge system for a PVC production process

A technology of acetylene sodium hypochlorite and sodium hypochlorite, which is applied in filtration treatment, hydrocarbon purification/separation, multi-stage water treatment, etc. It can solve the problems of cleaning tower scaling, calcium salt enrichment, high-salt wastewater discharge, etc., and achieve the goal of solving scaling problems, reduction in salinity, and the effect of saving reused water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

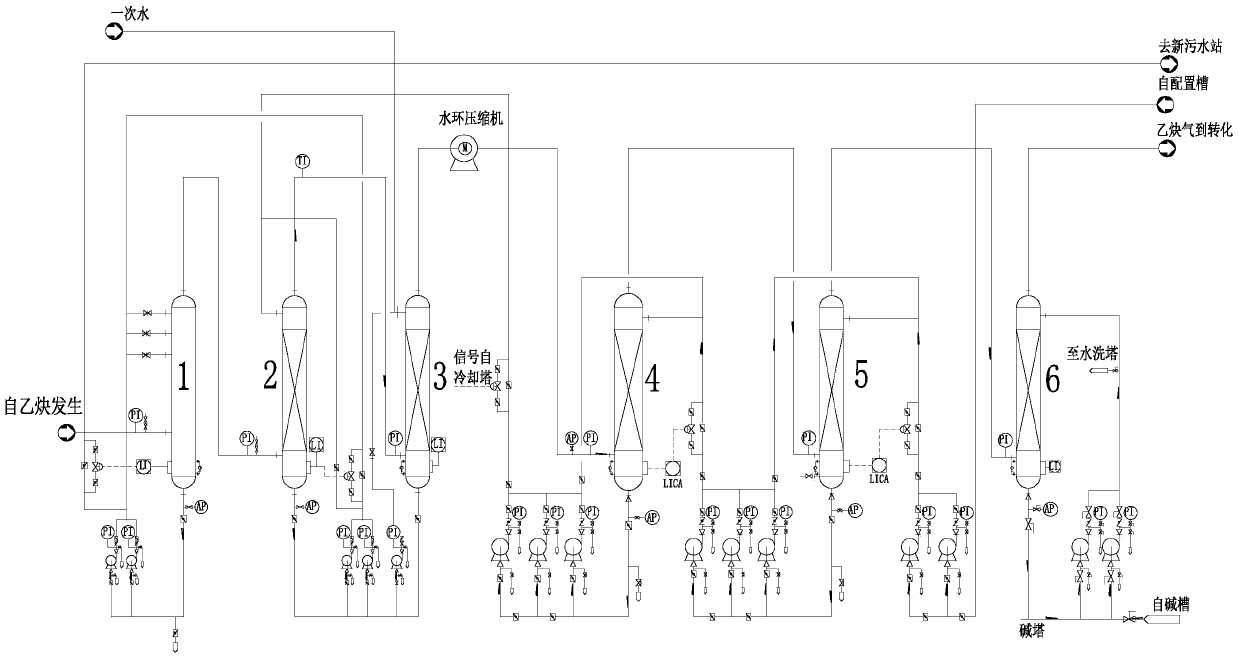

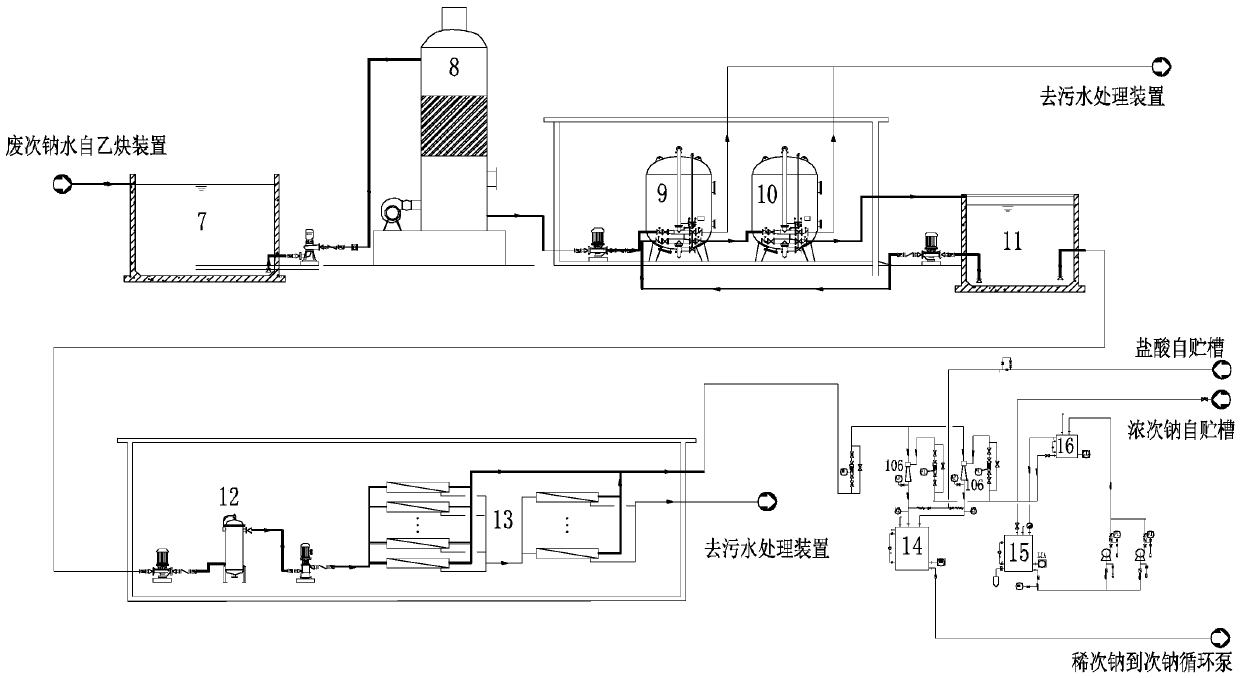

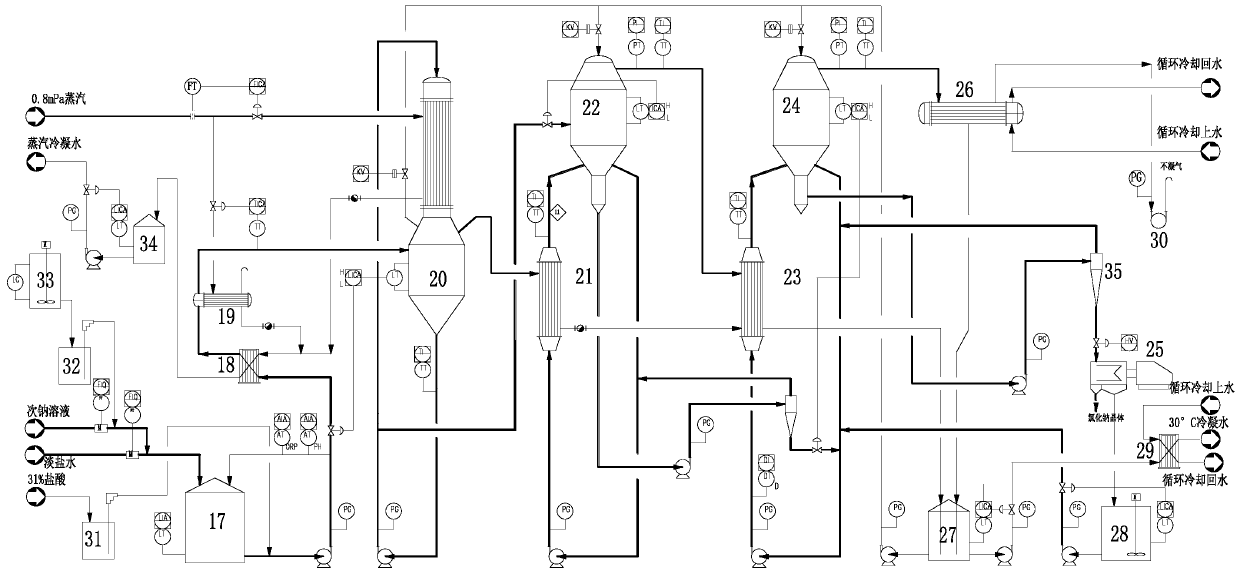

[0031] A kind of acetylene sodium hypochlorite clean waste liquid circulation zero discharge system used in PVC production process of the present invention mainly comprises such as figure 1 The clean tower system shown and as figure 2 Shown dilute sodium hypochlorite preparation system and waste sodium hypochlorite water purification system, further, also can include such as image 3 The three-effect evaporative desalination device shown. Among them, the cleaning principle is to use the strong oxidation properties of sodium hypochlorite to oxidize impurities such as hydrogen sulfide and phosphine in acetylene into acidic substances and remove them. The reaction formula is as follows:

[0032] 4NaClO+H2S→H2SO4+4NaCl

[0033] 4NaClO+PH3→H3PO4+4NaCl

[0034] 4NaClO+AsH3→H3AsO4+4NaCl

[0035] The neutralization operation is to spray the cleane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com