Spunlacing machine allowing rotation direction of suction roller to be adjusted

A technology of rotation direction and spunlace machine, which is applied in the field of nonwoven fabric manufacturing, can solve the problems of difficult processing, unfavorable development of spunlace nonwoven fabric, and inability to adjust, and achieve the effect of simple operation, low cost and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

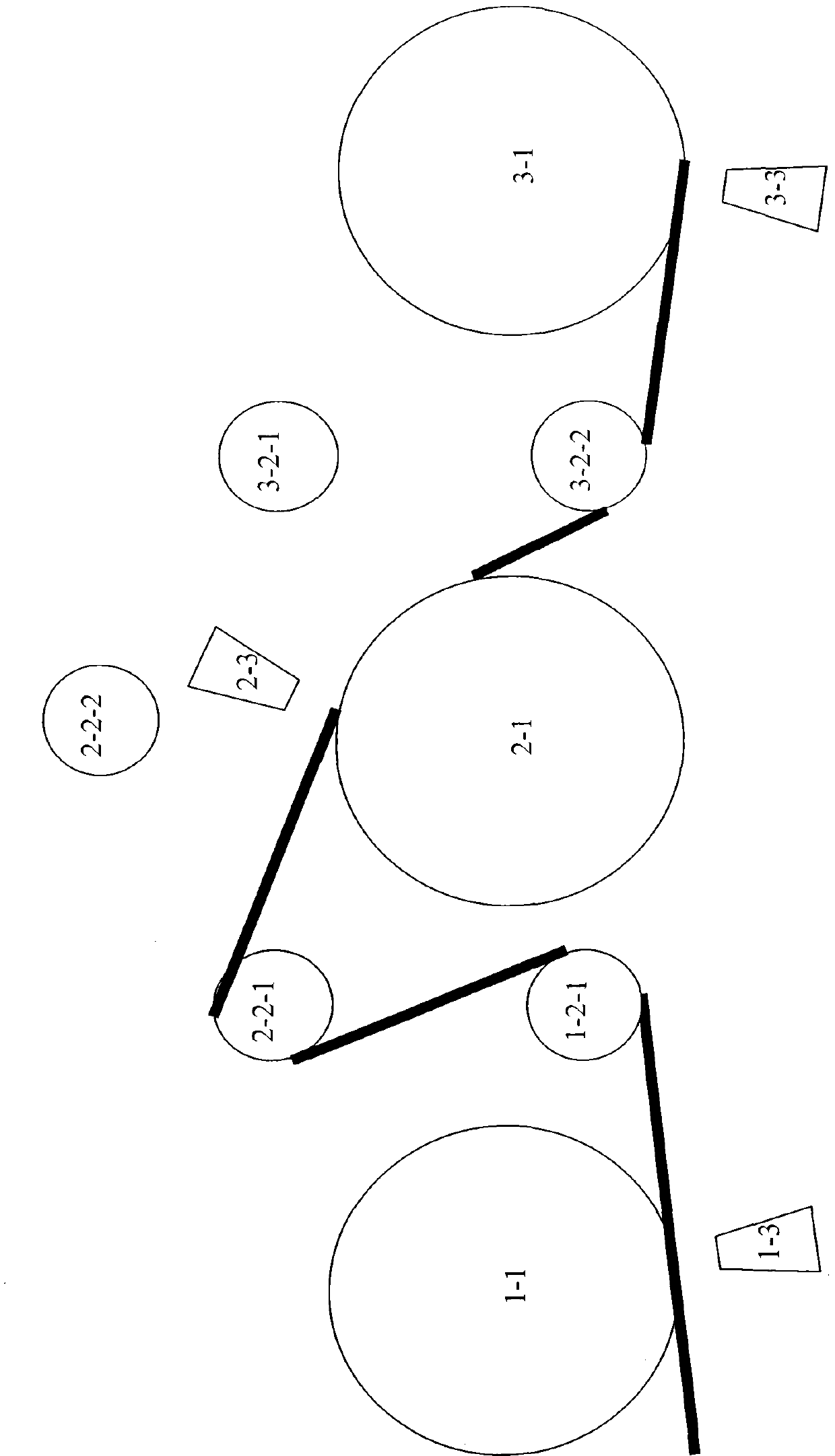

[0024] The cloth feeding direction is as figure 2 shown. The roller 1-1 in the spunlace mechanism 1 of the spunlace machine rotates counterclockwise, and the fabric guide roller 1-2-1 rotates counterclockwise; the roller 2-1 in the spunlace mechanism 2 rotates clockwise, and the fabric guide roller 2 -2-1 rotates clockwise, cloth guide roller 2-2-2 is idle; roller 3-1 in spunlace mechanism 3 rotates counterclockwise, cloth guide roller 3-2-2 rotates counterclockwise, cloth guide roller 3- 2-1 idle. This kind of processing method can form "reverse-front-reverse" processing of spunlace nonwovens, that is, the reverse side is spunlace twice and the front side is spunlace once.

Embodiment 2

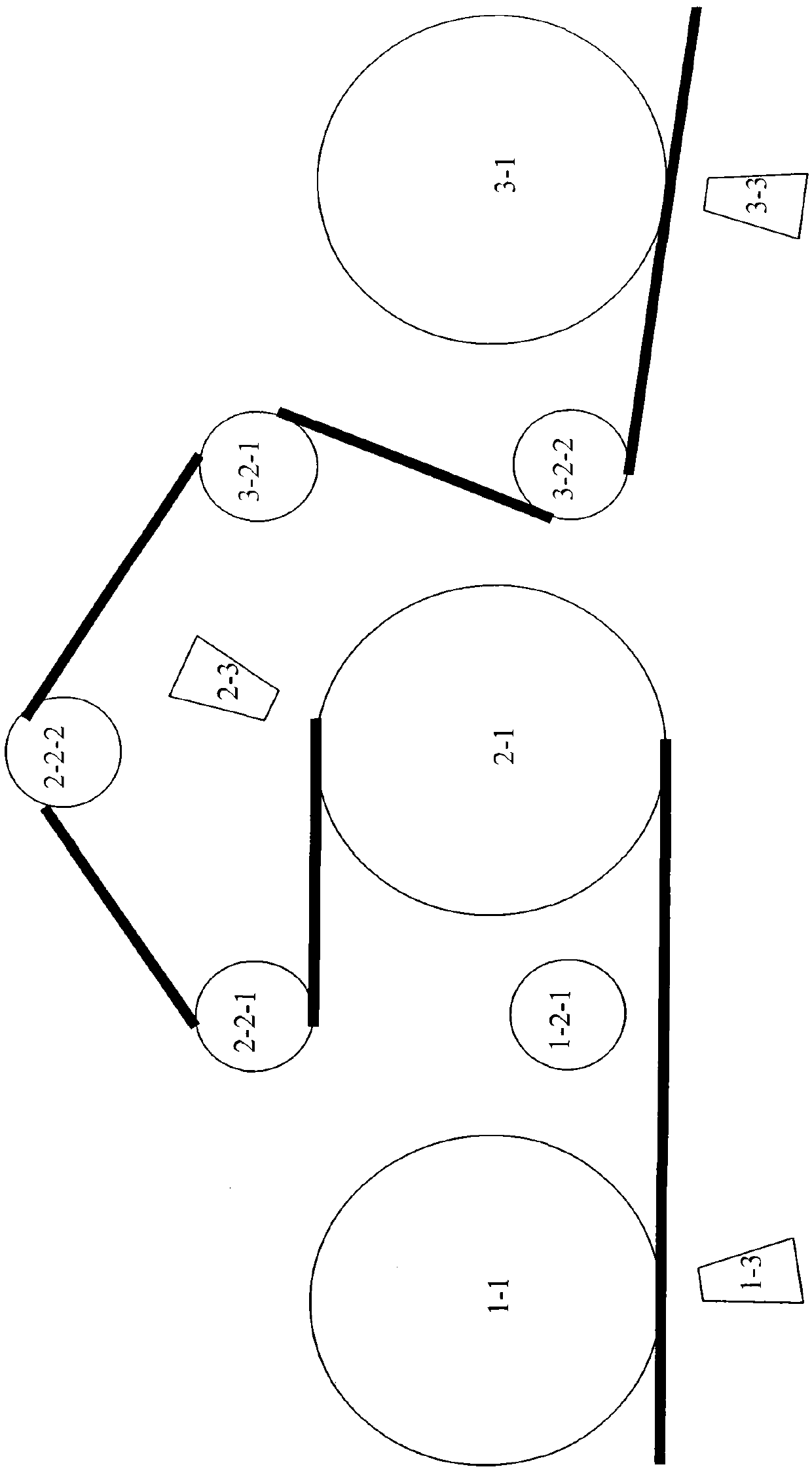

[0026] The cloth feeding direction is as image 3 shown. The roller 1-1 in the spunlace mechanism 1 of the spunlace machine rotates counterclockwise, and the cloth guide roller 1-2-1 is idle; the roller 2-1 in the spunlace mechanism 2 rotates counterclockwise, and the cloth guide roller 2-2 -1 rotates clockwise, cloth guide roller 2-2-2 rotates clockwise; roller 3-1 in spunlace mechanism 3 rotates counterclockwise, cloth guide roller 3-2-1 rotates clockwise, cloth guide roller 3- 2-2 Rotate counterclockwise. This kind of processing method can form "reverse and reverse" processing of spunlace nonwovens, that is, reverse spunlace three times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com