Process for carded polyester and cotton blending differential white and simple staining yarn

A carded polyester-cotton differential technology, which is applied in the technical field of carded polyester-cotton blended differential blanking and single-dyed yarn, which can solve the problems of uneven white silk, unreachable carding degree, blending ratio and absolute value Problems such as extreme differences, to achieve the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

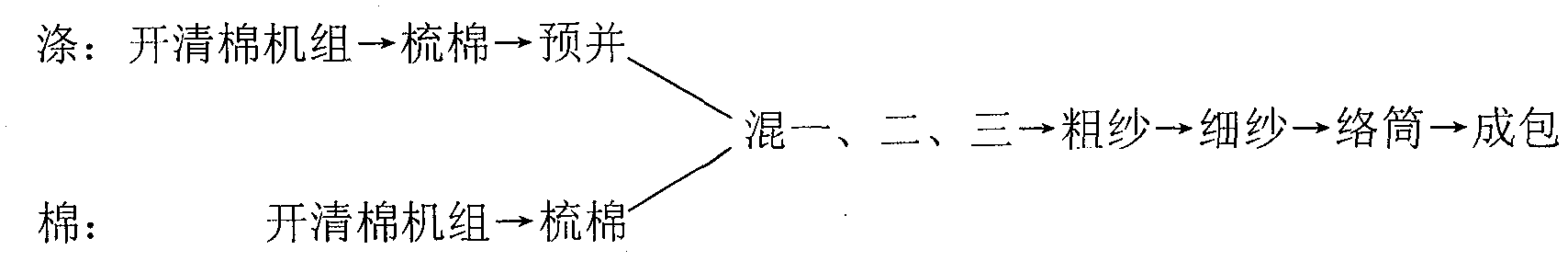

[0018] (1) Process route of woven weft blank yarn:

[0019] Artificial cotton blending→first cleaning→second cleaning→carding→combining one, two, three→roving→spinning→winding→packing

[0020] (2) Woven weft blank yarn

[0021] 2.1 First cleaning

[0022] 2.1.1 Option 1: Manual cotton blending→loading→opening and cleaning unit→rolling

[0023] 2.1.2 Scheme 2: Manual cotton blending→Packing (A002D Cotton Grabber)→(A035C Cotton Mixing Opener)→(FA0256 Warehouse)→(FA106 Cotton Opener)→(SFU1506 Hydraulic Baler)→Packing Polyester Cotton clip

[0024] 2.2 Second cleaning

[0025] 2.2.1 Plan 1: The mixed rolls produced by the two lapping machines are arranged in the other A002D plucking machine in sequence, and the second lap is formed after the first stage is opened and cleaned for carding.

[0026] 2.2.2 Plan 2: Each box of baler is punched into polyester-cotton clips and arranged, and then one or two clips per box are loaded into the A002D cotton grabbing machine for two rolls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com